Preparing method of porous monocrystal IT MoS2 nanosheet and application thereof

A nanosheet, single-layer technology, applied in nanotechnology, nanotechnology, chemical instruments and methods, etc., can solve the problem of not reaching MoS2, and achieve the effect of reducing electron transport resistance, simple and easy method, and large specific surface area.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

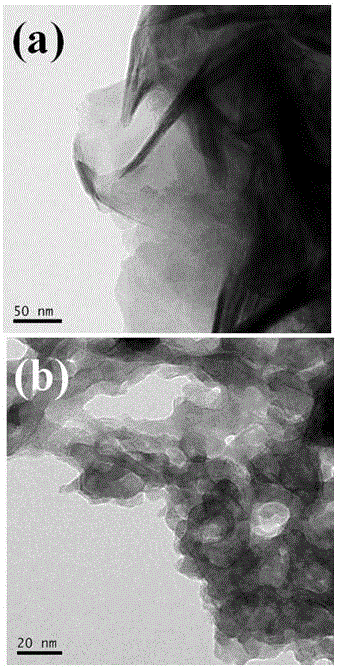

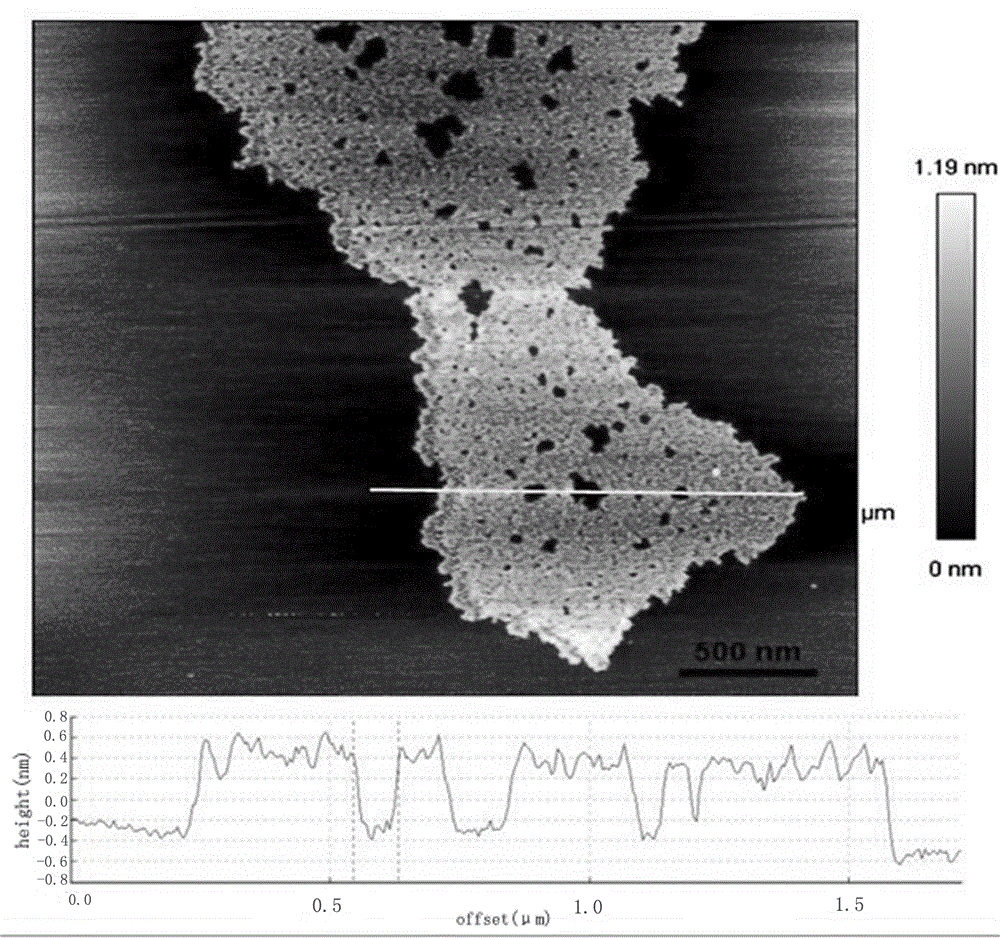

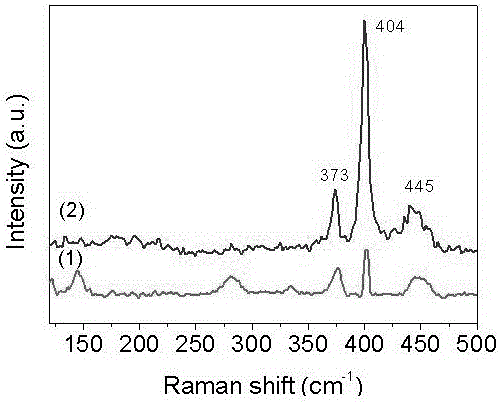

[0027] The porous monolayer 1T MoS of this example 2 The preparation method of nanosheet, the steps are as follows:

[0028] (1) Preparation of MoS in 2H crystal form by hydrothermal method 2 Nanosheets;

[0029] 1) Mix 67.5 mg sodium molybdate and 135.0 mg thiourea (the molar ratio of Mo / S is 1:6.5) and 30 mL deionized water to obtain mixture A;

[0030] 2) Stir the mixture A into a transparent solution, put it in a 40mL hydrothermal reaction kettle, heat it at 220°C for 10 hours, and obtain sample B after precipitation and filtration;

[0031] 3) B was naturally cooled to room temperature, washed with ethanol, and dried at 60 °C for 12 hours to obtain a multilayer 2H crystal form of MoS 2 Nanosheets;

[0032](2) Ultrasonic-assisted Li-ion intercalation method for multilayer 2H crystal MoS 2 The nanosheets are peeled off as follows:

[0033] 2g MoS of 2H crystal form 2 and 10 mL of n-butyllithium n-hexane solution with a concentration of 5 mol / L, and put it into a 50 m...

Embodiment 2

[0035] The porous monolayer 1T MoS of this example 2 The preparation method of nanosheet, the steps are as follows:

[0036] (1) Preparation of MoS in 2H crystal form by hydrothermal method 2 Nanosheets;

[0037] 1) Mix 45.0 mg sodium molybdate and 90.0 mg thiourea (the molar ratio of Mo / S is 1:6.5) and 20 mL deionized water to obtain mixture A;

[0038] 2) Stir the mixture A into a transparent solution, put it in a 40mL hydrothermal reaction kettle, heat it at 180°C for 26 hours, and obtain sample B after precipitation and filtration;

[0039] 3) B was naturally cooled to room temperature, washed with ethanol, and dried at 80 °C for 12 h to obtain multilayer 2H crystal MoS 2 Nanosheets;

[0040] (2) Ultrasonic-assisted Li-ion intercalation method for multilayer 2H crystal MoS 2 The nanosheets are peeled off as follows:

[0041] 2g MoS of 2H crystal form 2 and 10 mL, 10 mol / L n-butyllithium n-hexane solution, put it into a 50 mL Schlenk reaction tube, this process must ...

Embodiment 3

[0043] The porous monolayer 1T MoS of this example 2 The preparation method of nanosheet, the steps are as follows:

[0044] (1) Preparation of MoS in 2H crystal form by hydrothermal method 2 Nanosheets;

[0045] 1) Mix 56.3 mg sodium molybdate and 112.5 mg thiourea (the molar ratio of Mo / S is 1:6.5) and 25 mL deionized water to obtain mixture A;

[0046] 2) Stir mixture A into a transparent solution, put it in a 40mL hydrothermal reaction kettle, heat it at 200°C for 20 hours, and obtain sample B after precipitation and filtration;

[0047] 3) B was naturally cooled to room temperature, washed with ethanol, and dried at 70 °C for 12 hours to obtain a multilayer 2H crystal form of MoS 2 Nanosheets;

[0048] (2) Ultrasonic-assisted Li-ion intercalation method for multilayer 2H crystal MoS 2 The nanosheets are peeled off as follows:

[0049] 2g MoS of 2H crystal form 2 and 10 mL of n-butyllithium n-hexane solution with a concentration of 8mol / L, and put them into a 50mL S...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com