High-temperature fused salt synchrotron radiation in-situ research device

A high-temperature molten salt, in-situ technology, used in measuring devices, material analysis using wave/particle radiation, instruments, etc., can solve problems such as large surface tension, testing, and destroying the original state of molten salt, and achieve a high detection angle. , uniform heating, good sealing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048] The high-temperature molten salt synchrotron radiation in-situ research device of the present invention will be further described in detail below in conjunction with the accompanying drawings and specific examples.

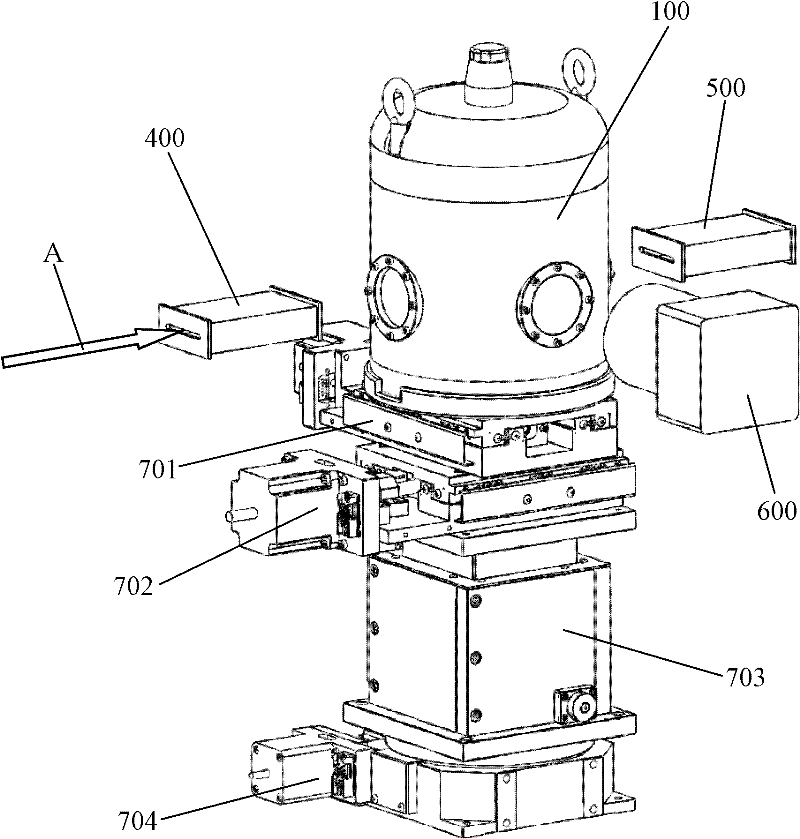

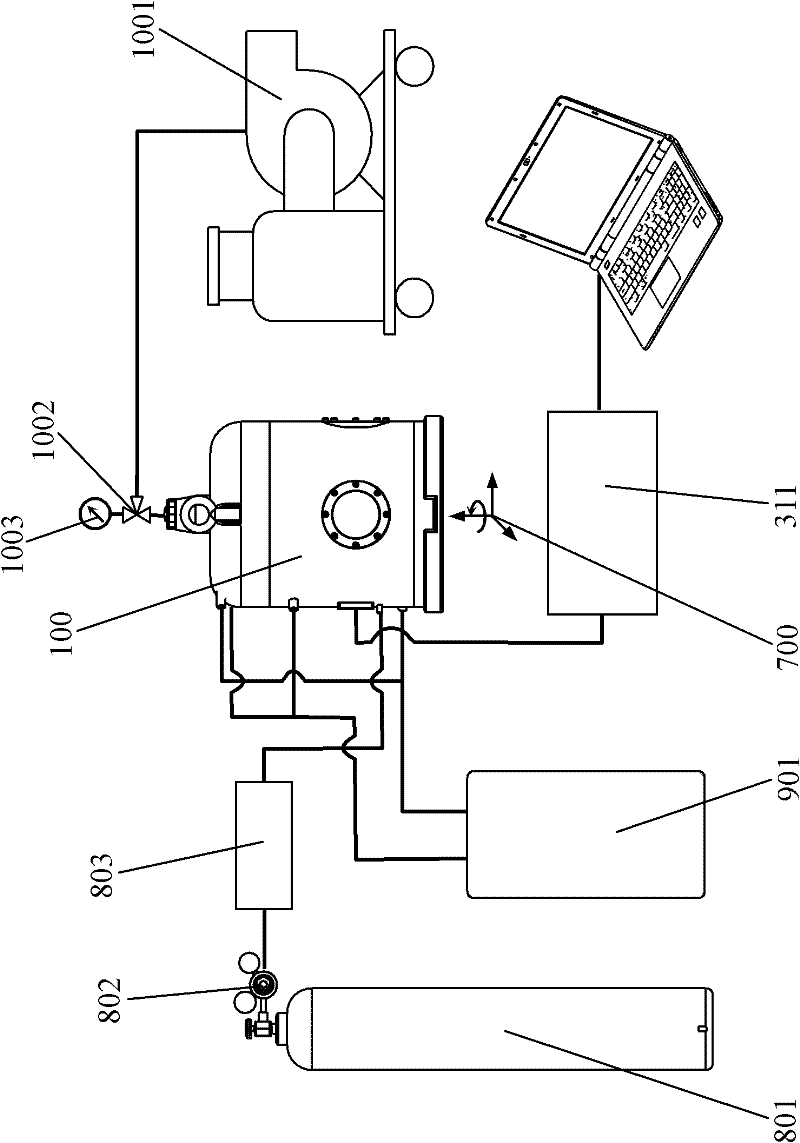

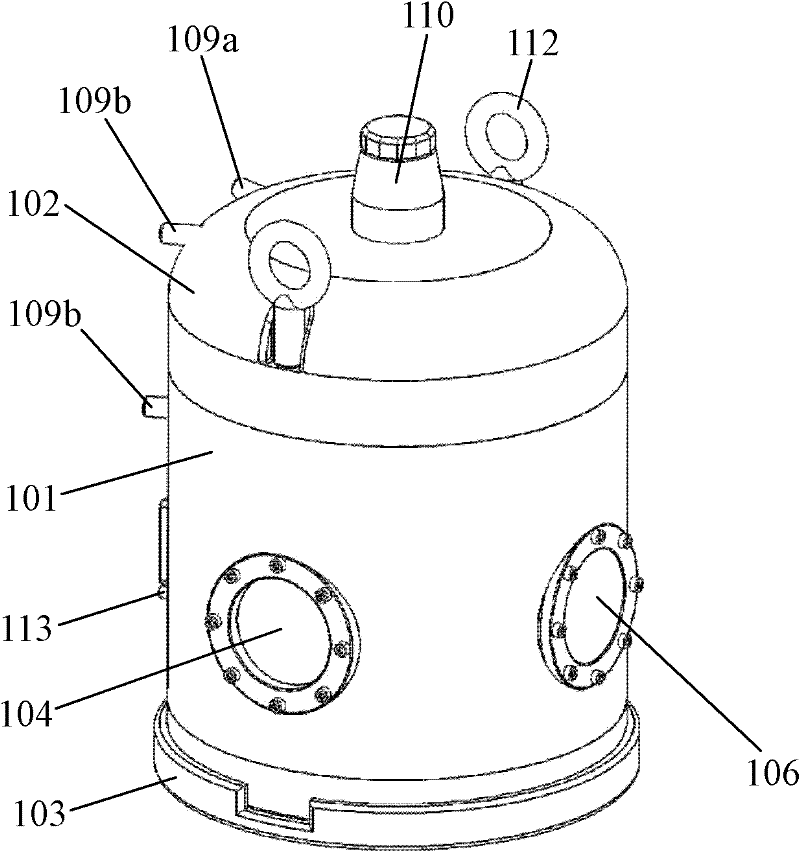

[0049] figure 1 It shows the structure of the high-temperature molten salt synchrotron radiation in-situ research device described in the invention in this embodiment. Such as figure 1 As shown, the vacuum furnace 100 is set on the positioning platform, and the furnace wall is respectively provided with an incident window, a transmission window and a fluorescent window, wherein the incident window and the transmission window are arranged coaxially and collinearly, and the axis of the fluorescent window is aligned with the incident window and the transmission window. axis vertical. The molten salt test tube and the heating device are set in the cavity of the vacuum furnace 100 (such as Figure 4 , Figure 5 shown). The positioning stage adjusts the posi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The inside diameter of | aaaaa | aaaaa |

| Outer diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com