Preparation method for molybdenum disulfide nanosheet with reactive group-containing surface

A reactive group, molybdenum disulfide technology, applied in the field of nanomaterials, can solve problems such as limiting the application range of molybdenum disulfide nanosheets, and achieve the effects of easy separation, good application prospects, and high synthesis safety.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] (1) 0.4 grams of molybdenum disulfide, 1.2 grams of n-butyllithium and 6.8 grams of n-hexane were added to the hydrothermal reaction kettle, heated at 100°C for 2 hours, then cooled to room temperature, centrifuged and mixed with n-hexane After washing 5 times, it was dried at 50° C. for 12 hours to obtain molybdenum disulfide powder intercalated with lithium ions.

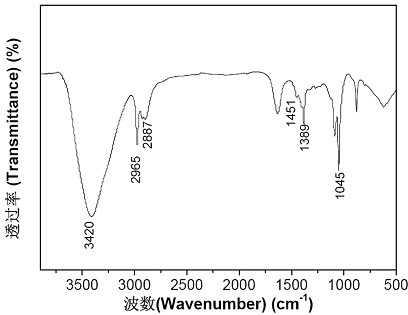

[0023] (2) Add 0.4 gram of molybdenum disulfide powder, 1 gram of 1-thioglycerol, and 400 gram of water into a beaker for ultrasonication, the ultrasonic time is 1 hour, and the ultrasonic power is 300 Watts, that is, molybdenum disulfide nanosheets containing hydroxyl groups on the surface are prepared.

Embodiment 2

[0025] (1) Add 0.1 g of molybdenum disulfide, 0.5 g of n-butyllithium and 2 g of n-hexane together into a hydrothermal reactor, heat at 150°C for 0.5 hours, then cool to room temperature, and wash with n-hexane after centrifugation After 5 times, dry at 50° C. for 12 hours to obtain molybdenum disulfide powder intercalated with lithium ions.

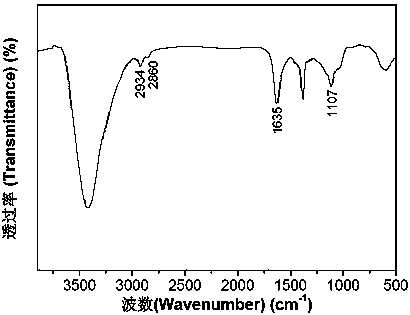

[0026] (2) Add 0.1 gram of molybdenum disulfide powder, 0.2 gram of 3-mercaptopropionic acid, and 50 gram of water into a beaker for ultrasonication, the ultrasonic time is 3 hours, and the ultrasonic power is 200 Watt, that is, molybdenum disulfide nanosheets containing carboxyl groups on the surface are prepared.

Embodiment 3

[0028] (1) Add 0.25 g of molybdenum disulfide, 0.5 g of n-butyllithium and 2.5 g of n-hexane together into a hydrothermal reaction kettle, heat at 80°C for 3 hours, then cool to room temperature, and wash by centrifugation and n-hexane After 5 times, dry at 50° C. for 12 hours to obtain molybdenum disulfide powder intercalated with lithium ions.

[0029] (2) Add 0.2 gram of molybdenum disulfide powder, 2 gram of cysteine, and 20 gram of water into a beaker for the lithium ion intercalation prepared in step (1) for ultrasonication, the ultrasonic time is 1 minute, and the ultrasonic power is 1000 watts , that is, molybdenum disulfide nanosheets containing amino groups on the surface are prepared.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com