Method for measuring content of hydrogen element in nuclear-grade zirconium material

A technology of hydrogen element and hydrogen content, which is applied in the preparation of test samples, testing metals, material inspection products, etc., can solve the problems of long analysis cycle, complicated operation and high cost, and achieve the effect of ensuring accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Example 1: Cut a pure zirconium sample (identified value of hydrogen: 0.00007% to 0.00015%) into a solid sample with a mass of 0.21g, and mix it with a mixed acid (recipe: 45ml HNO 3 +8ml HF+47ml H 2 O) pickling for 15s; then put the solid sample in acetone and wash it for 20s, and then dry it at 50-60°C; put the pretreated solid sample into the RH-600 hydrogen determination instrument, and measure the pure zirconium sample The hydrogen content in is measured three times respectively (promptly measuring three times), and the measured results are shown in the table below. Among them, the operating parameters of the hydrogen determination instrument are: analysis time 40s, purge time 20s, exhaust time 20s, degassing power 5200w, analysis power 4900w.

Embodiment 2

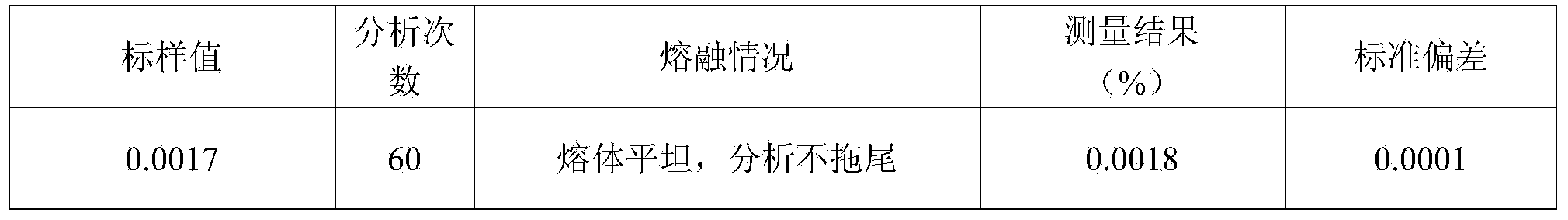

[0029] Embodiment 2: Zirlo product (hydrogen identification value: less than 0.00020%) is cut into the solid sample that quality is 0.25g, and with mixed acid (recipe is: 40ml HNO 3 +10ml HF+50ml H 2 O) pickling for 10s; then put the solid sample in acetone and wash it for 15s, and then dry it at 50-60°C; put the pretreated solid sample into the RH-600 hydrogen determination instrument, and measure the Zirlo sample The hydrogen content of the hydrogen content is measured three times respectively (promptly measuring three times), and the measured results are shown in the table below. Among them, the operating parameters of the hydrogen determination instrument are: analysis time 20s, purge time 10s, exhaust time 15s, degassing power 5400w, analysis power 5000w.

Embodiment 3

[0030] Embodiment 3: The Zr-4 product (certified value of hydrogen: less than 0.00020%) is cut into a solid sample with a quality of 0.15g, and mixed acid (recipe: 50ml HNO 3 +5ml HF+45ml H 2 O) Pickling for 20s; then put the solid sample in acetone and wash it for 40s, and then dry it at 50-60°C; put the pretreated solid sample into the RH-600 hydrogen determination instrument, and measure the Zr-4 test The hydrogen content in the sample was measured three times respectively (i.e. measured three times), and the measured results are shown in the table below. Among them, the operating parameters of the hydrogen determination instrument are: analysis time 60s, purge time 30s, exhaust time 30s, degassing power 5000w, analysis power 4700w.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com