Lithium supplement method and system of pole plate

A pole piece and lithium supplementation technology, applied in electrode manufacturing, battery electrodes, electrode rolling/calendering, etc., can solve the problems of easily broken strips, difficult continuous production, low strength, etc., to enhance strength, avoid tearing or pinch off effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0063] The present application will be described in further detail below through specific embodiments and in conjunction with the accompanying drawings. "Front", "back", "left", "right", "upper" and "lower" mentioned in the text are all based on the placement state of the pole piece lithium supplement system in the attached drawing.

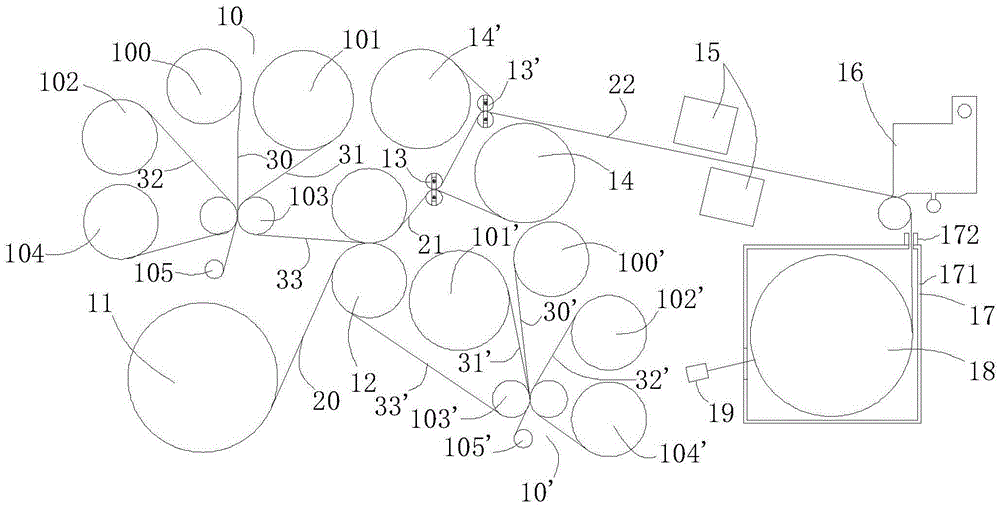

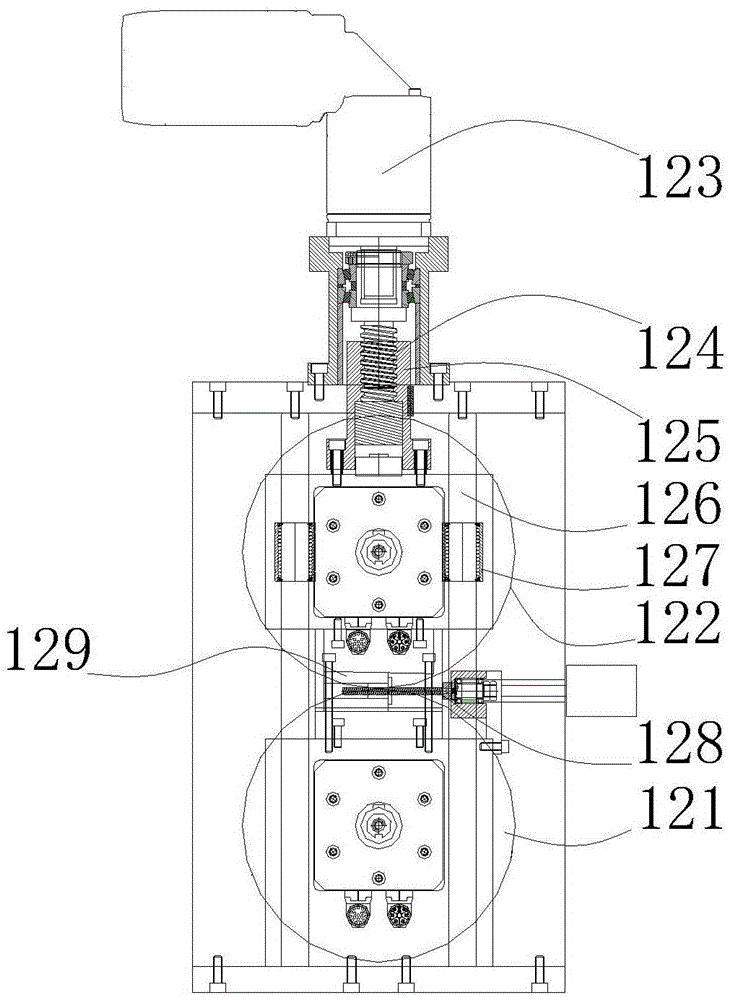

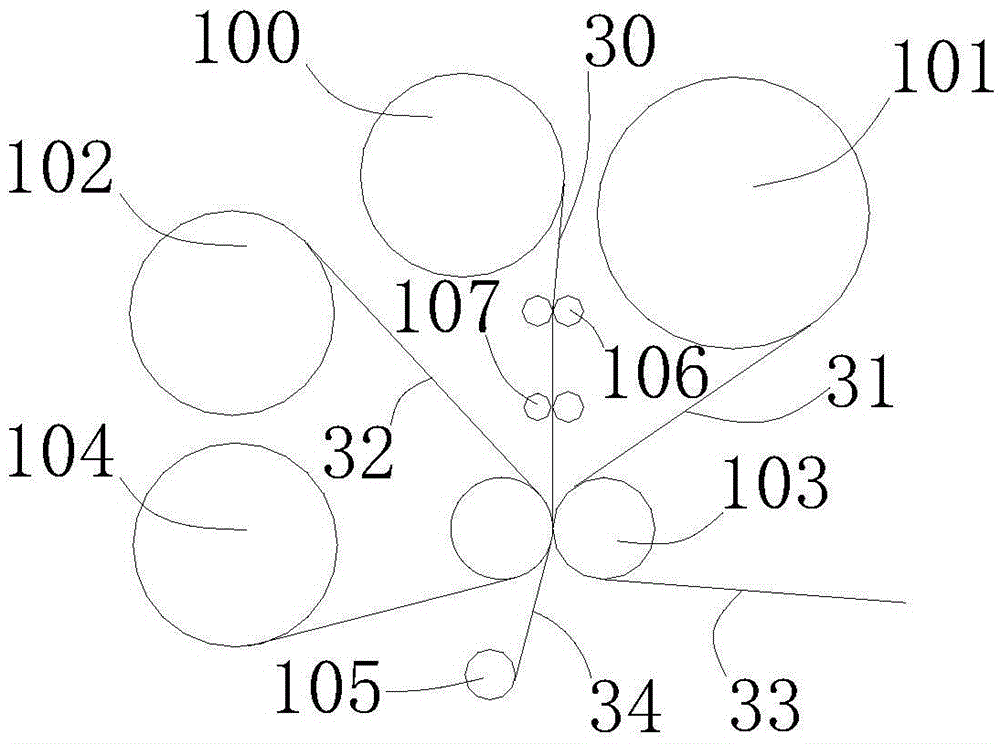

[0064] Such as figure 1 As shown, the embodiment of the present application provides a pole piece lithium replenishment system, including a first composite lithium belt conveying device 10, a second composite lithium belt conveying device 10', a pole piece unwinding device 11, a pole piece lithium supplementary roller press Device 12, first pole piece peeling device 13, second pole piece stripping device 13', first base material winding device 14, third base material winding device 14', appearance inspection device 15, bad product labeling device 16 , a pole piece winding cooling device 17, a lithium-supplemented pole piece winding device 18, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com