Preparation method for photonic crystal structure film electrode of dye solar cell

A technology for solar cells and photonic crystals, applied in capacitor electrodes, photosensitive devices, electric solid devices, etc., can solve the problems of high cost, wide application limitation, and inability to mass-produce, and achieves light weight, simplified process, high short-circuit current and the effect of the fill factor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

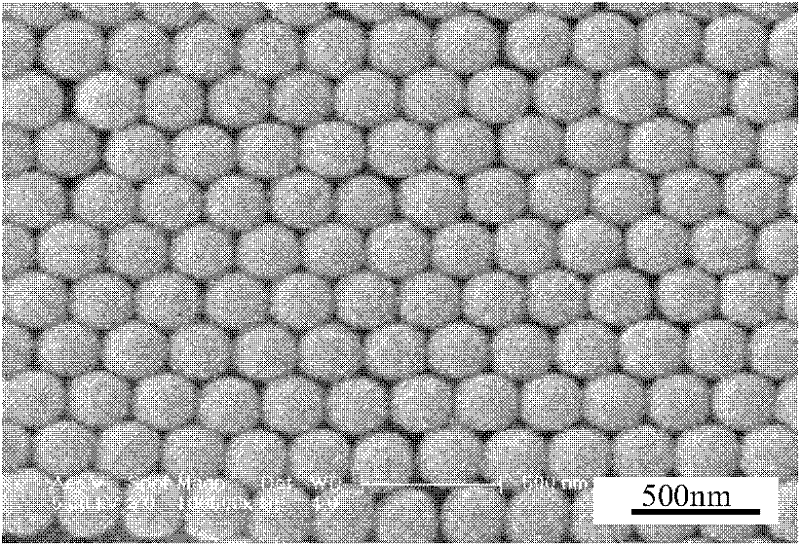

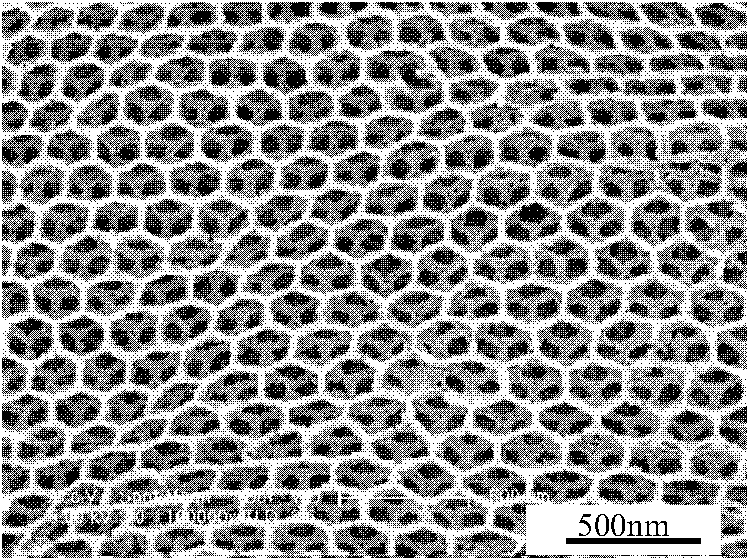

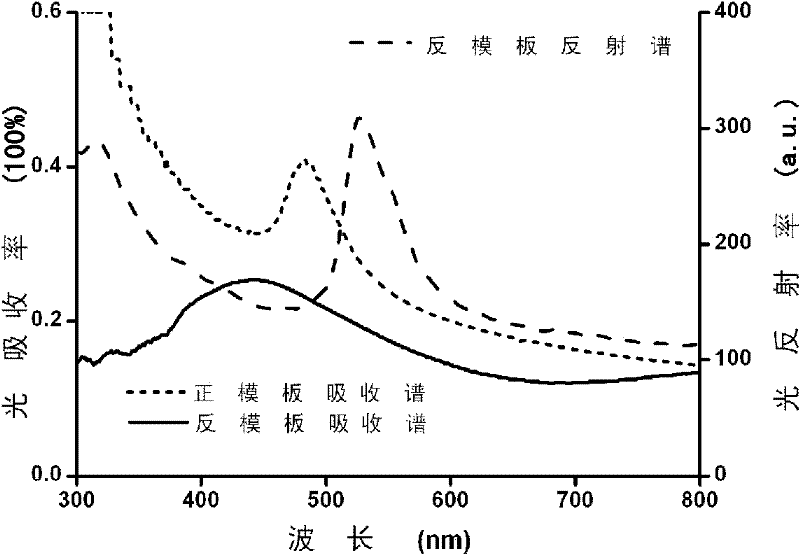

[0033] (1) FTO conductive glass is cut into 1cm×4cm glass slides, soaked in piranha solution (3:1 H2SO4:30% H2O2) for 24 hours, and then washed with deionized water. 10g monomer styrene, 0.74g methacrylic acid and 0.1g potassium persulfate were mixed into 100ml deionized water, and the temperature was raised to 75°C under nitrogen gas to carry out soap-free emulsion polymerization for about 10 hours.

[0034] (2) After 5 centrifugal filtration and purification of the obtained polystyrene colloid, it was diluted with deionized water at a volume ratio of 0.2% to a monodisperse polystyrene bead solution, and poured into a glass vial with a vertical FTO slide; and Place it in a drying oven with a constant temperature of 45°C (±0.5) and a humidity of 90% (±2%) to grow for a week, and a light red smooth film is formed on the surface, which is used as a photonic crystal positive template.

[0035] (3) Dissolve tetra-n-butyl titanate in 100 ml of absolute ethanol at a volume ratio of 5%, a...

Embodiment 2

[0040] (1) Cut the FTO conductive glass into 1cm×4cm glass slides, soak in piranha solution (3:1 H2SO4:30% H2O2) for 24 hours and then rinse with deionized water. 10g monomer styrene, 0.5g methacrylic acid and 0.1g potassium persulfate were mixed into 100ml deionized water, and the temperature was raised to 75°C under nitrogen gas to carry out soap-free emulsion polymerization for about 10 hours.

[0041] (2) After 5 centrifugal filtration and purification of the obtained polystyrene colloid, it was diluted with deionized water at a volume ratio of 0.2% to a monodisperse polystyrene bead solution, and poured into a glass vial with a vertical FTO slide; and Place it in a drying oven with a constant temperature of 45°C (±0.5) and a humidity of 90% (±2%) to grow for a week. A light green smooth film is formed on the surface, which is used as the positive template of the photonic crystal.

[0042] (3) Dissolve tetra-n-butyl titanate in 100 ml of absolute ethanol at a volume ratio of 5%...

Embodiment 3

[0048] (1) FTO conductive glass is cut into 1cm×4cm glass slides, soaked in piranha solution (3:1 H2SO4:30% H2O2) for 24 hours, and then washed with deionized water. 10g monomer styrene, 0.3g methacrylic acid and 0.1g potassium persulfate were mixed into 100ml deionized water, and the temperature was raised to 75°C under nitrogen gas to carry out soap-free emulsion polymerization for about 10 hours.

[0049] (2) After 5 centrifugal filtration and purification of the obtained polystyrene colloid, it was diluted with deionized water at a volume ratio of 0.2% to a monodisperse polystyrene bead solution, and poured into a glass vial with a vertical FTO slide; and Place it in a drying oven with a constant temperature of 45°C (±0.5) and a humidity of 90% (±2%) to grow for a week. A lavender smooth film is formed on the surface, which is used as a positive template for the photonic crystal.

[0050] (3) Dissolve tetra-n-butyl titanate in 100 ml of absolute ethanol at a volume ratio of 5%,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com