High-frequency and high-voltage single electrode plasma thruster

A high-frequency high-voltage power supply, high-frequency high-voltage technology, applied in the direction of using plasma, thrust reverser, machine/engine, etc., can solve the problems of electrode ablation, complicated circuit, and low efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

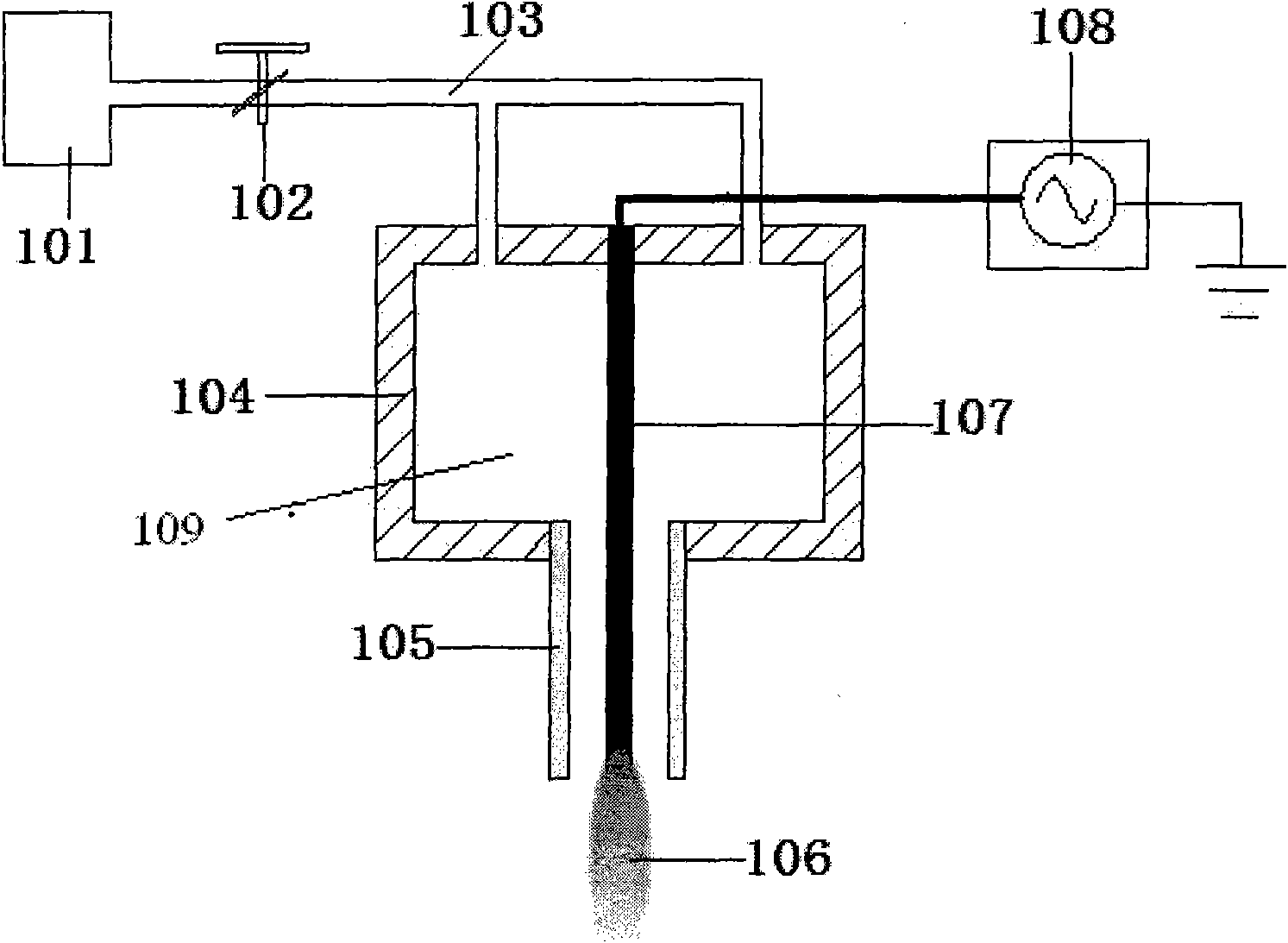

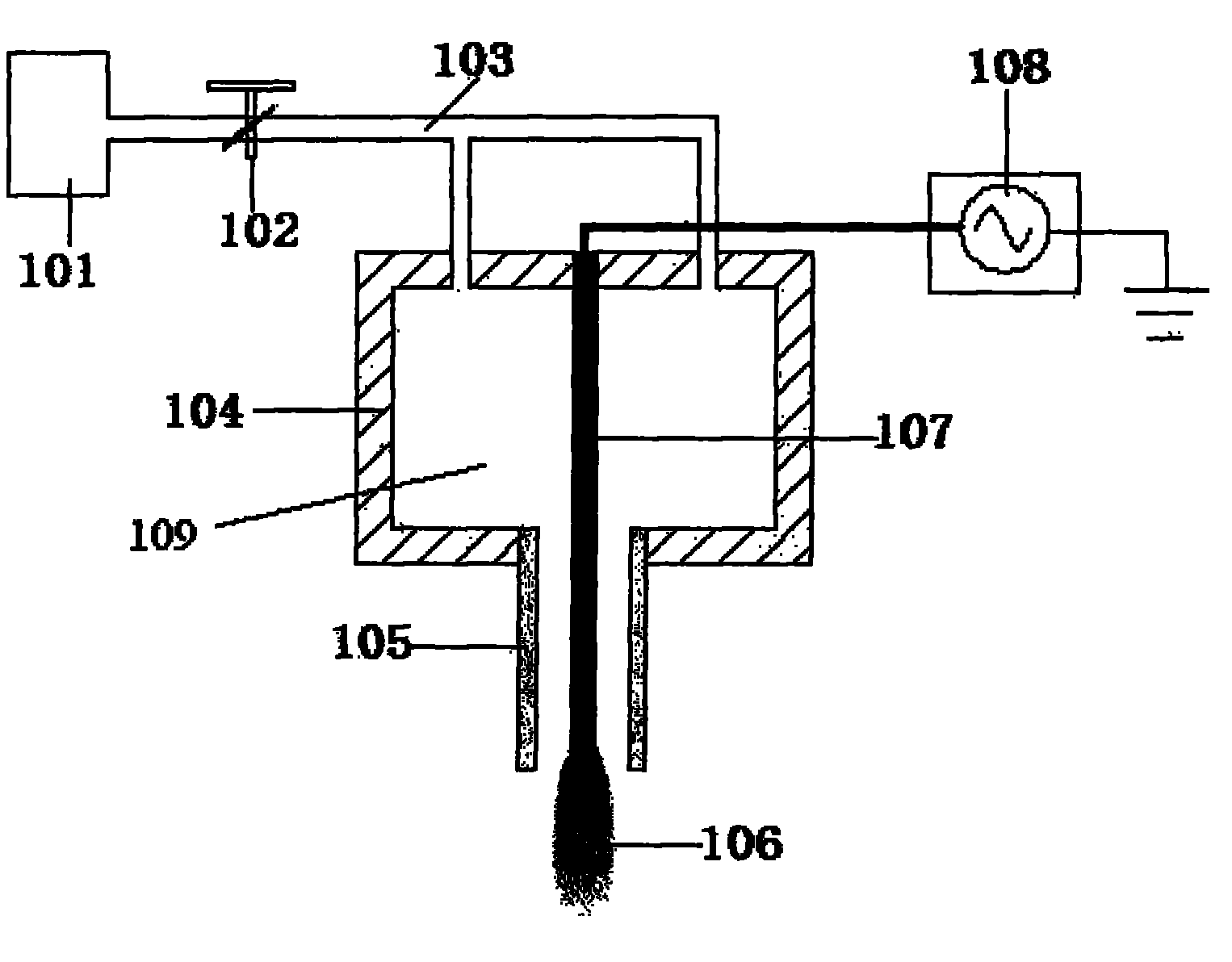

[0014] figure 1 It is a structural schematic diagram of a high-frequency high-voltage single-electrode plasma thruster of the present invention.

[0015] see figure 1 , a high-frequency high-voltage tip electrode 107 is installed on the center line of a jet tube 105, and the jet tube 105 is fixed on an insulating material 104 provided with an air inlet channel, and the gas of the gas source 101 is passed through the gas in the insulating material 104 Passage 109 enters in the jet pipe 105, and is sprayed out by the mouth of jet pipe, is provided with gas flow switch 102 on gas pipe; The other end of the high voltage and high frequency power supply 108 is connected to the ground. When the line is connected, a high-frequency high-voltage electric field is formed at the end of the tip electrode 107 and breaks down the ionized surrounding gas to form a plasma 106 ejected outward through the nozzle, and the plasma will generate a reverse thrust at the same time. Installed on a s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com