Oxidized grapheme/polyaniline super capacitor composite electrode material and preparation method and application thereof

A technology for supercapacitors and composite electrodes, applied in inorganic composite materials and organic fields, can solve the problems of insignificant improvement of composite material performance, high cost of carbon nanotube preparation, limited application performance, etc., and achieves superior performance, improved mechanical properties, good Application prospects and economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

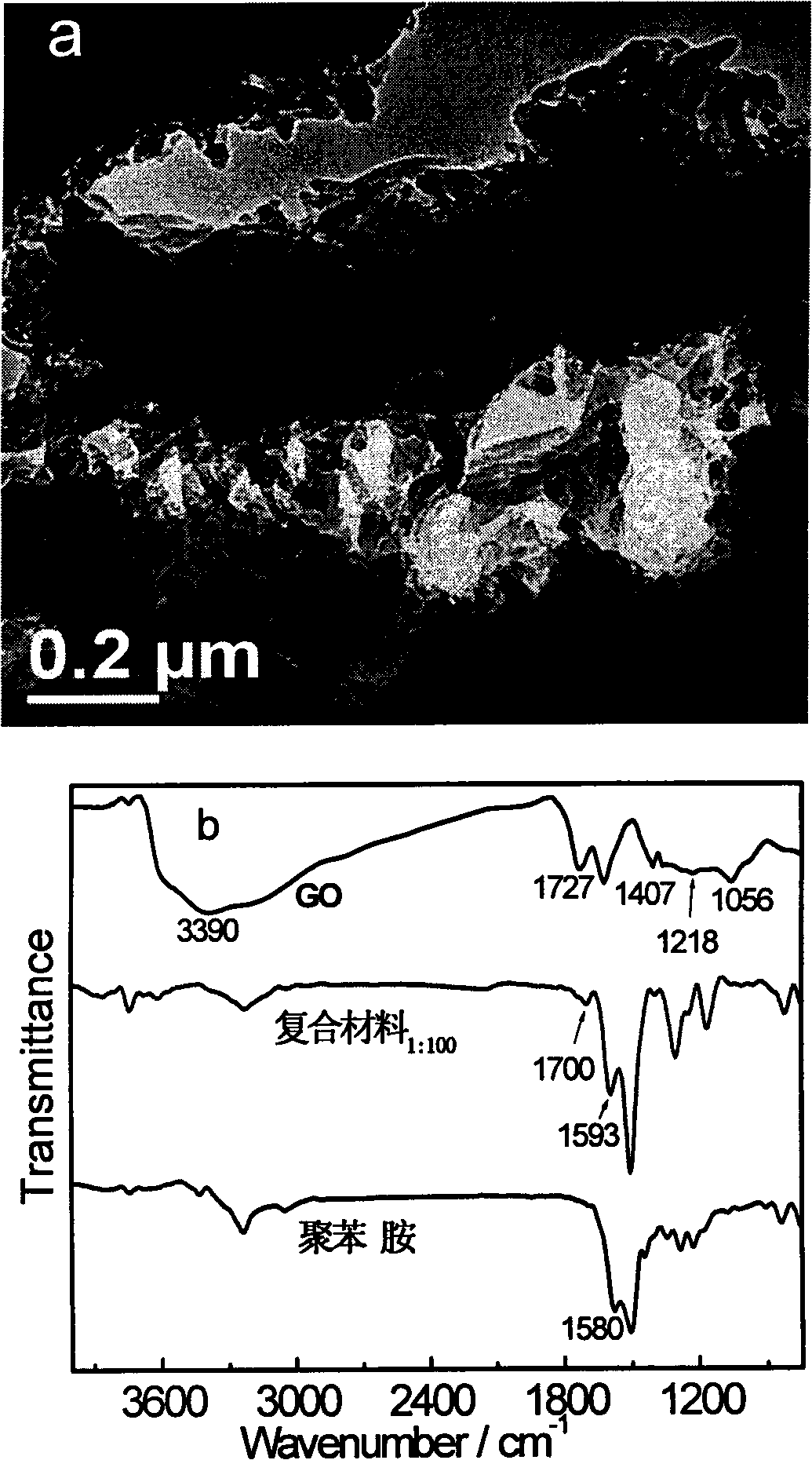

[0029] Embodiment 1: the preparation of graphite oxide. Add 10g of phosphorus pentoxide and 10g of potassium persulfate into 30mL of concentrated sulfuric acid at 80°C and stir for 30 minutes, take it out, react at room temperature for 6 hours, filter the product, wash to neutral and dry at room temperature to constant weight. Add the above product into 460mL of concentrated sulfuric acid at 0°C, stir and slowly add potassium permanganate, while controlling the temperature of the system not to exceed 15°C, stir evenly and raise the temperature to 35±3°C, continue stirring for a certain period of time, and then pour into the system Slowly add 1L of deionized water, control the temperature not to exceed 100°C, and continue stirring for 15 minutes. Add 2.8L of deionized water and 50mL of 30% hydrogen peroxide. After stirring for 5 min, the resulting brown suspension was suction-filtered and dialyzed until there was no sulfate ion in the filtrate. The product was vacuum dried at...

Embodiment 2

[0033] Embodiment 2: the preparation of graphite oxide is the same as embodiment 1.

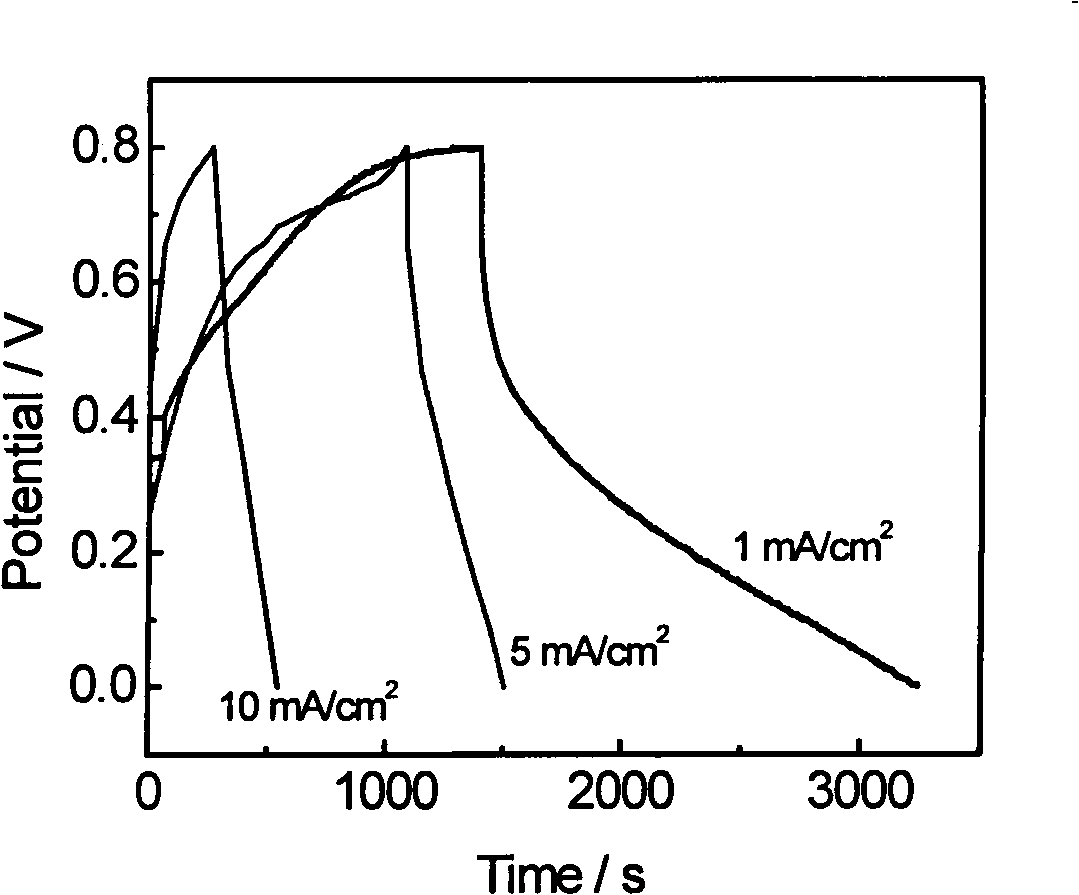

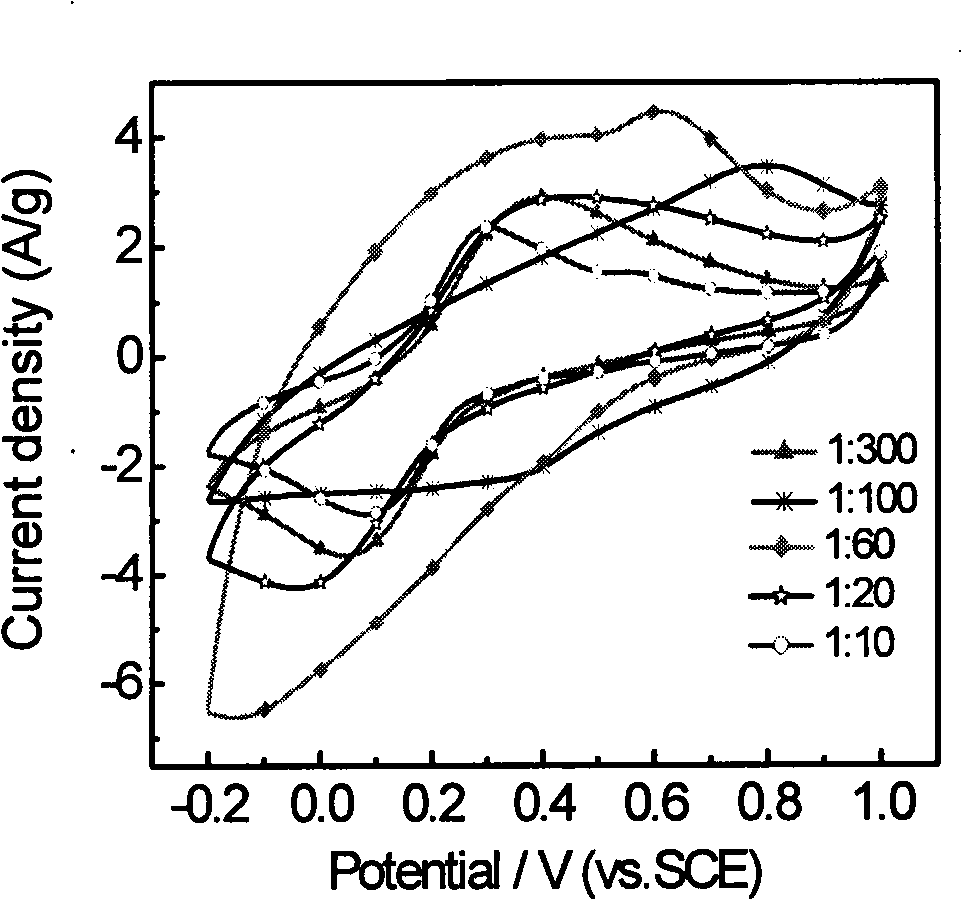

[0034] (1) Add 15.5 mg of graphite oxide to 196.79 mL of water and sonicate for 20-120 min to form a graphene oxide solution uniformly dispersed in a single layer; (2) Add 0.93 mL of aniline dropwise to the obtained graphene oxide solution at room temperature , sonicated for 10 to 60 minutes to disperse and form a mixed solution of 0.05mol / L aniline; (3) at 0°C, add 1.72mL of 30% hydrogen peroxide and 0.33mL of 0.1mol / L trichloro Ferric chloride and 0.23mL of 37% hydrochloric acid solution, the concentration of hydrogen peroxide is 0.083mol / L, the concentration of hydrochloric acid is 0.1mol / L, stirring and polymerizing for 24h; (4) After the reaction is completed, the obtained mixed solution is centrifuged, water, After repeated washing with ethanol, the graphene oxide / polyaniline composite electrode material with a mass ratio of graphite oxide to aniline (GO:ANI) of 1:60 was obtained by vac...

Embodiment 3

[0036] Embodiment 3: the preparation of graphite oxide is the same as embodiment 1.

[0037] (1) Add 186.2 mg of graphite oxide to 190.61 mL of water and sonicate for 20 to 120 min to form a graphene oxide solution uniformly dispersed in a single layer; (2) Add 3.73 mL of aniline dropwise to the obtained graphene oxide solution at room temperature , sonicated for 10 to 60 minutes to disperse and form a mixed solution of 0.2mol / L aniline; (3) at 10°C, add 4.12mL of 30% hydrogen peroxide and 0.4mL of 0.1mol / L trichloro Ferric chloride and 1.14mL of 37% hydrochloric acid solution, the concentration of hydrogen peroxide is 0.2mol / L, the concentration of hydrochloric acid is 0.5mol / L, stirred and polymerized for 12h; (4) After the reaction is completed, the obtained mixed solution is centrifuged, washed with water, After repeated washing with ethanol, the graphene oxide / polyaniline composite electrode material with a mass ratio of graphite oxide to aniline (GO:ANI) of 1:20 was obta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com