Preparation method of lithium silicon alloy membrane electrode used for lithium ion battery

A technology of lithium-ion batteries and lithium-silicon alloys, applied in battery electrodes, electrode manufacturing, circuits, etc., can solve problems such as difficult process control, difficult large-scale production, and complex processes, achieving good adhesion, reducing impact, and effective The effect of regulating the circulation capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] (1) under argon protection, 1.8618g lithium perchlorate and 1.44ml silicon tetrachloride are joined in the propylene carbonate, stirring and dissolving, obtain 25.0ml electrolytic solution, the molar concentration of silicon tetrachloride in the electrolytic solution is 0.5mol L -1 , the molar concentration of lithium perchlorate is 0.7mol L -1 ;

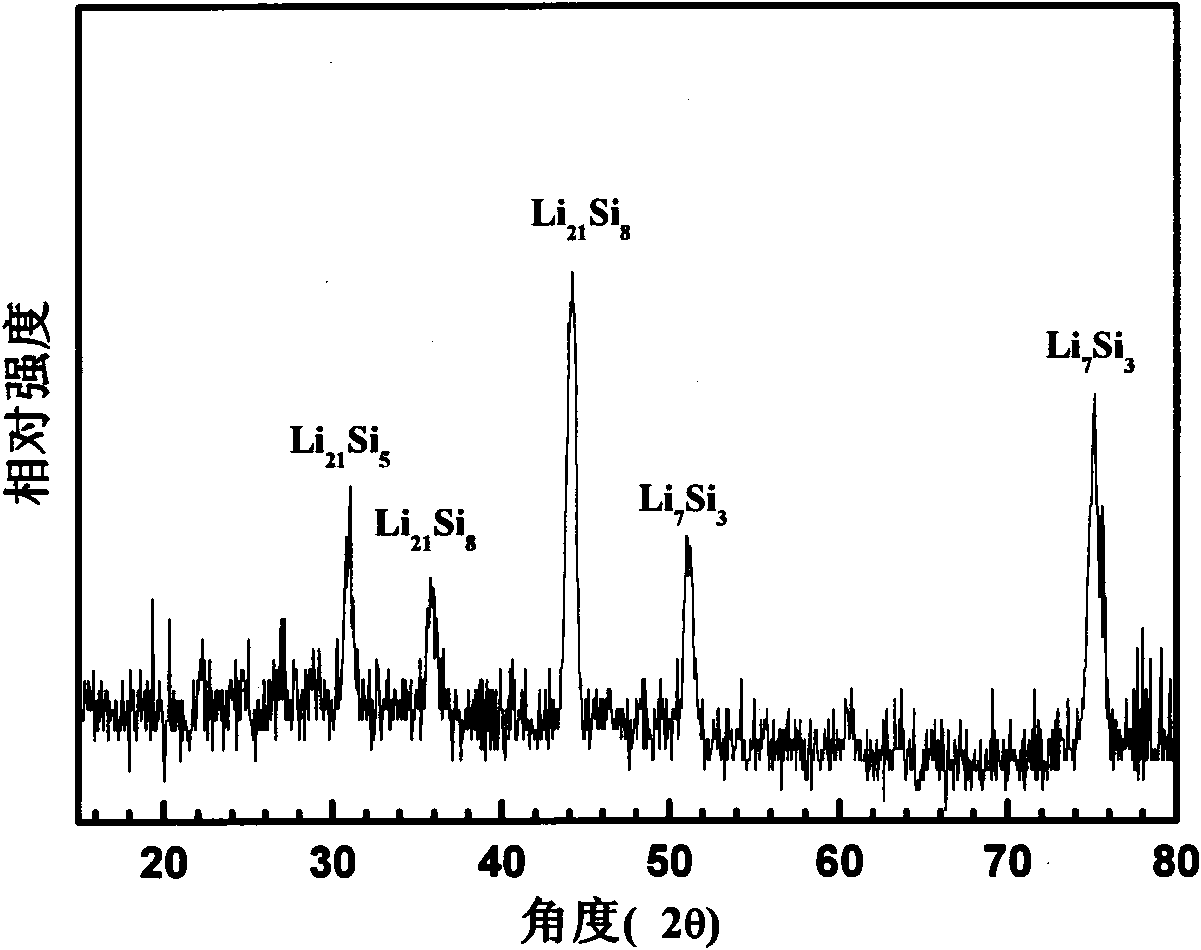

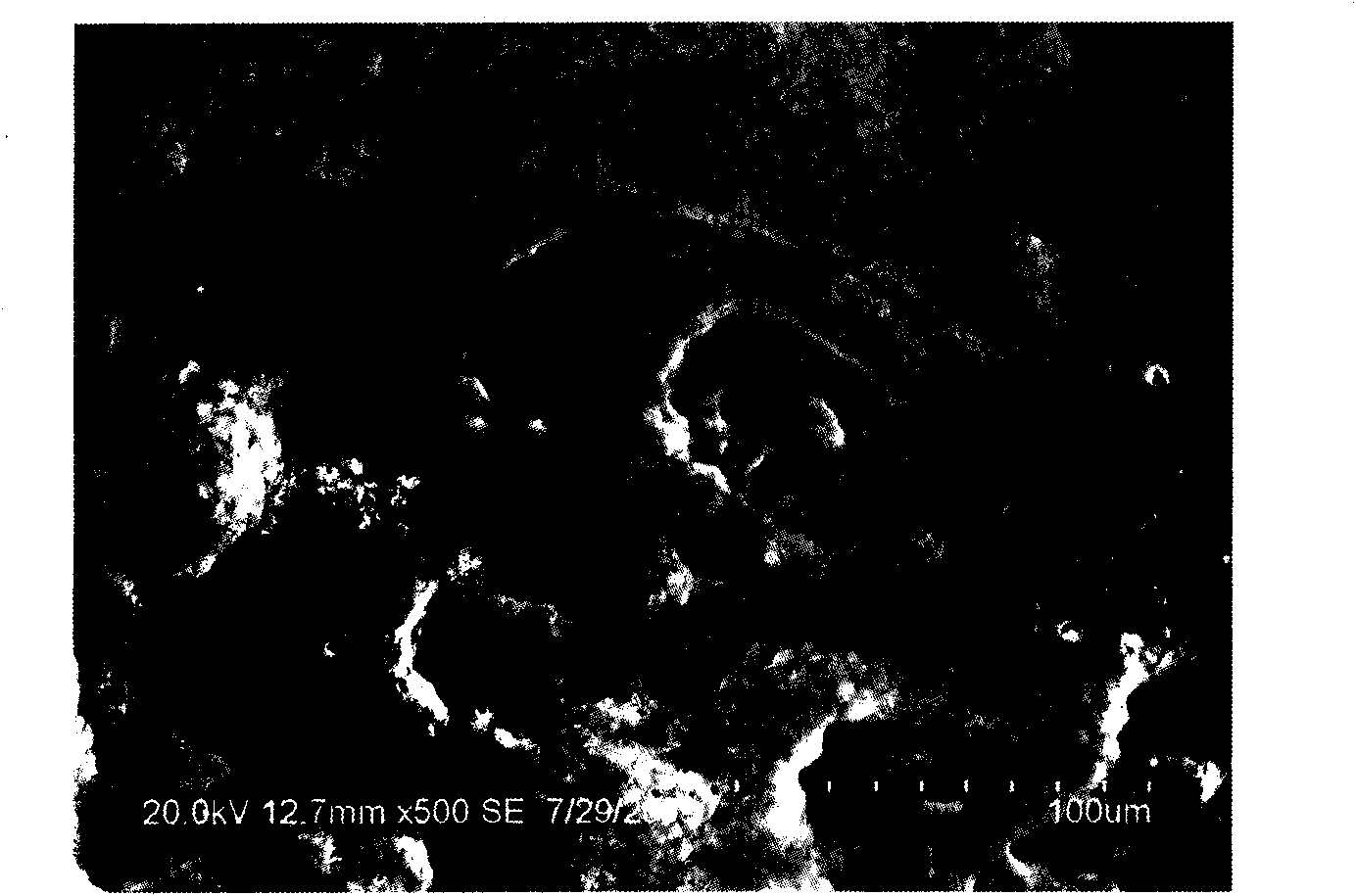

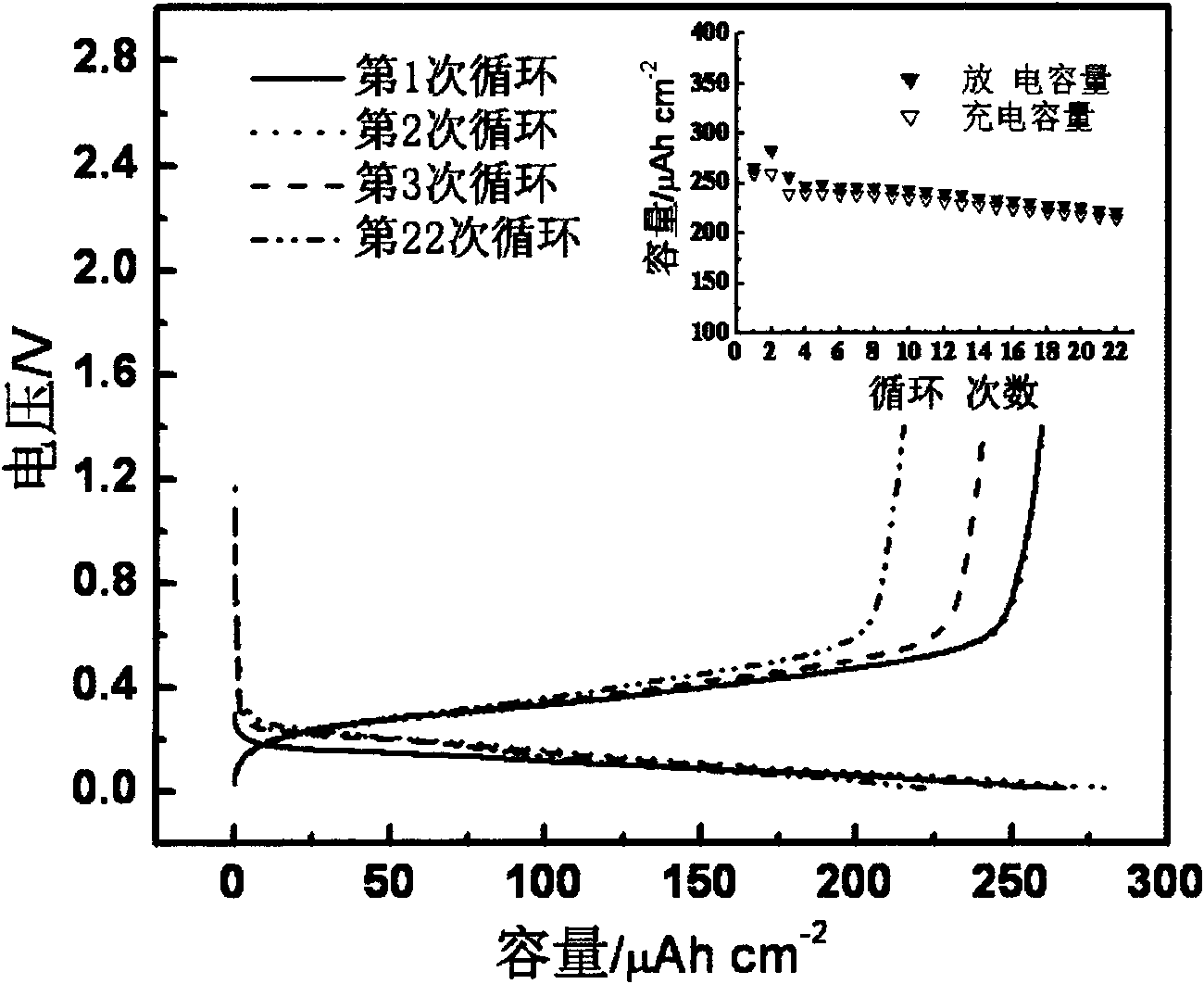

[0030] (2) Place the above electrolyte in a two-chamber electrolytic cell, and conduct lithium-silicon alloy electrodeposition at 25°C under the protection of argon: the cathode is copper foil with a thickness of 0.02mm; the electrodeposition adopts multi-current step technology , the apparent area current density of the first step is 3.8mA cm -2 , the step time of the first step is 600 seconds, and the apparent area current density of the second step is 1.3mA cm -2 , the step time of the second step is 7200 seconds. After the electrodeposition is completed, the electrodeposited copper foil is rinsed with propylene carbona...

Embodiment 2

[0035] (1) Under the protection of argon, add 1.8988g lithium hexafluorophosphate and 1.44ml silicon tetrachloride to propylene carbonate, stir and dissolve to obtain 25.0ml electrolyte, the molar concentration of silicon tetrachloride in the electrolyte is 0.5mol L -1 , the molar concentration of lithium hexafluorophosphate is 0.5mol L -1 ;

[0036] (2) Place the above electrolyte in a two-chamber electrolytic cell, and conduct lithium-silicon alloy electrodeposition at 30°C under the protection of argon: the cathode is a copper sheet with a thickness of 0.50mm; the electrodeposition adopts multi-current step technology , the apparent area current density of the first step is 3.8mA cm -2 , the step time of the first step is 600 seconds, and the apparent area current density of the second step is 1.3mA cm -2 , the step time of the second step is 7200 seconds. After the electrodeposition is completed, the electrodeposited copper sheet is rinsed with propylene carbonate to obt...

Embodiment 3

[0039] (1) under argon protection, 1.8618g lithium perchlorate and 1.44ml silicon tetrachloride are joined in the propylene carbonate, stirring and dissolving, obtain 25.0ml electrolytic solution, the molar concentration of silicon tetrachloride in the electrolytic solution is 0.5mol L -1 , the molar concentration of lithium perchlorate is 0.7mol L -1 ;

[0040] (2) Place the above electrolyte in a two-chamber electrolytic cell, and conduct lithium-silicon alloy electrodeposition at 25°C under the protection of argon: the cathode is copper foil with a thickness of 0.02mm; the electrodeposition adopts multi-current step technology , the apparent area current density of the first step is 3.8mA cm -2 , the step time of the first step is 600 seconds, and the apparent area current density of the second step is 1.3mA cm -2 , the step time of the second step is 10800 seconds. After the electrodeposition is completed, the electrodeposited copper foil is rinsed with propylene carbon...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com