A kind of carbon-based composite electrode material and preparation method thereof

A composite electrode and carbon-based technology, which is applied in the manufacture of hybrid capacitor electrodes, hybrid/electric double layer capacitors, etc., can solve the problems of cumbersome and time-consuming synthesis steps, high cost, and difficulty in industrial production, and achieve a wide range of raw material selection and large pores. Capacity, improve the effect of utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

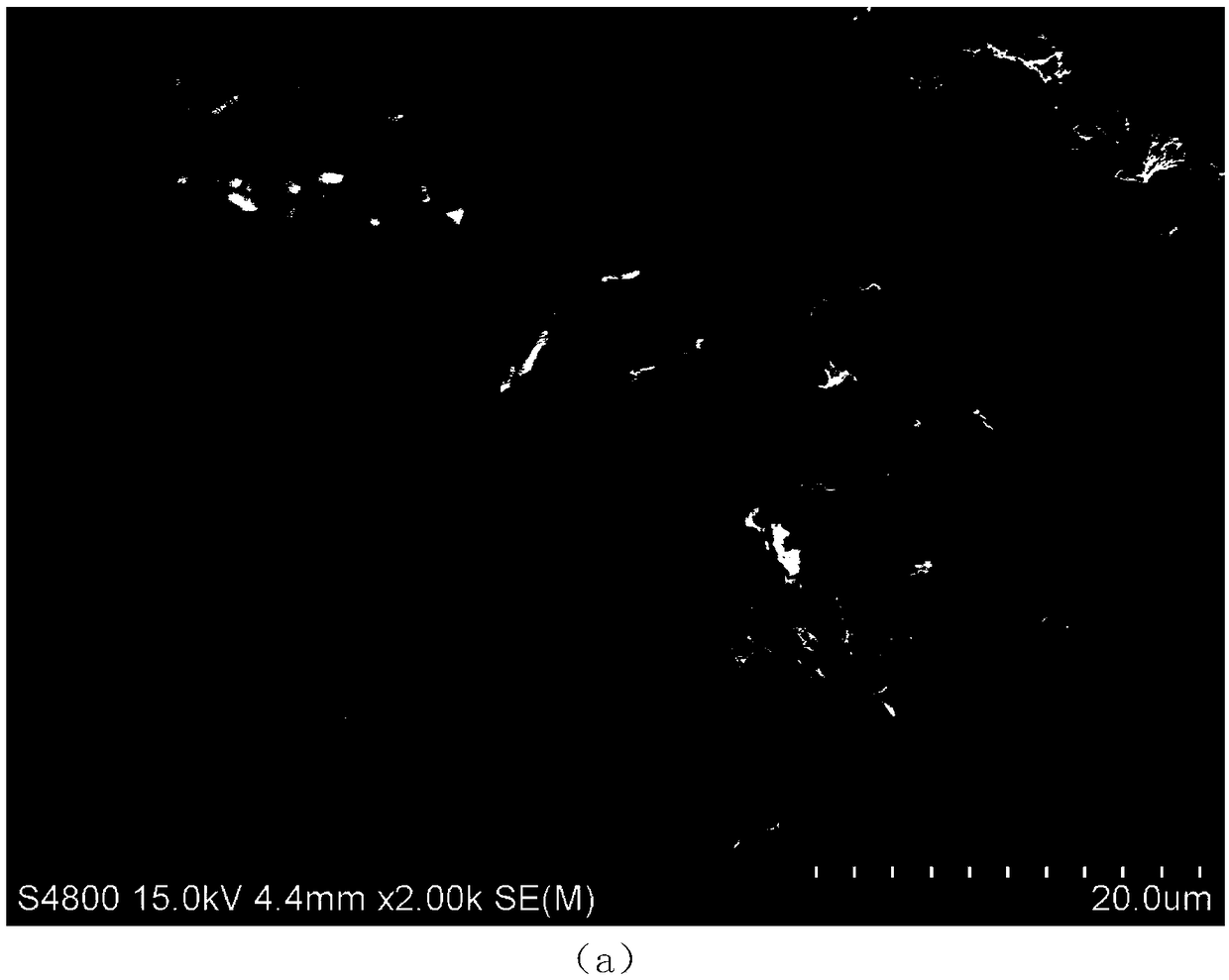

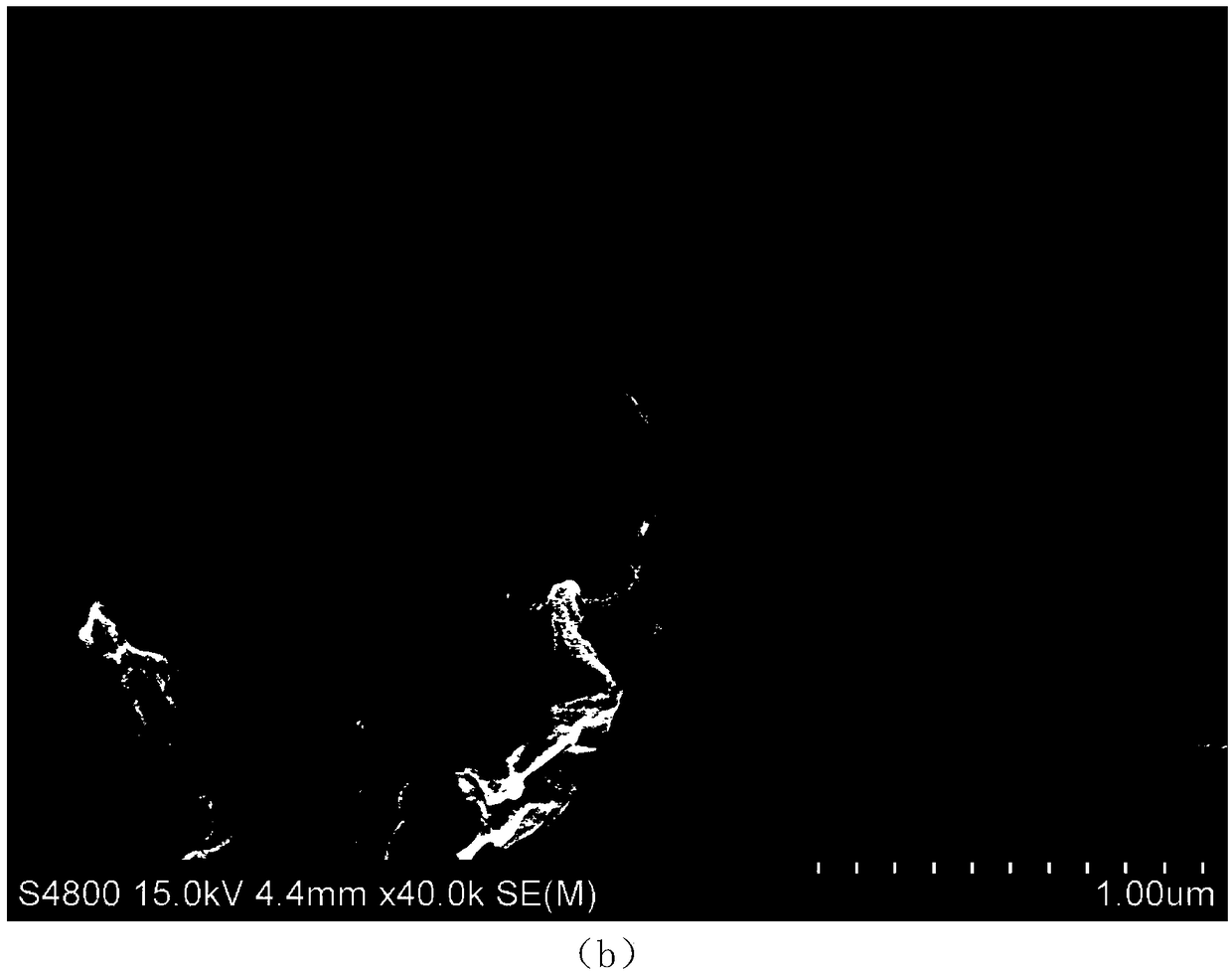

Image

Examples

Embodiment 1

[0060] A method for preparing a carbon-based composite electrode material, comprising the following steps:

[0061] 1) Preparation of oligomeric phenolic resin Resol

[0062] Dissolve 1.0g of phenol and 3.5mL of formaldehyde in 5mL of sodium hydroxide solution and stir at 70°C for 0.5h to obtain the oligomeric phenolic resin Resol;

[0063] The concentration of the sodium hydroxide solution is 0.5mol / L;

[0064] 2) Preparation of graphene oxide

[0065] 2.1) Under ice-water bath conditions, 150ml of concentrated sulfuric acid was added to a mixture of 2.5g of sodium nitrate and 1g of graphite, and stirred for 30min to obtain mixture A;

[0066] The concentration of the concentrated sulfuric acid is 95%;

[0067] 2.2) Add 15 g of potassium permanganate in portions to the mixture A obtained in step 2.1) and react for 12 hours to obtain a mixture B; control the reaction temperature not to exceed 20°C;

[0068] 2.3) Add 150ml of deionized water to the mixture B obtained in ste...

Embodiment 2

[0093] A method for preparing a carbon-based composite electrode material, comprising the following steps:

[0094]1) Preparation of oligomeric phenolic resin Resol

[0095] Dissolve 0.9g of phenol and 3.5mL of formaldehyde in 8mL of sodium hydroxide solution and stir at 70°C for 0.5h to obtain the oligomeric phenolic resin Resol;

[0096] The concentration of the sodium hydroxide solution is 0.3mol / L;

[0097] 2) Preparation of graphene oxide

[0098] 2.1) Under ice-water bath conditions, 150ml of concentrated sulfuric acid was added to a mixture of 2.5g of sodium nitrate and 1g of graphite, and stirred for 30min to obtain mixture A;

[0099] The concentration of the concentrated sulfuric acid is 96%;

[0100] 2.2) Add 15 g of potassium permanganate in portions to the mixture A obtained in step 2.1) and react for 12 hours to obtain a mixture B; control the reaction temperature not to exceed 20°C;

[0101] 2.3) Add 150ml of deionized water to the mixture B obtained in step...

Embodiment 3

[0115] A method for preparing a carbon-based composite electrode material, comprising the following steps:

[0116] 1) Preparation of oligomeric phenolic resin Resol

[0117] Dissolve 1.1g of phenol and 4.5mL of formaldehyde in 4mL of sodium hydroxide solution and stir at 65°C for 0.7h to obtain the oligomeric phenolic resin Resol;

[0118] The concentration of the sodium hydroxide solution is 0.6mol / L;

[0119] 2) Preparation of graphene oxide

[0120] 2.1) Under ice-water bath conditions, 150ml of concentrated sulfuric acid was added to a mixture of 2.5g of sodium nitrate and 1g of graphite, and stirred for 30min to obtain mixture A;

[0121] The concentration of the concentrated sulfuric acid is 97%;

[0122] 2.2) Add 15 g of potassium permanganate in portions to the mixture A obtained in step 2.1) and react for 12 hours to obtain a mixture B; control the reaction temperature not to exceed 20°C;

[0123] 2.3) Add 150ml of deionized water to the mixture B obtained in ste...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com