Synthesis of series nanometer lithium and manganese oxide for lithium ion battery

A technology of lithium manganese oxide and synthesis method, which is applied in the direction of lithium oxide;/hydroxide, battery electrode, manganese oxide/manganese hydroxide, etc., to achieve the effects of convenient control operation, low energy consumption, and good electrical performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Example 1: LiMnO 2 Preparation of Nanorods or Nanoparticles

[0031] 0.100g γ-MnOOH nanorods (or nanowires), 5.035g LiOH·H 2 O, 10ml of distilled water and 20ml of absolute ethanol were reacted for 5 days at 120°C and 1.0-1.5Mpa in a 50ml reactor. After the reaction was completed, the product was taken out and rinsed with distilled water for several times until the pH value of the supernatant was around 7. The obtained black precipitate was dried in a vacuum oven at 60°C. The appearance of the product was black powder.

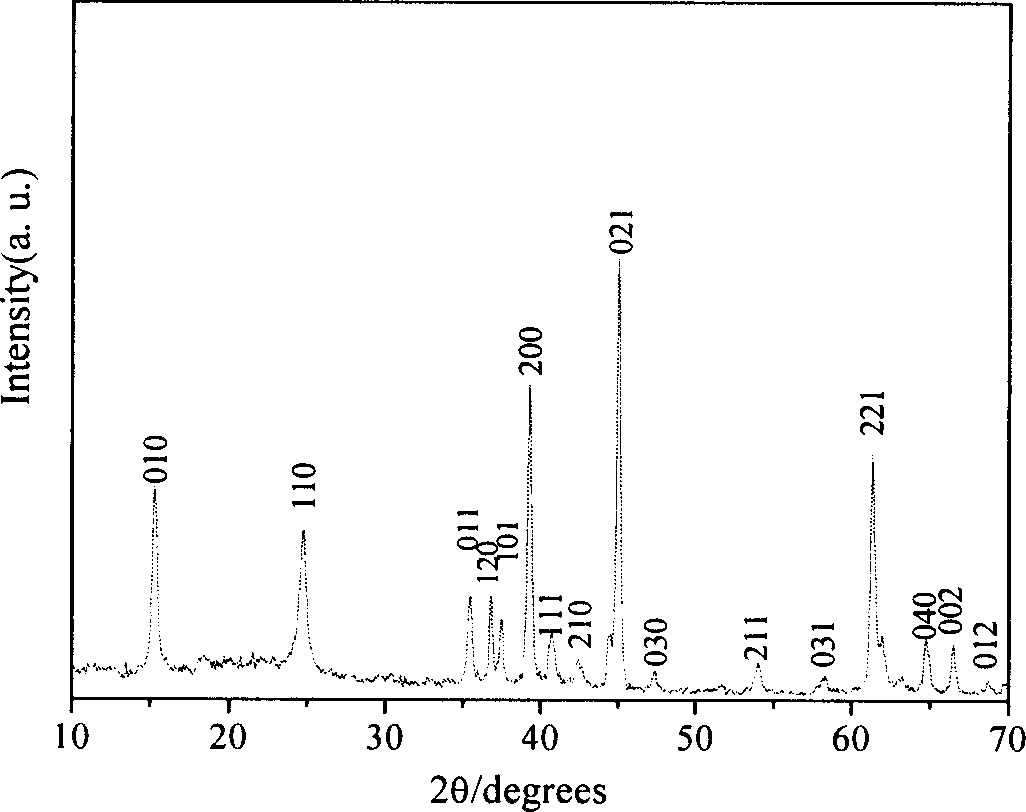

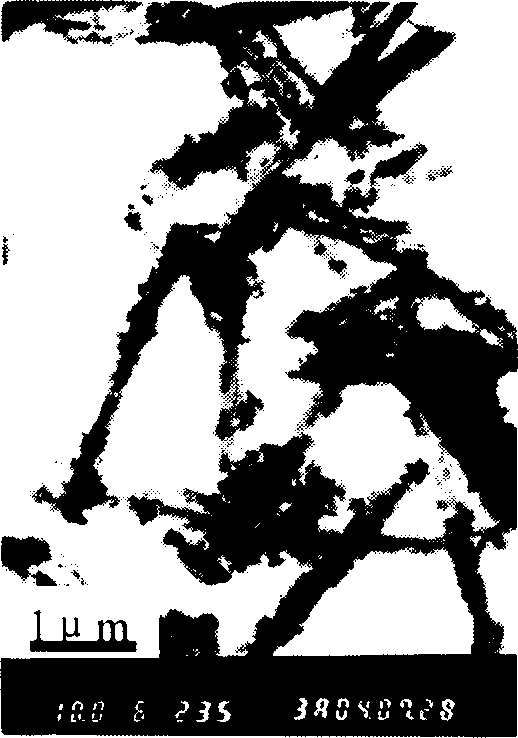

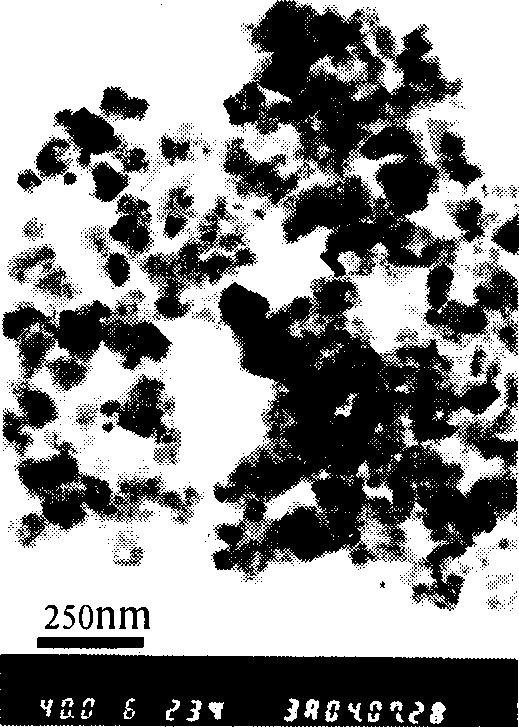

[0032] The XRD figure of product ( figure 1 ) analysis results show that the product is orthorhombic LiMnO 2 powder. The TEM image results of the product show that the morphology of the product is divided into two types due to the different morphology of the precursor. The precursor is γ-MnOOH nanorods, and the product is nanorods ( figure 2 ), the diameter is about 150nm-250nm, and the length is between 1-5μm. The precursor is γ-MnOOH nanowir...

Embodiment 2

[0033] Example 2: LiMn 2 0 4 Preparation of nanoparticles

[0034] 0.4g Mn 3 o 4 Nanoparticles, 33.568g LiOH·H 2 O. 200ml of distilled water was mixed evenly in a magnetically stirred reactor, and reacted for 7 days at a stirring speed of 150-250r / min under the conditions of a temperature of 160-170°C and a pressure of 1.3-1.5MPa. After the reaction was completed, the product was taken out, and the sample was washed with distilled water for several times until the pH value of the supernatant was around 7, and the obtained black precipitate was dried at 60°C. The appearance of the product was black powder.

[0035] By XRD ( Figure 4 ) analysis shows that: the product is cubic LiMn 2 o 4 powder. TEM photo ( Figure 5 ) shows that: the morphology of the product is nanoparticles, and its diameter is about 20nm-100nm.

Embodiment 3

[0036] Example 3: Li 2 MnO 3 Preparation of Nanorods or Nanoparticles

[0037] 0.100g precursor γ-MnOOH nanorods (or nanowires) or 0.1gMn 3 o 4 Nanoparticles with 6.758gK 2 S 2 o 8 , 5.035g LiOH·H 2 O and 30ml of distilled water were mixed evenly, then put into a 50ml reactor and reacted for 2 days at 150°C and 0.25-1.0MPa. After the reaction, the product was taken out, and the sample was washed with distilled water for several times until the pH value of the supernatant was around 7, and the obtained black precipitate was dried at 60°C. The appearance of the product was black powder.

[0038] By XRD ( Figure 6 ) analysis shows that the product is monoclinic Li 2 MnO 3 powder. The TEM photos show that the morphology of the product is divided into two types due to the different morphology of the precursor. If the precursor is γ-MnOOH nanorods, the product is nanorods ( Figure 7 ), its diameter is about 150nm-250nm, and its length is between 1-10μm. If the precu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com