Vertical tank capable of real-time monitoring leakage of tank bottom

A vertical storage tank, real-time monitoring technology, applied in the direction of containers, packaging, transportation and packaging, etc., can solve the problems of unreached detection and positioning accuracy, expensive equipment, etc., achieve stable overall performance, increase manufacturing costs, significantly direct and The effect of indirect economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

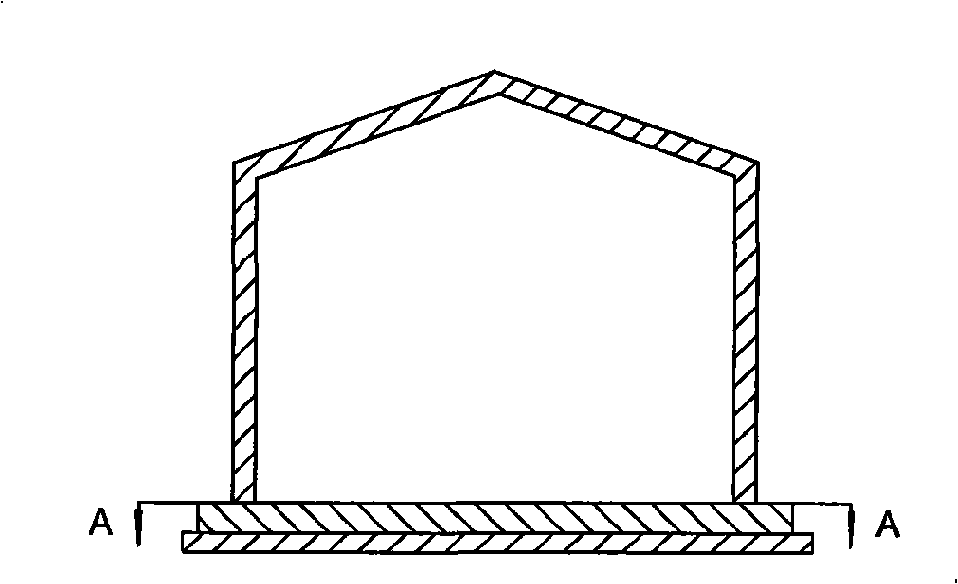

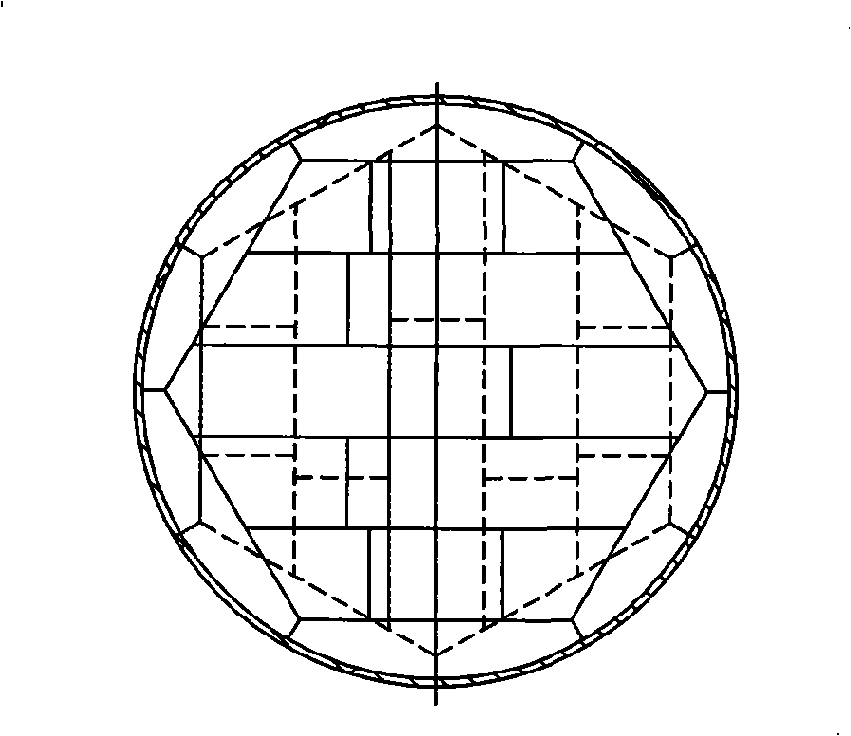

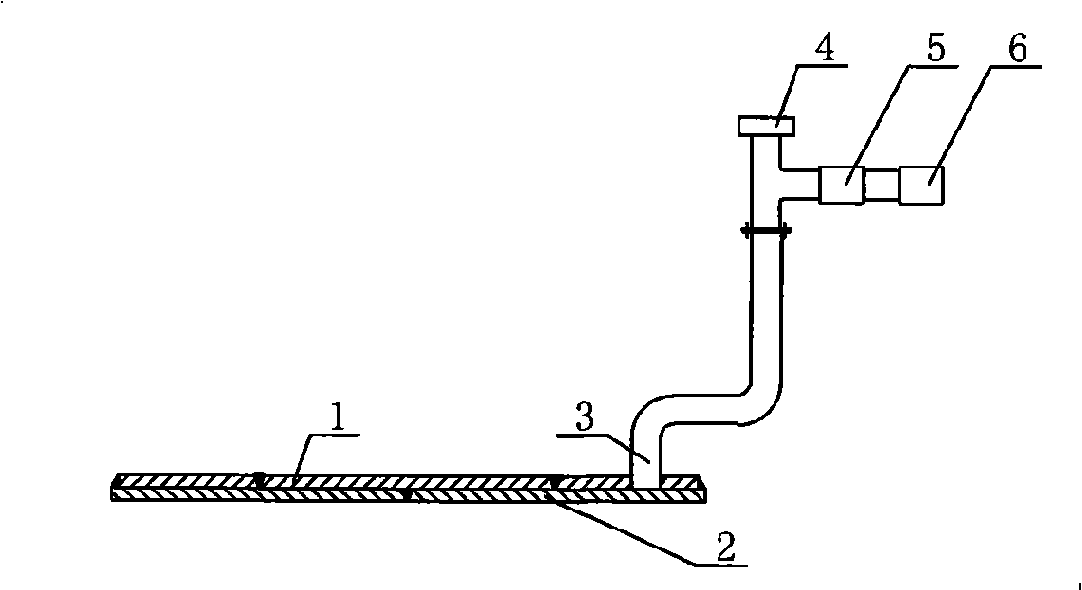

[0016] As shown in the figure, the vertical storage tank includes a tank body and a tank bottom. The bottom of the vertical storage tank is composed of upper and lower two-layer boards, and the surroundings of the two-layer boards are all sealed and fixedly connected, so that the two layers A cavity is formed between the board surfaces (because the gap between the upper and lower layers is small, generally a few millimeters are enough, so it is omitted in the figure); due to the huge volume of the vertical storage tank (the diameter of the tank body generally has Tens of meters or even hundreds of meters), so among the two layers of plates at the bottom of the tank, each layer is formed by splicing and welding multiple steel plates ( figure 2 The solid line is the welding seam of the upper plate 1, and the dotted line is the welding seam of the lower plate 2) There is also a connecting pipe 3 on the bottom of the tank, which communicates with the cavity; a gas component is arr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com