Graphene oxide/polyaniline supercapacitor composite electrode material and preparation method thereof

A supercapacitor and composite electrode technology, which is applied in the direction of hybrid capacitor electrodes, hybrid/electric double layer capacitor manufacturing, capacitors, etc., to achieve the effects of improved supercapacitor performance, improved mechanical properties, and simple operation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

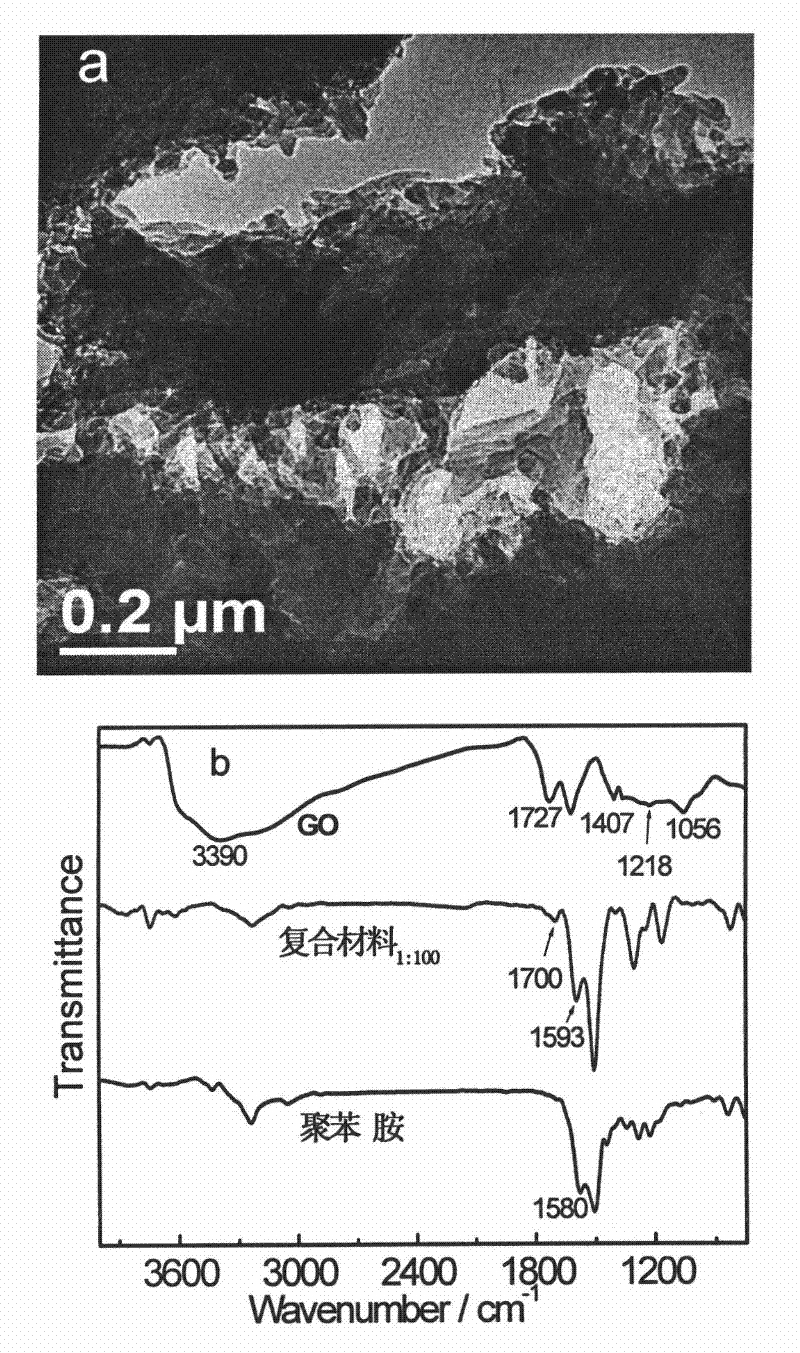

[0030] Embodiment 1: the preparation of graphite oxide. Add 10g of phosphorus pentoxide and 10g of potassium persulfate into 30mL of concentrated sulfuric acid at 80°C and stir for 30 minutes, take it out, react at room temperature for 6 hours, filter the product, wash to neutral and dry at room temperature to constant weight. Add the above product into 460mL of concentrated sulfuric acid at 0°C, stir and slowly add potassium permanganate, while controlling the temperature of the system not to exceed 15°C, stir evenly and raise the temperature to 35±3°C, continue stirring for a certain period of time, and then pour into the system Slowly add 1L of deionized water, control the temperature not to exceed 100°C, and continue stirring for 15 minutes. Add 2.8L of deionized water and 50mL of 30% hydrogen peroxide. After stirring for 5 min, the resulting brown suspension was suction-filtered and dialyzed until there was no sulfate ion in the filtrate. The product was vacuum dried at...

Embodiment 2

[0034] Embodiment 2: the preparation of graphite oxide is the same as embodiment 1.

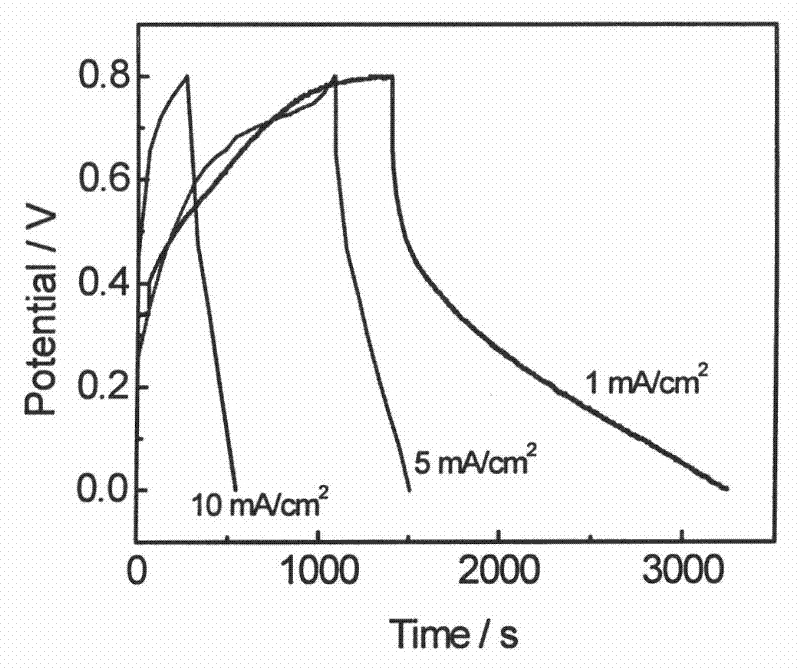

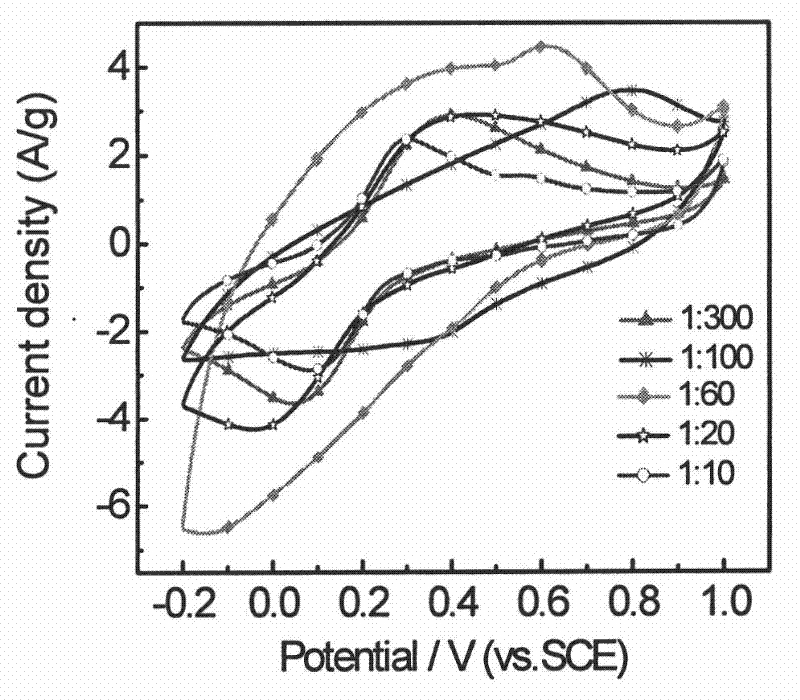

[0035] (1) Add 15.5 mg of graphite oxide to 196.79 mL of water and sonicate for 20-120 min to form a graphene oxide solution uniformly dispersed in a single layer; (2) Add 0.93 mL of aniline dropwise to the obtained graphene oxide solution at room temperature , sonicated for 10 to 60 minutes to disperse and form a mixed solution of 0.05mol / L aniline; (3) at 0°C, add 1.72mL of 30% hydrogen peroxide and 0.33mL of 0.1mol / L trichloro Ferric chloride and 0.23mL of 37% hydrochloric acid solution, the concentration of hydrogen peroxide is 0.083mol / L, the concentration of hydrochloric acid is 0.1mol / L, stirring and polymerizing for 24h; (4) After the reaction is completed, the obtained mixed solution is centrifuged, water, After repeated washing with ethanol, the graphene oxide / polyaniline composite electrode material with a mass ratio of graphite oxide to aniline (GO:ANI) of 1:60 was obtained by vac...

Embodiment 3

[0037] Embodiment 3: the preparation of graphite oxide is the same as embodiment 1.

[0038] (1) Add 186.2 mg of graphite oxide to 190.61 mL of water and sonicate for 20 to 120 min to form a graphene oxide solution uniformly dispersed in a single layer; (2) Add 3.73 mL of aniline dropwise to the obtained graphene oxide solution at room temperature , sonicated for 10 to 60 minutes to disperse and form a mixed solution of 0.2mol / L aniline; (3) at 10°C, add 4.12mL of 30% hydrogen peroxide and 0.4mL of 0.1mol / L trichloro Ferric chloride and 1.14mL of 37% hydrochloric acid solution, the concentration of hydrogen peroxide is 0.2mol / L, the concentration of hydrochloric acid is 0.5mol / L, stirred and polymerized for 12h; (4) After the reaction is completed, the obtained mixed solution is centrifuged, washed with water, After repeated washing with ethanol, the graphene oxide / polyaniline composite electrode material with a mass ratio of graphite oxide to aniline (GO:ANI) of 1:20 was obta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com