Mixed aquo-lithium ion battery

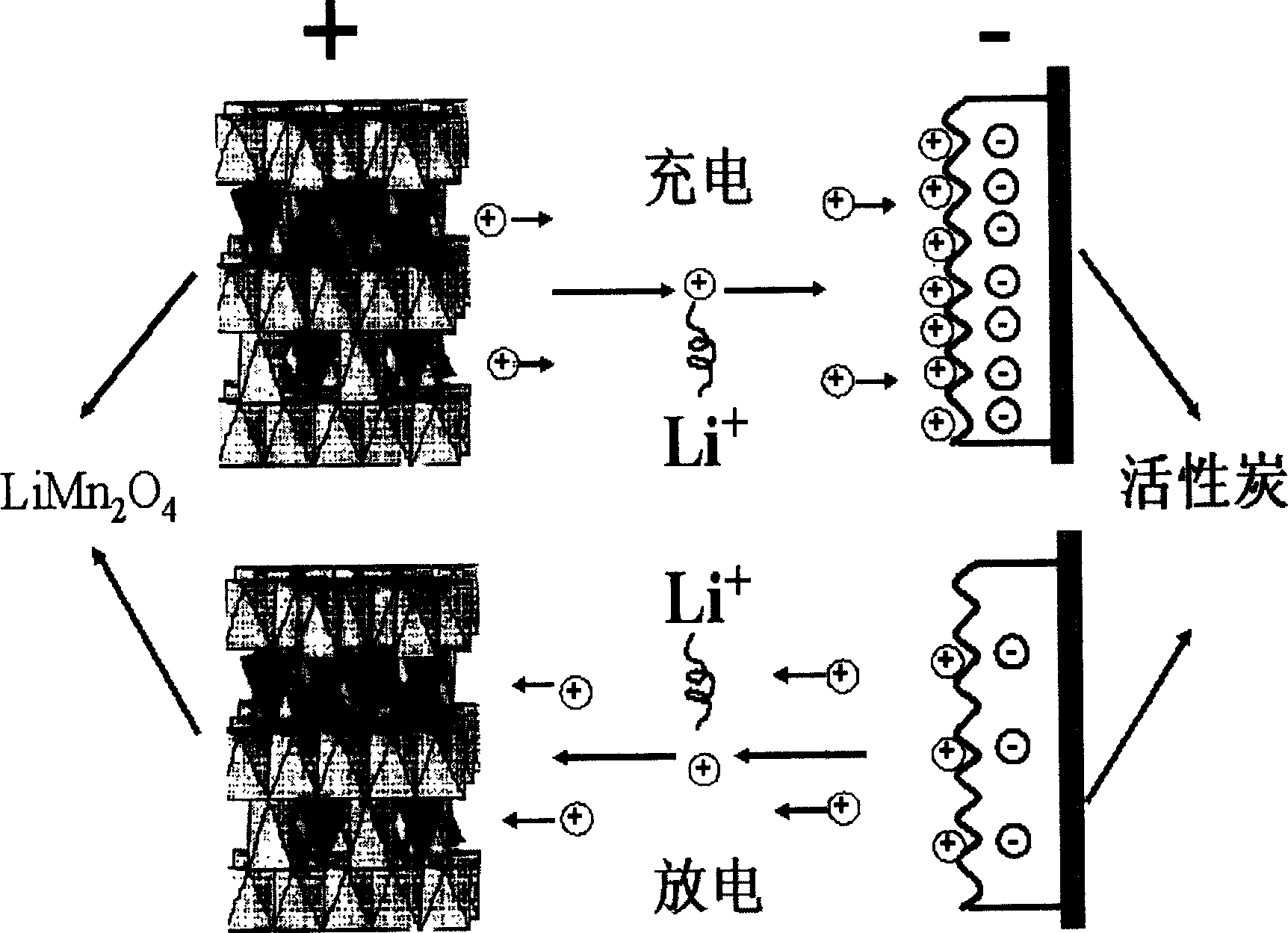

A lithium-ion battery and hybrid technology, applied in the direction of hybrid capacitors, hybrid capacitor electrodes, hybrid capacitor electrolytes, etc., can solve the problems of difficult to find electrode pair materials, poor cycle performance, poor cycle performance, etc., to achieve low cost and long cycle The effect of life and high power

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

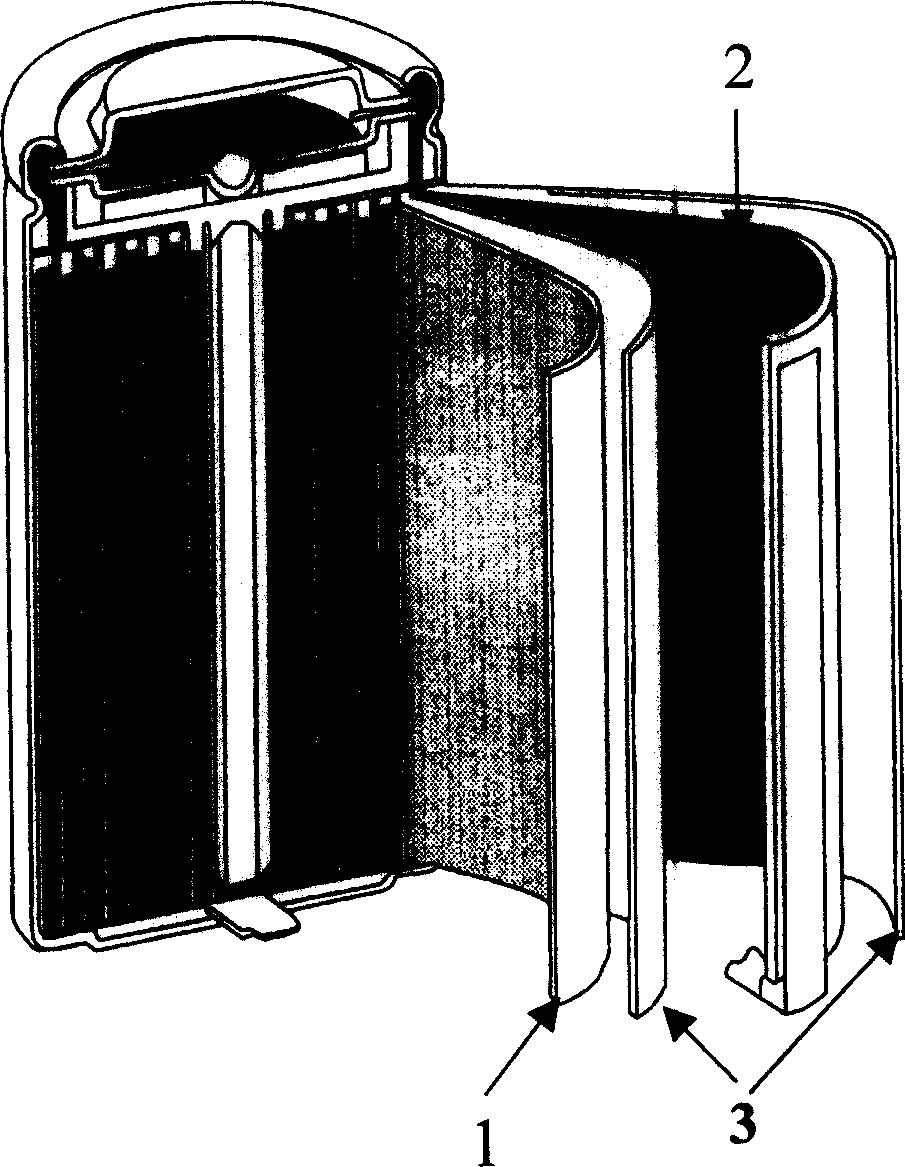

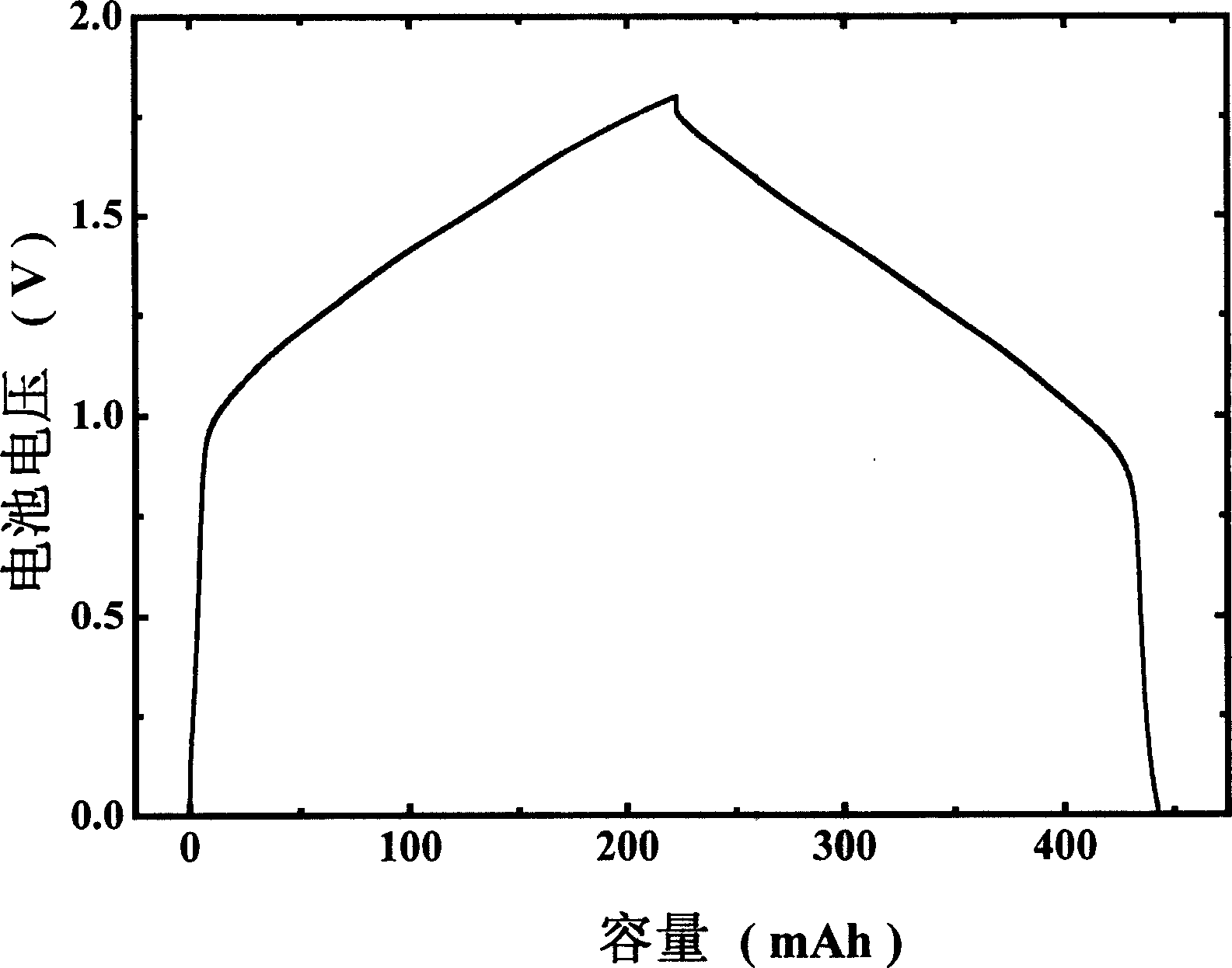

[0021] The positive electrode material adopts spinel type LiMn for commercial lithium-ion batteries 2 O 4 . The composition of the positive electrode is based on LiMn 2 O 4 : carbon black: binder=80:10:10 weight ratio mixed slurry, uniformly coated on the nickel mesh current collector, dried and pressed into electrodes. The negative electrode material is commercial activated carbon, and the slurry ratio is mixed according to activated carbon: conductive agent: binder = 85:5:10, and then evenly coated on the nickel mesh current collector, dried and pressed into electrodes. In this example, the actual capacity of the positive electrode material is 80 mAh / g, the negative electrode is 40 mAh / g, and the single-sided coating amount of the positive electrode is 5 mg / cm 2 , the negative electrode is 10mg / cm 2 . Then, the two electrodes were cut according to the specifications, and assembled into a 2# battery (diameter 14mm * height 50mm), the separator used was that of a commerc...

Embodiment 2

[0023]The cathode material is LiCoO for commercial lithium-ion batteries 2 , and the rest are the same as in Example 1, and the steps and conditions in Example 1 are followed for slurry mixing, electrode coating and battery preparation. The actual capacity of the positive electrode material is 120mAh / g, the negative electrode is 40mAh / g, and the single-side coating amount of the positive electrode is 3.4mg / cm 2 , negative electrode 10mg / cm 2 . In the 0V-1.8V working range, the discharge current is 2C, the capacity is 250mAh, the average working voltage is 1.2V, and the 10C charge and discharge capacity is maintained at 240mAh. After 10,000 cycles, the capacity retention rate can be 87% (see Table 1 for details) .

Embodiment 3

[0025] The cathode material is LiCo for commercial lithium-ion batteries. 1 / 3 Ni 1 / 3 mn 1 / 3 o 2 , and the rest are the same as in Example 1, and the steps and conditions in Example 1 are followed for slurry mixing, electrode coating and battery preparation. The actual capacity of the positive electrode material is 100mAh / g, the negative electrode is 40mAh / g, and the single-side coating amount of the positive electrode is 4mg / cm 2 , negative electrode 10mg / cm 2 . In the 0V-1.8V working range, the discharge current is 1C, the capacity is 230mAh, the average working voltage is 1.0V, and the 10C charge and discharge capacity is maintained at 210mAh. After 10,000 cycles, the capacity retention rate can reach 92% (see Table 1 for details) .

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com