Nano electrode structure for silicon-based three-dimensional micro-battery

A three-dimensional micro-battery and nano-electrode technology, applied in battery electrodes, micro-structure technology, micro-structure devices, etc., can solve problems such as degradation, affecting the practical application of silicon materials, and battery capacity due to material pulverization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

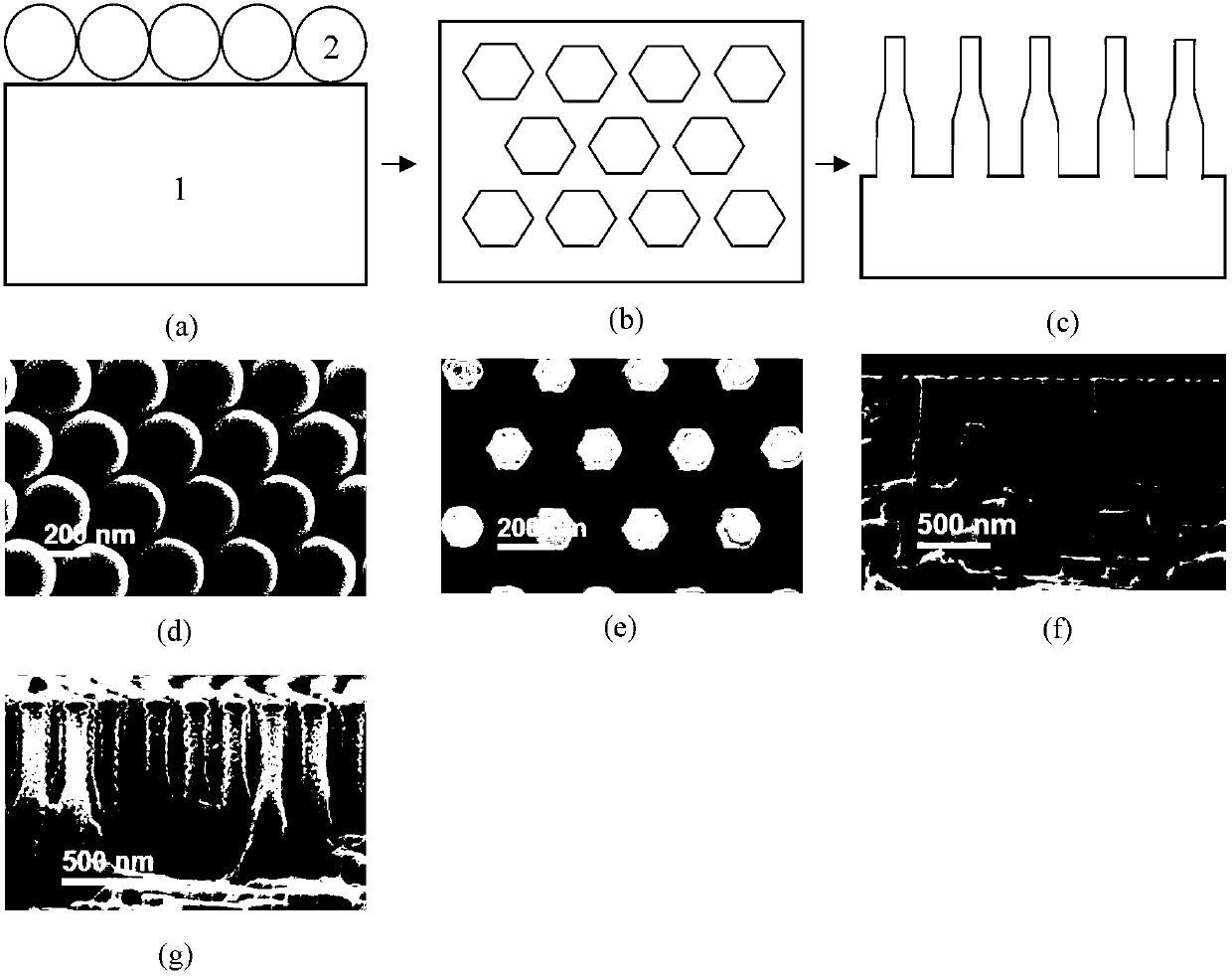

Embodiment 1

[0035] First, the standard cleaned silicon wafer (size: 100mm, that is, the size of a 4-inch silicon wafer) is activated for 5 minutes under the RIE system with a power of 80W, and then self-assembled single-layer PS nanospheres (diameter 300nm), the rotation speed is controlled at a low speed 500rpm, spin coating time 30s, high speed 2500rpm, spin coating time 60s. In the next step, put the above-mentioned treated sample (Figure-1d) into the ICP system for etching treatment, the ion source power is 1000W, and the reaction chamber temperature is 20°C. Finally, the etched samples were soaked in tetrahydrofuran for 10 hours, ultrasonically cleaned with acetone and alcohol for 10 minutes, and then the residual organic solvents on the surface were rinsed with deionized water, and the surface of the samples was dried with nitrogen. In this way, the final three-dimensional electrode structure of the hexagonal bottle-shaped silicon nanopillar array was obtained (Figure-1e, the diamet...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com