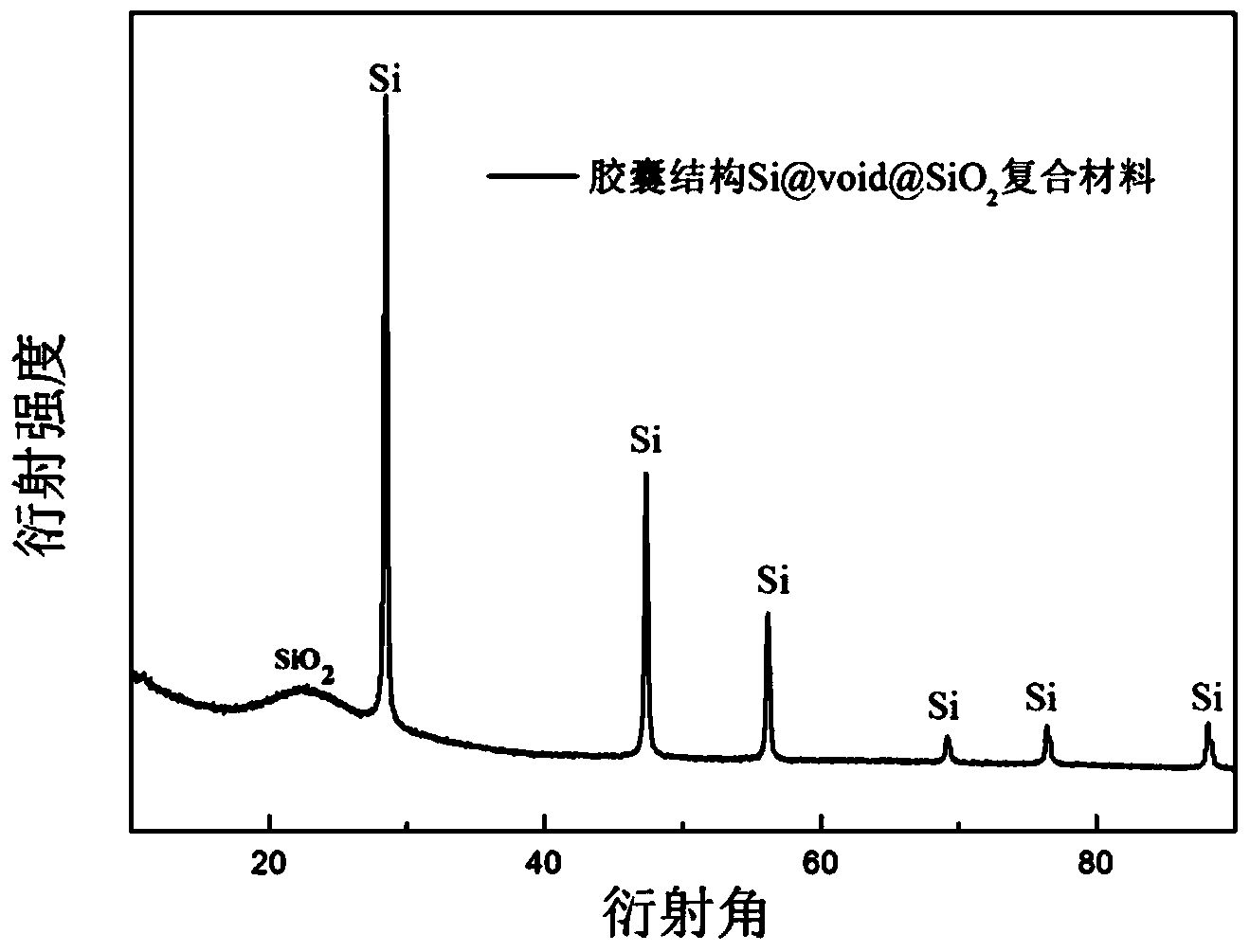

Silicon-based lithium ion battery negative electrode material and preparation method thereof

A technology for lithium-ion batteries and negative electrode materials, applied in battery electrodes, nanotechnology for materials and surface science, circuits, etc., can solve problems such as capacity decay, inability to fundamentally suppress volume effects, and poor cycle performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] Preparation of negative electrode material: at room temperature, add 0.017g sodium dodecylbenzenesulfonate and 0.0165g dodecyl sulfobetaine to 10ml deionized water, and magnetically stir for 0.5 hours to form a mixed surfactant solution; Then, add nano-silica powder into deionized water, stir magnetically for 0.5 hours, configure a 10mg / ml silicon powder suspension, add 20ml of silicon powder suspension (10mg / ml) dropwise to the above mixed surfactant solution, and Stir continuously for 0.5 hours during this process; heat the above solution to 40°C in a water bath environment, and stir for 1 hour; drop 47ul of 3-aminopropyltriethoxysilane and 300ul of ethyl orthosilicate into the above solution respectively, and stir 2 hours; then the mixed solution was heated to 80°C in an oil bath and kept for 24 hours; after the reaction, the product was collected by centrifugation, washed with ethanol and deionized water for several times, and dried; then the product was added to 50...

Embodiment 2

[0044] Negative material preparation

[0045] At room temperature, mix 0.017g sodium dodecylbenzenesulfonate and 0.0165g dodecyl sulfobetaine in a molar ratio of 1:1, add 10ml deionized water, and stir magnetically for 1 hour; Add the powder into deionized water and stir it magnetically for 1 hour to form a 6mg / ml silicon powder suspension. Add 10ml of the silicon powder suspension (6mg / ml) dropwise to the above mixed surfactant solution, and keep stirring during this process ;Heat the above solution to 50°C in a water bath environment, stir for 1 hour, drop 47ul of 3-aminopropyltriethoxysilane and 300ul of ethyl orthosilicate into the above solution respectively, and stir for 1 hour; then mix the solution Heat to 80°C in an oil bath and keep warm for 30 hours; after the reaction, the product is collected by centrifugation, washed with ethanol and deionized water, and dried; then the product is mixed with 26ml of concentrated hydrochloric acid (38%) acetonitrile solution (the...

Embodiment 3

[0049] Negative material preparation

[0050] At room temperature, mix 0.088g sodium dodecylbenzenesulfonate and 0.086g dodecyl sulfobetaine in a molar ratio of 1:1, add 10ml deionized water, and stir magnetically for 2 hours; then, mix 10ml silicon The powder suspension (8mg / mL) was added dropwise into the above mixed surfactant solution, and the stirring was continued during this process; the above solution was heated to 40°C in a water bath environment, and stirred for 2 hours; the 3-aminopropyltri Ethoxysilane 94ul, tetraethyl orthosilicate 300ul were dropped into the above solution respectively, and stirred for 0.5 hours; then the mixed solution was heated to 90°C in an oil bath, and kept for 48 hours; after the reaction, the product was collected by centrifugation , wash the product with ethanol and deionized water respectively, and dry; then add the product to 30ml of concentrated hydrochloric acid (38%) acetonitrile mixed solution (the volume ratio of hydrochloric acid...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com