High-performance supercapacitor electrode material and preparation method thereof

A technology for supercapacitors and electrode materials, which is applied in the manufacture of hybrid capacitor electrodes and hybrid/electric double layer capacitors. It can solve the problems of performance improvement, poor structural stability, and small specific surface area, so as to improve electrochemical energy storage performance, Mild conditions and the effect of increasing the specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

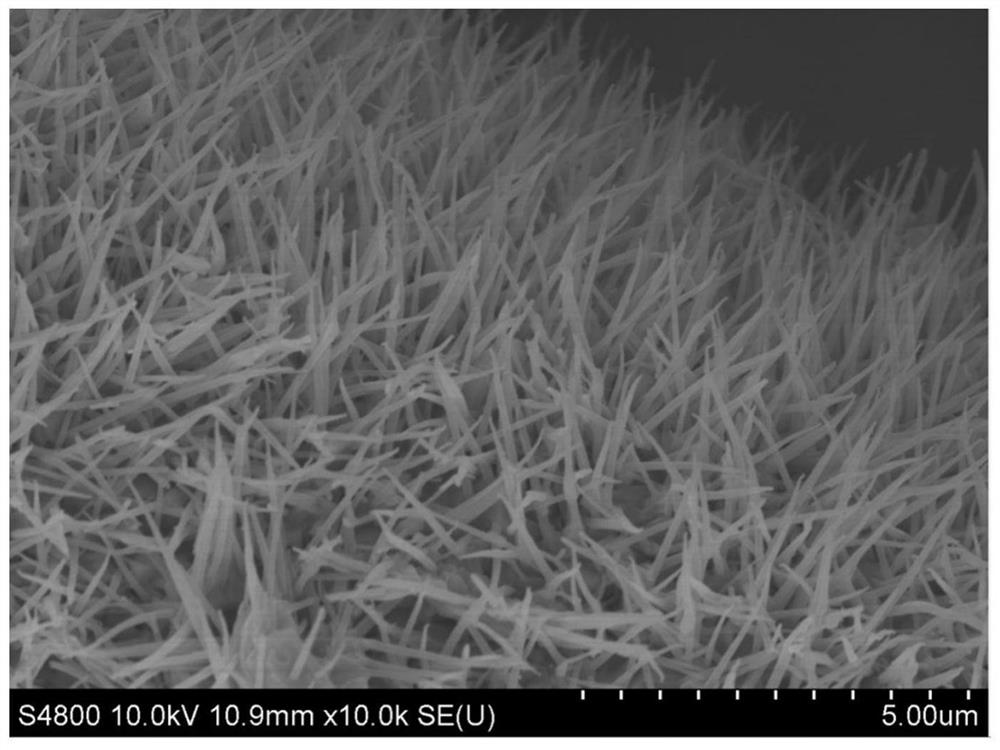

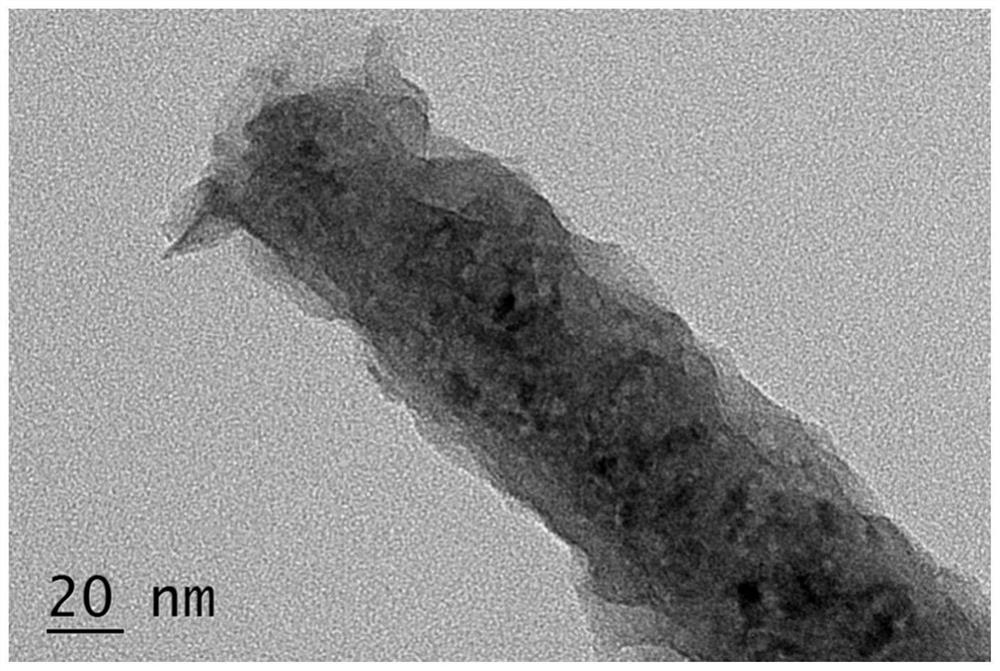

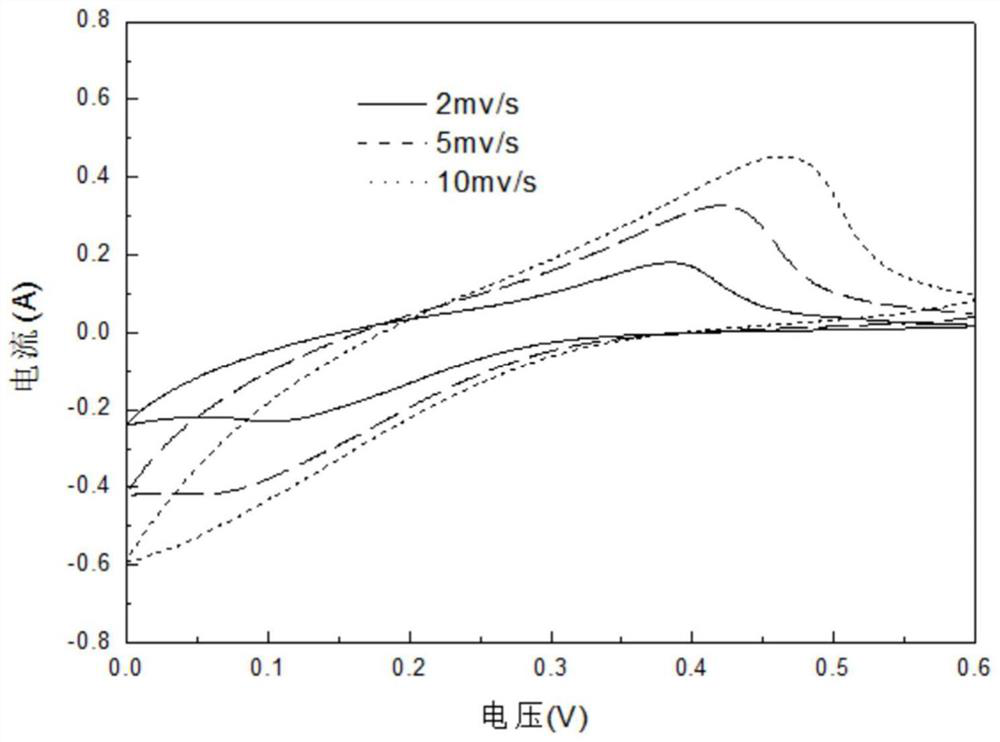

[0041]Example 1: Preparation of a hierarchical porous carbon-coated CoNiMn-S nanowire composite electrode material supported on nickel foam

[0042] Follow these steps:

[0043] (1) Preparation of oligophenolic resin Resol

[0044] Add 1.0 g of phenol and 2.5 mL of 40% formaldehyde solution to 4 mL of 0.5 M NaOH solution, and stir at 65° C. for 0.7 h to obtain the oligophenolic resin Resol.

[0045] (2) Preparation of Hierarchical Porous Carbon Materials (HPC)

[0046] 0.6g P123 (EO 20 PO 70 EO 20 ), 1.1g F127(EO 106 PO 70 EO 106 ), added to the above-mentioned oligophenolic resin Resol, stirred at 65°C for 4h, cooled to room temperature, transferred the obtained solution to a hydrothermal kettle, heated at 100°C for 18h, filtered out the obtained material, washed repeatedly with distilled water, Vacuum dried at 50°C for 24h, then transferred to a tube furnace for calcination at 800°C for 1.5h under nitrogen gas protection, cooled to room temperature and ground to obta...

Embodiment 2

[0060] Example 2: Preparation of a hierarchical porous carbon-coated CoNiMn-S nanowire composite electrode material supported on nickel foam

[0061] Follow these steps:

[0062] (1) Preparation of oligophenolic resin Resol

[0063] Add 1.0 g of phenol and 4.5 mL of 37% formaldehyde solution to 6 mL of 0.5M NaOH solution, and stir at 75° C. for 0.4 h to obtain the oligophenolic resin Resol.

[0064] (2) Preparation of Hierarchical Porous Carbon Materials (HPC)

[0065] 0.9g of P123 and 1.5g of F127 were added to the above oligophenolic resin Resol, stirred at 75°C for 2h, cooled to room temperature, and then transferred to a hydrothermal kettle, heated at 130°C for 10h, and the resulting material was filtered out , repeatedly washed with distilled water, vacuum dried at 80 °C for 6 h, then transferred to a tube furnace for calcination at 550 °C for 5 h under nitrogen gas protection, cooled to room temperature and ground to obtain multi-level porous carbon materials.

[0066...

Embodiment 3

[0078] Example 3: Preparation of a hierarchical porous carbon-coated CoNiMn-S nanowire composite electrode material supported on nickel foam

[0079] Follow these steps:

[0080] (1) Preparation of oligophenolic resin Resol

[0081] Add 1.0 g of phenol and 3.5 mL of formaldehyde solution with a concentration of 39% to 5 mL of 0.5M NaOH solution, and stir at 65° C. for 0.7 h to obtain the oligophenolic resin Resol.

[0082] (2) Preparation of Hierarchical Porous Materials (HPC)

[0083] 0.85g of P123 and 1.15g of F127 were added to the above oligophenolic resin Resol, stirred at 70°C for 3h, cooled to room temperature, and then transferred to a hydrothermal kettle, heated at 120°C for 15h, and the resulting material was filtered out , repeatedly washed with distilled water, dried in vacuum at 60 °C for 15 h, and then transferred to a tube furnace for calcination at 700 °C for 4 h under the protection of argon gas, cooled to room temperature, and ground to obtain a multi-level...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com