Preparation method of nitrogen-manganese co-doped hierarchical porous carbon material

A co-doping and multi-level pore technology, which is applied in the preparation/purification of carbon, hybrid capacitor electrodes, etc., can solve the problems of cumbersome and time-consuming preparation steps, high toxicity of raw material reagents, expensive template agents, etc., and achieve reliable material structure and performance. control, the reaction process is easy to control, and the effect of simple steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

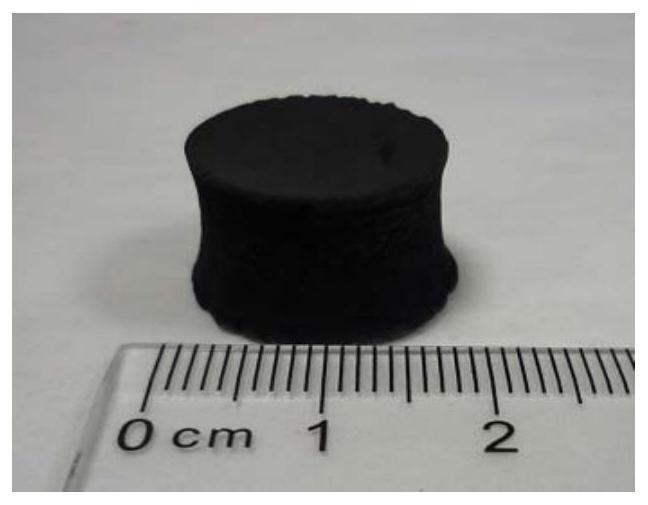

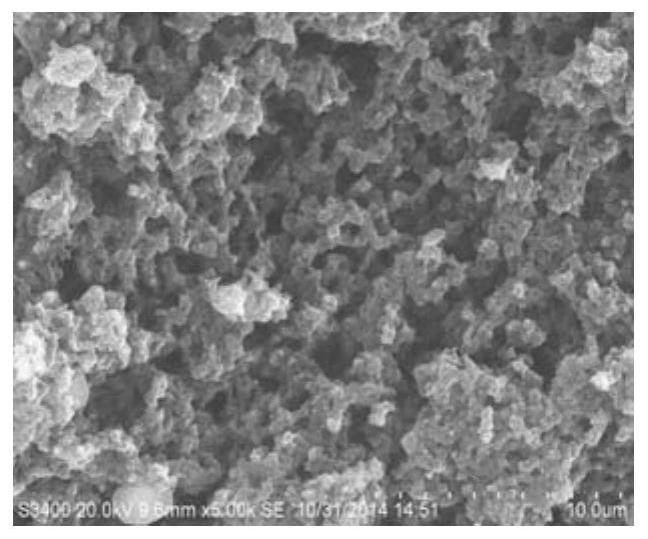

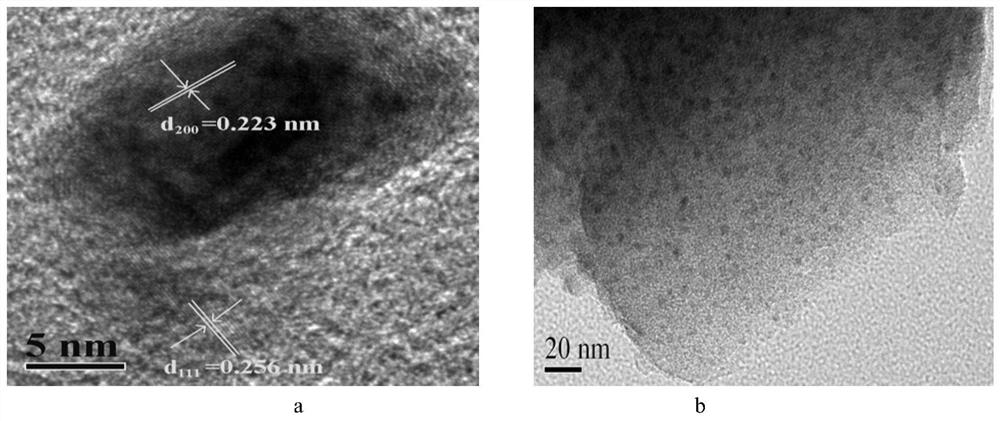

[0038] Example 1: Preparation of a nitrogen-manganese co-doped hierarchical porous carbon material

[0039] Follow the steps below:

[0040] (1) Preparation of oligomeric phenolic resin Resol

[0041] Add 1.0 g of phenol and 2.5 mL of 40% formaldehyde solution to 4 mL of 0.5 M NaOH solution, and stir at 65° C. for 0.7 h to obtain the oligomeric phenolic resin Resol.

[0042] (2) Preparation of hierarchically porous carbon bulk materials co-doped with nitrogen and manganese oxide

[0043] 0.6g P123 (EO 20 PO 70 EO 20 ), 1.1g F127 (EO 106 PO 70 EO 106 ), 0.05g melamine, added to the above-mentioned oligomeric phenolic resin Resol, stirred at 65°C for 4h, after cooling to room temperature, added 0.05g MnCl 2 4H 2 O, continue stirring at 65°C for 3h, transfer the obtained solution to a hydrothermal kettle, heat at 100°C for 18h, filter out the obtained block material, wash repeatedly with distilled water, dry in vacuum at 50°C for 24h, and then transfer to a tube furnace ...

Embodiment 2

[0052] Electrochemical impedance spectroscopy was used to study the transport resistance of the N-MnO-HPCM material, and the Nyquist curve was as follows Figure 8 As shown, the inset is the Nyquist curve of the N-MnO-HPCM material in the high frequency region. The intercept of the semicircle on the horizontal axis is the equivalent series resistance (Rs), which is 0.34Ω, which represents the sum of the resistance from the electrolyte and the active material, and the contact resistance between the active material and the current collector, which is relatively small , indicating that the supercapacitor has good rate capacity or power density. The diameter of the semicircle corresponds to the charge transfer resistance at the electrode-electrolyte interface, which is 0.14Ω, indicating that the N-MnO-HPCM material has a lower charge transfer resistance and higher conductivity. The Nyquist curve is close to a straight line in the low frequency region, showing ideal capacitive beh...

Embodiment 3

[0063] Example 3: Preparation of a nitrogen-manganese co-doped hierarchical porous carbon material

[0064] Follow the steps below:

[0065] (1) Preparation of oligomeric phenolic resin Resol

[0066] Add 1.0 g of phenol and 3.5 mL of 39% formaldehyde solution into 5 mL of 0.5 M NaOH solution, and stir at 65° C. for 0.7 h to obtain the oligomeric phenolic resin Resol.

[0067] (2) Preparation of hierarchically porous carbon bulk materials co-doped with nitrogen and manganese oxide

[0068] Add 0.85g P123, 1.15g F127, 0.5g urea to the above oligomeric phenolic resin Resol, stir at 70°C for 3h, cool to room temperature, add 0.4g MnCl 2 4H 2 O, continue stirring at 70°C for 2h, transfer the obtained solution to a hydrothermal kettle, heat at 120°C for 15h, filter out the obtained block material, wash repeatedly with distilled water, dry in vacuum at 60°C for 15h, and then transfer to a tube furnace Under the protection of nitrogen gas, it was calcined at 700°C for 4h, and aft...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com