Recycled aluminium alloy non-gaseous impurity removing method

A technology of aluminum alloy melt and aluminum alloy, which is applied in the field of recycled metals, can solve the problems of difficult impurity removal in the smelting process and the complex composition of waste aluminum, and achieve the effect of significant impurity removal and effective control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

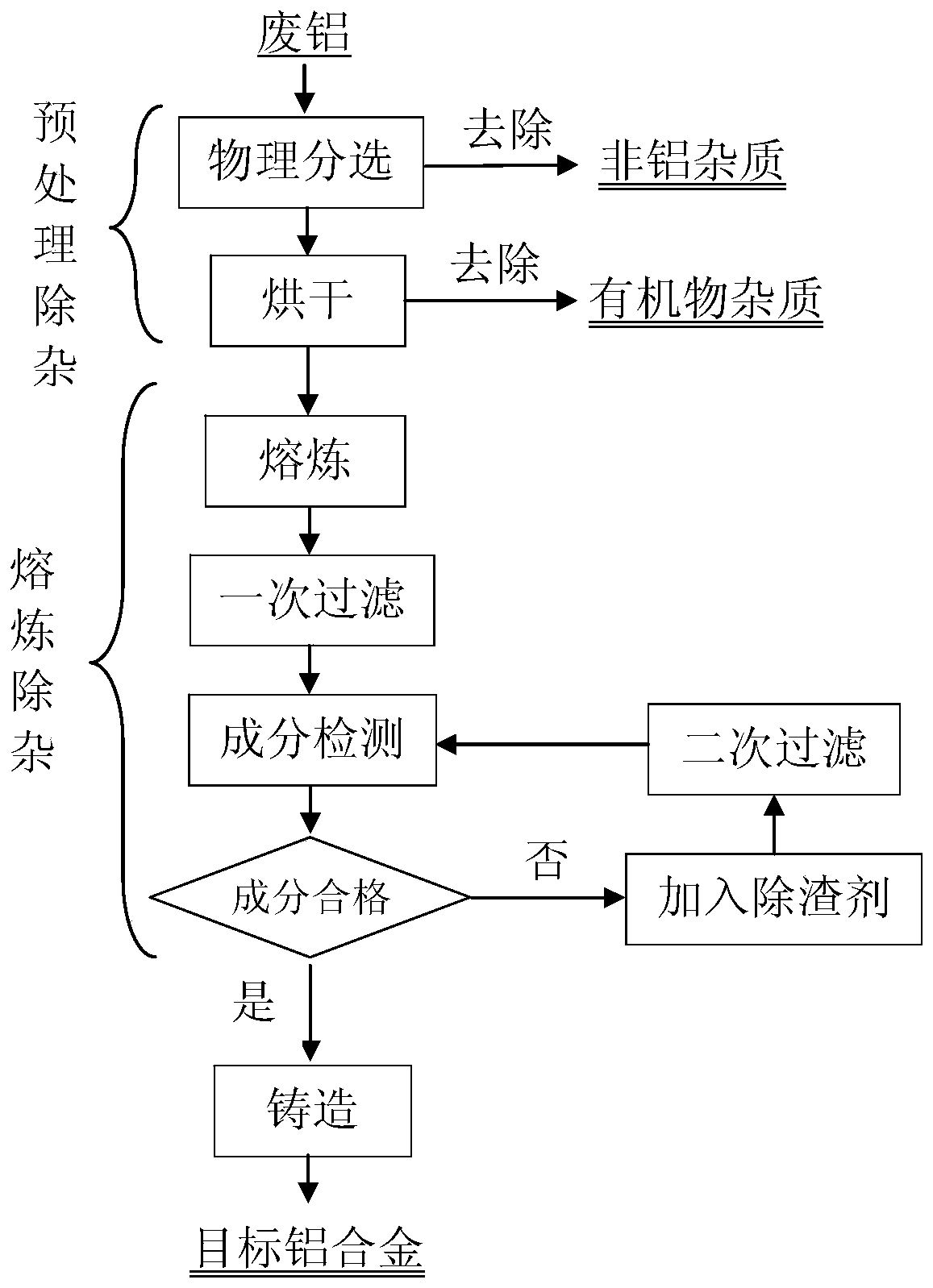

Method used

Image

Examples

Embodiment 1

[0045] A method for removing non-gas impurities from recycled 1040 aluminum alloys with waste aluminum alloys as the main raw material, the steps are as follows:

[0046] (1) Magnetic separation removes 100% ferromagnetic impurities; eddy current separation removes 100% non-adhesive rubber, resin and plastic; sieving removes 95% of sand and dust;

[0047] (2) heating the waste miscellaneous aluminum alloy after pretreatment to 100 ℃ and drying for 30 minutes, removing 98% of the moisture, oil stain and coating on the surface of the waste miscellaneous aluminum alloy;

[0048] (3) The waste miscellaneous aluminum alloys after dehydration and depainting are melted at 680° C., stirred, and left still;

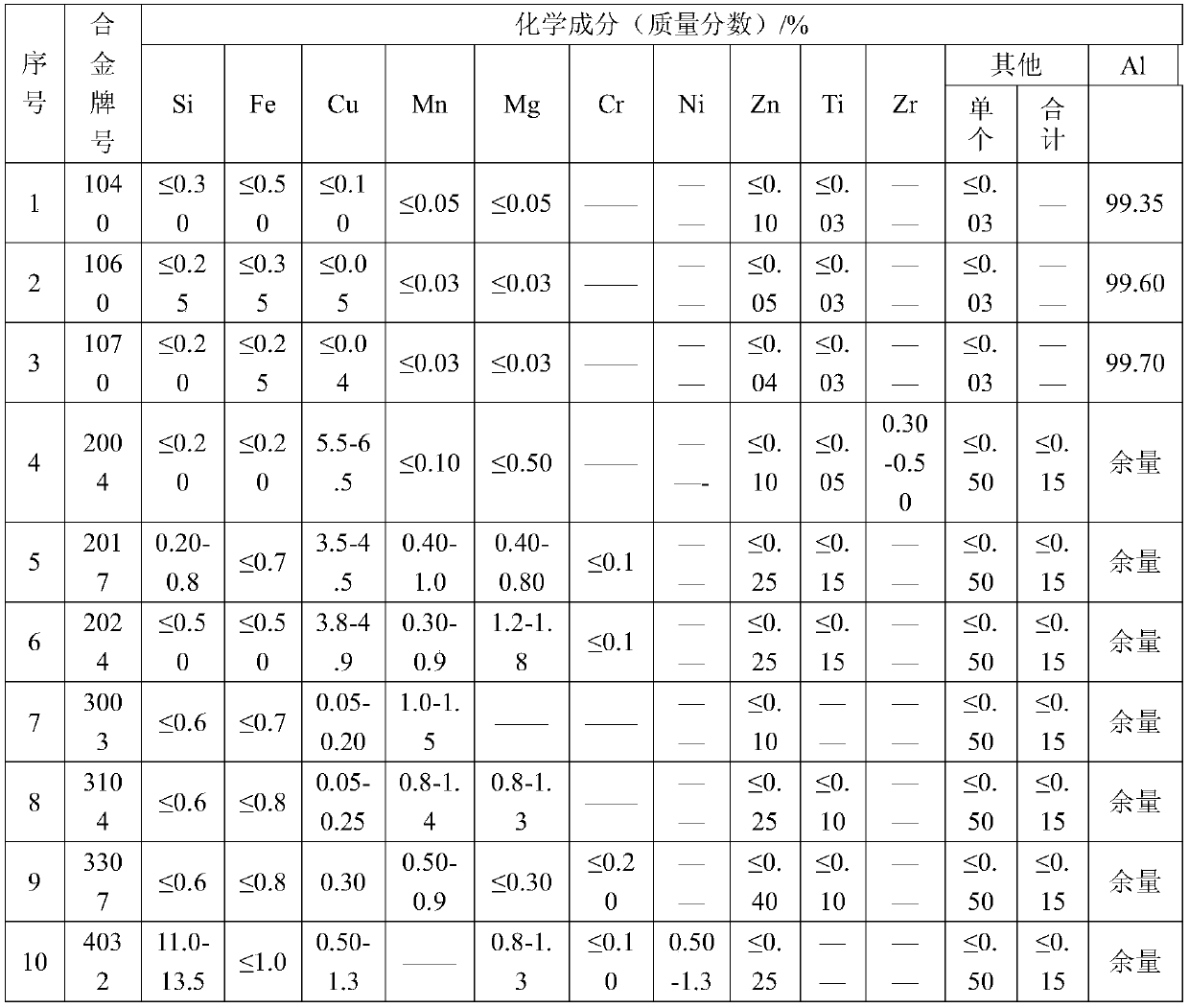

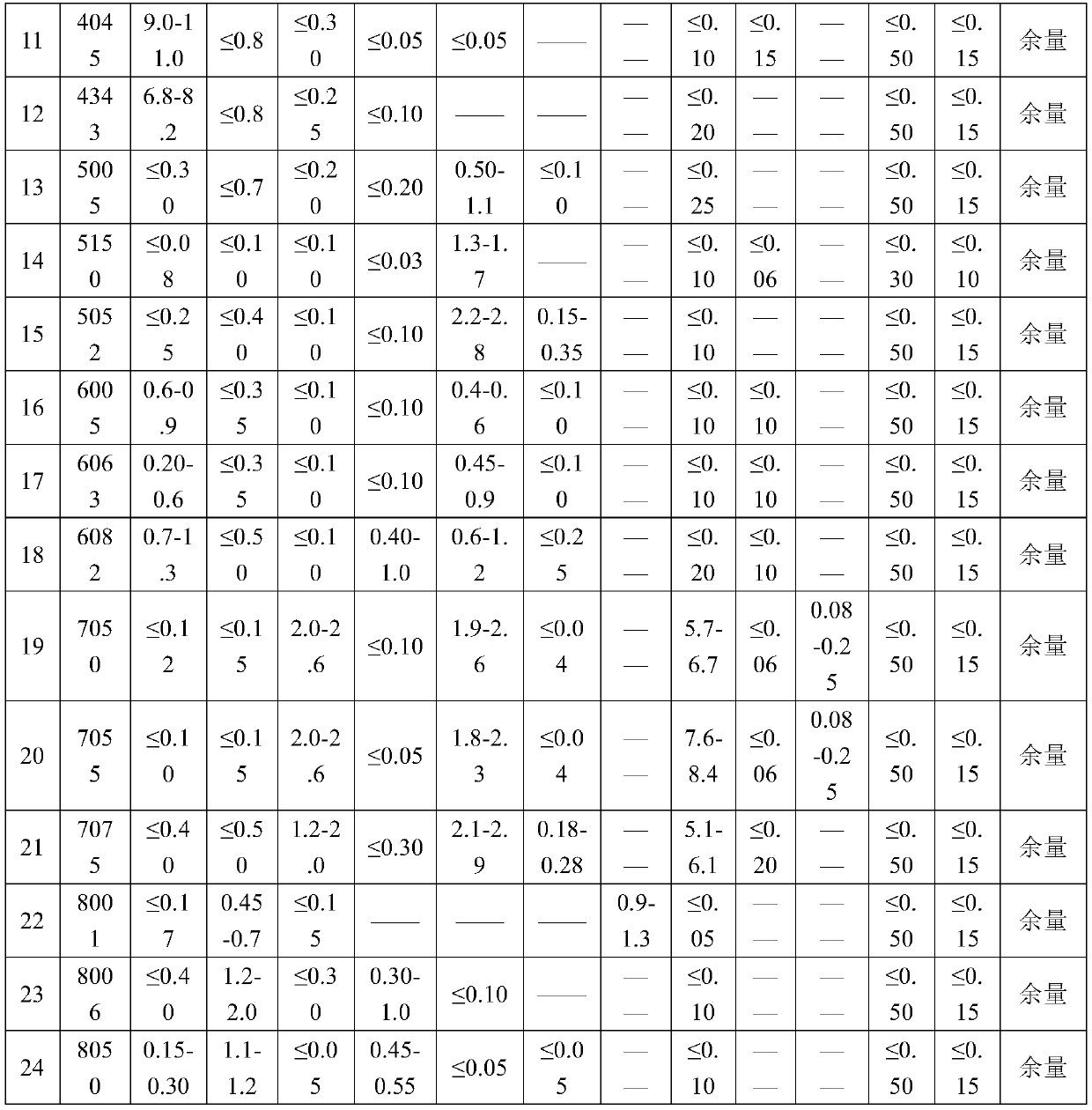

[0049] (4) After using a 30ppi ceramic filter plate to filter and remove non-aluminum solid impurities, the online composition detection, compared with Table 1, needs to further remove the Cu element in the melt;

[0050] (5) Use a mixed gas of nitrogen and chlorine with a volume r...

Embodiment 2

[0053] A method for removing non-gas impurities from recycled 1060 aluminum alloys with waste aluminum alloys as the main raw material, the steps are as follows:

[0054] (1) Magnetic separation removes 100% ferromagnetic impurities; eddy current separation removes 100% non-adhesive rubber, resin and plastic; sieving removes 95% of sand and dust;

[0055] (2) The pretreated waste aluminum alloy was heated to 150° C. and dried for 25 minutes to remove 98% of the moisture, oil and coating on the surface of the waste aluminum alloy;

[0056] (3) The waste miscellaneous aluminum alloys after dehydration and depainting are melted at 680° C., stirred, and left still;

[0057] (4) After using a 30ppi ceramic filter plate to filter and remove non-aluminum solid impurities, the online composition test, compared with Table 1, meets the requirements of GBT3190-2008 "Chemical Composition of Deformed Aluminum and Aluminum Alloys";

[0058] (5) Obtain recycled 1060 aluminum alloy ingots by...

Embodiment 3

[0060] A method for removing non-gas impurities from recycled 1070 aluminum alloys using waste aluminum alloys as the main raw material, the steps are as follows:

[0061] (1) Magnetic separation removes 100% ferromagnetic impurities; eddy current separation removes 100% non-adhesive rubber, resin and plastic; sieving removes 95% of sand and dust;

[0062] (2) The pretreated waste aluminum alloy was heated to 150° C. and dried for 25 minutes to remove 98% of the moisture, oil and coating on the surface of the waste aluminum alloy;

[0063] (3) The waste miscellaneous aluminum alloys after dehydration and depainting are melted at 680° C., stirred, and left still;

[0064] (4) After using a 30ppi ceramic filter plate to filter and remove non-aluminum solid impurities, the online composition test, compared with Table 1, meets the requirements of GBT3190-2008 "Chemical Composition of Deformed Aluminum and Aluminum Alloys";

[0065] (5) Obtain recycled 1070 aluminum alloy ingots b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com