Silicon monoxide composite cathode material for lithium ion battery, and preparation method thereof

A lithium-ion battery, silicon oxide technology, applied in battery electrodes, circuits, electrical components, etc., can solve the problems of limited preparation methods, waste of resources, and high cost of nano-silicon powder

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

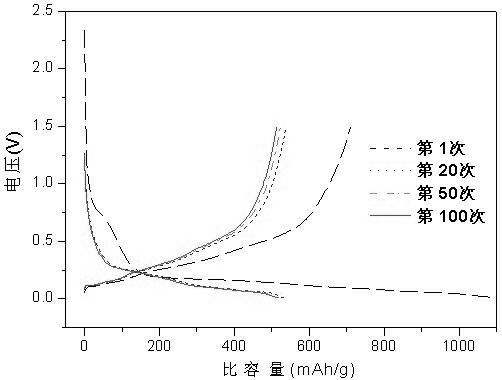

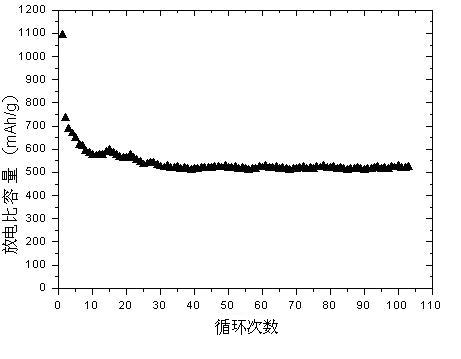

[0019] Silicon oxide was sintered at high temperature under an inert atmosphere, and the temperature was raised to 900°C at a rate of 3°C / min, and then kept for 4 hours, and then cooled down to room temperature naturally. Accurately weigh 2g of silicon oxide, 0.6g of graphite, and 1.4g of expanded graphite, add them to a planetary ball mill, evacuate into a vacuum or in an inert atmosphere, ball mill at a speed of 400 r / min for 5 hours, and mix evenly to obtain a silicon oxide composite Negative material.

[0020] Mix the composite material, conductive agent acetylene black, and binder PVDF (polyvinylidene fluoride) according to the mass ratio of 8:1:1, and use NMP (1-methyl-2-pyrrolidone) to prepare the mixture into a slurry. Coat evenly on copper foil, put it in an oven, dry at 80-120°C for 1 hour, take it out and punch it into a pole piece, dry it in vacuum at 85°C for 12 hours, press it, and dry it in vacuum at 85°C for 12 hours to prepare the test battery pole piece. Wi...

Embodiment 2

[0022] Silicon oxide is sintered at high temperature under an inert atmosphere, and the temperature is raised to 1000°C at a rate of 5°C / min, and then kept for 4 hours, and then naturally cooled to room temperature. Accurately weigh 0.9g of silicon oxide and 2.1g of carbon black, add them to a planetary ball mill, evacuate into a vacuum or in an inert atmosphere, ball mill at a speed of 500 r / min for 4.5 hours, and mix evenly to obtain a silicon oxide composite negative electrode material . The test method of the assembled battery is the same as that in Example 1, and the first discharge specific capacity is measured to be 745.95mAh / g, which remains at 430mAh / g after 100 cycles.

Embodiment 3

[0024] The silicon oxide was sintered at high temperature under an inert atmosphere, and the temperature was raised to 800°C at a rate of 3°C / min, and then kept for 5 hours, and then cooled down to room temperature naturally. Accurately weigh 2g of silicon oxide and 1g of expanded graphite, add them to a planetary ball mill, evacuate into a vacuum or in an inert atmosphere, ball mill at a speed of 400 r / min for 6 hours, and mix evenly to obtain a silicon oxide composite negative electrode material. The test method of the assembled battery is the same as that of Example 1, and the first discharge specific capacity is measured to be 1215.284mAh / g, which remains at 542mAh / g after 100 cycles.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com