Lithium ion supplementing technology of lithium ion batteries

A technology for lithium-ion batteries and lithium supplementation, which is applied in the fields of battery electrodes, electrolyte storage batteries, non-aqueous electrolyte storage batteries, etc. It can solve the problems of irreversible capacity loss, achieve the elimination of irreversible capacity loss, improve cycle stability, and reduce volume deformation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

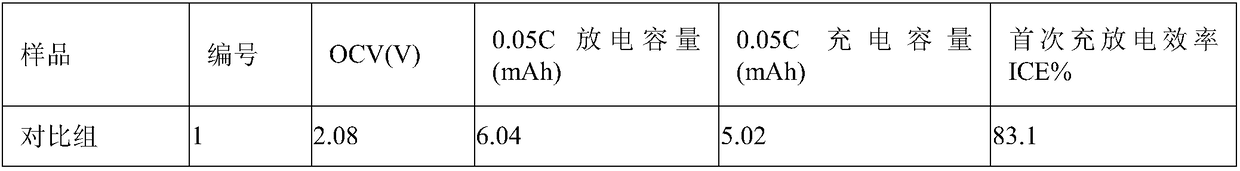

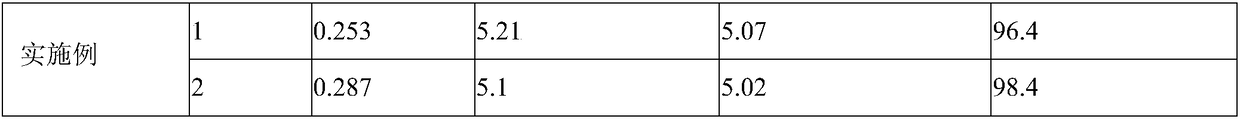

Examples

Embodiment 1

[0029] A lithium-ion battery supplement lithium process, the preparation method of the silicon carbon negative pole piece is:

[0030] 1) Glue compounding: Take 0.5 parts by weight of hydroxymethylcellulose sodium powder and pour it into the aqueous solution, stir quickly at 2000rpm, add 0.5 parts by weight of polyacrylate, mix until the solid content of the glue is 5%, stir slowly at 400rpm for 30min , to get the glue;

[0031] 2) Add conductive agent: add conductive agent Super P of 1% by weight of the glue solution to the glue solution obtained in step 1), and stir rapidly at 2000rpm for 2 hours to obtain a conductive solution;

[0032] 3) Add the main material: add 10 parts by weight of SiO negative electrode powder to the conductive liquid obtained in step 2), stir slowly at 400 rpm for 10 minutes, then stir quickly at 2000 rpm for 1 hour; then add 1 part by weight of hard carbon, and stir slowly at 400 rpm for 10 minutes, Add deionized water to adjust the stirring consi...

Embodiment 2

[0044] A lithium-ion battery supplement lithium process, the preparation method of the silicon carbon negative pole piece is:

[0045] 1) Glue compounding: Take 3 parts by weight of hydroxymethylcellulose sodium powder and pour it into the aqueous solution, stir quickly at 3000rpm, add 2 parts by weight of polyacrylate, mix until the solid content of the glue is 15%, stir slowly at 800rpm for 30min , to get the glue;

[0046] 2) Add conductive agent: add conductive agent Super P with 45% glue weight to the glue solution obtained in step 1), and stir rapidly at 3000rpm for 2 hours to obtain conductive solution;

[0047]3) Add the main material: add 55 parts by weight of SiO negative electrode powder to the conductive liquid obtained in step 2), stir slowly at 800 rpm for 10 minutes and then stir quickly at 3000 rpm for 1 hour; then add 6 parts by weight of natural graphite and 6 parts by weight of soft carbon , after stirring slowly at 800rpm for 10min, add deionized water to ...

Embodiment 3

[0059] A lithium-ion battery supplement lithium process, the preparation method of the silicon carbon negative pole piece is:

[0060] 1) Glue compounding: Take 5 parts by weight of hydroxymethyl cellulose sodium powder and pour it into the aqueous solution, stir quickly at 4000rpm, add 3 parts by weight of polyacrylate, mix until the solid content of the glue is 25%, stir slowly at 1200rpm for 30min , to get the glue;

[0061] 2) Add conductive agent: add conductive agent Super P with 70% glue weight to the glue solution obtained in step 1), and stir rapidly at 4000rpm for 2 hours to obtain conductive solution;

[0062] 3) Add the main material: add 92 parts by weight of SiO negative electrode powder to the conductive liquid obtained in step 2), stir slowly at 1200 rpm for 10 minutes and then stir quickly at 4000 rpm for 1 hour; then add 20 parts by weight of artificial graphite, and stir slowly at 1200 rpm for 10 minutes, Then add 10 parts by weight of styrene-butadiene rub...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com