Graphene modified high-heat-conductivity aluminum-based composite material and powder metallurgy preparation method

An aluminum-based composite material and graphene modification technology, which is applied in the fields of nanotechnology, nanotechnology, and nanotechnology for materials and surface science, and can solve the problem that the thermal conductivity of the composite material is far away from the theoretical value, and the particle surface The thickness and uniformity of the coating are difficult to control, and the interface modification effect is not ideal, so as to achieve the effects of easy dispersion and adsorption, easy thickness and uniformity, and thickness and uniformity control.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

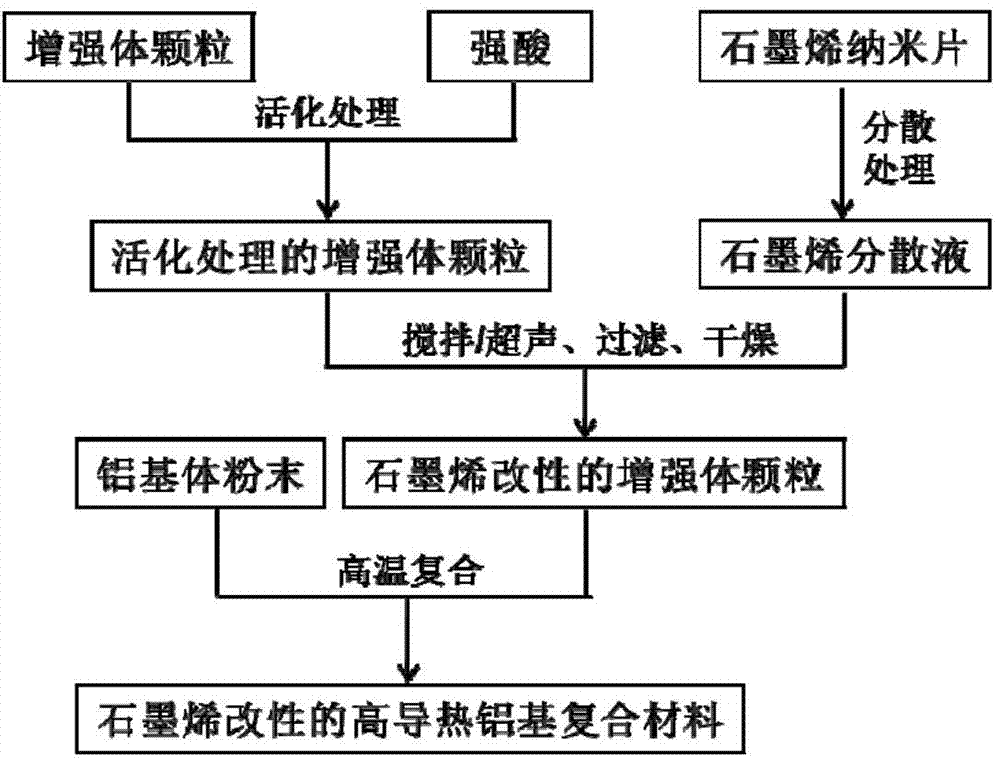

Method used

Image

Examples

Embodiment 1

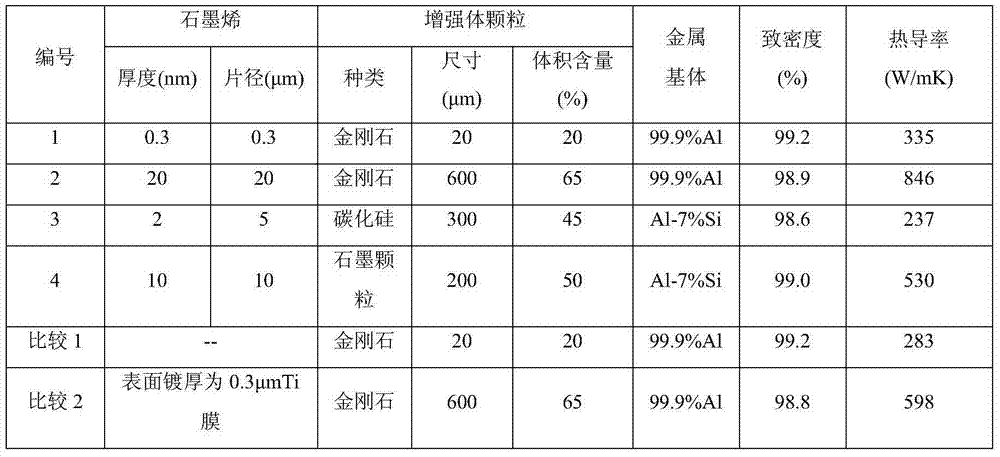

[0038] Soak the diamond with a particle size of 20 μm in strong acid, wash it with pure water until it is neutral, and dry it, put it into the graphene dispersion and stir for 2.0 hours, and rinse it with water after filtering to obtain graphene-modified diamond particles; % volume fraction of graphene-modified diamond particles mixed with pure aluminum powder with a purity of 99.9%, compacted, and sintered at 630°C for 2 hours. The prepared graphene-modified diamond-reinforced aluminum matrix composite has a density of 99.2% and a thermal conductivity of It is 335W / mK.

Embodiment 2

[0040] Soak the diamond with a particle size of 600 μm in strong acid, wash it with pure water to neutrality, and dry it, put it into the graphene dispersion and stir for 2.0 hours, and rinse it with water after filtering out to obtain graphene-modified diamond particles; 65 % volume fraction of graphene-modified diamond particles mixed with pure aluminum with a purity of 99.9%, compacted, and sintered at 645°C for 2 hours. The prepared graphene-modified diamond-reinforced aluminum matrix composite has a density of 98.9% and a thermal conductivity of 846W / mK.

Embodiment 3

[0042] Soak silicon carbide with a particle size of 300 μm in strong acid, wash it with pure water until it is neutral, and dry it, put it into the graphene dispersion and stir for 2.0 hours, filter it out and rinse it with water to obtain graphene-modified silicon carbide particles; The graphene-modified silicon carbide particle-reinforced aluminum matrix composite material prepared by mixing 45% volume fraction of graphene-modified silicon carbide particles with Al-7% Si aluminum alloy powder, compacted, and sintered at 615°C for 2 hours was 98.6 %, thermal conductivity is 237W / mK.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Thermal conductivity | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com