A shape memory alloy leaf spring and a method for realizing variable stiffness

A leaf spring, memory alloy technology, applied in the direction of spring, spring/shock absorber, spring/shock absorber functional characteristics, etc., can solve the problem of limiting ride comfort and ride comfort, reducing leaf spring life, affecting ride comfort, etc. problems, to achieve the effect of improving ride comfort, saving energy, and overcoming high quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further explained below in conjunction with the drawings:

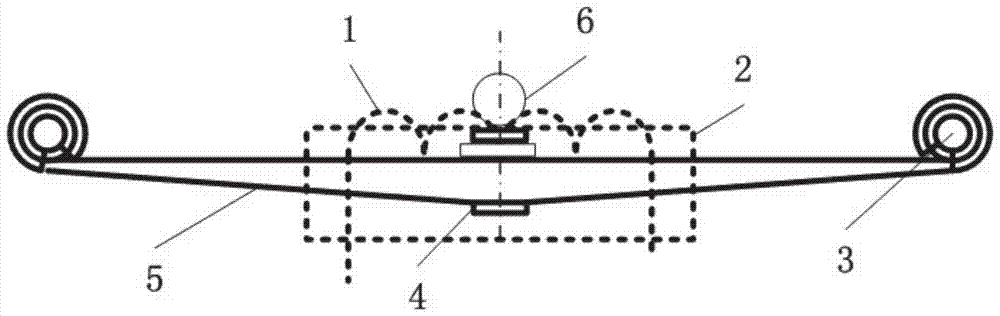

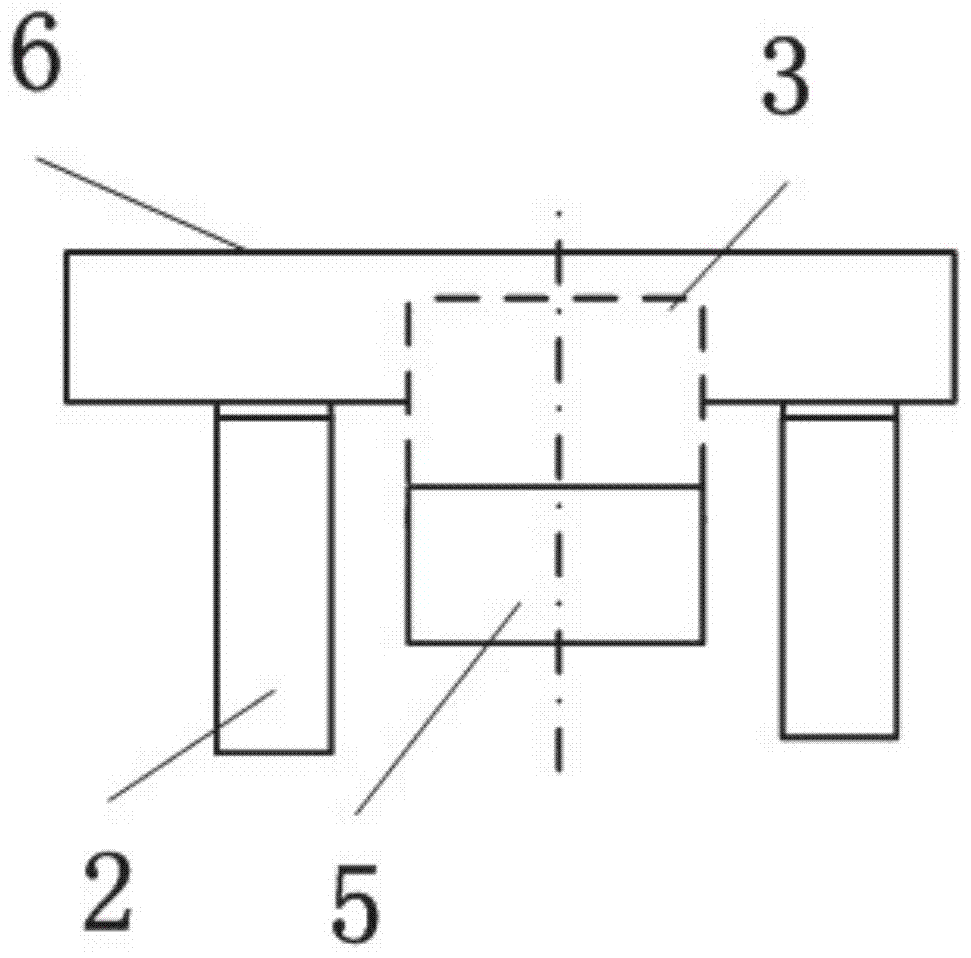

[0022] Such as Figure 1-2 As shown, a shape memory alloy type leaf spring includes an axle 6, a spring leaf 5, a riding bolt 4, a lug 3, an electromagnet 2, an energized coil 1. The center of the spring sheet 5 is clamped and fixed on the axle 6 with a horse-riding bolt 4, and the two ends of the spring sheet are bent into curling ears 3. The material of the spring sheet 5 is a magnetron type shape memory alloy, and typical ferromagnetron type shape memory alloys include Ni-Mn-Ga, Ni-Fe-Ga, Fe-based alloys (Fe-Pd, Fe-Ni -Co-Ti, etc.) and Co-based alloys (Co-Ni, Co-Mn based alloys, etc.). Along the direction of the axle 6, a pair of electromagnets 2 are arranged equidistantly on the left and right sides of the spring sheet 5 respectively. The electromagnets 2 are wound with an energized coil 1. The electromagnet is controlled by controlling the current flowing through the energized ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| bending strain | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com