Coal mine spontaneous fire fiber temperature detection beam tube monitoring system and method

A technology of bundle tube monitoring and optical fiber temperature measurement, applied in the direction of fire prevention, mining equipment, mining equipment, etc., can solve problems such as difficulty in finding fire sources, economic losses, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047] The present invention will be further described below in conjunction with embodiment:

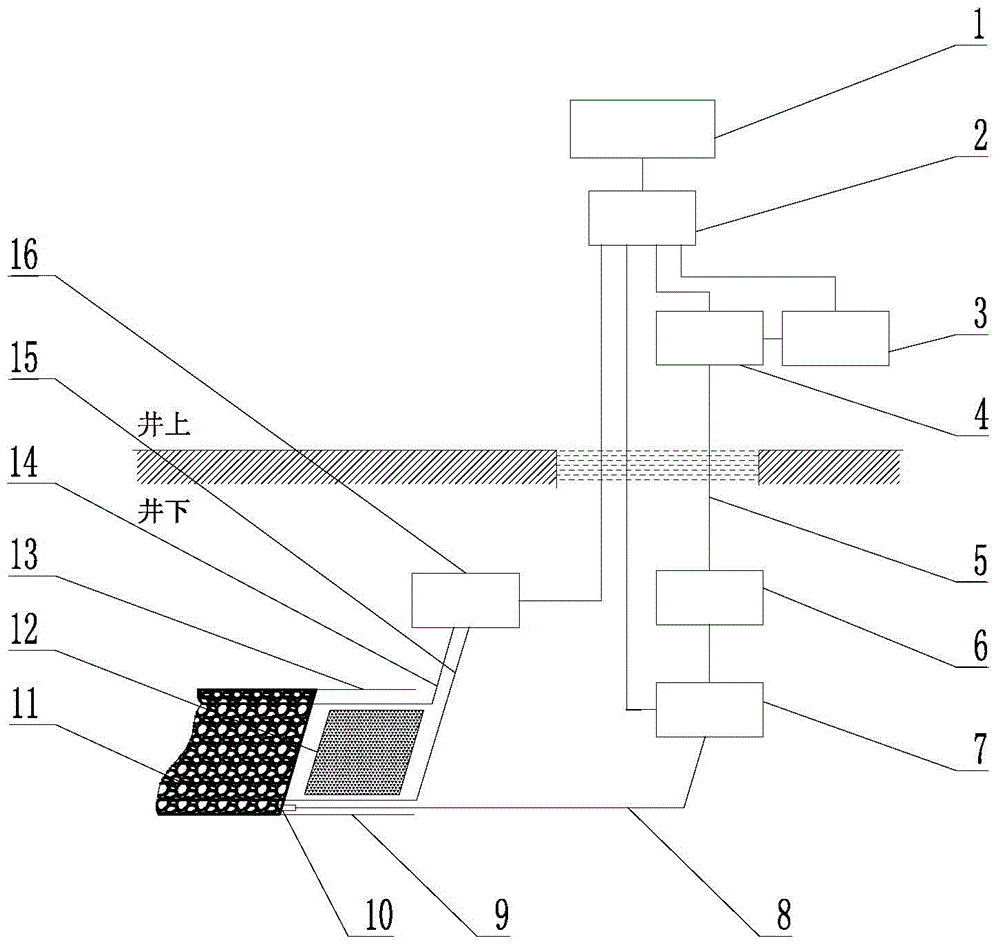

[0048] Such as figure 1 As shown, the coal mine spontaneous combustion fire optical fiber temperature measurement beam tube monitoring system of the present invention includes a beam tube monitoring system, a distributed optical fiber temperature measurement monitoring system and a monitoring and analysis system; the beam tube monitoring system includes a beam tube assembly, and the beam tube assembly is connected with The control cabinets 4 on the well are connected through bundle tubes 5, the control cabinet 4 is connected to the chromatograph 3, and the chromatograph 3 is connected to the alarm device, and the chromatograph 3 is located on the well; Arranged and moved continuously with the advancement of the coal mining face 12, the dust filter 10 is installed at one end of the single pipe 8 located in the return air tunnel 9, and the other end is connected to the gas transmission...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com