Plasma treatment apparatus

A plasma and processing device technology, applied in the field of microelectronics, can solve the problems of poor adaptability, inability to realize plasma density adjustment, inability to meet various processing techniques, etc., and achieve the effect of improving adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

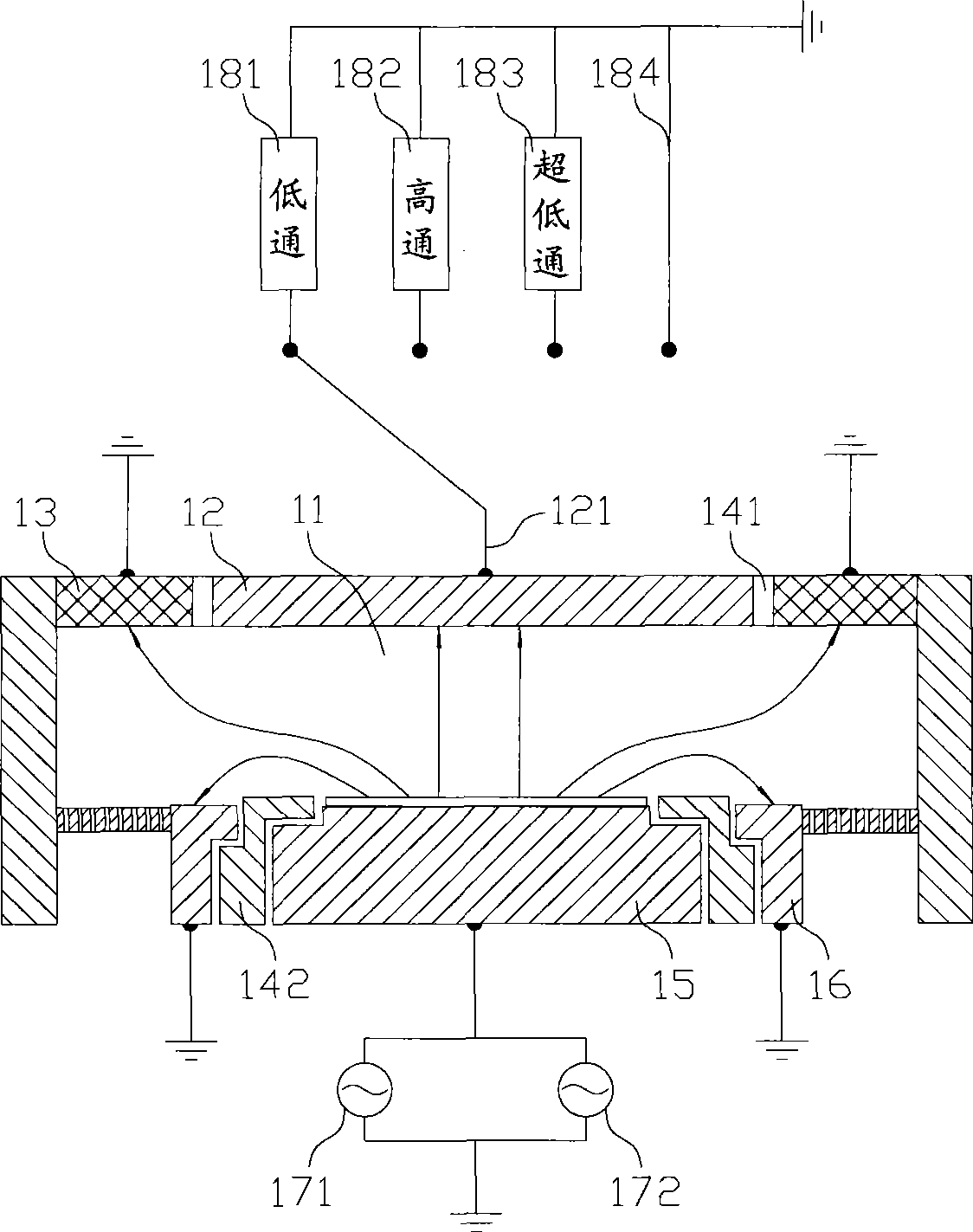

Method used

Image

Examples

Embodiment approach

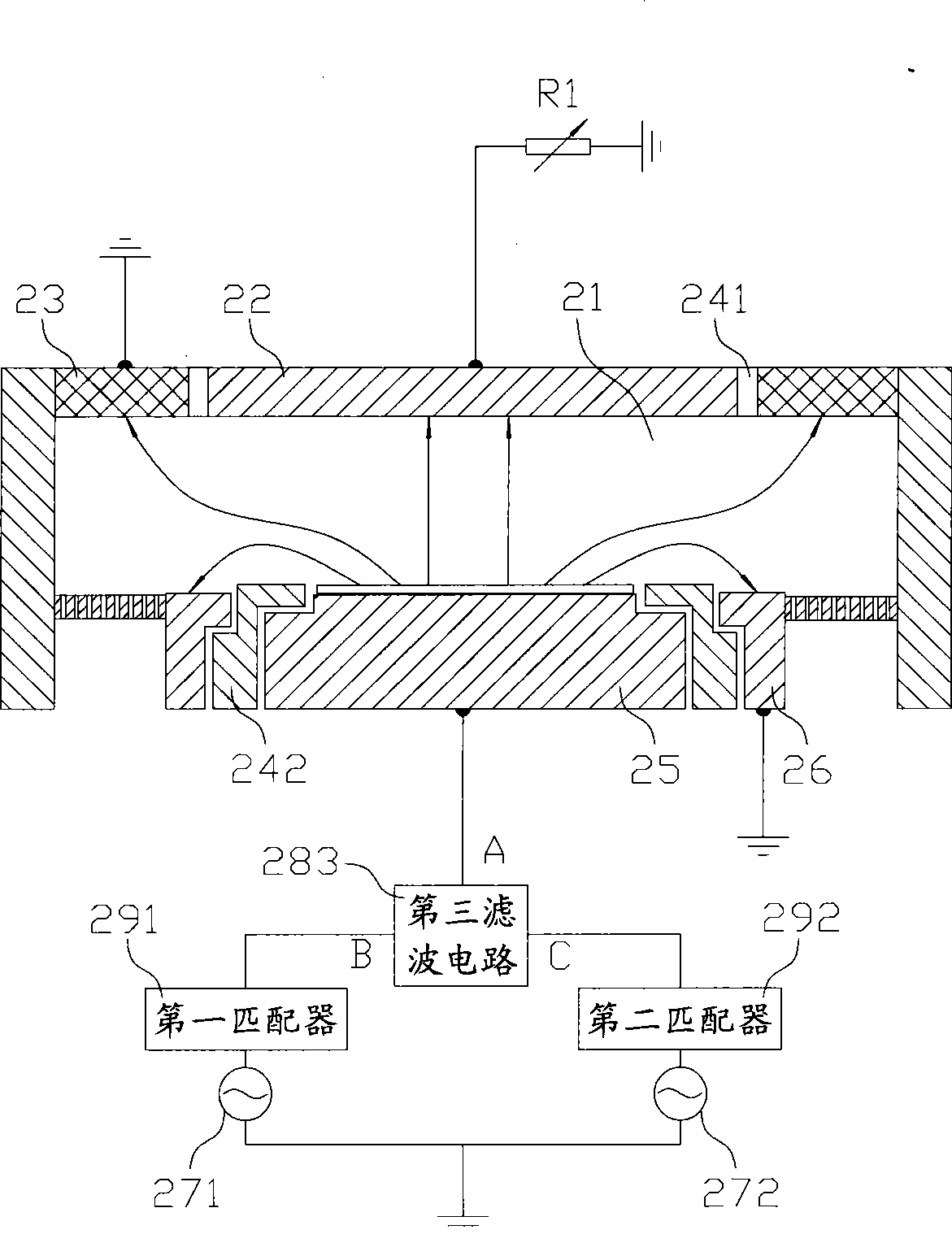

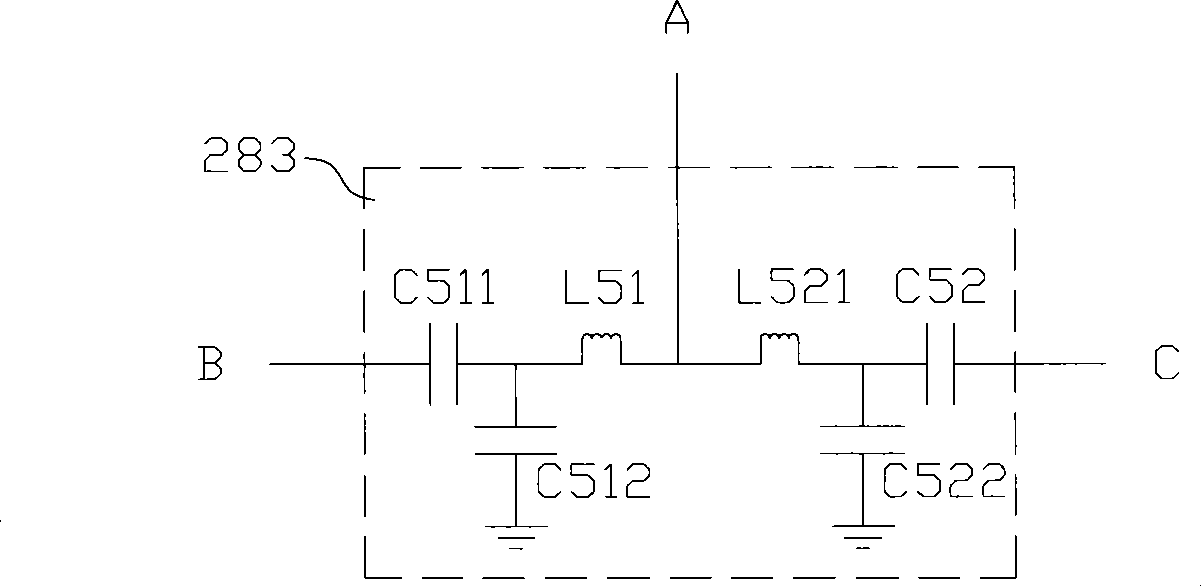

[0071] In the second specific implementation manner, the plasma processing apparatus provided by the embodiment of the present invention is further improved on the basis of the above-mentioned first specific implementation manner.

[0072] As mentioned above, in order to broaden the adaptability of the plasma processing apparatus, it should be possible to adjust the relevant parameters of the plasma in the reaction chamber 21 , and the relevant parameters generally involve density, energy, flow rate and the like. Usually, the adjustment of plasma energy is realized through the first radio frequency power supply 271 ; the adjustment of plasma density is realized through the second radio frequency power supply 272 .

[0073] When adjusting the above parameters in order to adapt to different processes, it is best to control the density and energy of the plasma separately; however, due to the coupling between the first radio frequency power supply 271 and the second radio frequency...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com