Method for massively preparing graphene with excellent electrical conductivity and thermal stability

A technology of thermal stability and conductivity, which is applied in the field of graphene preparation, can solve the problems of many defects in graphene, restrict the research and further application of physical properties, poor conductivity and thermal stability, etc., and achieve excellent conductivity, low cost, The effect of improving crystallinity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

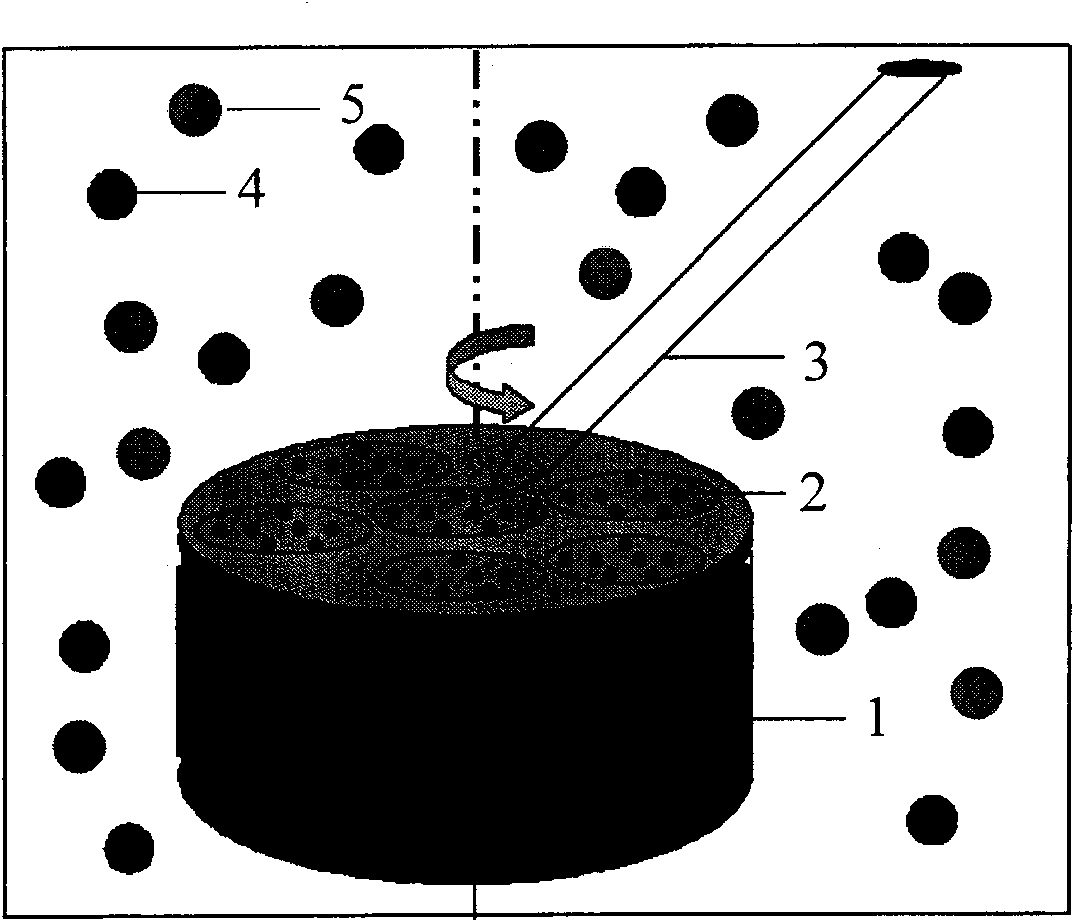

[0025] device attached figure 1 .

[0026] With the natural flake graphite powder of size<30 μm as raw material, graphite powder average particle size is 20 μm in the present embodiment, adopts Hummer method ["Hummer method" please refer to document: Hummers W, Offman R.Journal of The American Chemical Society 1958,80 : 1339.] Obtain graphite oxide by oxidation for 1.5h; use hydrogen arc method to expand and cleavage graphite oxide: the anode 1 is a graphite disk with holes drilled on it, and the hole is filled with graphite oxide 2 as an anode, a diameter of 5-15mm The graphite rod is used as the cathode 3, and the reaction chamber is filled with a mixed gas of 700 Torr hydrogen 4 and argon 5 (volume ratio 1:9), and the cathode rod is adjusted at 50° to the upper surface of the anode disc, and discharge between the two poles (DC , 150A), graphite oxide expands and cleavages in an instant (<20s, about 10s in this example) to obtain exfoliated graphite; ultrasonically disperse...

Embodiment 2

[0029] device attached figure 1 .

[0030] Using natural flake graphite powder with a size of <30 μm as raw material, the average particle size of the graphite powder in this embodiment is 20 μm, and the graphite oxide is obtained by oxidation for 3 hours by the Hummer method; the graphite oxide is expanded and cleaved by the hydrogen arc method: the anode 1 is a graphite disk, and Drill a hole, fill the hole with graphite oxide 2 as the anode, a graphite rod with a diameter of 5-15 mm as the cathode 3, and fill the reaction chamber with a mixed gas of 700 Torr hydrogen 4 and argon 5 (volume ratio 1:9) , adjust the cathode rod and the upper surface of the anode disk to be 30°, discharge between the two poles (direct current, 150A), and the graphite oxide expands and cleavages in an instant (<20s, about 10s in this embodiment) to obtain exfoliated graphite; 40°C condition The exfoliated graphite was ultrasonically dispersed in NMP for 2 hours (power 600W); 20,000 rpm high-spee...

Embodiment 3

[0033] device attached figure 1 .

[0034] Using artificial graphite powder with a size of <30 μm as the raw material, the average particle size of the graphite powder in this example is 25 μm, and the graphite oxide is obtained by oxidation for 3 hours by the Hummer method; the graphite oxide is expanded and cleaved by the hydrogen arc method: the anode 1 is a graphite disk, on which Drill a hole, fill the hole with graphite oxide 2 as the anode, and a graphite rod with a diameter of 5-15 mm as the cathode 3, fill the reaction chamber with a mixed gas of 700 Torr hydrogen 4 and argon 5 (volume ratio 1:9), Adjust the cathode rod and the upper surface of the anode disc to be 30°, discharge between the two poles (direct current, 150A), and the graphite oxide will expand and cleavage in an instant (<20s, about 10s in this embodiment) to obtain exfoliated graphite; at 40°C Ultrasonic disperse the exfoliated graphite in NMP for 2 hours (power 600W); use 20,000 rpm high-speed centr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Conductivity | aaaaa | aaaaa |

| Conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com