Preparation method for silicon negative electrode material for lithium ion battery and silicon negative electrode material

A technology for lithium ion batteries and silicon anodes, applied in battery electrodes, secondary batteries, circuits, etc., can solve the problems of low Coulomb efficiency, difficulty in embedding lithium in silicon particles, and decreased electronic conductivity of materials, so as to alleviate the volume effect and improve the Cyclic Stability and Coulombic Efficiency, Effect of Enhanced Stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

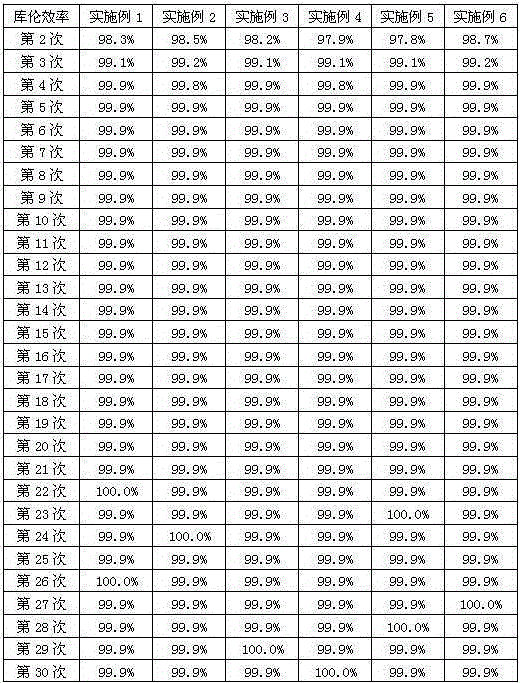

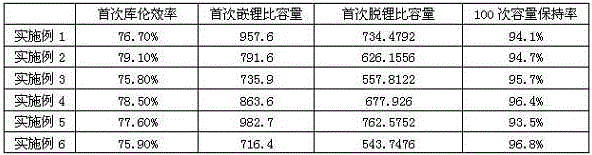

Examples

Embodiment 1

[0032] A preparation method of a silicon negative electrode material for a lithium ion battery, the preparation method is as follows:

[0033] Step 1. Surface hydroxylation: take 4.0g (particle size: 500nm) of silicon oxide, put it into a mixed solution of ammonia, hydrogen peroxide and water, heat, boil and stir for 30min, then wash with water, filter, and vacuum dry at 100°C for 8h; in the mixed solution The volumes of ammonia water (25% mass fraction), hydrogen peroxide (30% mass fraction) and water are 8ml, 8ml and 40ml respectively;

[0034] Step 2. Stirring: Take 1.0 g of the dried product in Step 1 and put it into an absolute ethanol solution containing 1.81 g of tetrabutyl titanate (10 ml of absolute ethanol), stir for 6 hours; then add 0.2 ml of water and stir for 60 min; then Add 3.3g of graphite (artificial graphite with a particle size of 5um), then add an anhydrous ethanol solution containing 0.287g of lithium acetate (the stoichiometric ratio of lithium atoms to ...

Embodiment 2

[0047] This embodiment provides a method for preparing a silicon negative electrode material for lithium ion batteries, the preparation method is as follows:

[0048] Step 1. Surface hydroxylation: Take 4.0g (particle size 15μm) of silicon oxide and put it into a mixed solution of ammonia, hydrogen peroxide and water, heat, boil and stir for 10 minutes, then wash with water, filter, and vacuum dry at 80°C for 12 hours; ammonia water in the mixed solution (25% mass fraction), hydrogen peroxide (30% mass fraction) and water volumes are 8ml, 8ml and 40ml respectively;

[0049] Step 2. Stirring: Take 3.1g of the dried product in step 1 and put it into an anhydrous ethanol solution containing 2.63g of tetraisopropyl titanate (10ml of anhydrous ethanol), stir for 2h, then add 0.2ml of water and stir for 10min, then Add 5.65g of graphite (natural graphite with a particle size of 1 μm), then add an anhydrous ethanol solution containing 0.51g of lithium nitrate (the stoichiometric rati...

Embodiment 3

[0062] This embodiment provides a method for preparing a silicon negative electrode material for lithium ion batteries, the preparation method is as follows:

[0063] Step 1. Surface hydroxylation: take 4.0g (particle size 1μm) of silicon oxide, put it into a mixed solution of ammonia, hydrogen peroxide and water, heat, boil and stir for 60 minutes, then wash with water, filter, and vacuum dry at 120°C for 2 hours; ammonia water in the mixed solution (25% mass fraction), hydrogen peroxide (30% mass fraction) and water volumes are 8ml, 8ml and 40ml respectively;

[0064] Step 2. Stirring: Take 3.1g of the dried product in step 1 and put it into an anhydrous ethanol solution containing 5.79g of tetrabutyl titanate (10ml of anhydrous ethanol), stir for 2h, then add 0.2ml of water and stir for 10min, then add 6.65g of graphite (expanded graphite with a particle size of 10 μm), then add an absolute ethanol solution containing 0.95g of lithium acetate (the stoichiometric ratio of li...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com