Catalyst for high-selectivity preparation of light aromatic hydrocarbon by using synthesis gas and preparation method thereof

A high-selectivity, light-weight aromatic hydrocarbon technology, applied in the direction of carbon compound catalysts, preparation of liquid hydrocarbon mixtures, catalysts, etc., can solve the problems of difficult life maintenance and low selectivity, and achieve low cost, simple preparation method, and high acid concentration. weakened effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

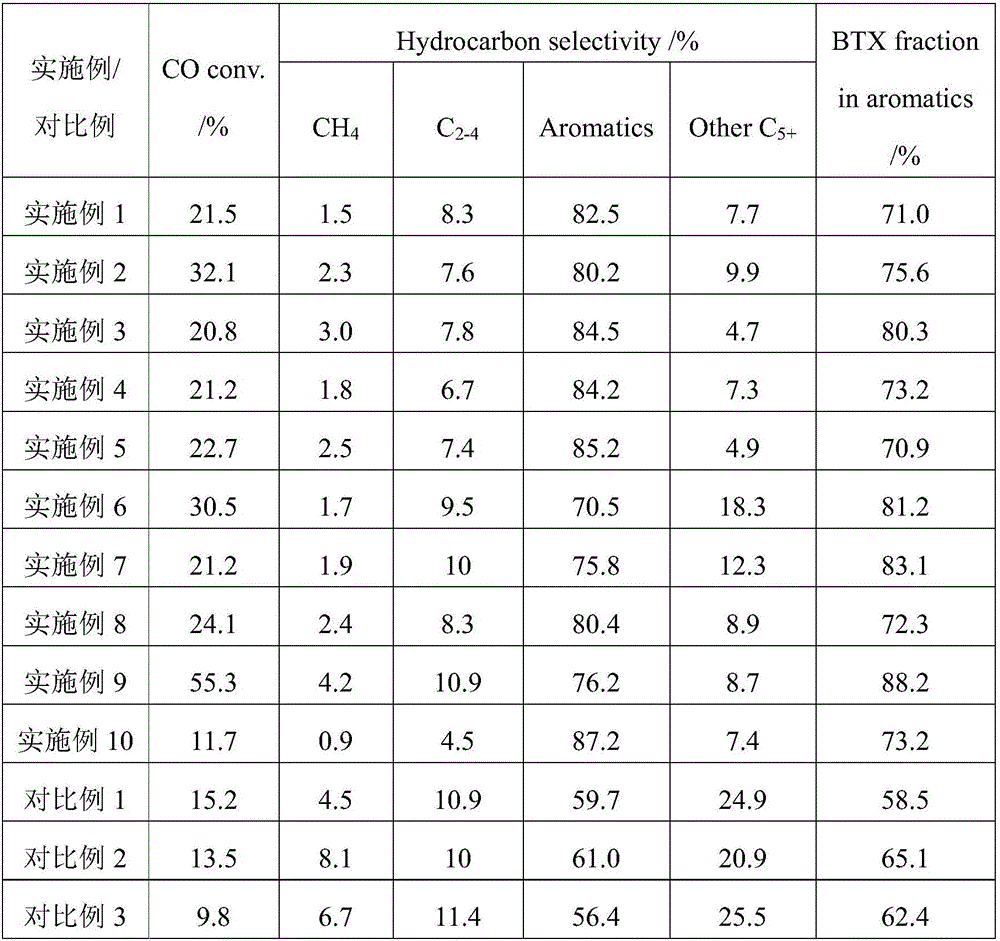

Examples

Embodiment 1

[0039] Weigh 12.5g Zr(NO 3 ) 4 ·5H 2 Add O to 100ml ethanol, stir at 50°C for 2h; add 0.2g polyvinyl alcohol (average molecular weight 300), continue stirring for 3h; add 0.055g MgCl 2 , continue to stir at 50°C for 2h; continue to add 10wt% sodium hydroxide solution, adjust the pH of the system to 9.5, heat up to 70°C and stir for 5h under reflux; after suction filtration and washing, the obtained sample is moved to a vacuum drying oven Dry at 100°C for 12h; move the dried sample to a muffle furnace and bake at 500°C for 6h, the product obtained is ZrO 2 - MgO (1 / 0.02).

[0040] Weigh 5.0g of zeolite molecular sieve Hbeta into a round bottom flask containing 50ml of n-heptane, raise the temperature to 80°C and stir for 2h; add 0.5g of butyl orthosilicate, continue to stir and reflux for 4h; then transfer the mixture to a rotary evaporator Heating in vacuum at 70°C for 3h; moving the dried sample in a muffle furnace to 450°C for 5h at a rate of 2°C / min; weighing 0.25g of s...

Embodiment 2

[0044] Weigh 12.5g Zr(NO 3 ) 4 ·5H 2 Add O to 100ml ethanol, stir at 50°C for 2h; add 0.2g polyvinyl alcohol (average molecular weight 300), continue stirring for 3h; add 0.14g LaCl 3 , continue stirring at 50°C for 2h; add 10wt% sodium hydroxide solution, adjust the pH value of the system to 9.5, heat up to 70°C and stir for 5h under reflux; after suction filtration and washing, the obtained sample is moved to a vacuum drying oven for Dry at 100°C for 12h; move the dried sample to a muffle furnace and bake at 500°C for 6h, and the product obtained is ZrO 2 -La 2 o 3 (1 / 0.02).

[0045] Weigh 5.0g of zeolite molecular sieve HZSM-5 into a round bottom flask containing 50ml of n-heptane, raise the temperature to 80°C and stir for 2h; add 0.35g of butyl orthosilicate, continue to stir and reflux for 4h; then transfer the mixture to a rotary In the evaporator, heat in vacuum at 70°C for 3h; move the sample after vacuum heating and drying to a muffle furnace and heat up to 450...

Embodiment 3

[0049] Weigh 12.5g Zr(NO 3 ) 4 ·5H 2 Add O to 100ml ethanol, stir at 50°C for 2h; add 0.2g polyvinyl alcohol (average molecular weight 300), continue stirring for 3h; add 0.073g MnCl 2 , continue stirring at 50°C for 2h; add 10wt% sodium hydroxide solution, adjust the pH value of the system to 9.5, heat up to 70°C and stir for 5h under reflux; after suction filtration and washing, the obtained sample is moved to a vacuum drying oven for Dry at 100°C for 12h; move the dried sample to a muffle furnace and bake at 500°C for 6h, and the product obtained is ZrO 2 -MnO (1 / 0.02).

[0050] Weigh 5.0g of zeolite molecular sieve HZSM-34 into a round bottom flask containing 50ml of n-heptane, raise the temperature to 80°C and stir for 2h; add 0.35g of butyl orthosilicate, continue to stir and reflux for 4h; then transfer the mixture to a rotary In the evaporator, heat in vacuum at 70°C for 3h; move the sample after vacuum heating and drying to a muffle furnace and heat up to 450°C fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com