Porous carbon-loaded molybdenum disulfide nanosheet composition material and preparation method and application thereof

A technology of molybdenum disulfide and composite materials, which is applied in the direction of chemical instruments and methods, nanotechnology, nanotechnology, etc., can solve the problems of incapable of large-scale use, small application value, and complicated preparation steps, and achieve excellent space confinement effect, Ease of mass production and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

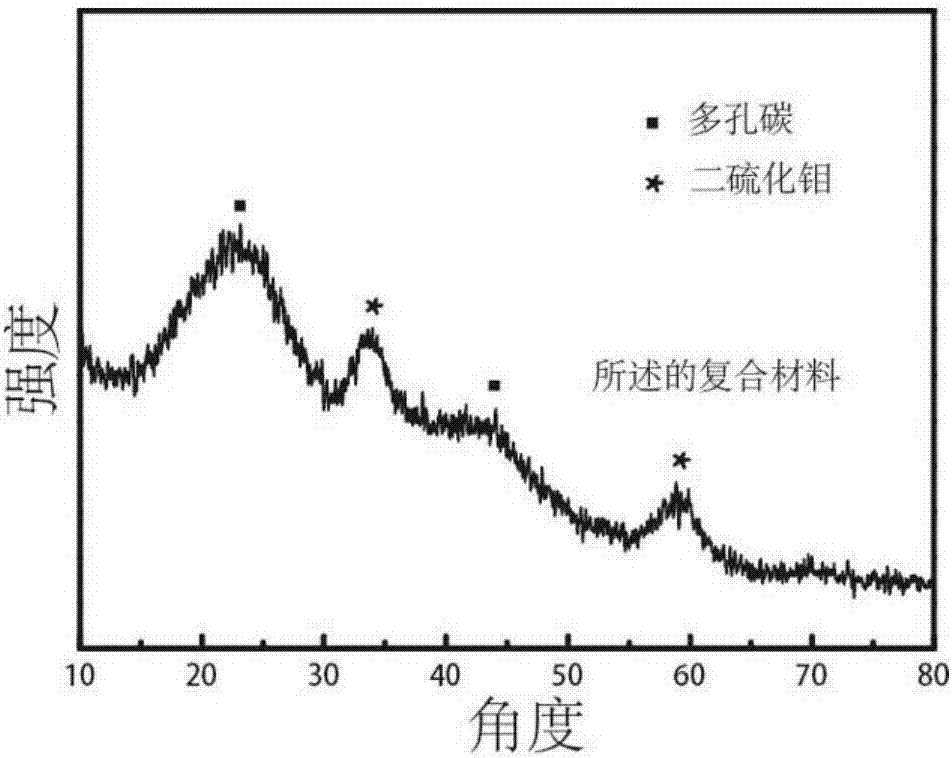

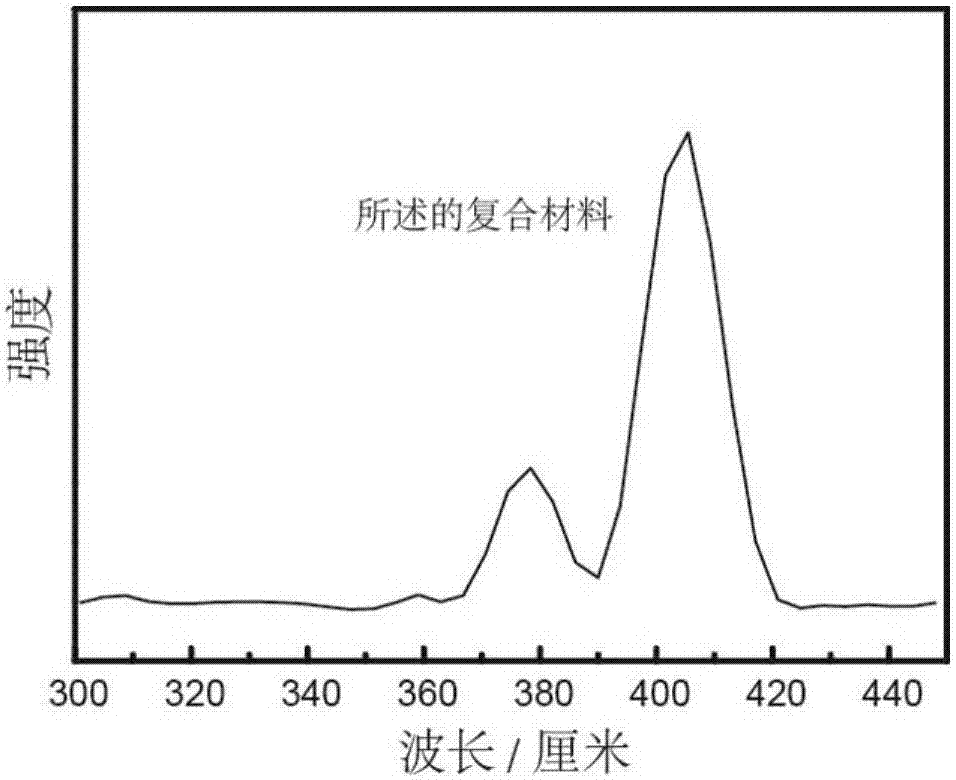

[0040] Example 1, preparation of porous carbon-supported molybdenum disulfide nanosheet composite material

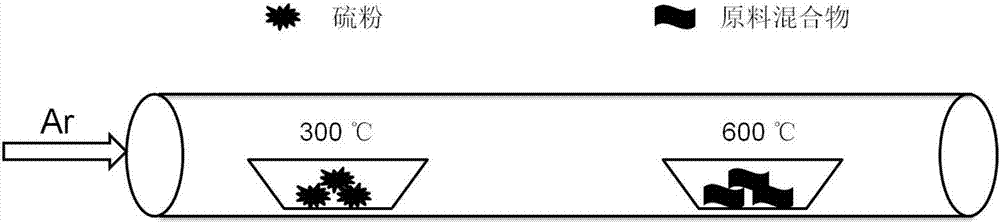

[0041] according to figure 1 The schematic diagram shown prepares porous carbon-supported molybdenum disulfide nanosheet composites, and the specific steps are as follows:

[0042] (1) Ketjen black (model ECP-600JD, with a pore diameter of 0.5 to 20 nanometers and a specific surface area of 1400m 2 / g) The mass ratio of porous carbon to ammonium molybdate is 12:5 (porous carbon is 60 mg, ammonium molybdate is 25 mg), add 5 ml of deionized water, ultrasonically disperse evenly, let stand soaking and adsorb for 24 hours, wash and centrifuge, Dry at 60°C for 24 hours under a vacuum of -0.1 MPa to obtain a precursor;

[0043](2) Transfer the precursor to the downstream of the dual-temperature zone heating furnace (downstream along the direction of gas introduction), and place excess sulfur powder (sulfur powder and precursor) in the upstream (upstream along the directio...

Embodiment 2

[0050] Example 2, preparation of porous carbon-supported molybdenum disulfide nanosheet composite material

[0051] Prepare the porous carbon-loaded molybdenum disulfide nanosheet composite material according to the same method as Example 1, the difference is: change the mass ratio of porous carbon and molybdenum source to 12:10 (60 mg for porous carbon, 50 mg for ammonium molybdate mg, 5 mL of deionized water). In the obtained composite material, the average particle size of the molybdenum disulfide nanosheets is 4.0 nanometers ± 0.5 nanometers, the number of layers is 1-3 layers, and the mass percentage is 20.2%.

Embodiment 3

[0052] Example 3, preparation of porous carbon-supported molybdenum disulfide nanosheet composite material

[0053] Prepare porous carbon-loaded molybdenum disulfide nanosheet composites according to the same method as Example 1, the difference is: change the mass ratio of porous carbon to molybdenum source to 12:20 (60 mg for porous carbon, 100 mg for ammonium molybdate mg, 5 mL of deionized water). In the obtained composite material, the average particle size of the molybdenum disulfide nanosheets is 5.4 nanometers ± 0.5 nanometers, the number of layers is 1-3 layers, and the mass percentage is 23.85%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com