Aqueous lithium ion flow battery

A flow battery, lithium ion technology, applied in water-based electrolyte fuel cells, battery electrodes, regenerative fuel cells, etc. High efficiency and energy density, low maintenance, high specific energy effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

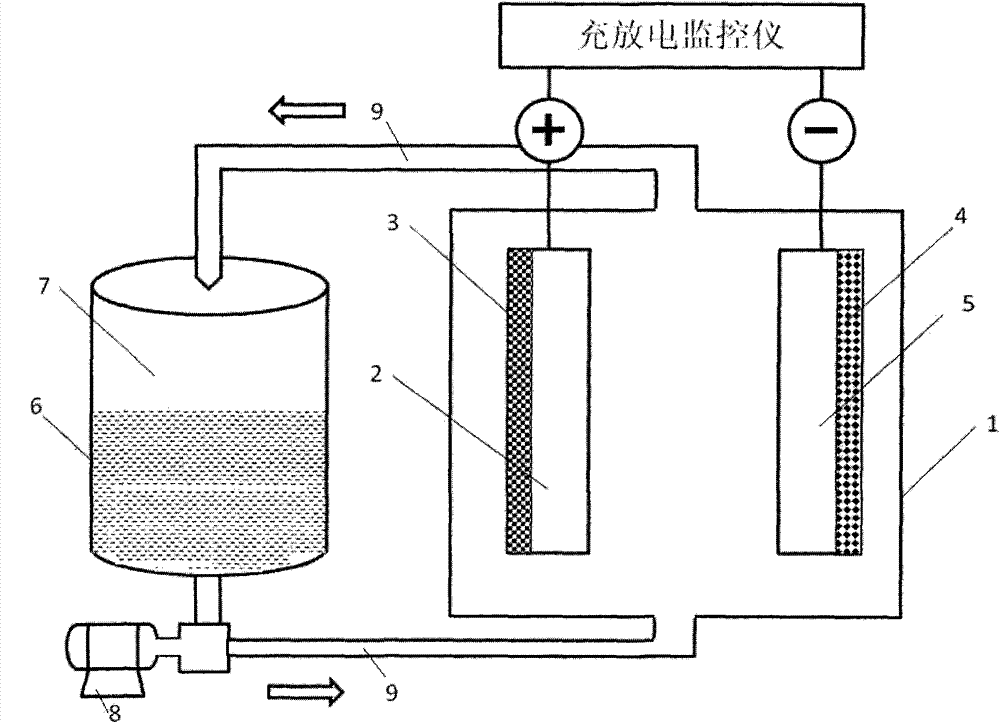

Method used

Image

Examples

example 1

[0021] Commercial LiMn after ball milling 2 o 4 Mix it with acetylene black and PTFE binder according to the weight ratio of 75:20:5 to make a slurry, press it into a sheet, press it on the foamed nickel current collector at a pressure of 10Mpa, and make an electrode after drying. After pre-charging and discharging, the actual capacity of the positive electrode is 78mAh / g, and the loading capacity of the active material is 11mg / cm 2 . by 1cm 2 The nickel-plated punching steel strip is the base electrode of the negative electrode zinc deposition, 50mL of 1.5M Li 2 SO 4 +1.5M Zn 2 SO 4 The solution (pH 4) is the electrolyte. The MP-10RN magnetic circulation pump is used as the power pump to circulate the electrolyte over the positive / negative electrode surface of the battery. The open-circuit voltage of the battery reaches 2.1V. When charged and discharged at 1C, the average discharge voltage is about 1.7V. The battery performance decay rate is lower than 10% after 1000 ...

example 2

[0023] Commercial carbon-coated LiFePO after ball milling 4 Mix it with 10% graphite powder and 5% PTFE binder to form a slurry, press it into a sheet, press it onto the foamed nickel current collector at a pressure of 10MPa, and make an electrode after drying; 2 The stainless steel mesh is the negative current collector, 50mL of 1.25M ZnSO 4 +2.0M Li 2 SO 4 The solution (pH value is 6) is the electrolyte, and the battery is assembled. The MP-10RN magnetic circulation pump is used to circulate the electrolyte over the positive / negative electrode surface of the battery. After pre-charging and discharging, the actual capacity of the positive electrode is 60mAh / g. The open-circuit voltage of the battery is about 1.20V. When charging and discharging at 1C, the average discharge voltage is about 1.0V. The charging and discharging cycles are 1000 times, and the battery performance decay rate is lower than 5. %.

example 3

[0025] Commercial LiMn after ball milling 2 o 4 Mix it with titanium dioxide powder and PVDF binder according to the weight ratio of 80:10:10 to make a slurry, evenly coat it on the conductive carbon paper, and make an electrode after drying. The active material loading capacity is 12mg / cm 2 . by 1cm 2 The nickel-plated punching steel strip is the base electrode of the negative electrode zinc deposition, 1.5M LiAC+1.5M Zn(AC) 2 The solution (pH 5) is the electrolyte. The MP-10RN magnetic circulation pump is used as the power pump to circulate the electrolyte over the positive / negative electrode surface of the battery. After pre-charging and discharging, the actual capacity of the positive electrode is 90mAh / g. The open-circuit voltage of the battery is 2.0V. When charging and discharging at 1C, the average discharge voltage is about 1.68V. The charging and discharging cycles are 1000 times, and the battery performance decay rate is small. .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com