Anode material for lithium-ion battery and preparation method and application of anode material

A technology for lithium ion batteries and negative electrode materials, applied in battery electrodes, circuits, electrical components, etc., can solve the problems of easy expansion of silicon-containing negative electrode materials, battery capacity attenuation, etc., and achieve the effects of low cost, simple operation, and industrialized production.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

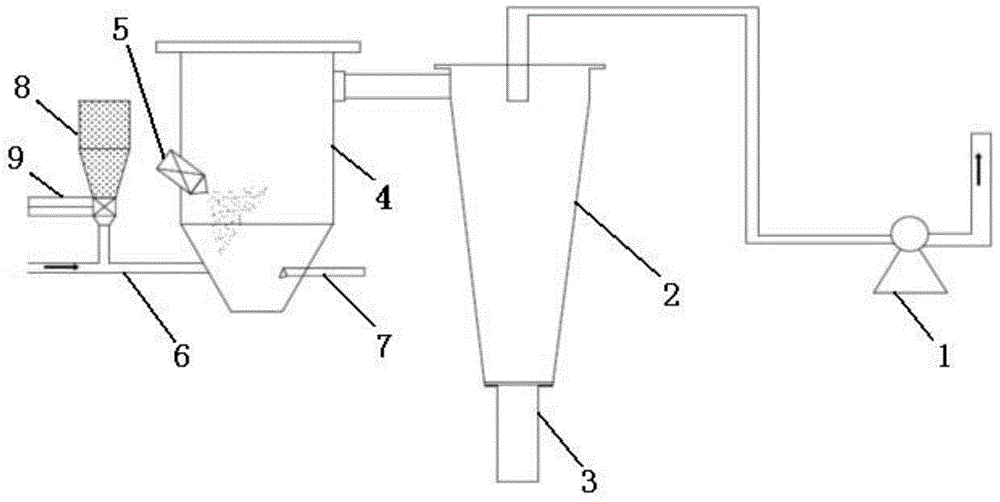

[0027] Correspondingly, an embodiment of the present invention also provides a method for preparing a negative electrode material of a lithium ion battery, comprising the following preparation steps:

[0028] S01. Preparation of basic raw materials: obtaining silicon / carbon composite materials;

[0029] S02. Formation of the first negative electrode material: atomize the metal salt solution, and coat the atomized metal salt solution on the fluidized silicon / carbon composite material to obtain a precursor film; After the precursor thin film is sintered and annealed at high temperature, the first negative electrode material coated with the metal oxide coating layer is obtained, wherein the metal salt solution can be sintered at high temperature and annealed to obtain the corresponding metal oxide. The metal oxide includes but not limited to at least one of aluminum oxide, silicon oxide, titanium oxide, magnesium oxide, zinc oxide, and zirconium oxide.

[0030]Specifically, in t...

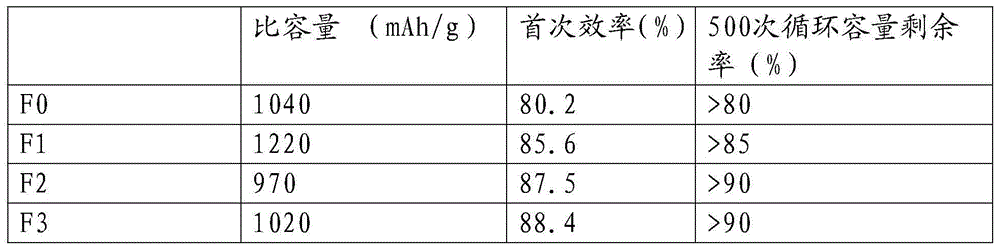

Embodiment 1

[0038] 1. Use self-made or purchased natural graphite, graphene, nano-carbon fiber or expanded graphite as the basic composite material raw material, that is, the carbon core layer raw material;

[0039] 2. Bake the above raw materials in an oven at 100-120 degrees Celsius for 12-24 hours to remove the moisture;

[0040] 3. Put the raw materials treated in step 2 into the CVD reactor, and pass the silane gas into the CVD reactor under the condition of 300-800 degrees Celsius for thermal decomposition reaction, so that the silicon element is deposited on the surface of the carbon core layer to form a certain thickness Metal silicon film or nano-scale silicon particles, the specific deposition time is 30-360min, to obtain a metal silicon film or metal silicon particles with a thickness of 20-200nm or 10-100nm;

[0041] 4. After the CVD deposition reaction in the previous step, carbon / silicon composite material particles were obtained;

[0042] 5. The carbon / silicon composite pa...

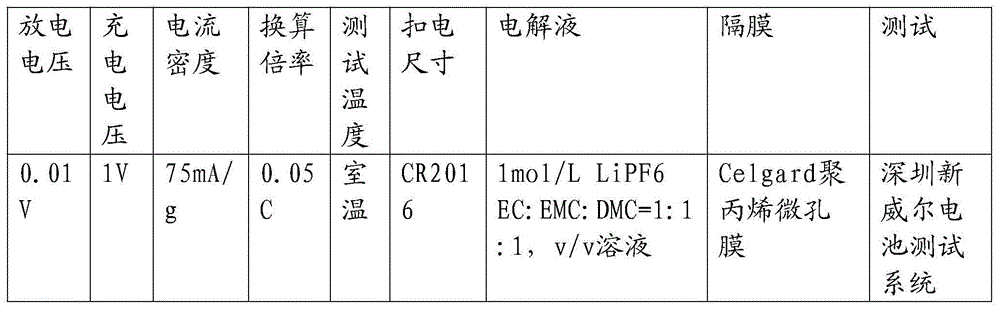

Embodiment 2

[0047] 1. Using self-made multi-layer 2-10 layer graphene as the carbon core layer raw material;

[0048] 2. Bake the above raw materials in an oven at 120°C for 24 hours to remove the moisture;

[0049] 3. Put the raw materials treated in step 2 into a CVD reactor, and put silane gas into the reactor at a rate of 100 sccm at 550°C for decomposition reaction and then deposit. The deposition time is 120 minutes, and the silane is decomposed to form a uniform thickness (40nm ) of silicon nanoparticles.

[0050] 4. Obtained graphene / silicon composite material particles through the CVD deposition reaction of the previous step.

[0051] 5. The graphene / silicon composite particle obtained in step 4 is used as the raw material particle for the next step for subsequent use.

[0052] 6. With aluminum isopropoxide as raw material, be configured into the aluminum isopropoxide solution of 0.2g / ml, be 1.5%: 1 coating amount with above-mentioned graphene / silicon composite material mass ra...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com