Patents

Literature

95 results about "Electron collision" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Electron-Ion Collisions. Electron Impact Ionization. When an electron collides with an atom or ion, there is a small probability that the electron kicks out another electron, leaving the ion in the next highest charge state (charge q increased by +1).

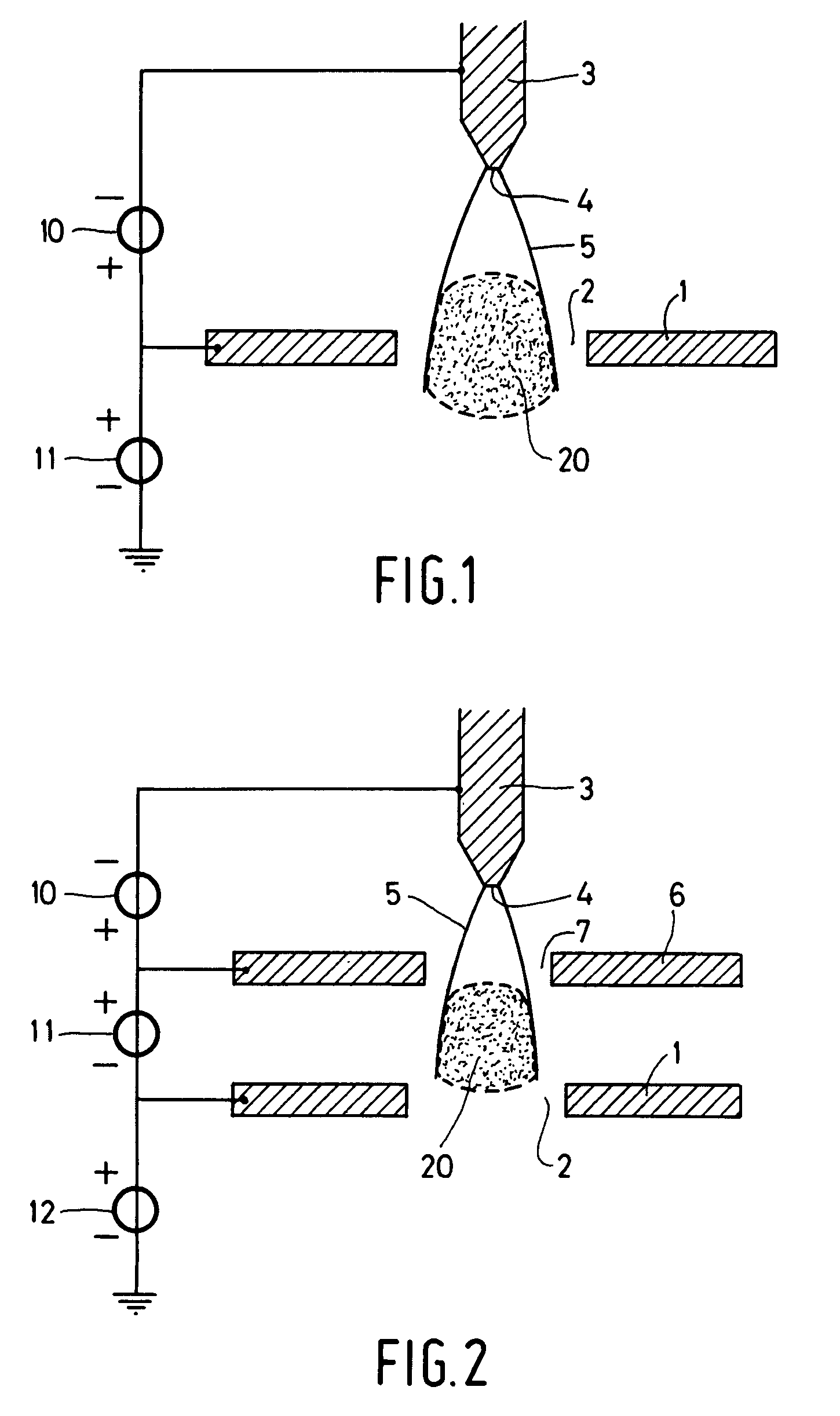

Method for controlling space charge-driven ion instabilities in electron impact ion sources

ActiveUS20060237641A1Inhibition effectMaterial analysis by optical meansIon sources/gunsVoltage pulseElectron collision

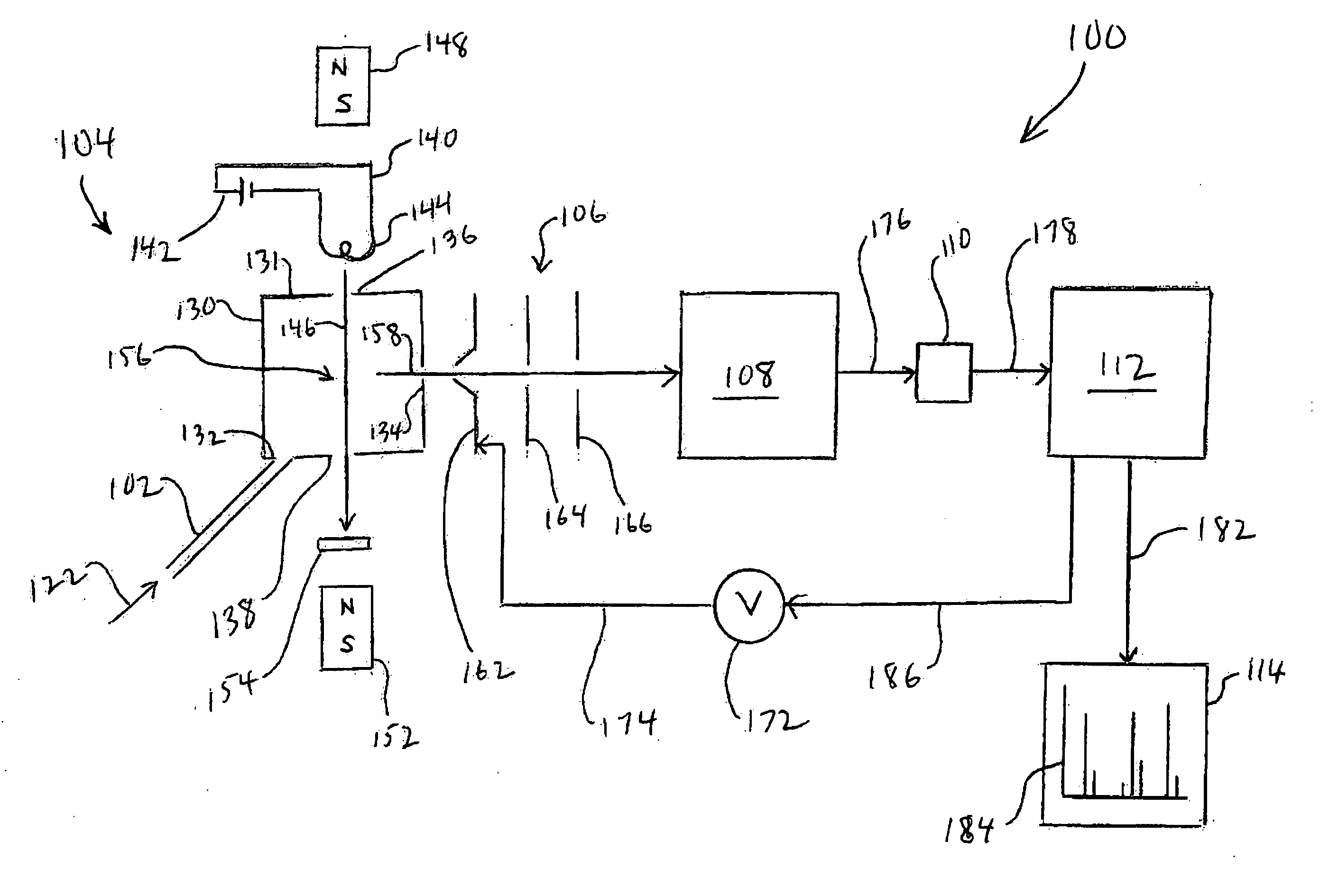

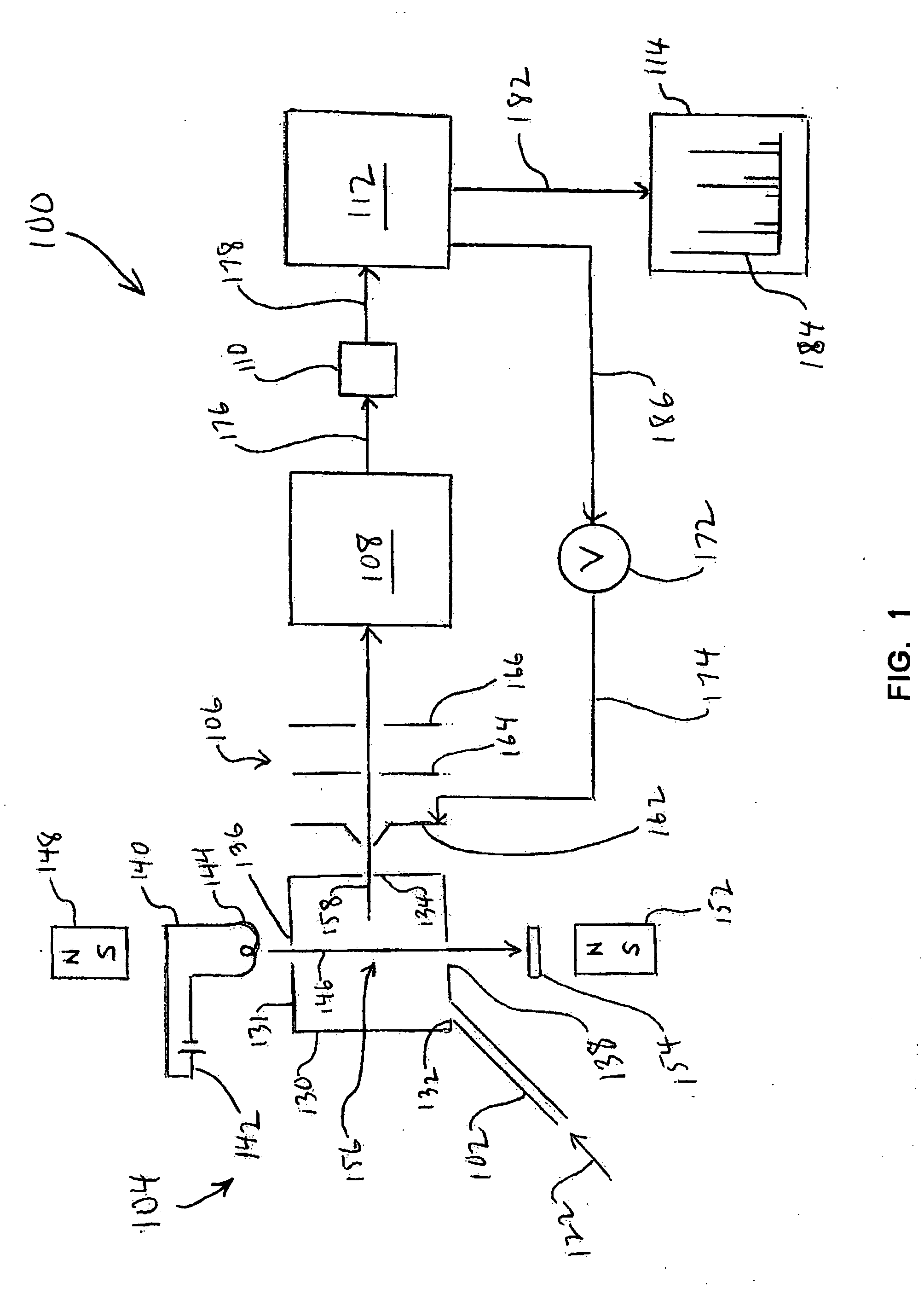

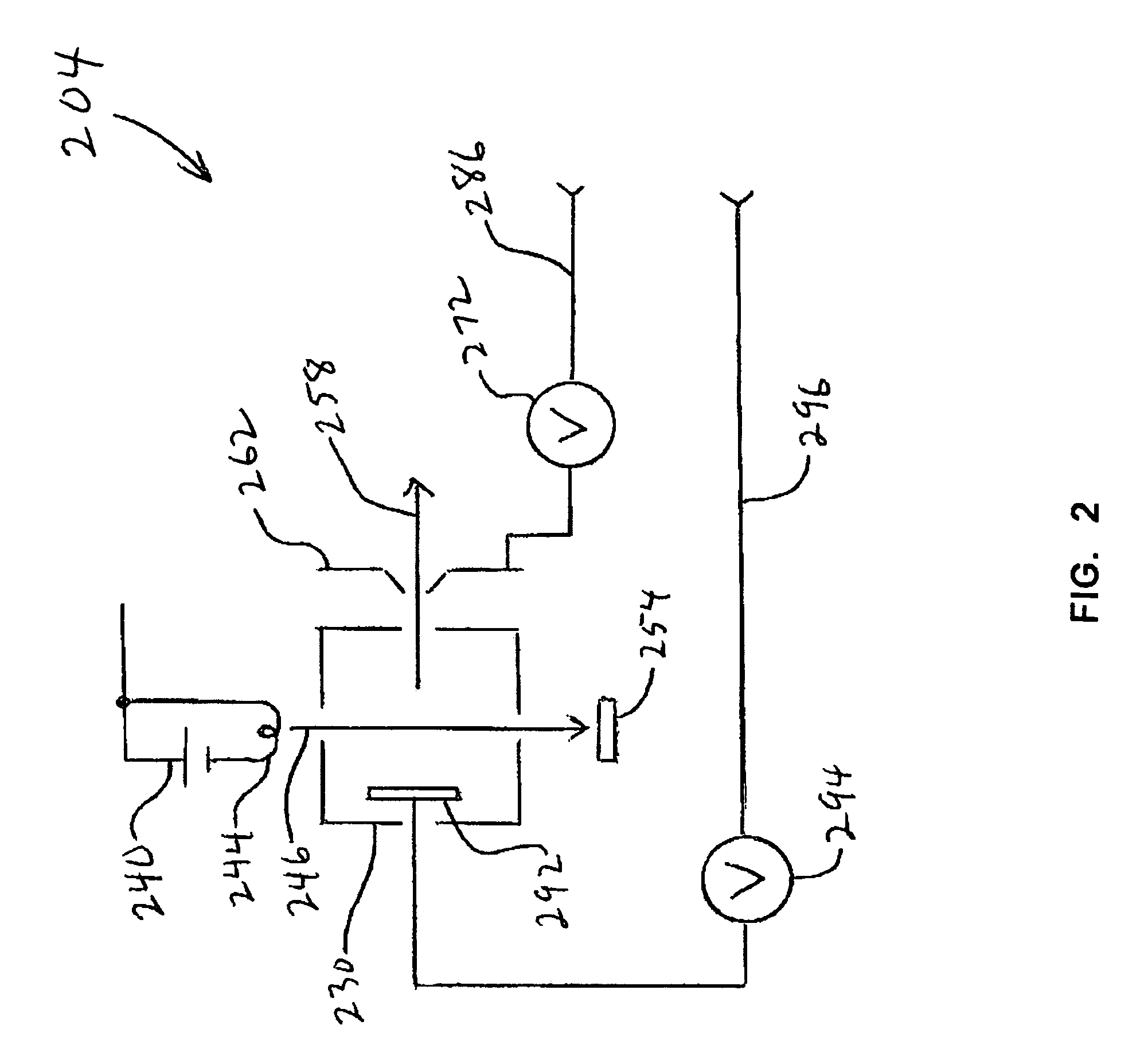

In a method for inhibiting space charge-related effects in an ion source, an electron beam is directed into a chamber to produce ions from sample material in the chamber. A voltage pulse is applied to the chamber to perturb an electron space charge present in the chamber. The ion source may be an electron impact ionization (EI) apparatus. The ion source may operated in conjunction with a mass spectrometry system.

Owner:BRUKER DALTONIK GMBH & CO KG

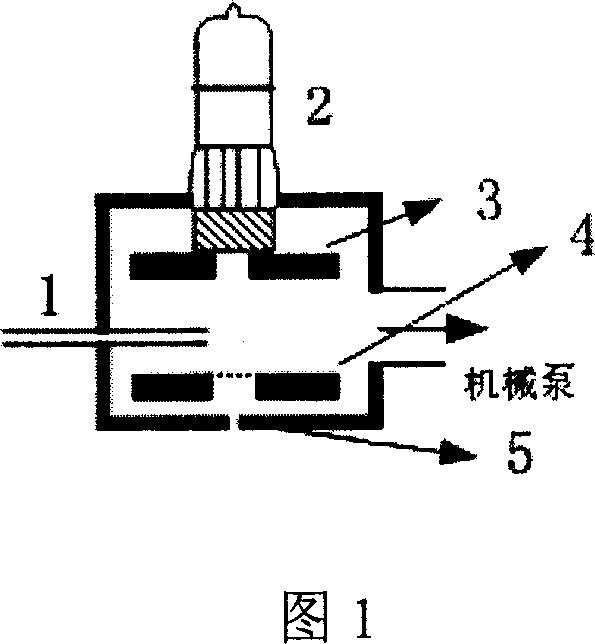

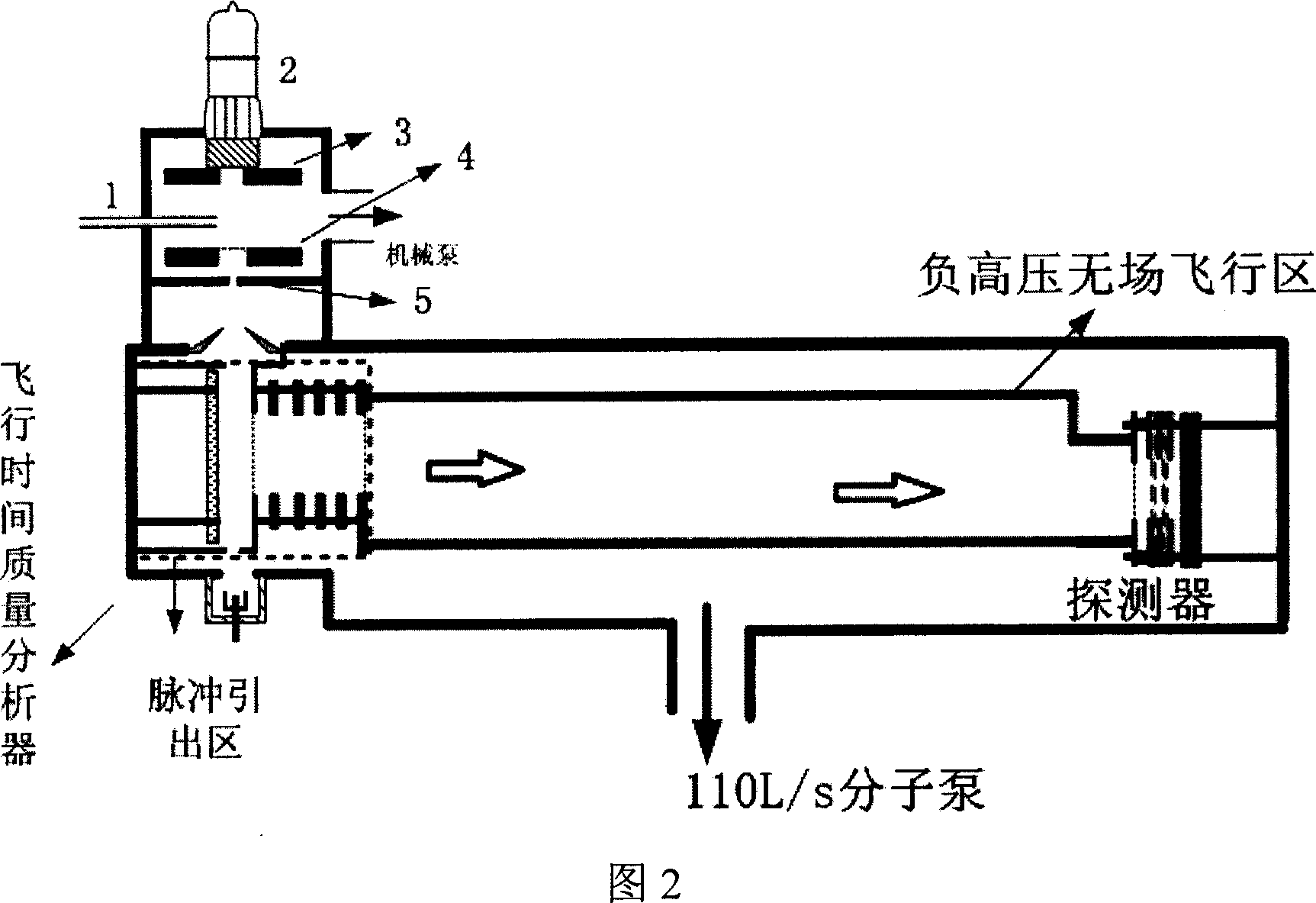

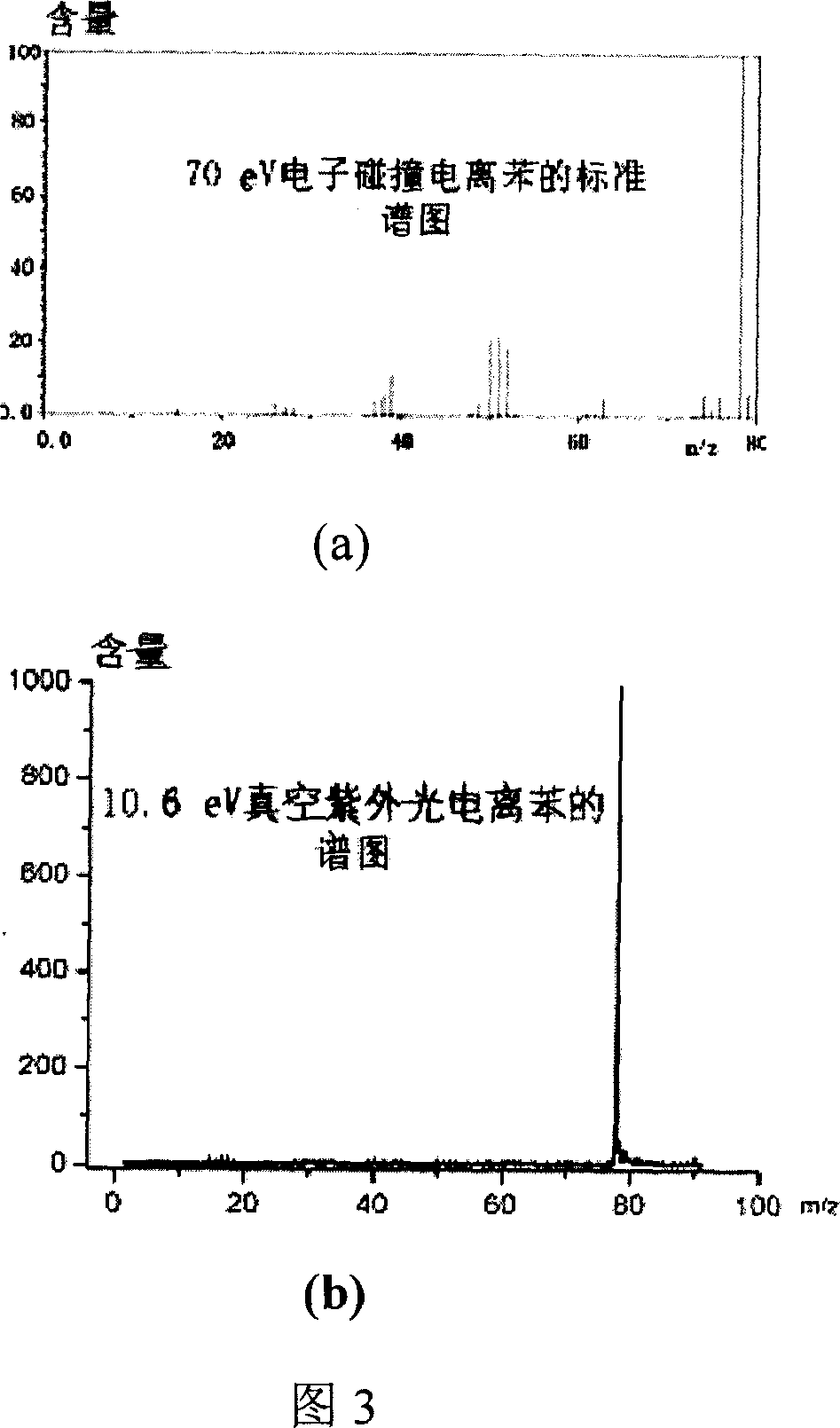

Vacuumeultraviolet lamp ionization device in time-of-flight mass spectrometer

ActiveCN101063673AImprove utilization efficiencyHigh sensitivityComponent separationTube electron sourcesMass analyzerTime of flight

This invention relates to one fly time mass spectrum vacuum ultraviolet isolation device, which comprises the following parts: one ionization chamber fixed with vacuum ultraviolet lamp as ion source; one ion repel electrode in one to four mm to the lamp window and earth electrode at ten to fifteen mm to the dispel electrode; ion repel electrode and earth connection electrode weak field acceleration ion electron for isolation; light exit hole with diameter as two to 8mm down the electrodes; one capillary to lead vacuum ultraviolet lamp front end with light axis vertical to gas sample in direction.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

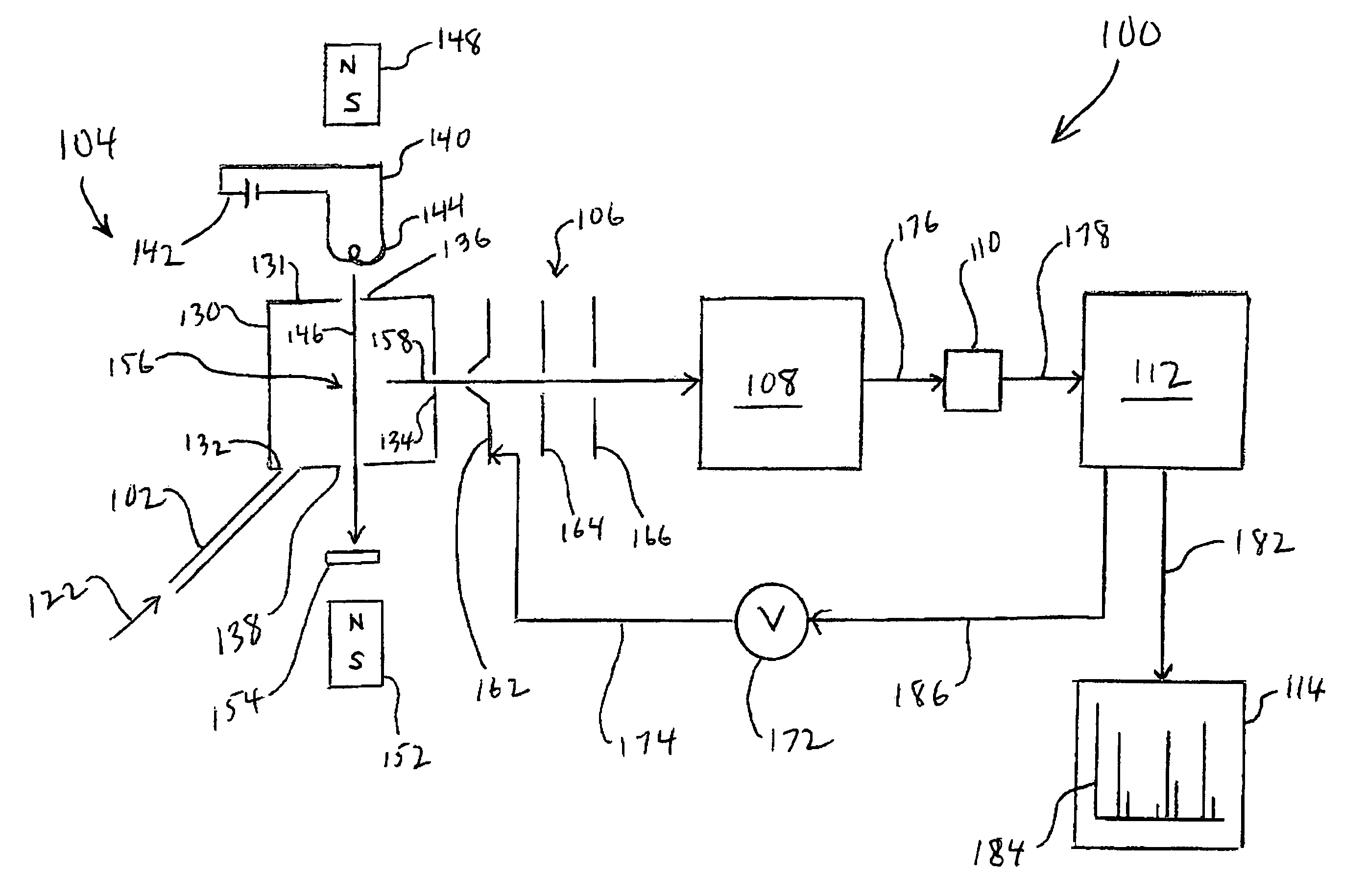

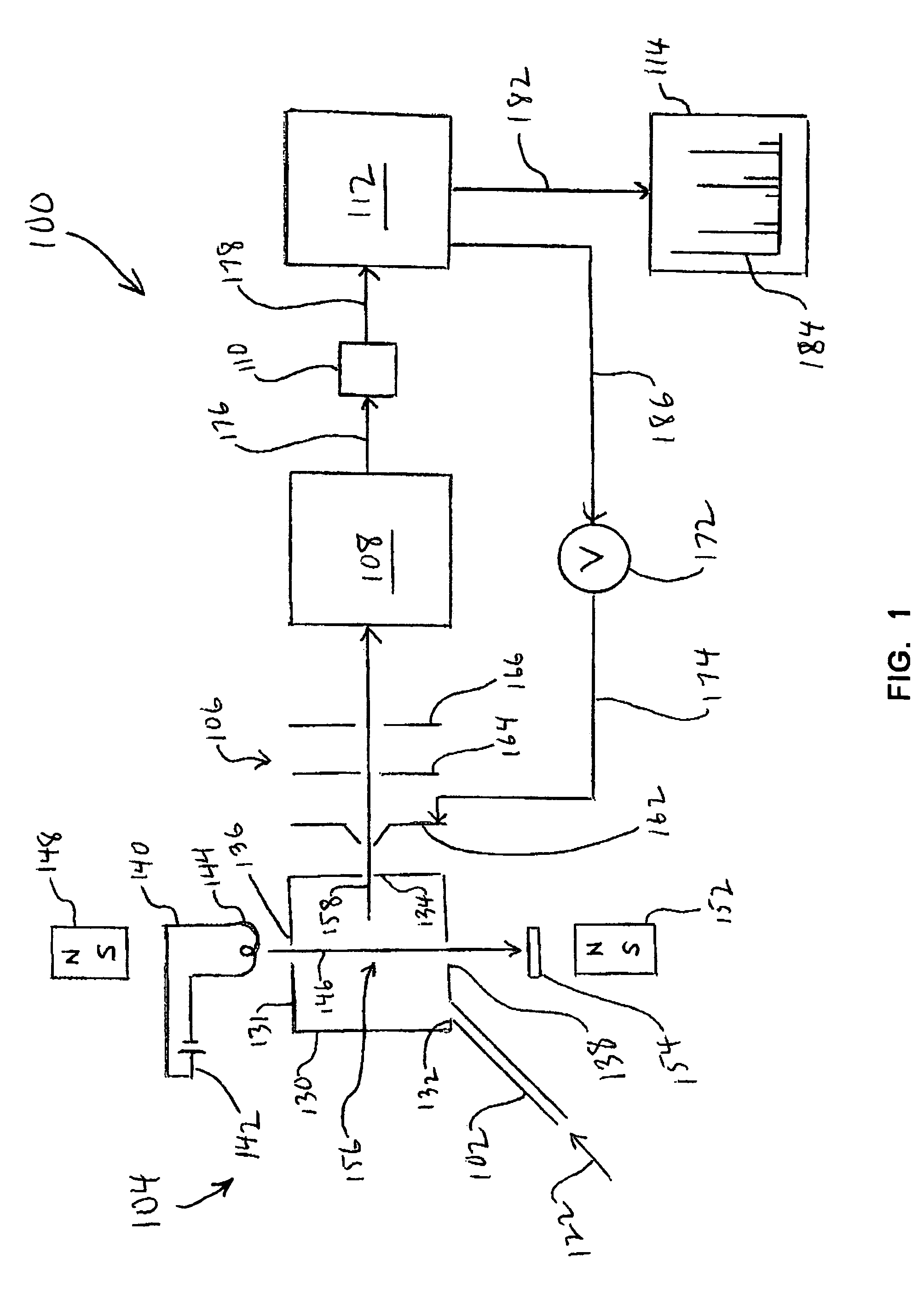

Method for controlling space charge-driven ion instabilities in electron impact ion sources

In a method for inhibiting space charge-related effects in an ion source, an electron beam is directed into a chamber to produce ions from sample material in the chamber. A voltage pulse is applied to the chamber to perturb an electron space charge present in the chamber. The ion source may be an electron impact ionization (EI) apparatus. The ion source may operated in conjunction with a mass spectrometry system.

Owner:BRUKER DALTONIK GMBH & CO KG

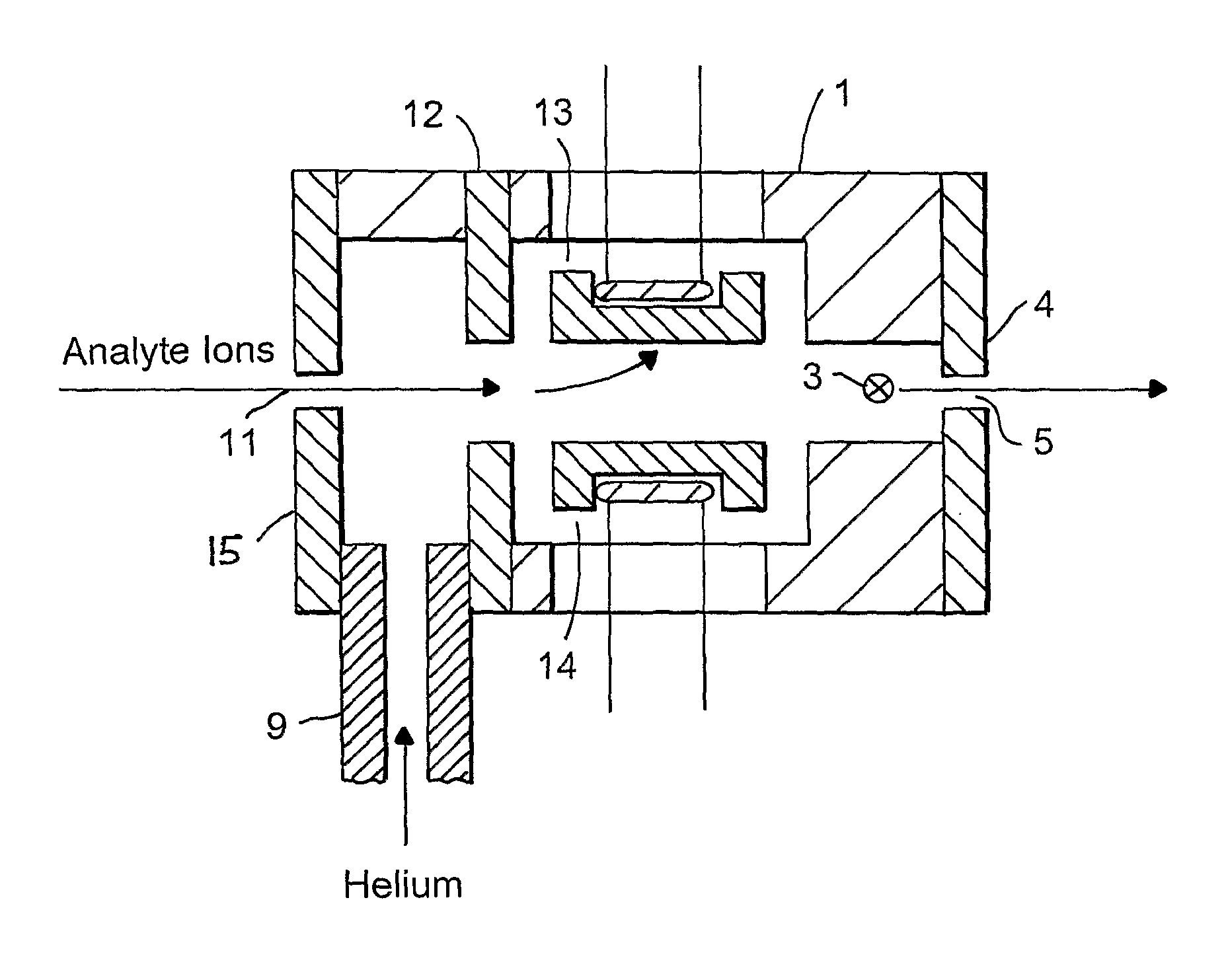

On-axis electron impact ion source

InactiveUS6998622B1Particle separator tubesMaterial analysis by optical meansAnalyteElectron collision

An electron impact ion source includes an ionization chamber in which a first rf multipole field can be generated and an ion guide positioned downstream from the ionization chamber in which a second rf multipole field can be generated wherein electrons are injected into the ionization chamber along the axis (on-axis) to ionize an analyte sample provided to the ionization chamber.

Owner:AGILENT TECH INC

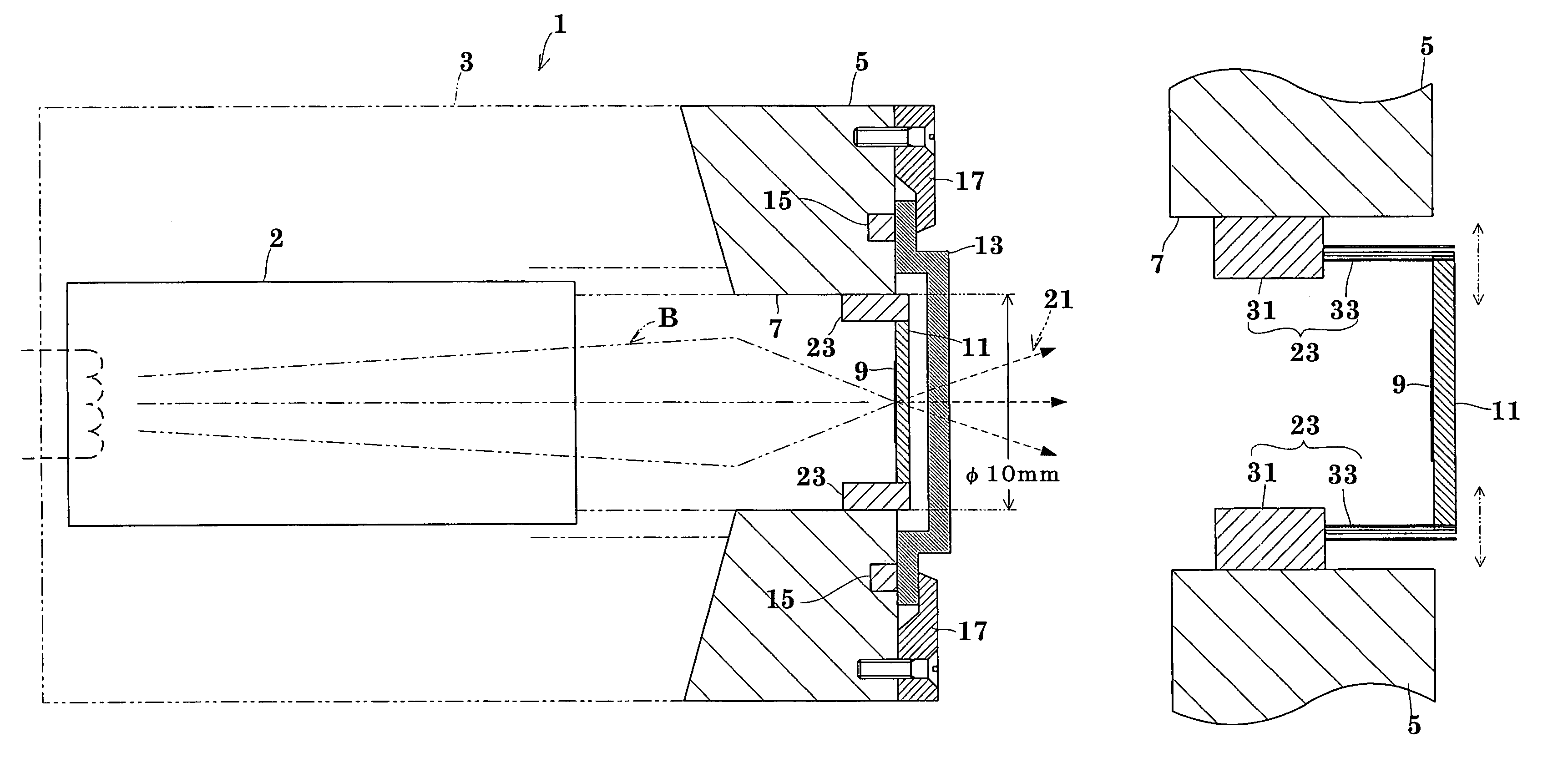

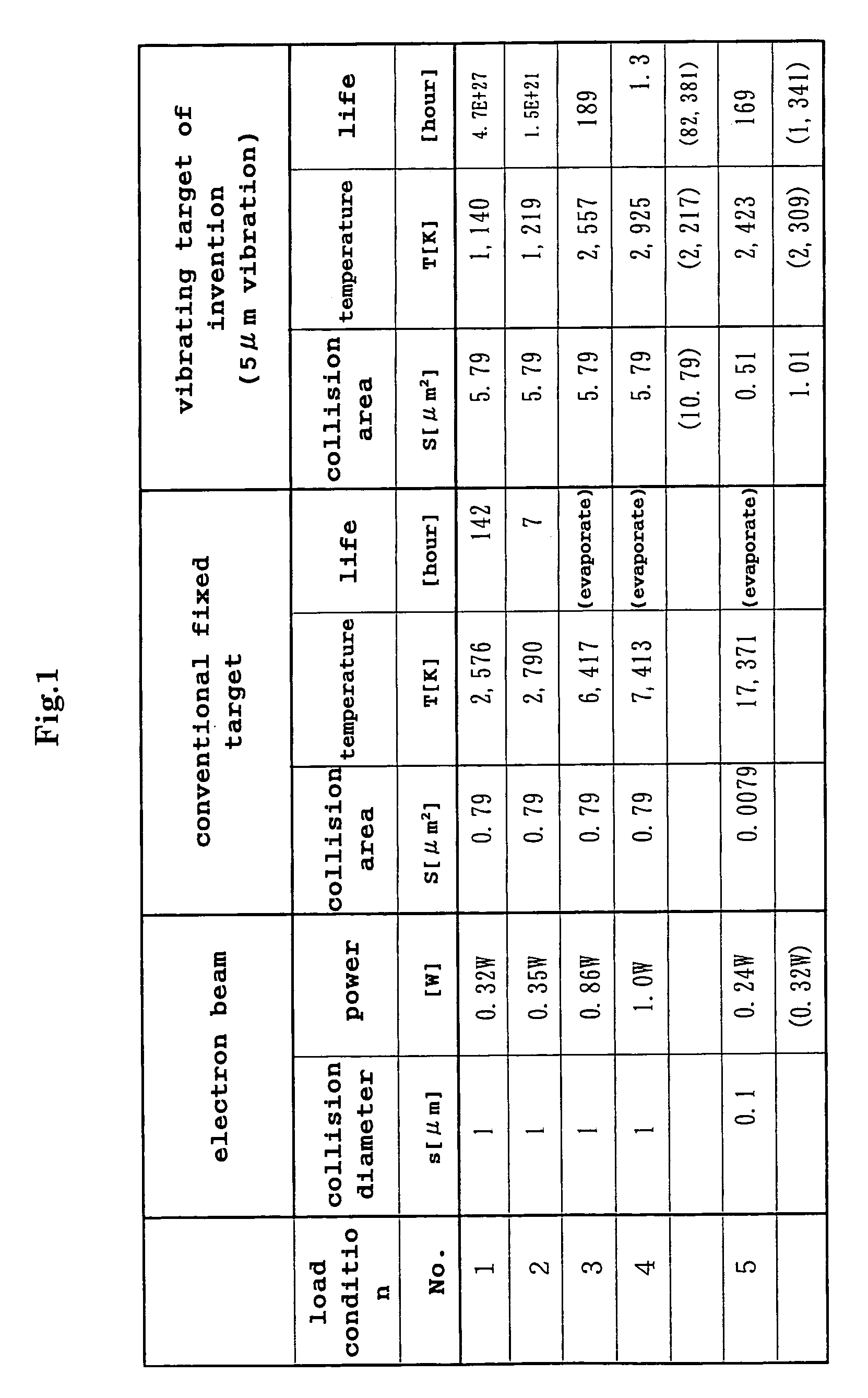

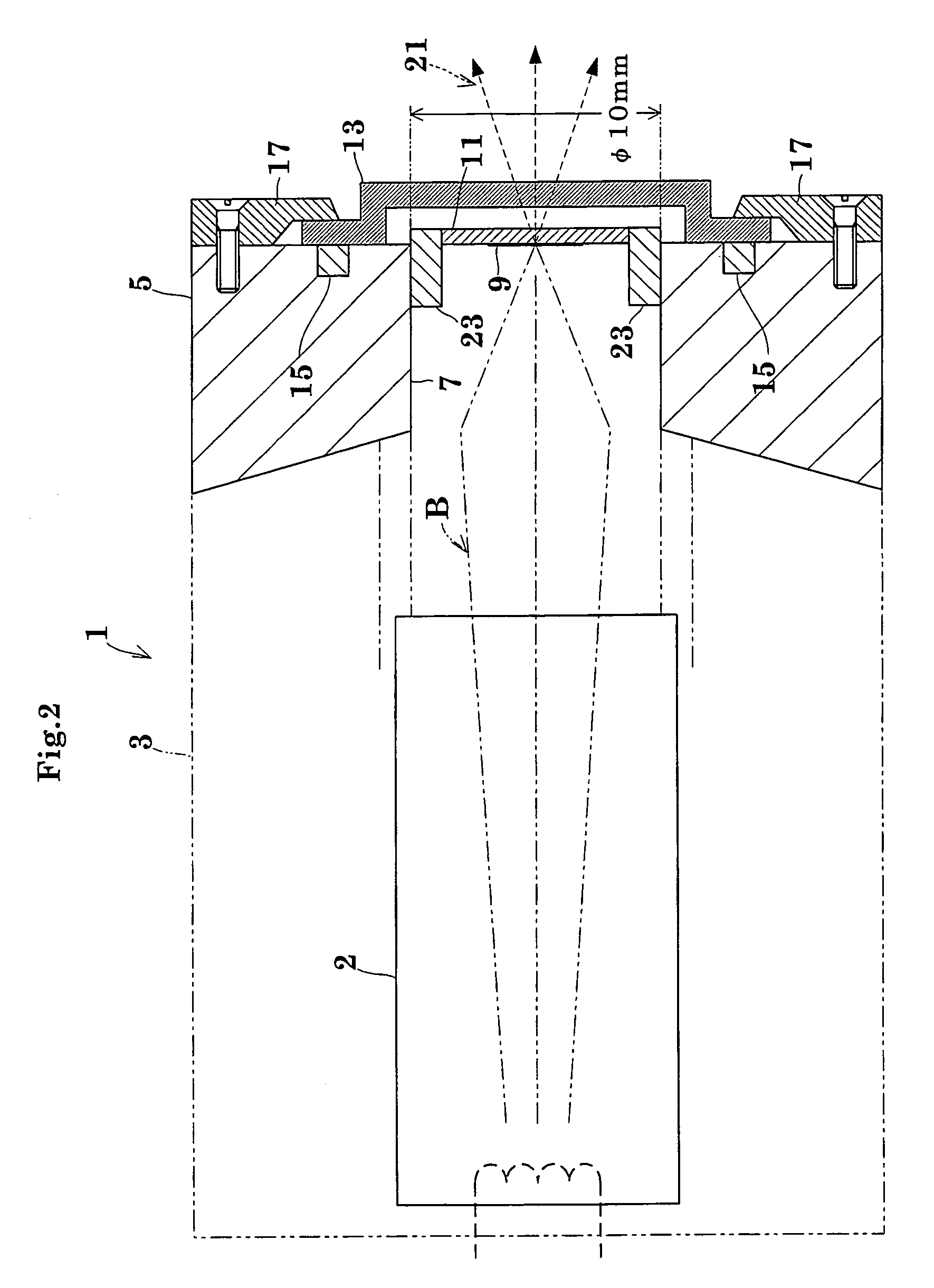

X-ray generating equipment

InactiveUS7305066B2High resolution and compactnessProlong lifeX-ray tube electrodesCathode ray concentrating/focusing/directingSoft x rayElectron collision

An X-ray generating apparatus for generating X-rays by irradiating a target with an electron beam. Wherein the apparatus includes a vibration applying means for vibrating the target in directions parallel to a surface thereof. A colliding spot of the electron beam is movable on the target while maintaining an X-ray focus in the same position on the electron beam without fluctuating the X-ray focal position. This enlarges an actual area of electron collision on the target to disperse the generated heat, thereby to suppress a local temperature rise of the target due to the electron collision. The X-ray generating apparatus is compact, and has a long life and a high X-ray intensity.

Owner:SHIMADZU CORP

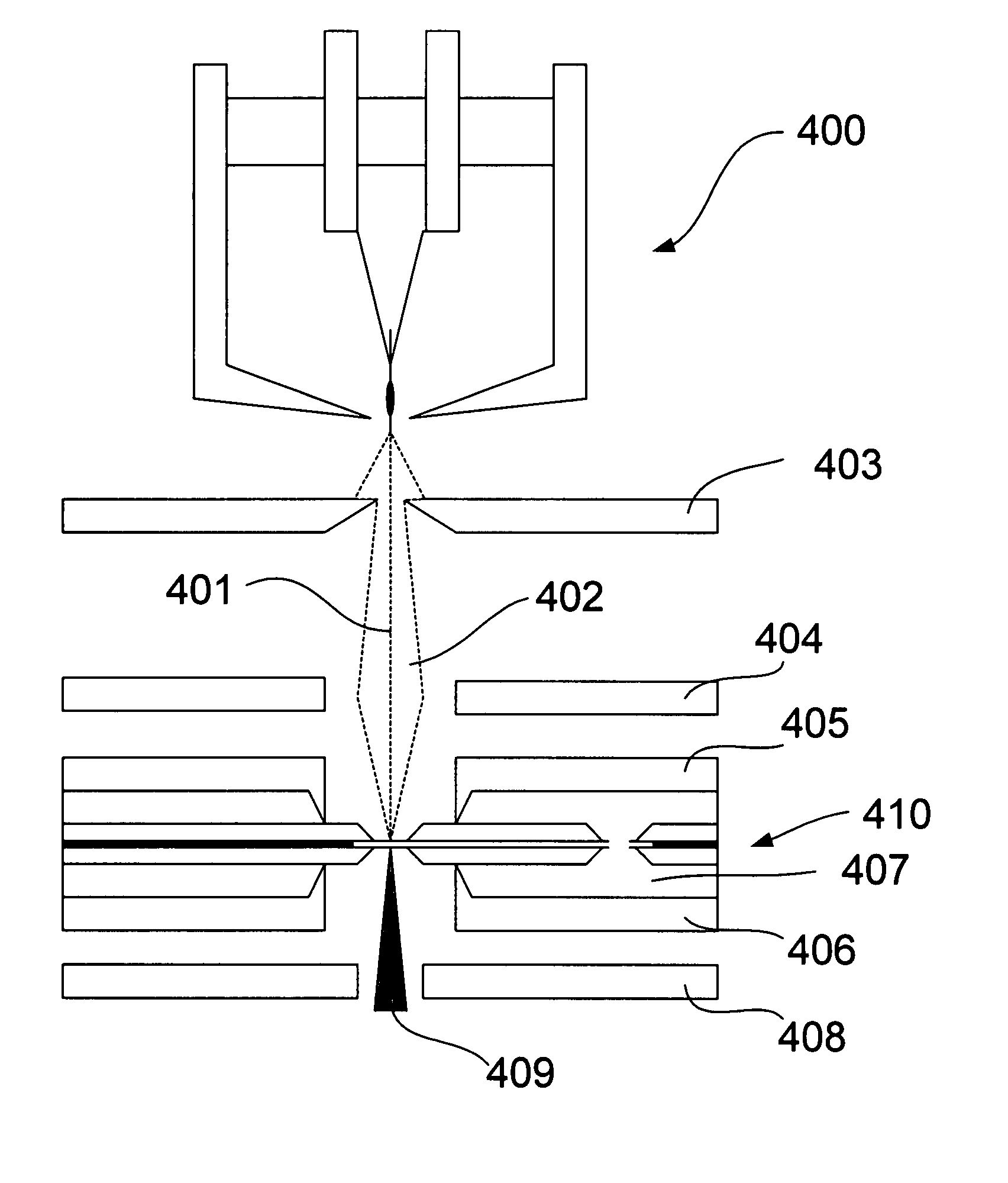

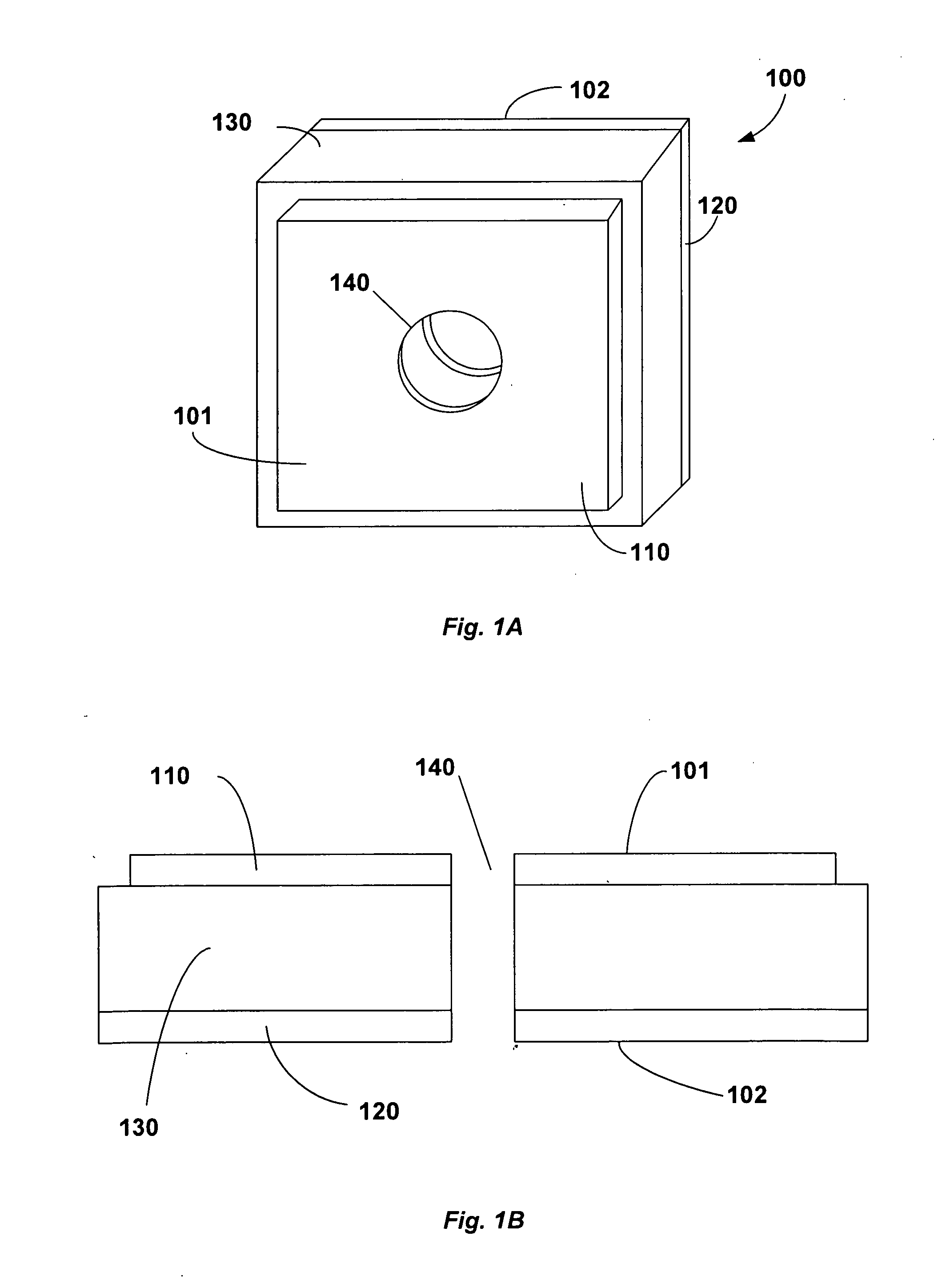

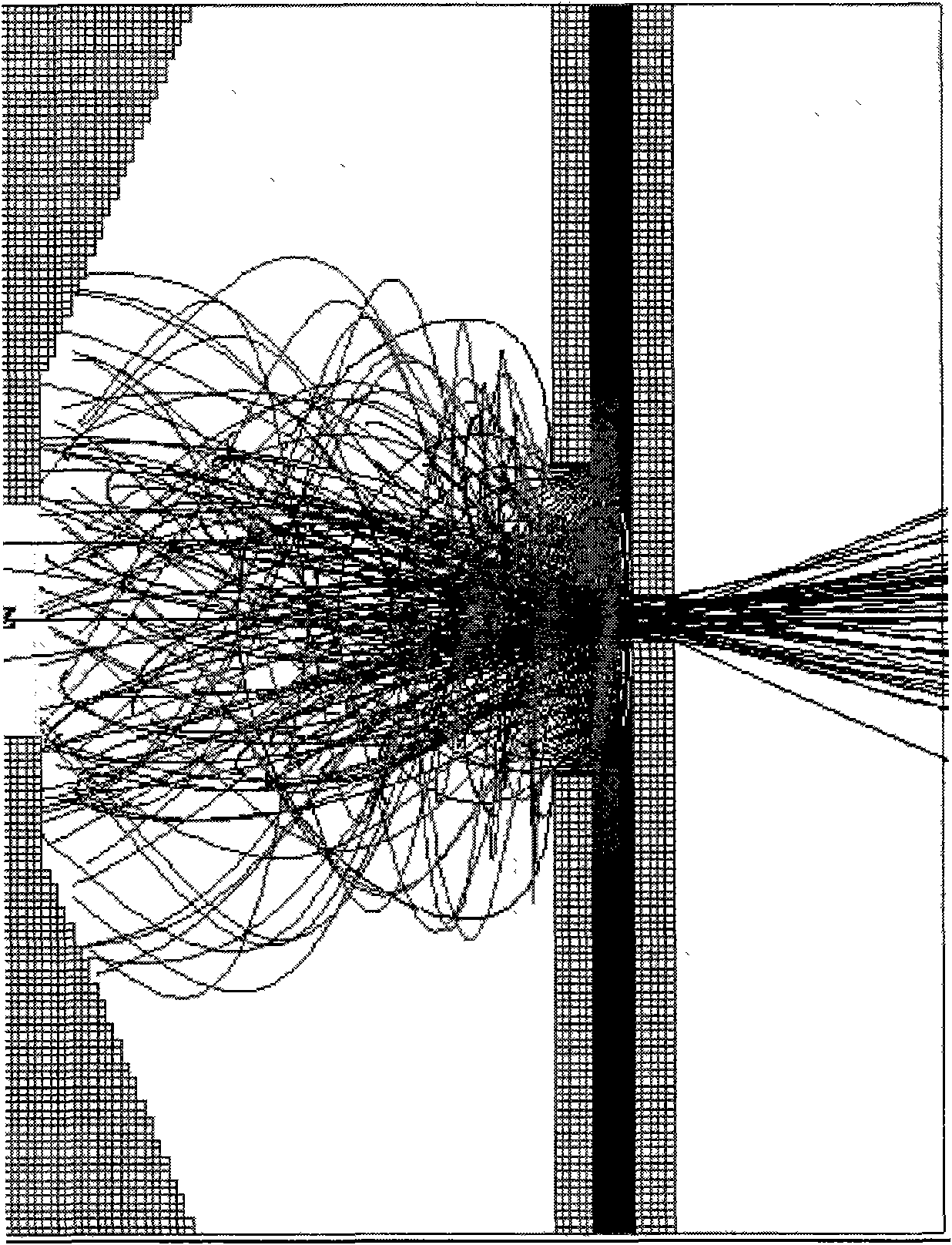

Particle-optical apparatus equipped with a gas ion source

ActiveUS7772564B2Increase current densityAvoid obstructionMaterial analysis by optical meansIon beam tubesElectron sourceElectron collision

The invention relates to an electron impact gas ion with high brightness and low energy spread. This high brightness is achieved by injecting electrons in a small ionization volume (from less than 1 μm to several tens of micrometers in size) from one side and extracting ions from the other. The electrons injected are produced by a high brightness electron source, such as a field emitter or a Schottky emitter.In one embodiment of the invention the required high electron density in the ionization volume is realized by placing a field emitter close to the ionization volume (e.g. 30 μm), without optics between source and ionization volume.In another embodiment of the invention the source is imaged onto a MEMS structure. Two small diaphragms of e.g. 50 nm are spaced e.g. 1 μm apart. The electrons enter through one of these diaphragms, while the ions leave the ionization volume through the other one. The two diaphragms are manufactured by e.g. drilling with an ion beam, resulting in two small and well aligned diaphragms.

Owner:FEI CO

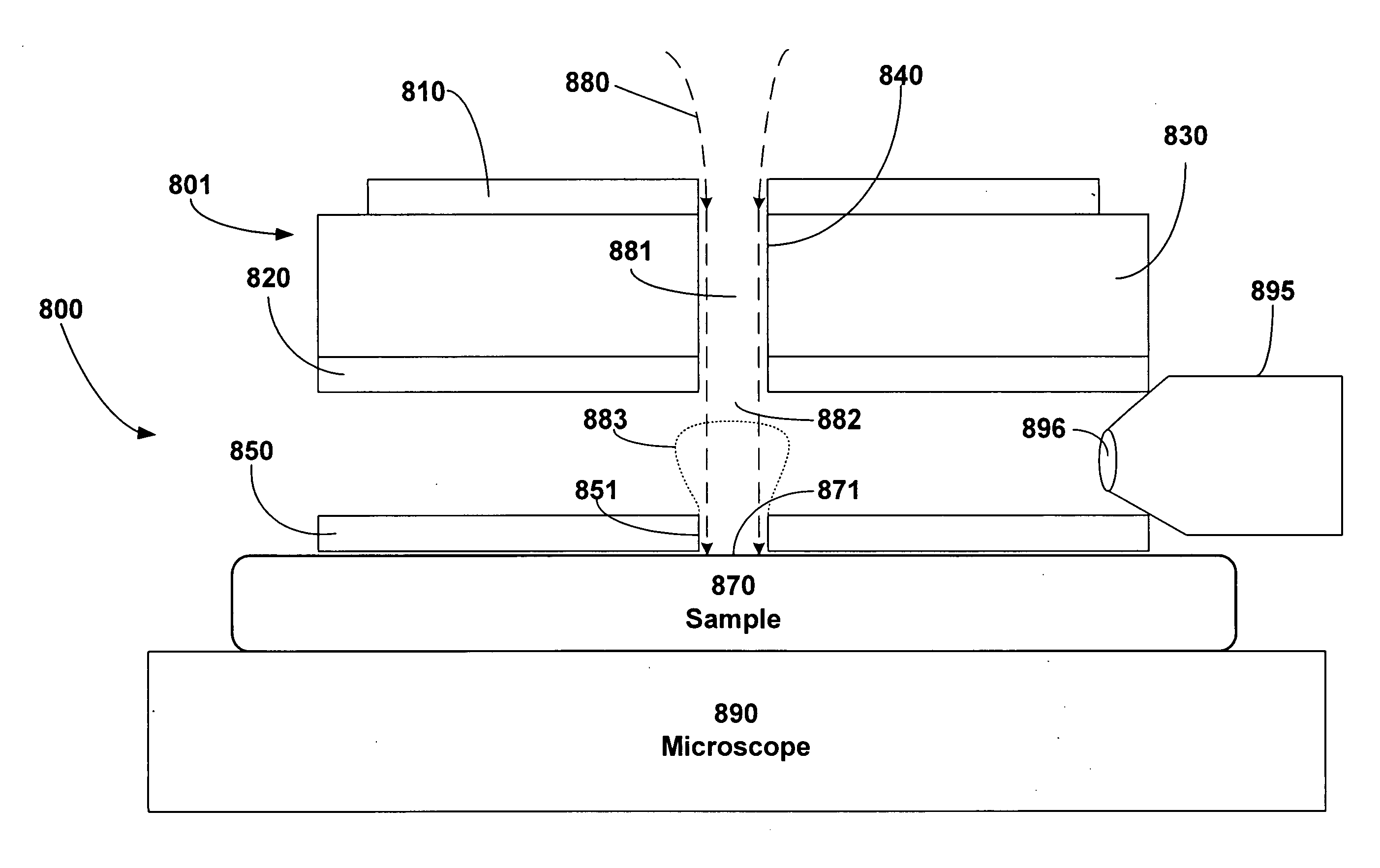

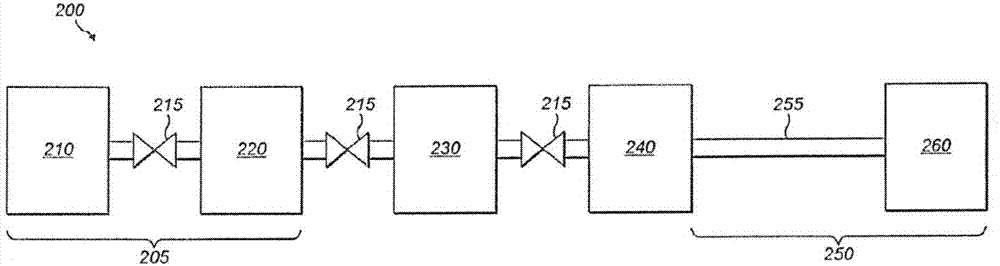

System and method for spatially-resolved chemical analysis using microplasma desorption and ionization of a sample

ActiveUS20090121127A1Damage to minimized eliminatedFragmentation and to minimized eliminatedParticle separator tubesMaterial analysis by optical meansNoble gasDesorption

A method and system for desorbing and ionizing molecules from a sample for mass spectrometry using a microplasma device is disclosed. The system and method relies upon a microplasma device, or array of such devices, to partially ionize a gas to form a microplasma. The ionized gas can be a mixture of a noble gas, such as neon or argon, and hydrogen (H2). The ionized gas can form a effluent stream directed onto the surface of a sample to desorb molecules from the remainder of the sample. The desorbed molecules can be ionized by the effluent stream as they leave the surface of the sample. The ionization process can include: photoionization, penning ionization, chemical ionization (proton transfer), and electron impact ionization. The ionized particles from the sample can be directed to a mass spectrometer for analysis. This can produce spatially-resolved mass spectral data, and can be conducted concurrently with another imaging system, such as a microscope.

Owner:GEORGIA TECH RES CORP

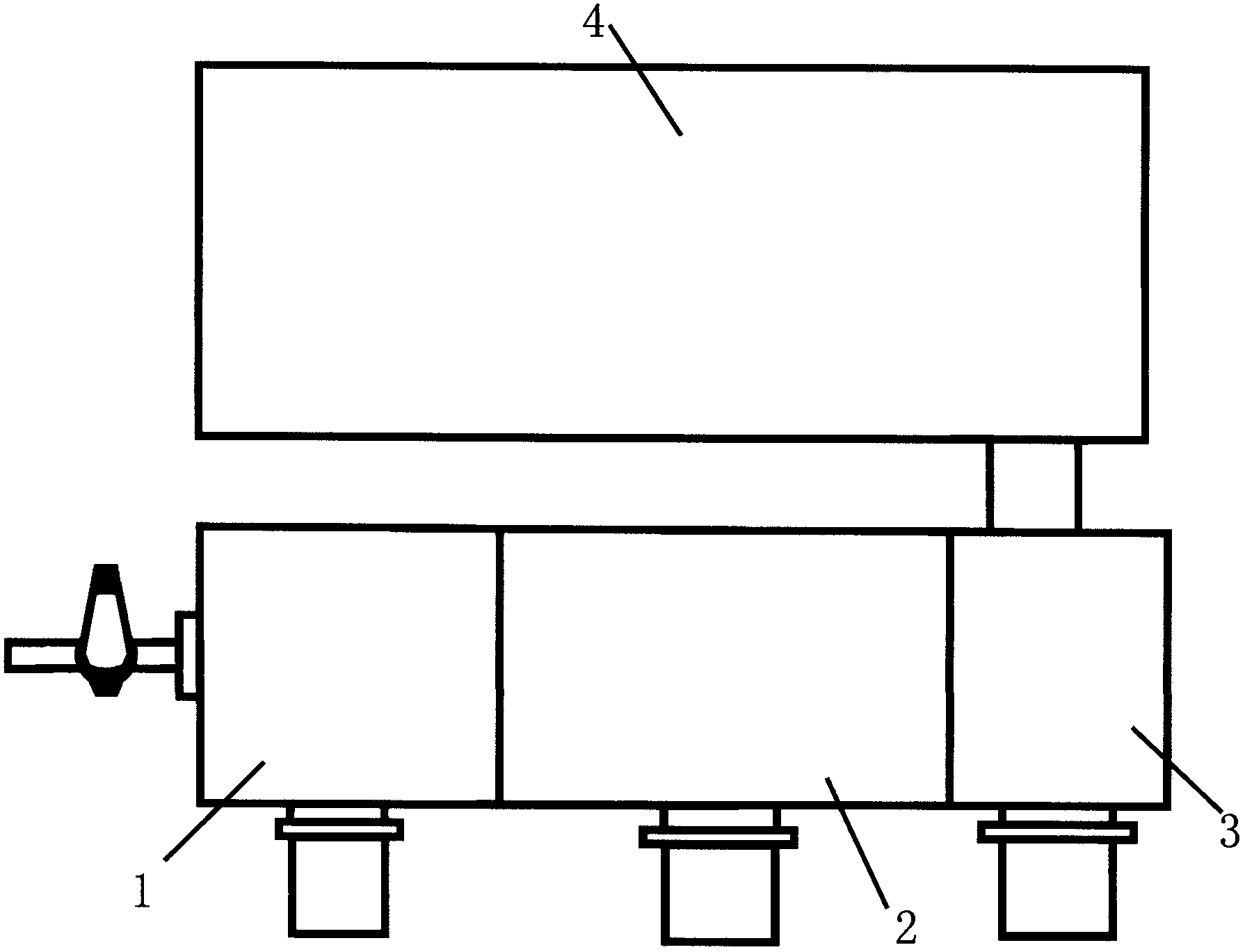

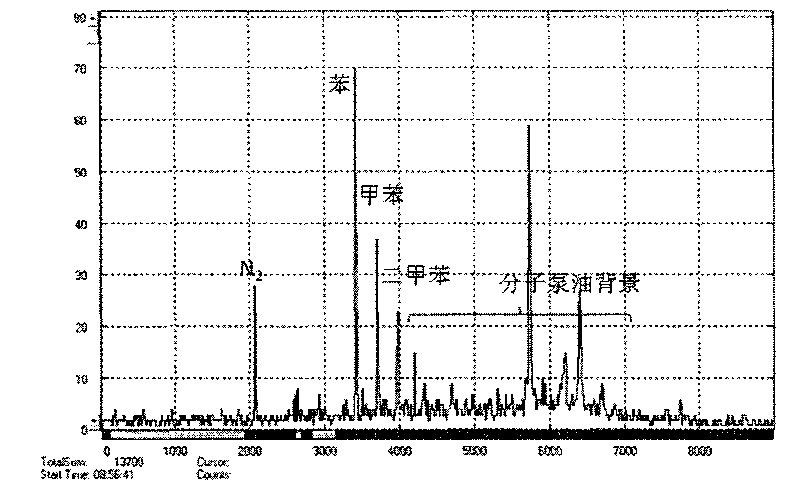

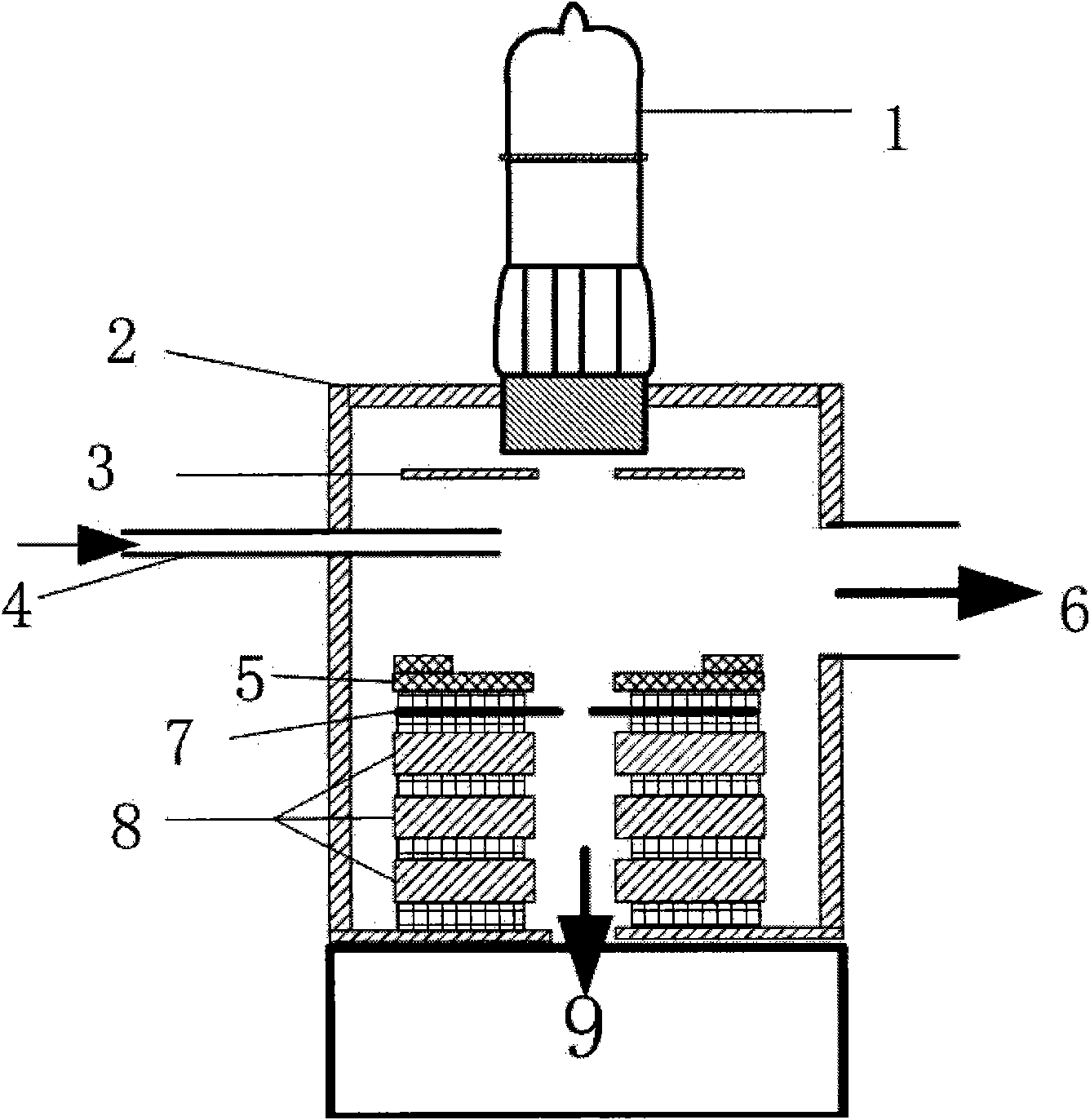

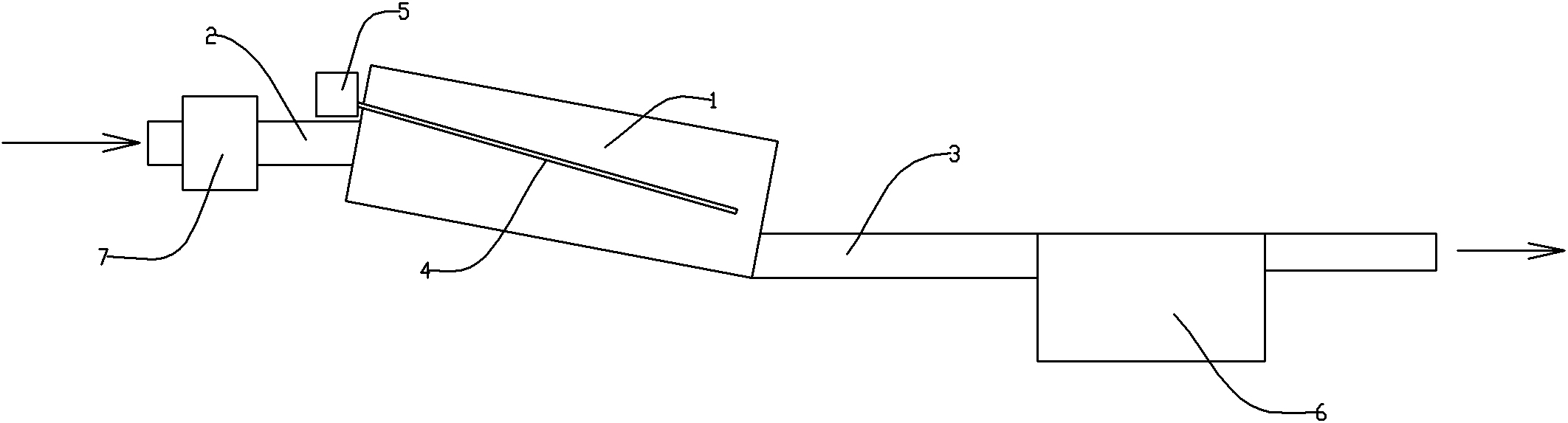

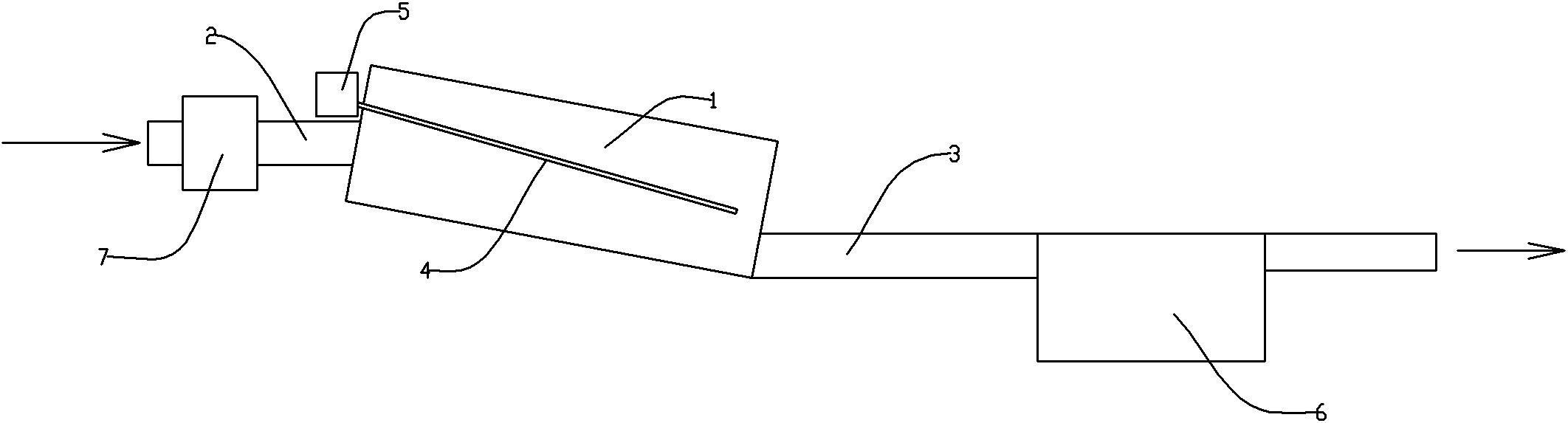

Aerosol mass spectrometer with particle size selection

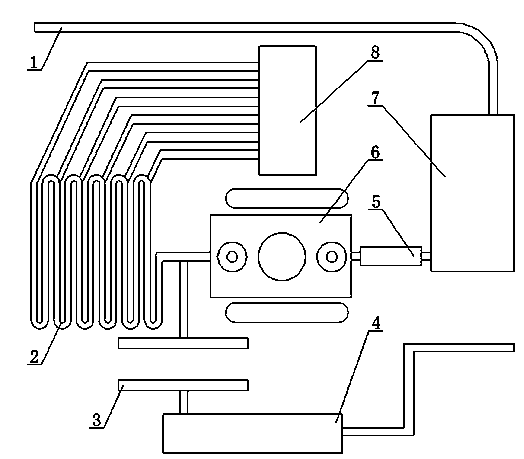

InactiveCN103426712AReduce storageReduce the difficulty of analysisDynamic spectrometersSamples introduction/extractionSynchronous motorParticle beam

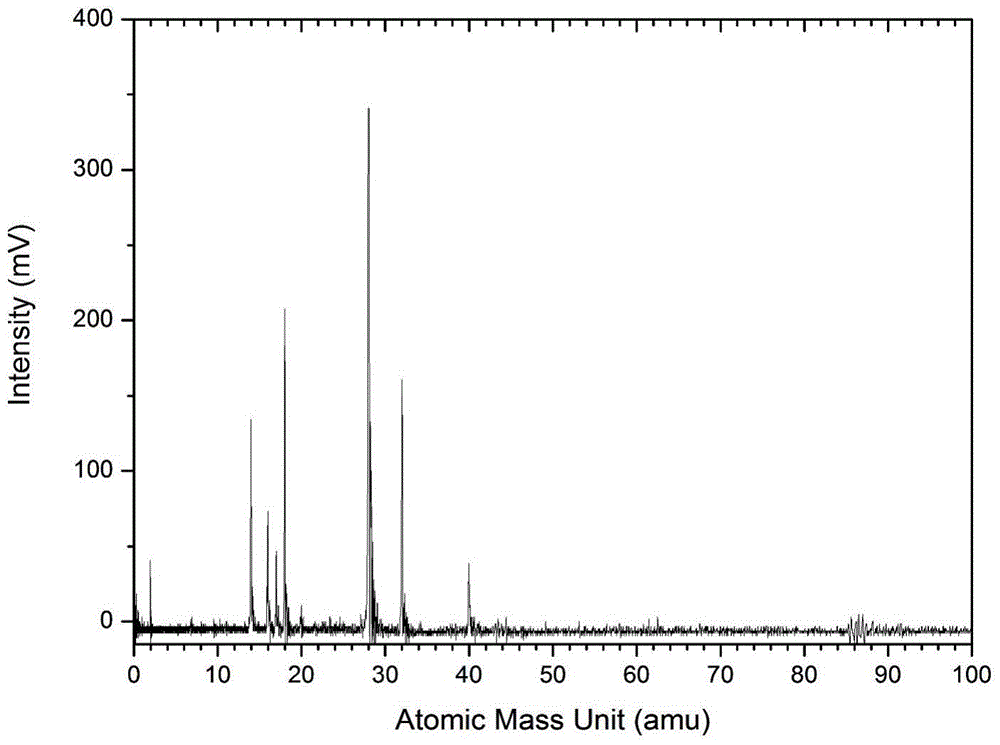

The invention applies for an aerosol mass spectrometer with particle size selection, wherein the aerosol mass spectrometer can simultaneously select the particle size, the concentration and the chemical component of the atmospheric aerosol. The aerosol mass spectrometer uses a sampling hole with the diameter of 100 micrometers to carry out direct sampling on an aerosol in a natural environment; aerosol particles are focused into a particle beam flow with the 0.5-milimeter diameter by a pneumatic focusing lens; the aerosol particles are selected by a particle size selector that is formed by three coaxial rotating plates with slits, wherein the rotating plates of the particle size selector are driven by a synchronous motor and the frequency of the synchronous motor power supply can be adjusted continuously; an aerosol particle that is selected by the particle size selector is gasified by a gasifier with the high temperature from 600 to 700 degrees; gas after gasification is ionized by an electron collision ionizer; a generated ion is detected by a W type reflection type mass spectrum apparatus so as to obtain the mass spectrum of the aerosol. Therefore, information including the particle size, the concentration and the chemical composition of the organic aerosol can be obtained by analyzing the sampling rate, the frequency of the synchronous motor power supply and the obtained mass spectrum.

Owner:RES CENT FOR ECO ENVIRONMENTAL SCI THE CHINESE ACAD OF SCI

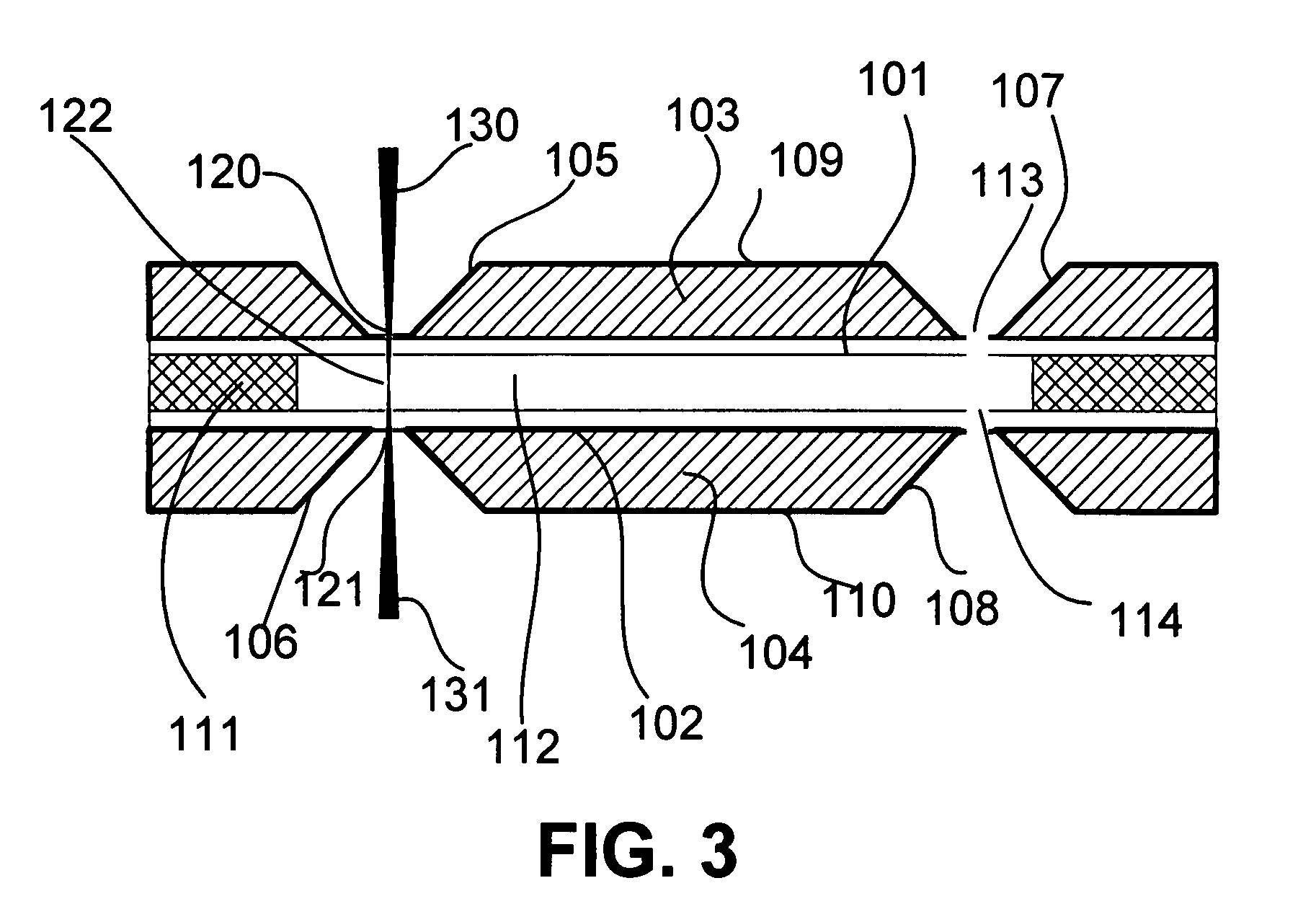

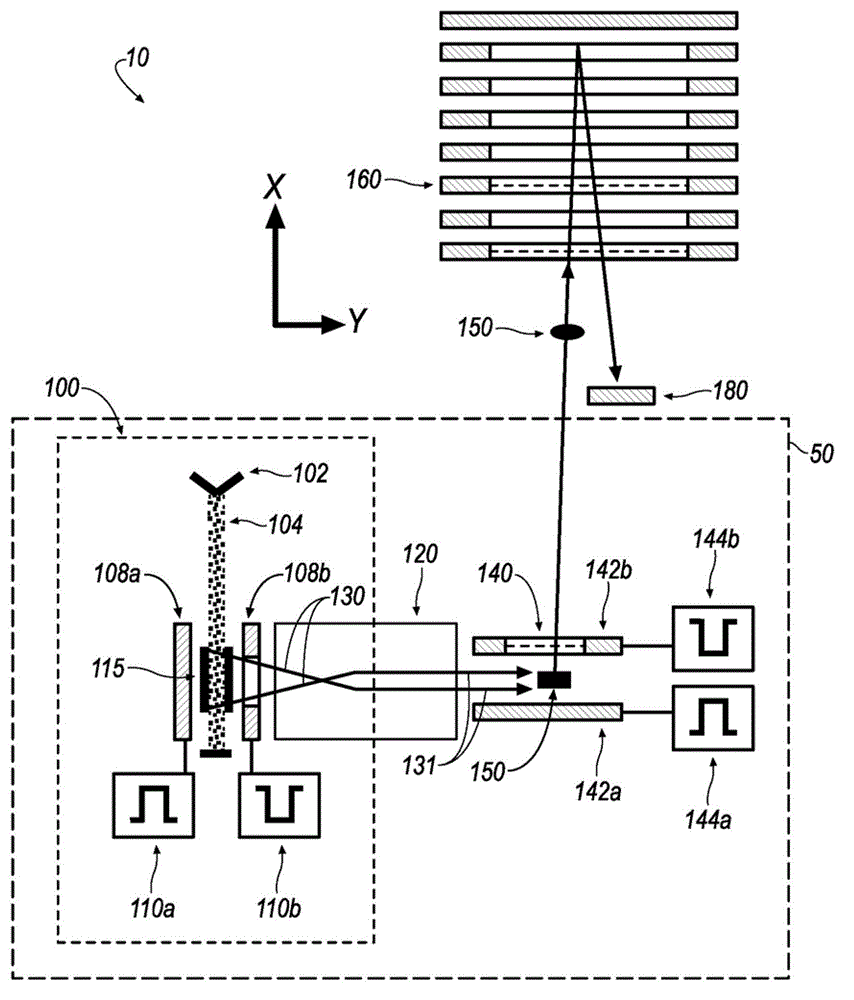

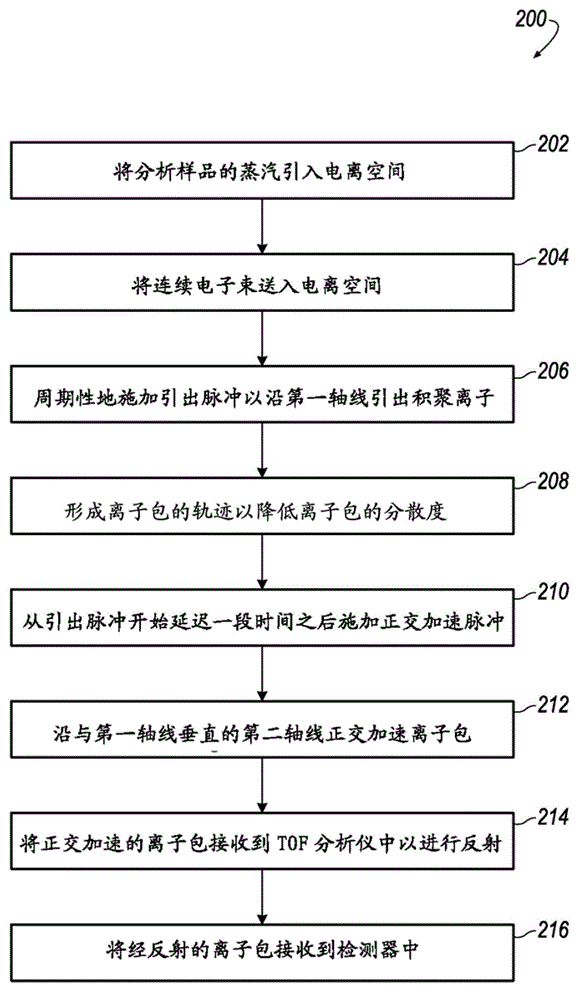

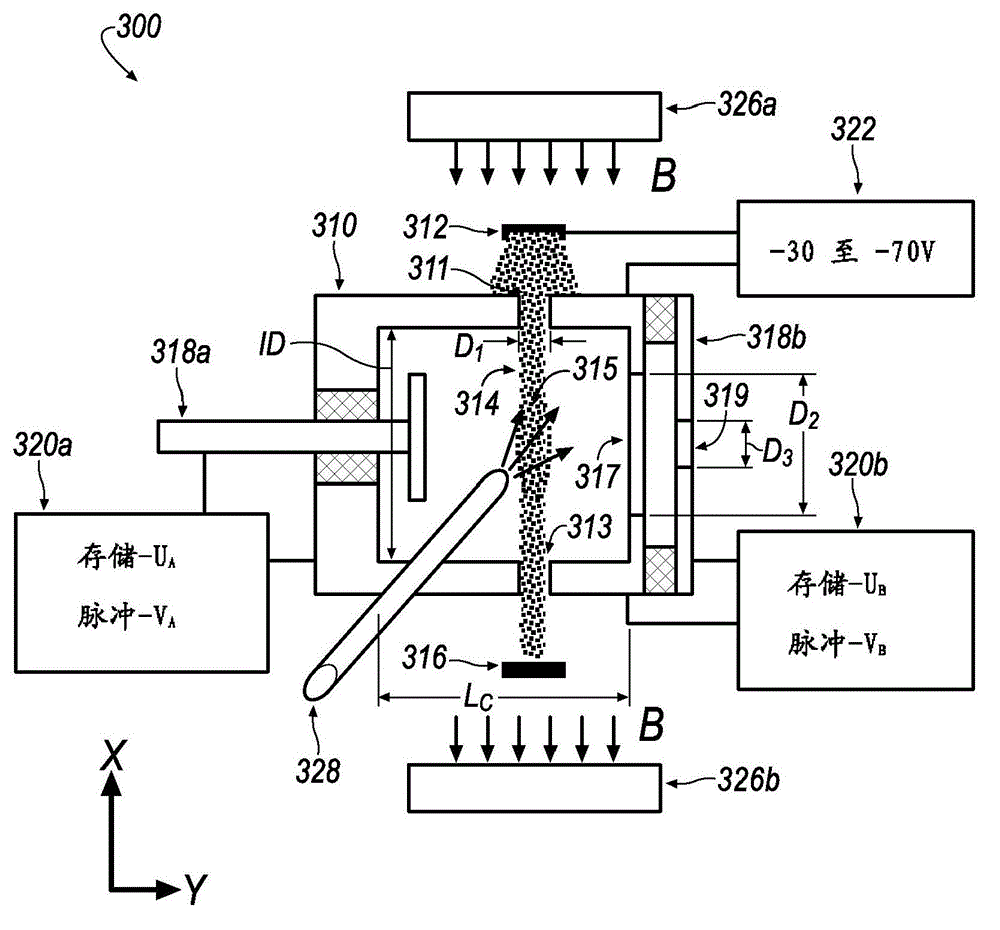

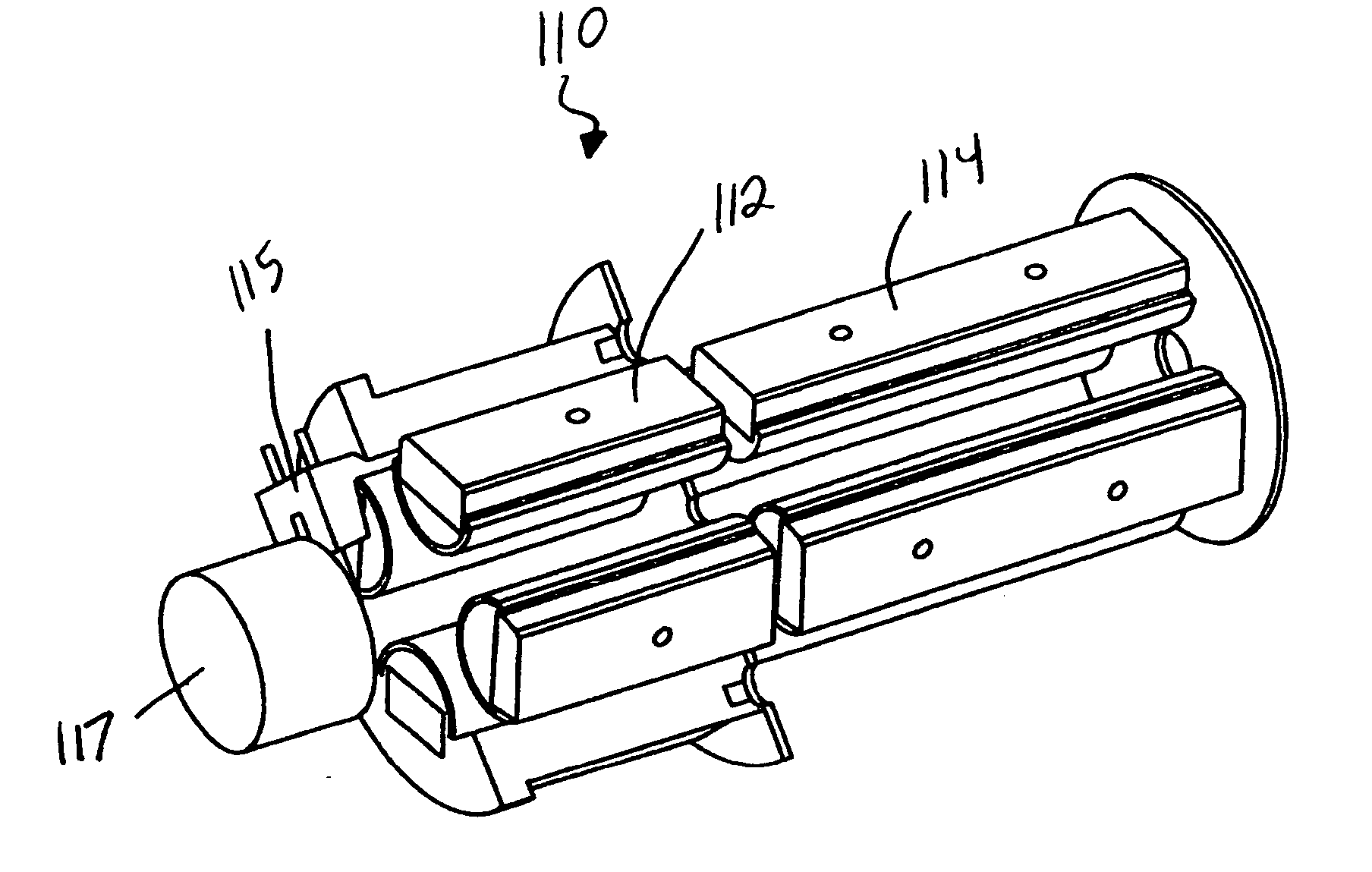

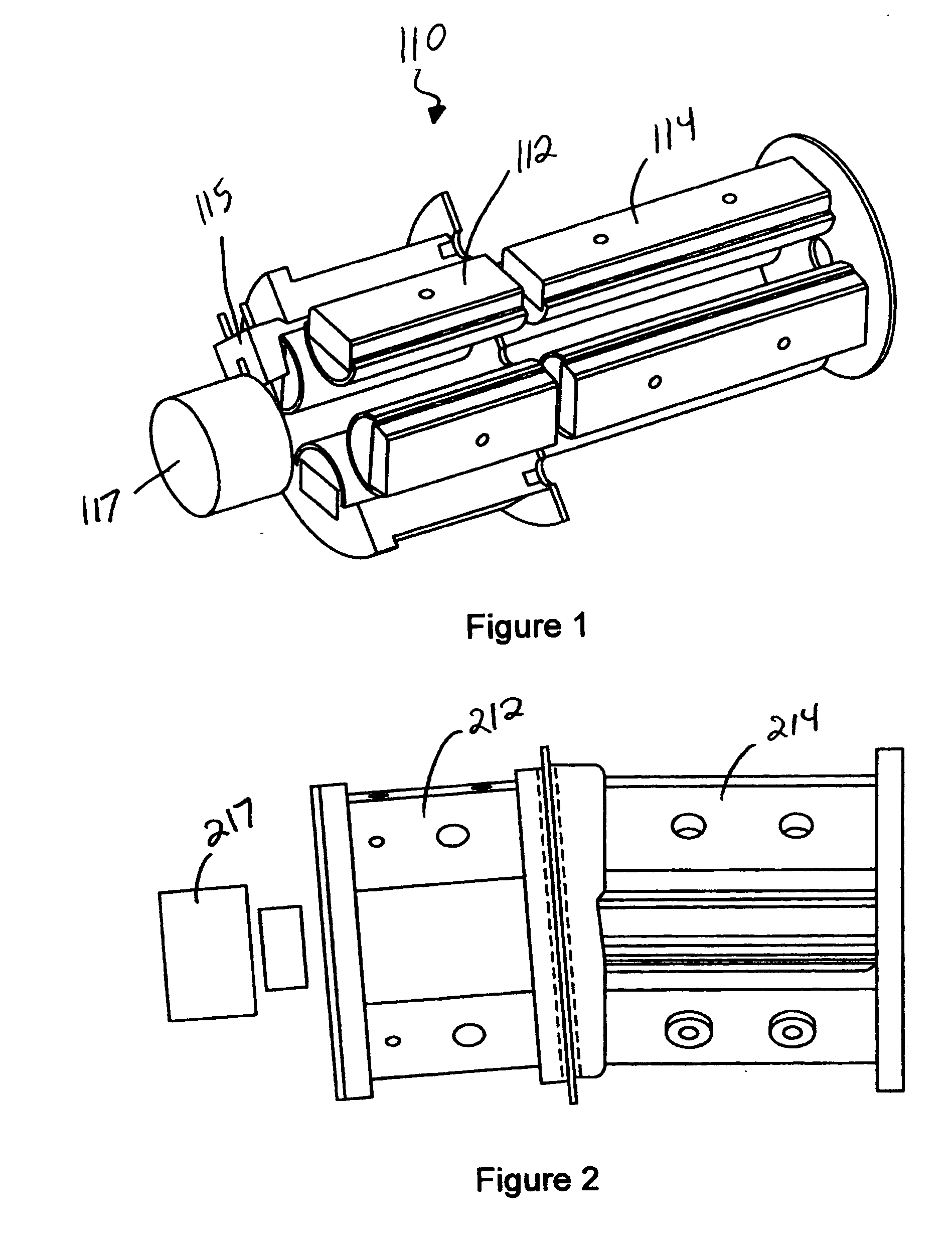

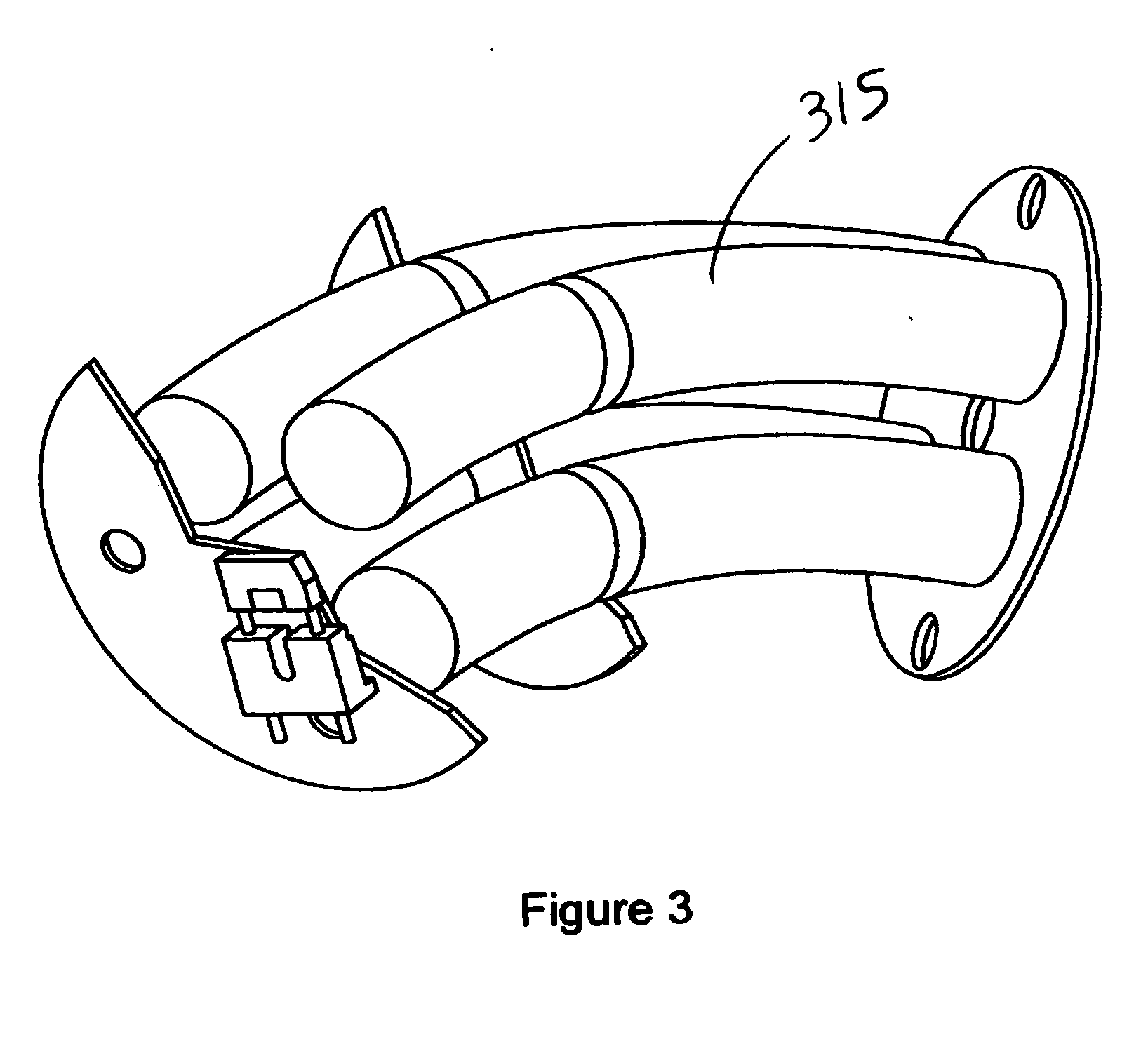

Time-of-flight mass spectrometer with accumulating electron impact ion source

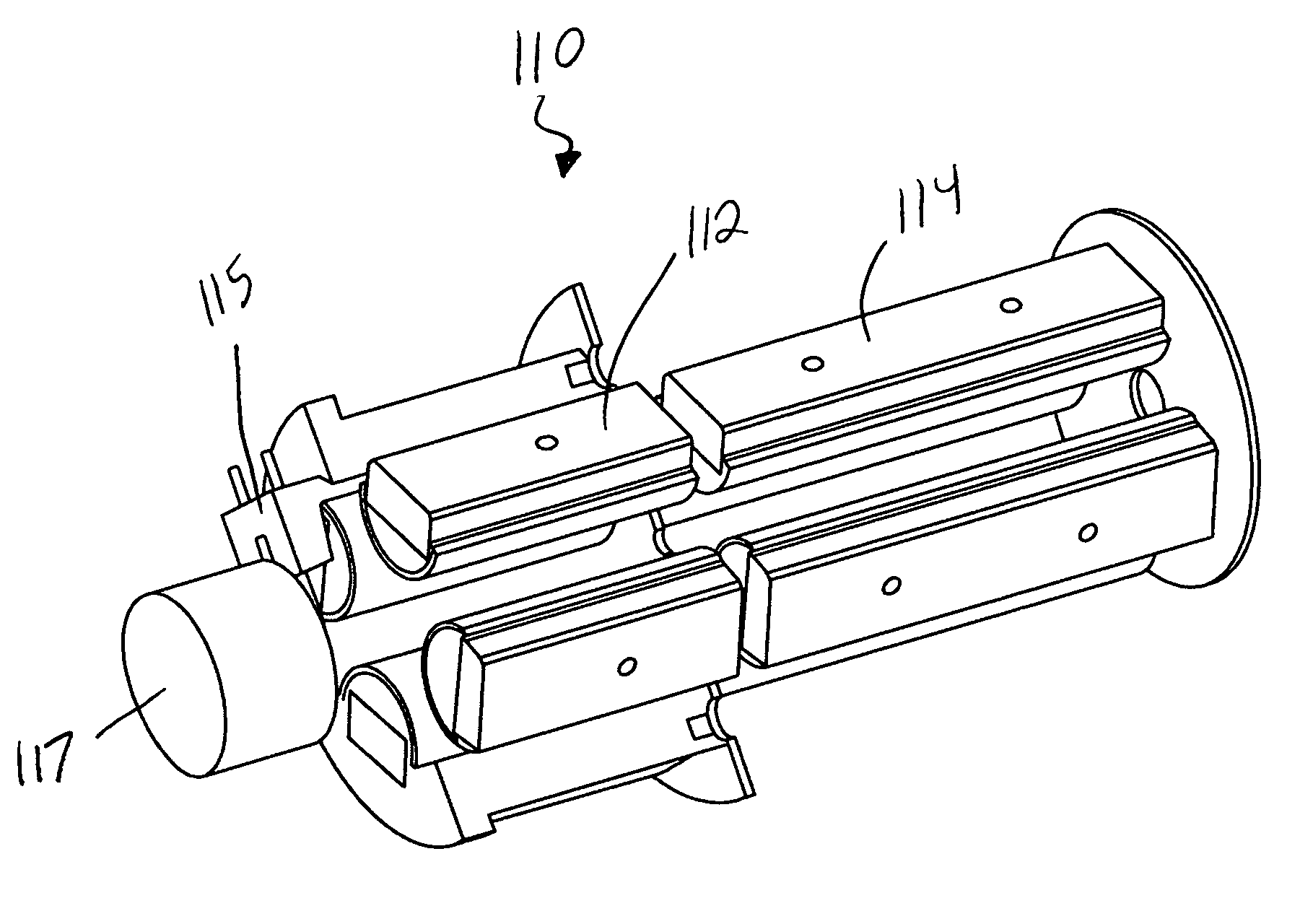

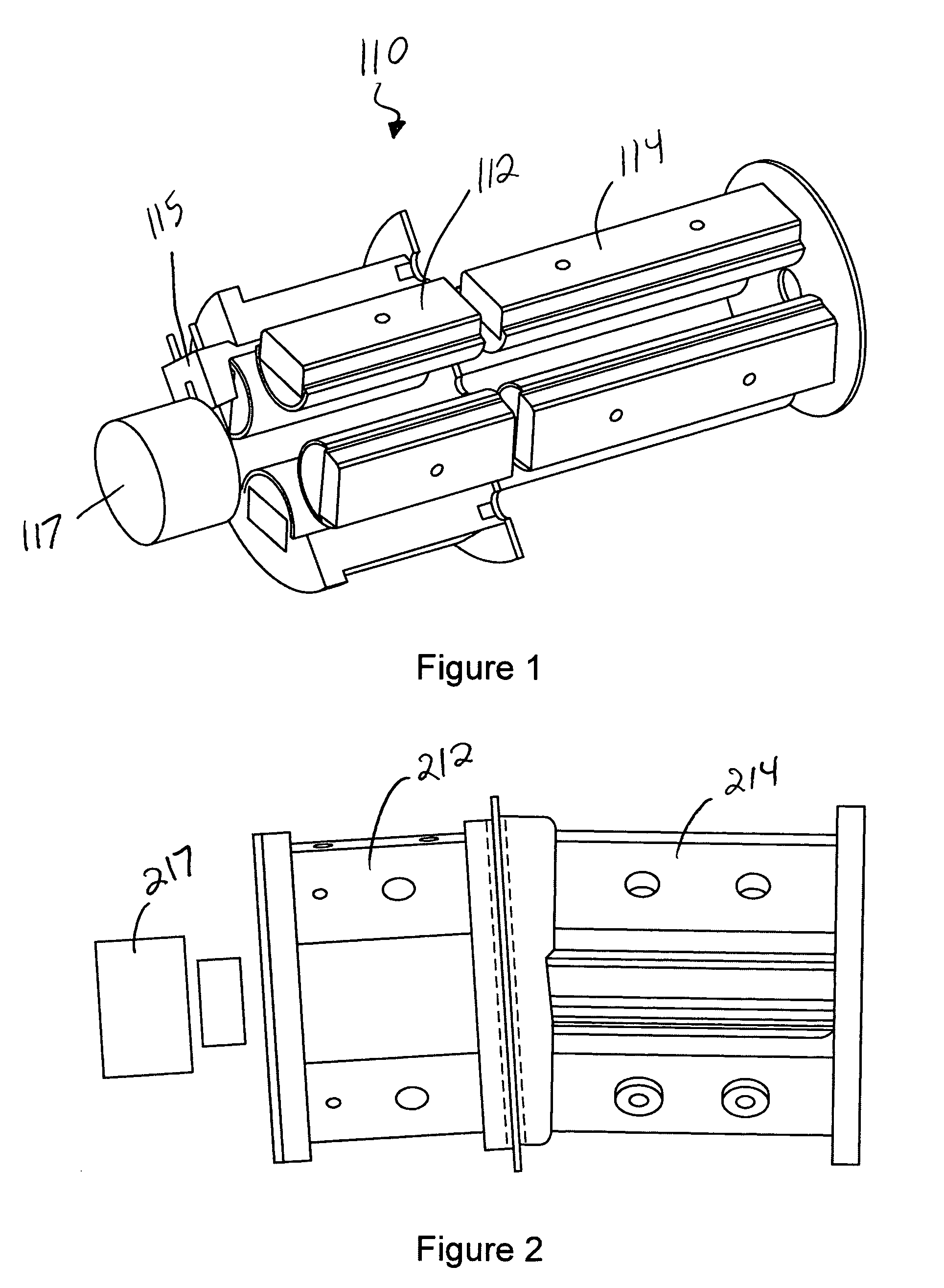

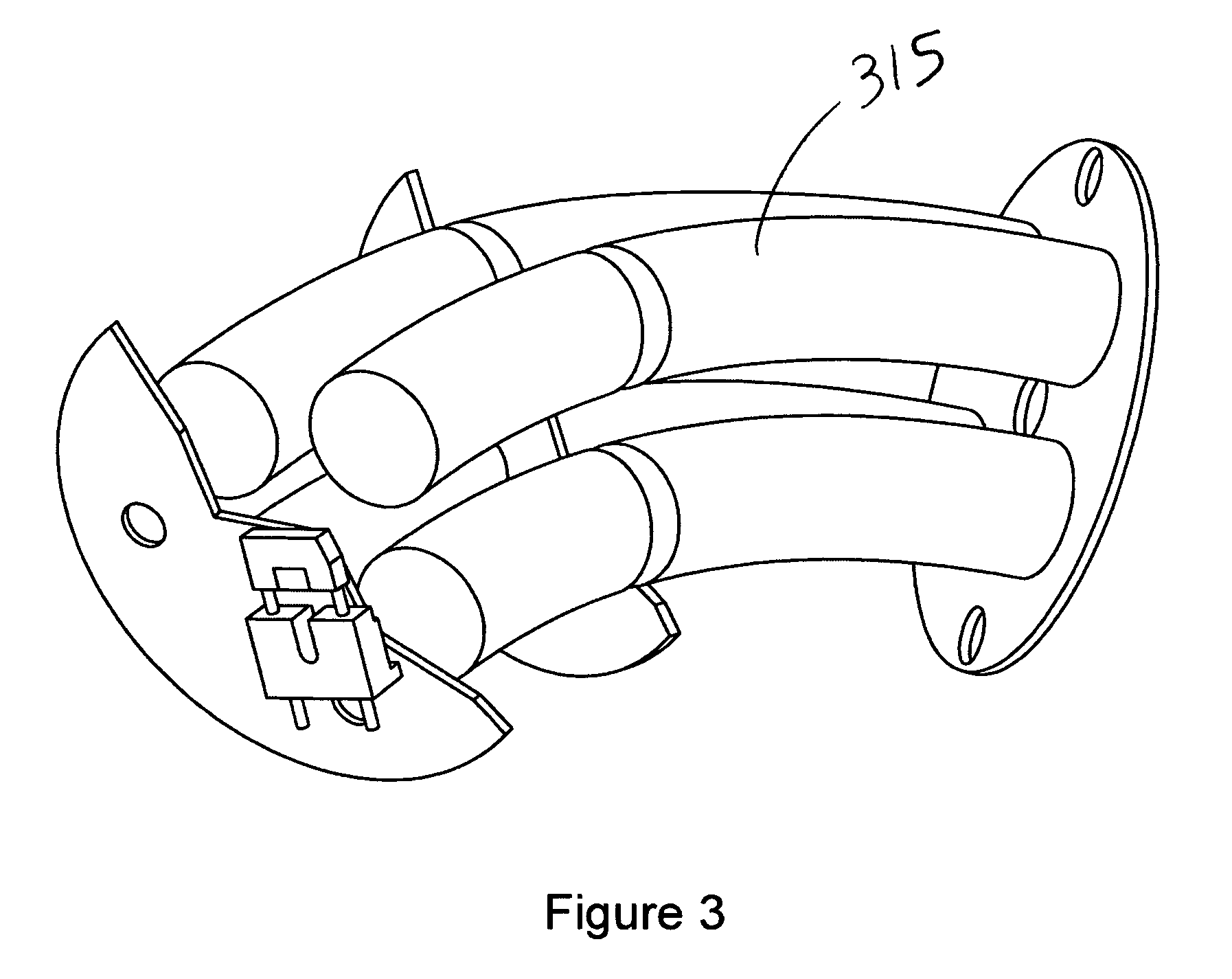

An accumulating ion source for a mass spectrometer that includes a sample injector (328) introducing sample vapors into an ionization space (115) and an electron emitter (102) emitting a continuous electron beam (104) into the ionization space (115) to generate analyte ions. The accumulating ion source further includes first and second electrodes (108a, 108b) arranged spaced apart in the ionization space (115) for accumulating analyte ions substantially therebetween. The first and second electrodes (108a, 108b) receive periodic extraction energy potentials to accelerate packets of analyte ions from the ionization space (115) along a first axis. An orthogonal accelerator (140) receives the packets of analyte ions along the first axis and periodically accelerates the packets of analyte ions along a second axis substantially orthogonal to the first axis.; A time delay between the extraction acceleration and the acceleration of each respective packet of analyte ions provides a proportional mass range of the respective packet of analyte ions.

Owner:LECO CORPORATION

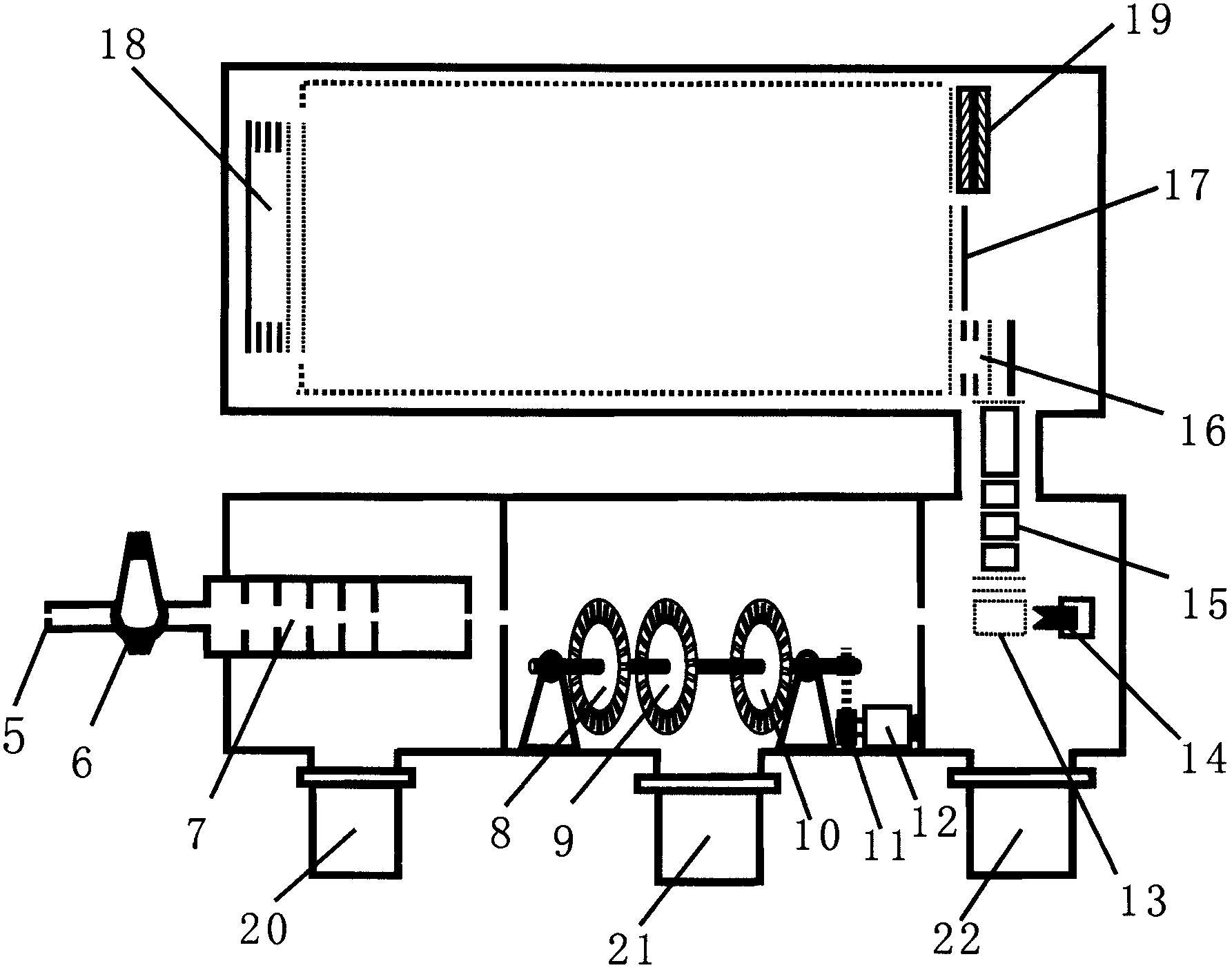

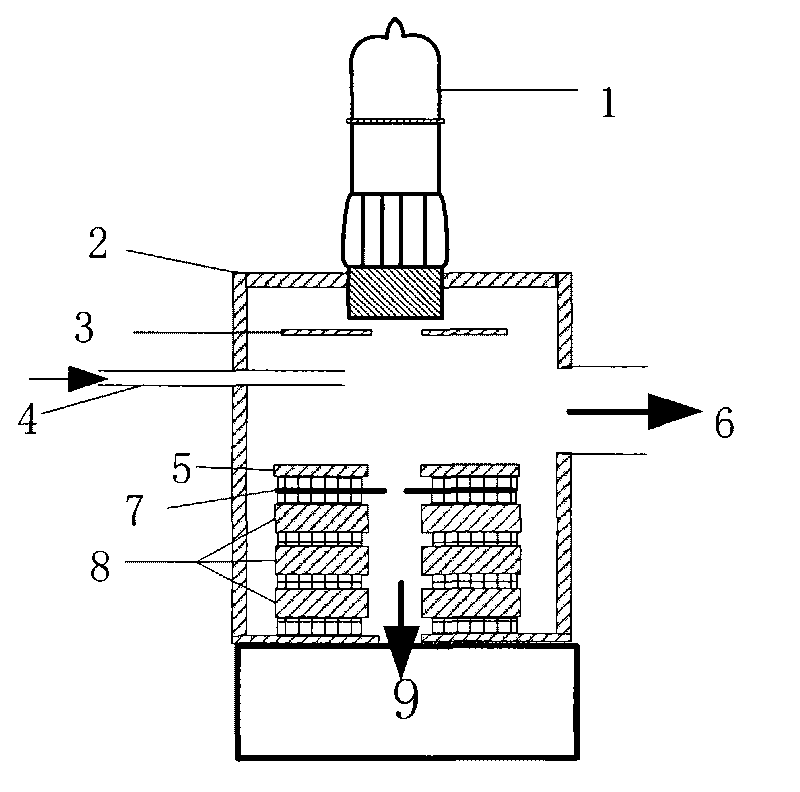

Ionization device of vacuum UV lamp

InactiveCN101752174AImprove transmission efficiencyReduce dispersionCathode ray tubes/electron beam tubesIon sources/gunsImpact ionizationSmall hole

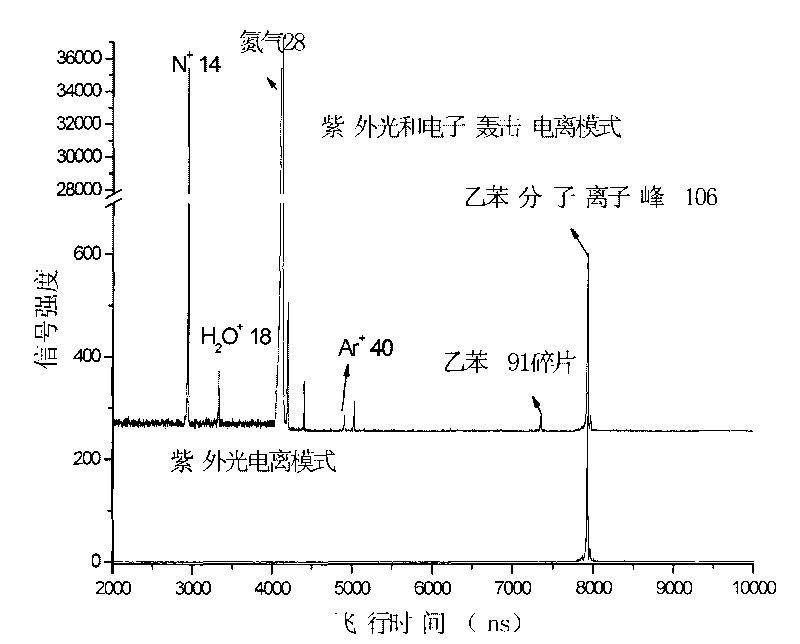

The invention relates to an ionization device of a vacuum UV lamp, comprising an ionization chamber, a UV lamp, a repulsion plate, a focusing ring, a small hole plate, a capillary sampling system and a lens system. The design of the focusing ring can increase about 2 orders of magnitude of signal strength. An ionization source in the ionization device has two working modes, namely a UV light ionization mode and a UV light and electron impact ionization mode, and the two modes can be converted by voltage regulation. The ionization device of the vacuum UV lamp has the characteristics of wide of range of sample to be detected, high sensitivity, low power consumption, long life, wide range of working air pressure, and the like, and has wide application prospects in process monitoring and real-time online analysis of organic pollutants.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

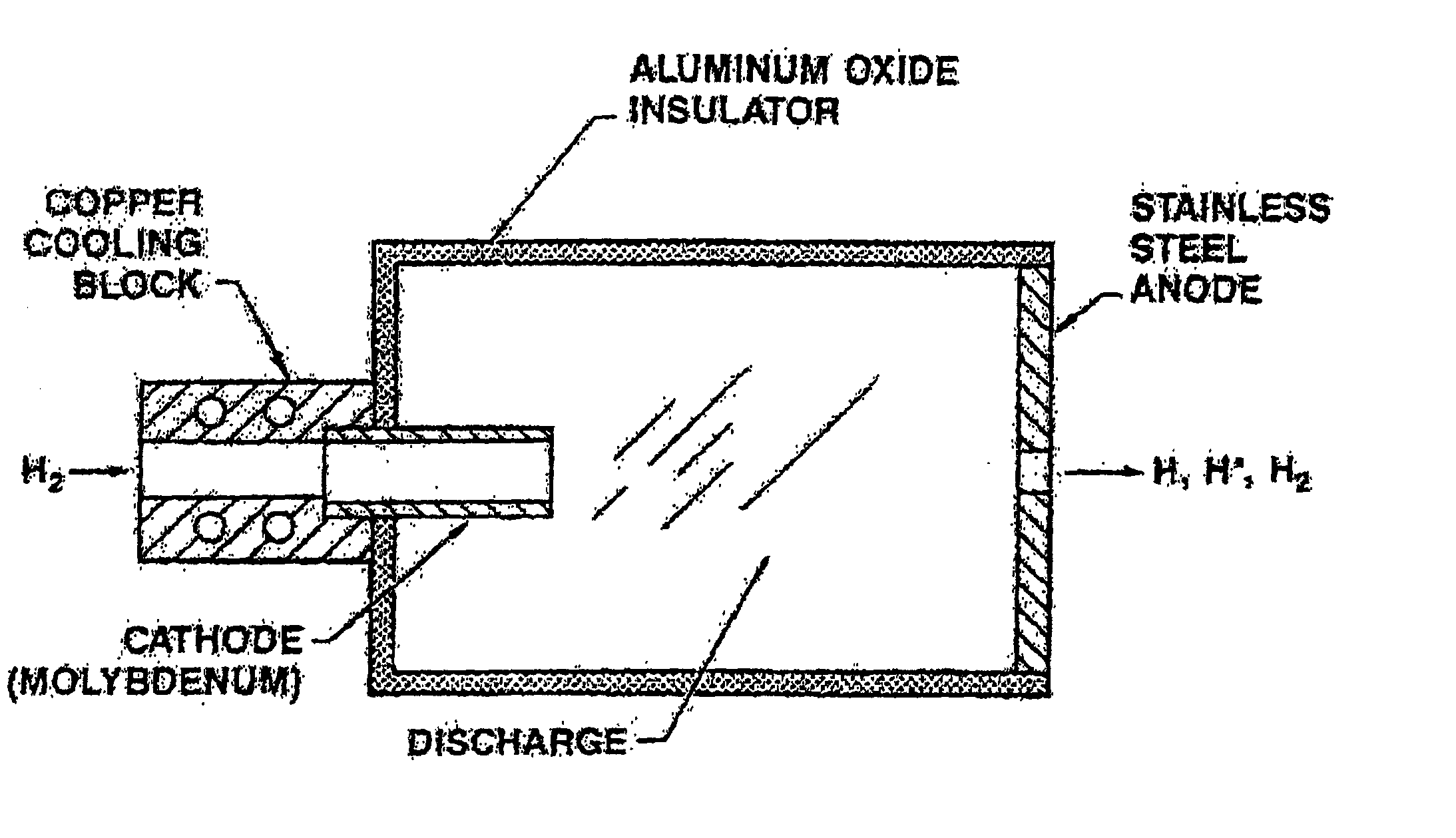

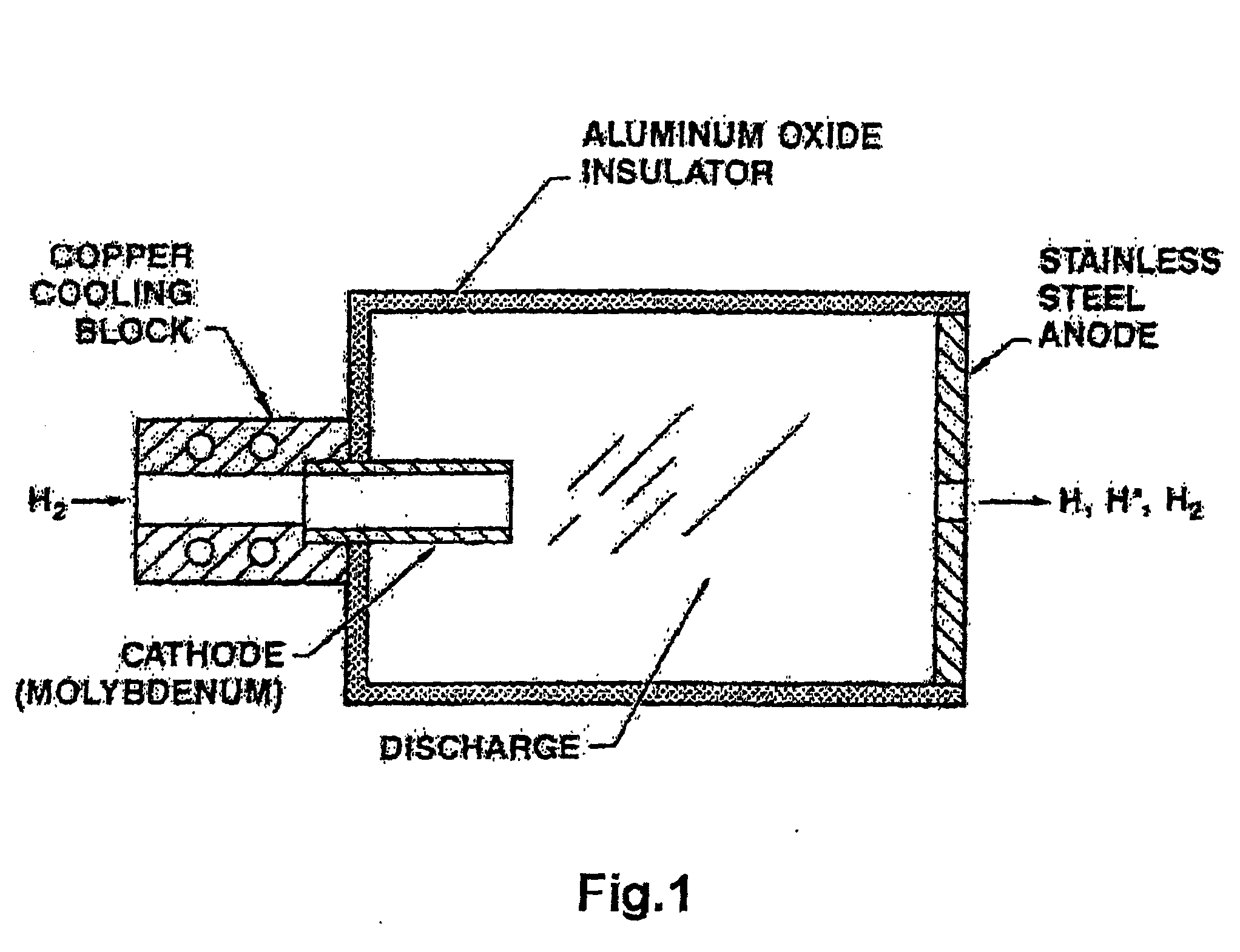

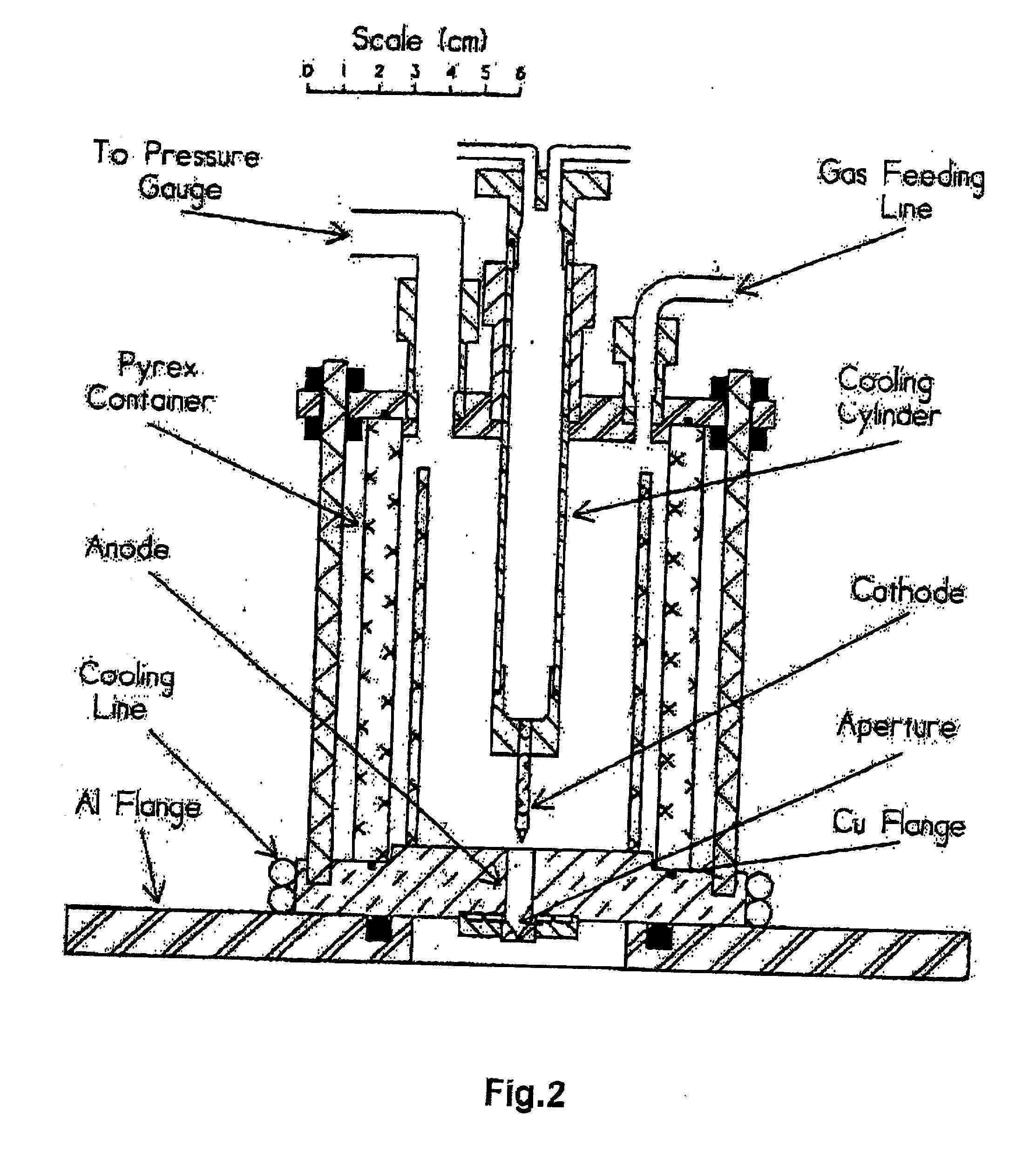

Method and appratatus for producing atomic flows of molecular gases

A method and device are presented for producing an intensive flow of atoms from an input flow of a molecular gas. Effects of ignition of a gas discharge of a complex type and dissociation of the gas molecules by electron impact in a discharge cell are utilized. The flow of atoms is output from the discharge cell through at least one emitting aperture. The complex gas discharge is composed of a main discharge and two auxiliary discharges of different types ignited in substantially coinciding zones of the discharge cell. The main discharge is an arc Penning discharge ignited in the vicinity of at least one emitting aperture. The first auxiliary discharge is a magnetron discharge with heated cathode, and the second auxiliary discharge is either a Penning discharge, or a Penning discharge with hollow cathode. The dissociation of the gas molecules is thereby carried out in the complex discharge and results in creation of the flow of hot and thermally atoms.

Owner:ATOMIC HYDROGEN TECH

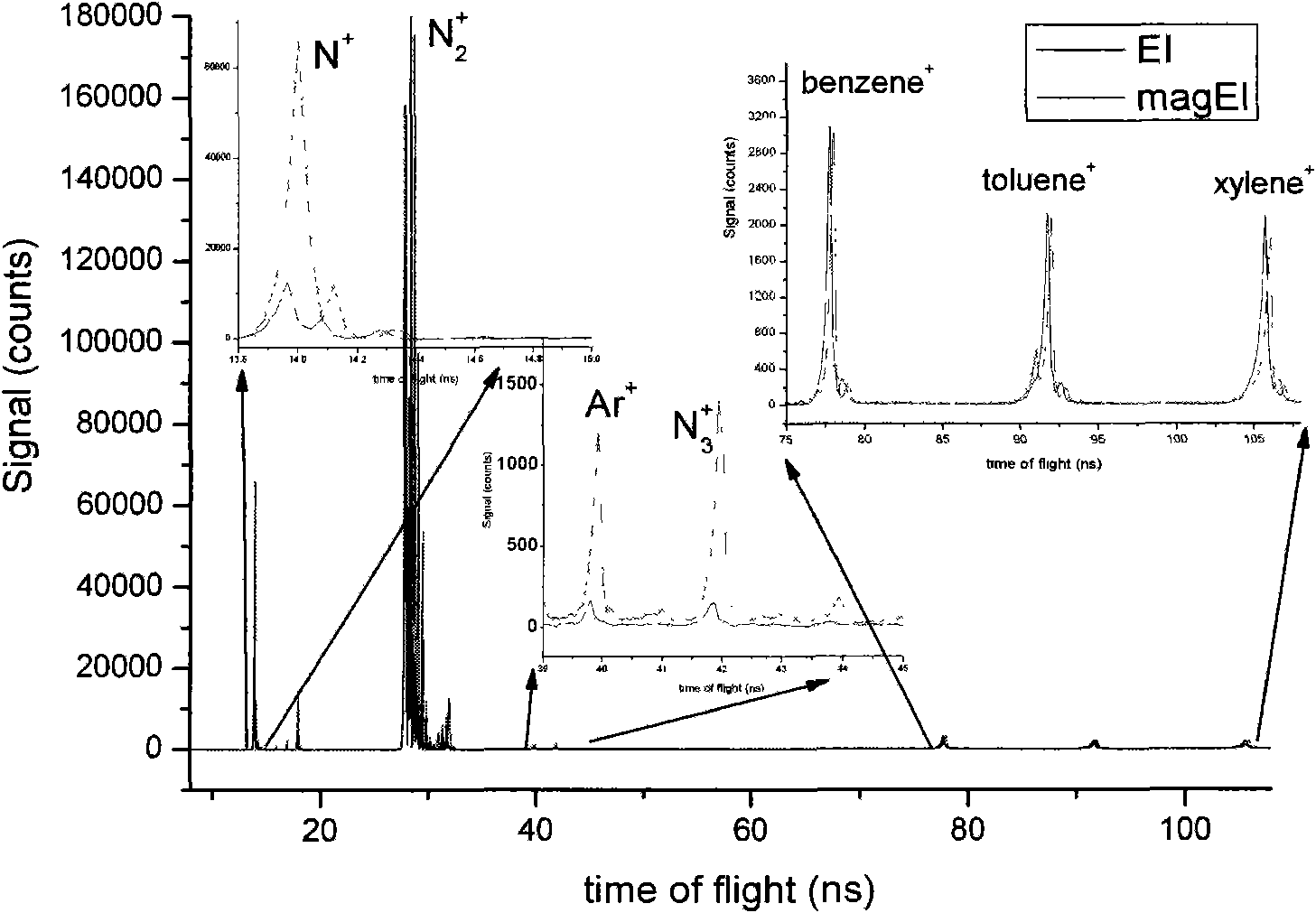

Vacuum ultraviolet lamp ionization device

The invention discloses a vacuum ultraviolet lamp ionization device, which comprises an ionization chamber, an ultraviolet lamp, a repulsion plate, a permanent-magnet focusing ring, a small-hole plate, a capillary sample injector and a lens system. An ionization source in the vacuum ultraviolet lamp ionization device has two working modes: an ultraviolet ionization mode and an ultraviolet and electron collision ionization mode, which can be converted by voltage regulation. An electron moves helically under the action of the permanent-magnet focusing ring on the electron, thereby increasing a probability of electron collision and improving the detection sensitivity of the electron collision ionization mode. The vacuum ultraviolet lamp ionization device is characterized by wide range of a sample to be detected, high sensitivity, low energy consumption, long service life, wide range of a working pressure and the like, and has a wide application prospect in process monitoring and environmental on-line analysis.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

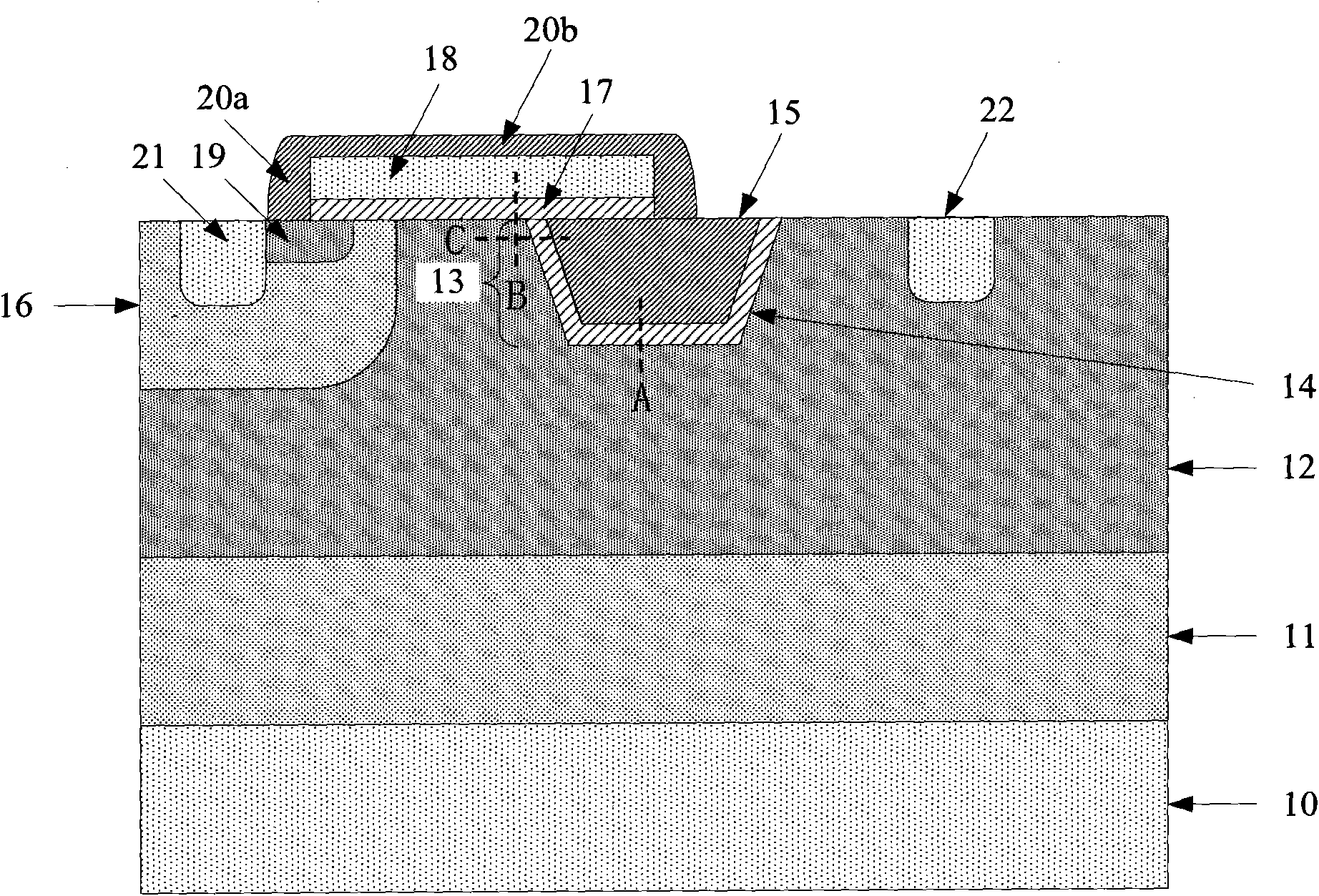

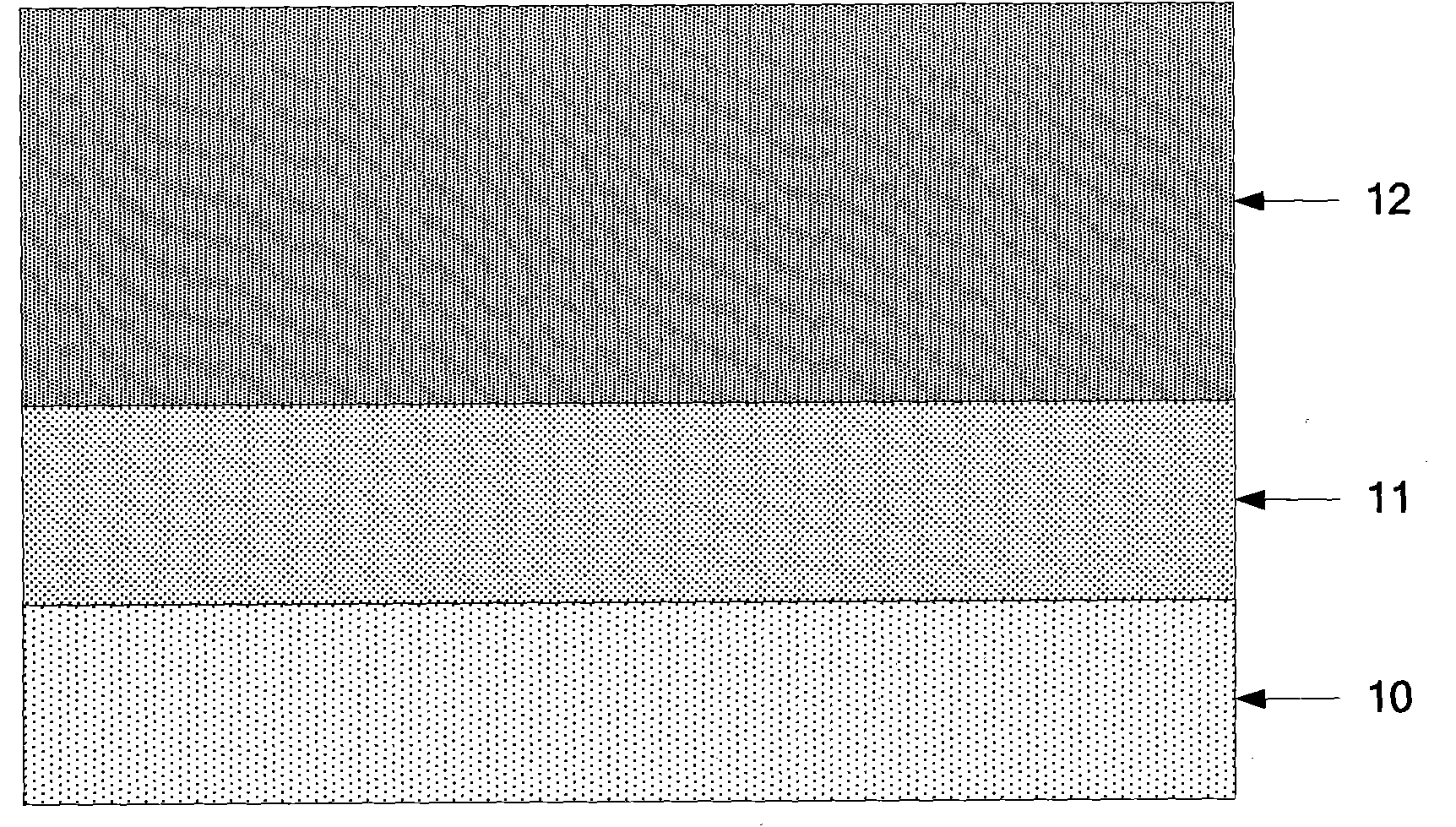

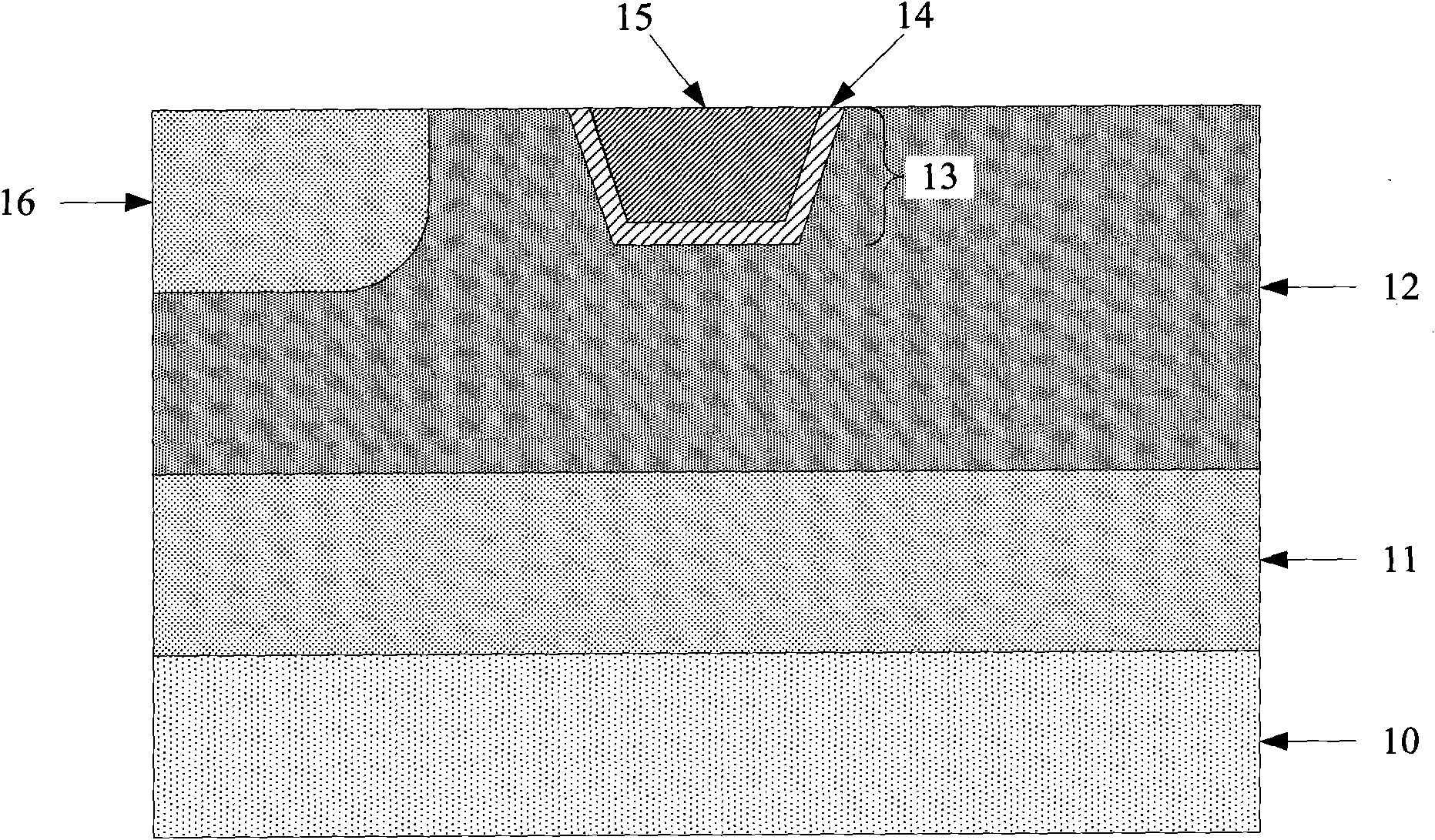

LDMOS (laterally diffused metal oxide semiconductor) and manufacturing method thereof

ActiveCN102054864AWork lessImprove reliabilitySemiconductor/solid-state device manufacturingSemiconductor devicesElectron collisionOptoelectronics

The invention discloses a LDMOS. Based on the traditional LDMOS (laterally diffused metal oxide semiconductor) structure, a light dope area (30) is arranged on the side wall and the bottom close to a groove (13) in a well (12). The doping types of the light dope area (30) and the well (12) are the same and the doping density of the light dope area (30) is lower. The invention also discloses a manufacturing method of an LDMOS. The shifting area of the traditional LDMOS is the well (12) but the shifting area of the LDMOS provided by the invention is the well (12) and the light dope area (30), so that the electric field along vertical and horizontal directions of the groove in the LDMOS provided by the invention is conveniently reduced, therefore reducing the electron collision strength in the shifting area, restraining the hot carrier injection effect, and increasing the safety working area and reliability of the LDMOS device.

Owner:SHANGHAI HUAHONG GRACE SEMICON MFG CORP

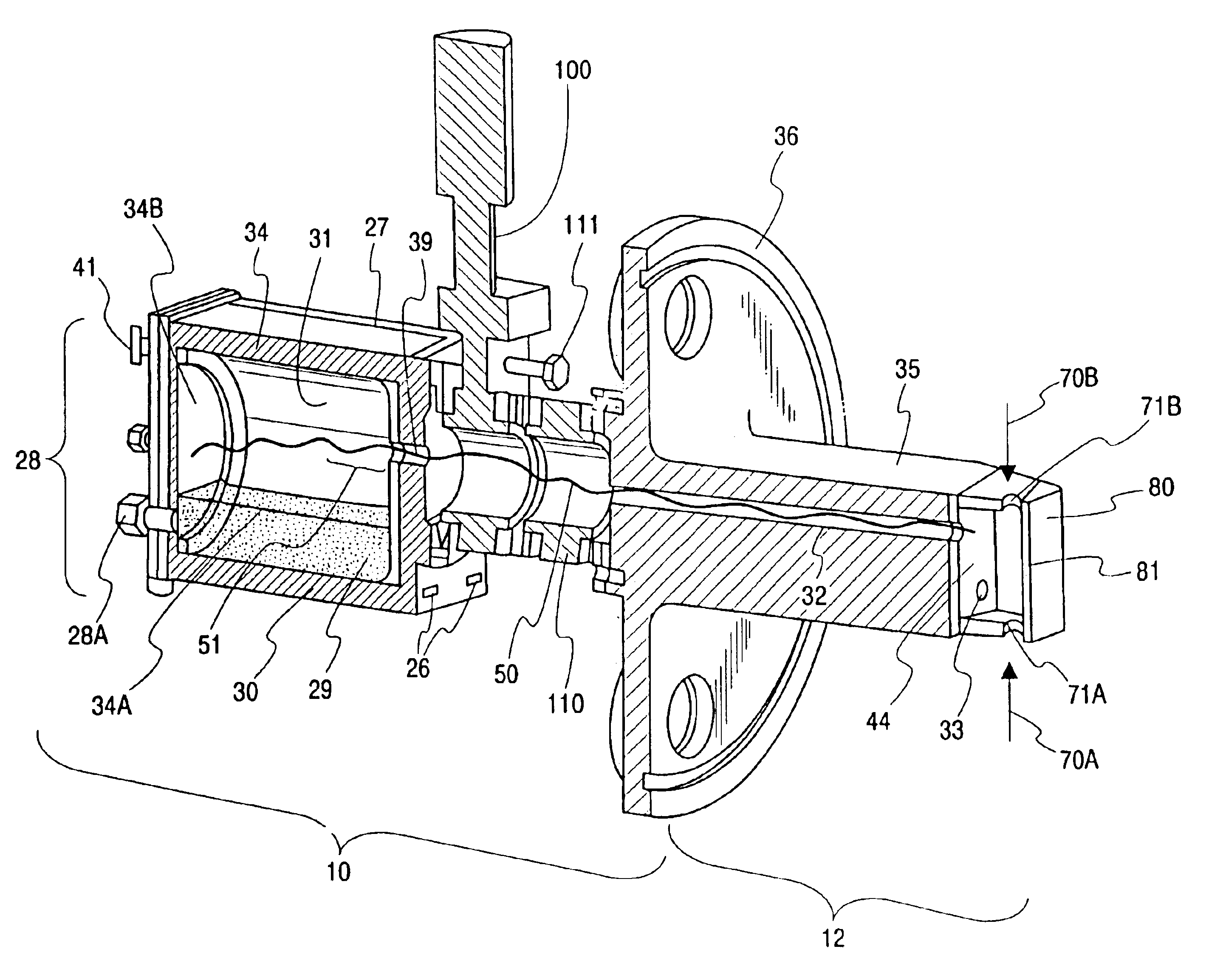

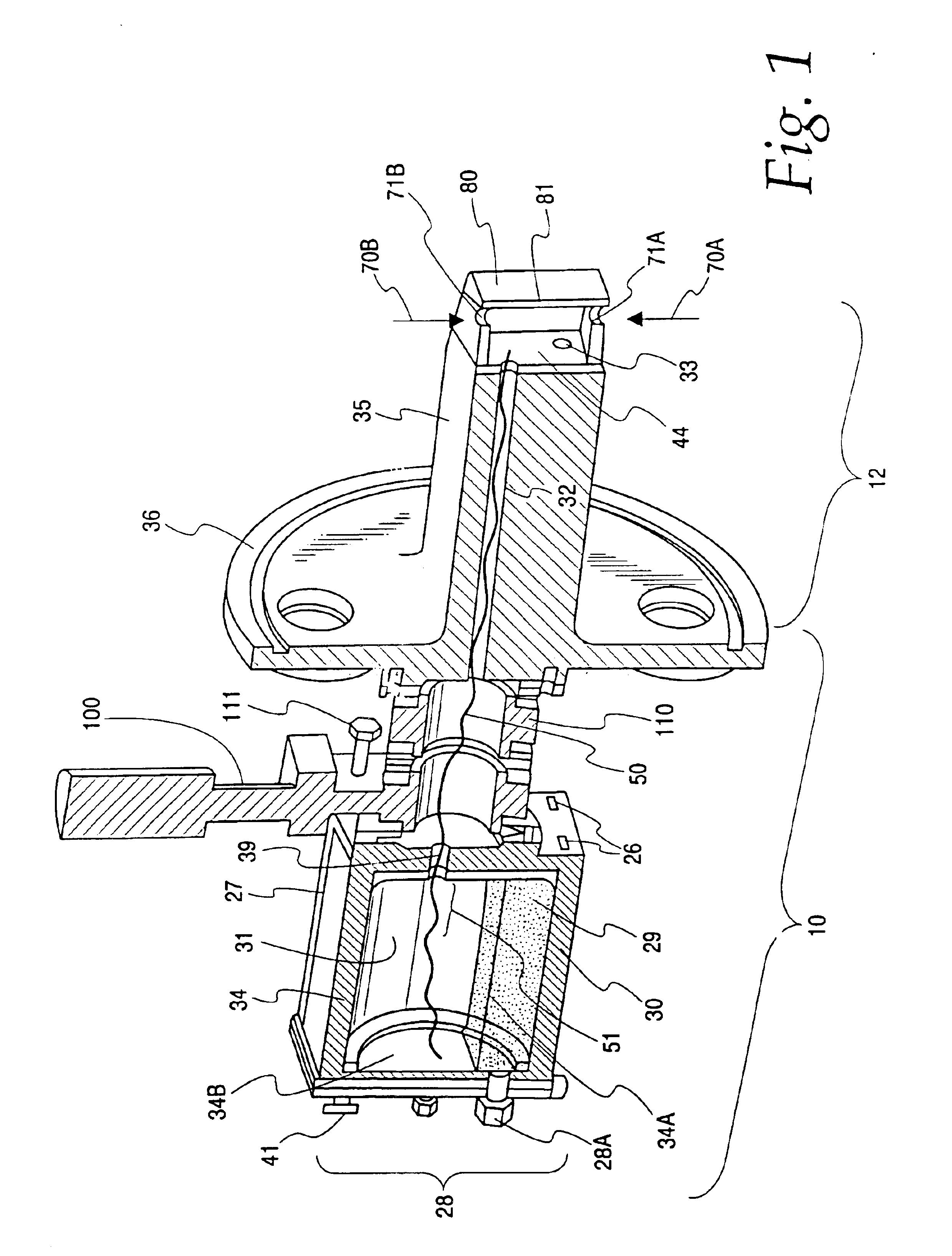

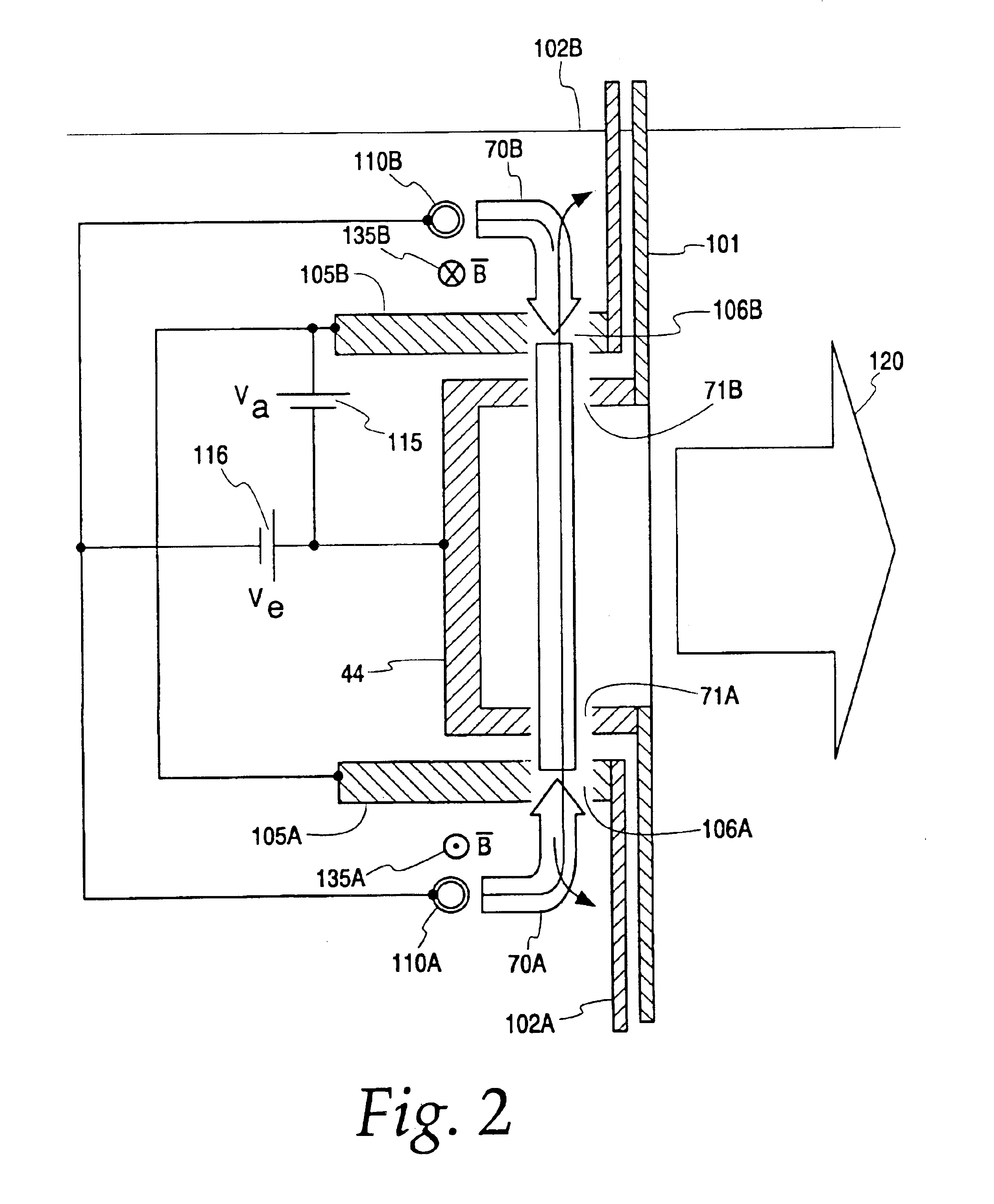

Electron impact ion source

InactiveUS7023138B2Extended service lifeTransistorParticle separator tubesElectron collisionIonization chamber

An ion source configured for integration into both existing ion implanters used in semiconductor manufacturing and emerging ion implantation platforms. The ion source in accordance with the present invention includes the following features, all of which depart from the prior art to produce a well-focused, collimated and controllable ion beam. These features include: ionizing electron beams generated external to the ionization chamber, thereby extending the emitter lifetime; 90 degree magnetic deflection of electron beams such that no line-of-sight exists between the emitter and the process gas load, and the emitter is protected from bombardment by energetic charged particles; two opposed electron beams which can be operated simultaneously or separately; and use of a deceleration lens to adjust the final energy of the electron beam, substantially without affecting electron beam generation and deflection.

Owner:SEMEQUIP

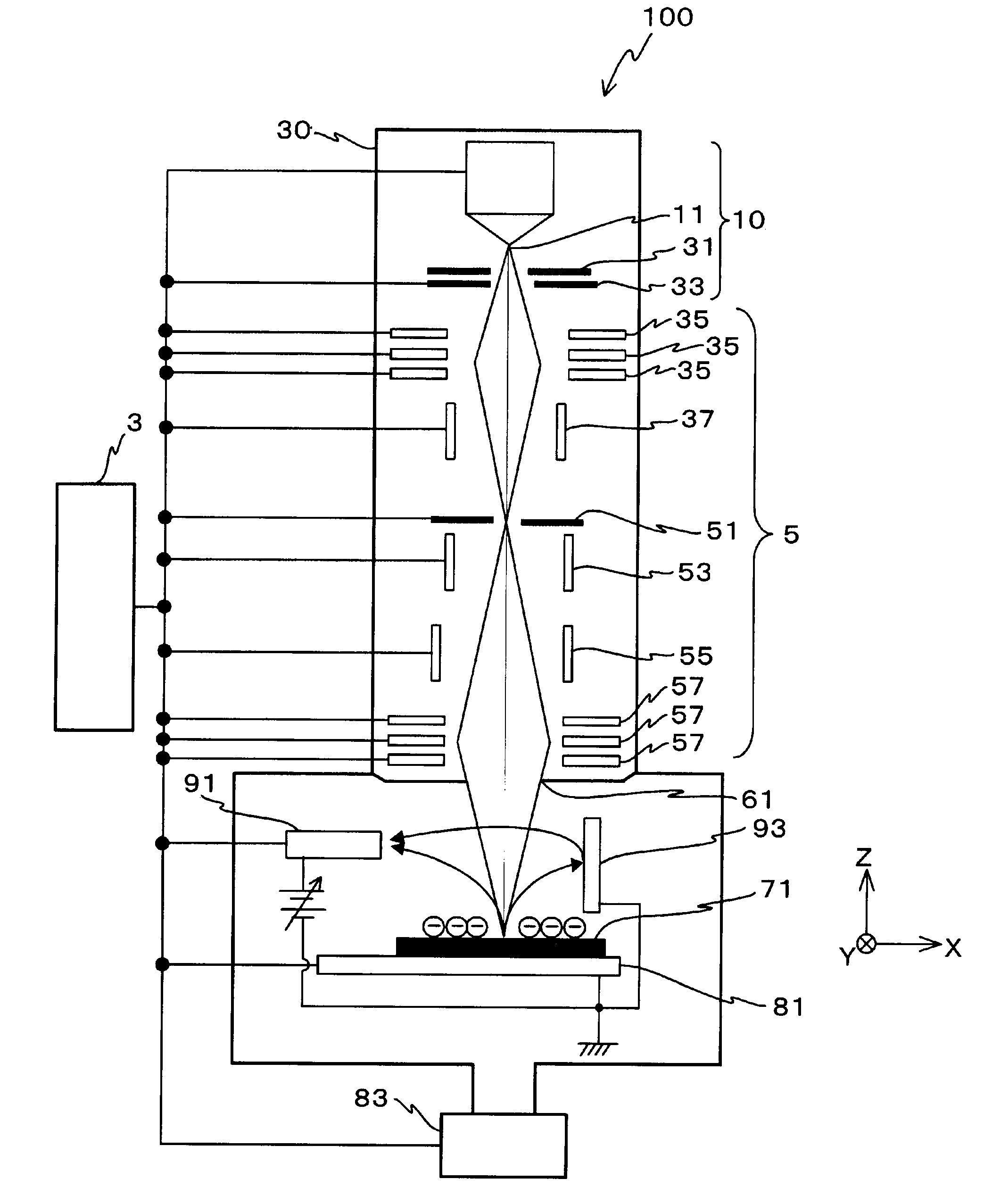

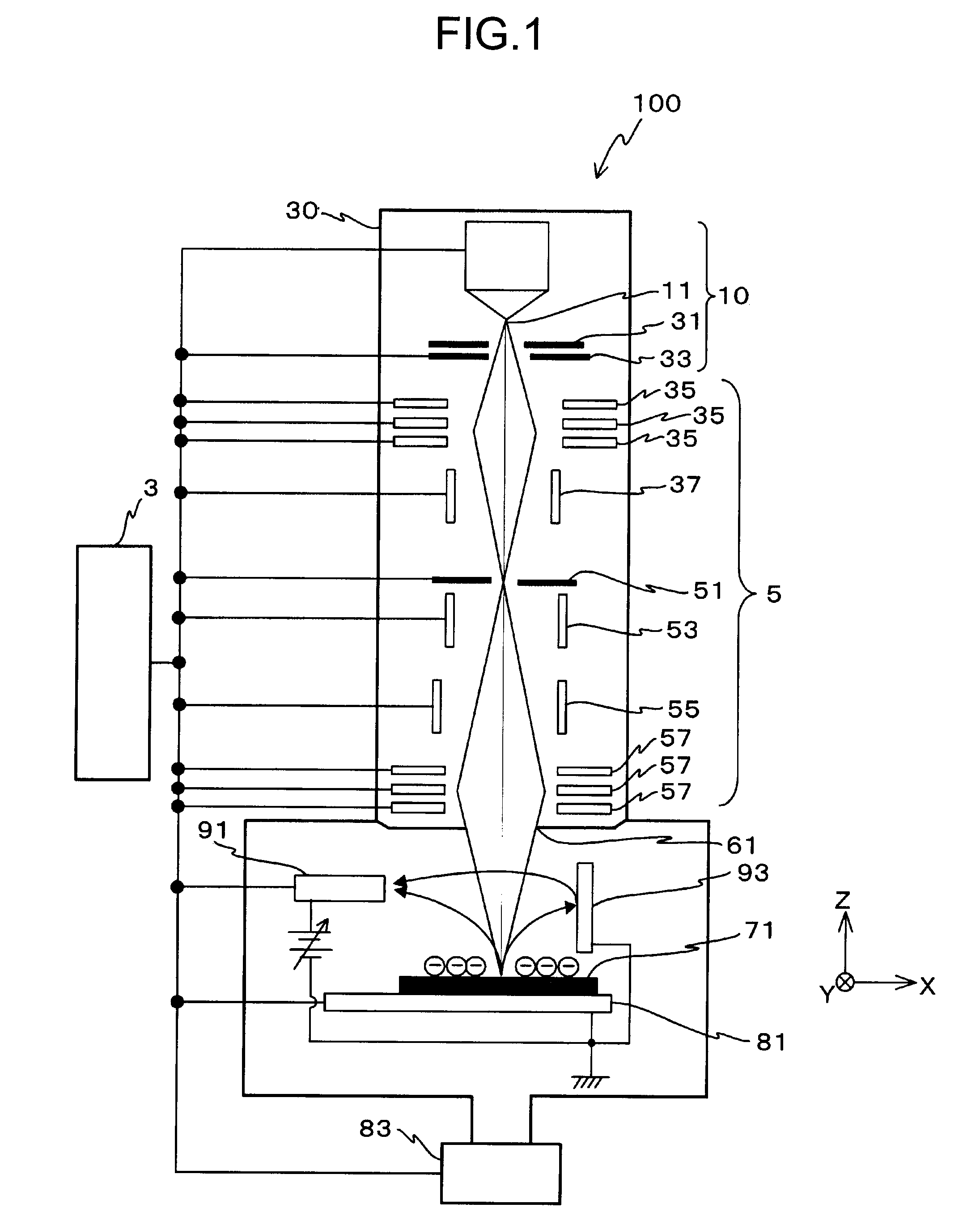

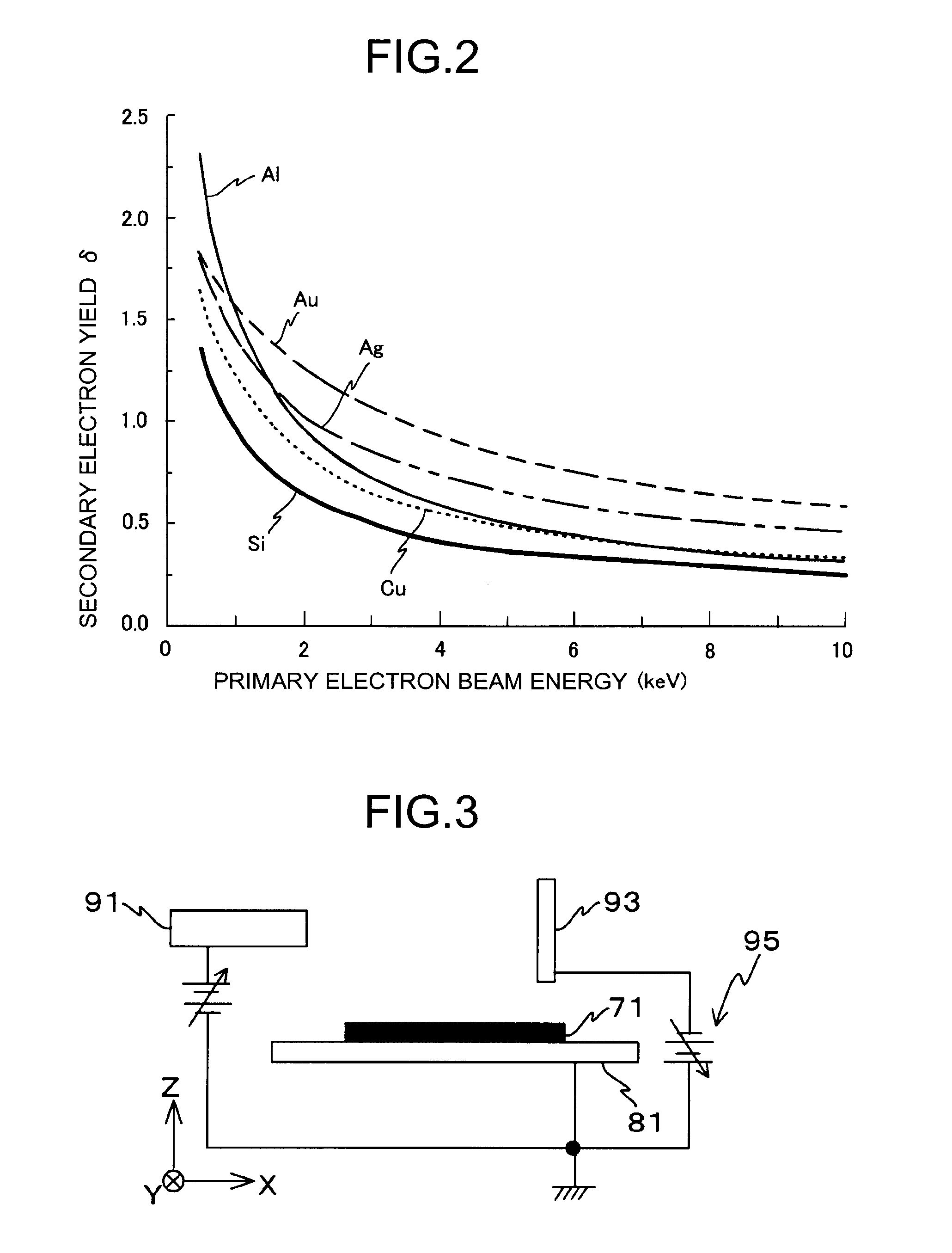

Surface-potential distribution measuring apparatus, image carrier, and image forming apparatus

ActiveUS7612570B2Electric discharge tubesElectrographic process apparatusControl systemElectron collision

A surface-potential distribution measuring apparatus includes an electron gun, an electron-beam optical system, an electron-emission panel, a detector, and a control system. The electron-beam optical system is located between the electron gun and a sample, and focuses a beam of electrons emitted from the electron gun to the surface of the sample. The electron-emission panel is located near the sample to be collided with at least part of the electrons via the sample, and emits secondary electrons corresponding to the number of collided electrons. The detector detects at least part of the secondary electrons. The control system obtains potential distribution on the surface of the sample based on a detection result obtained by the detector.

Owner:RICOH KK

Mechanism for classifying inhalable particles and measuring concentration as well as detection method thereof

InactiveCN103926178AImprove retention efficiencySimple technologyParticle size analysisParticle suspension analysisCorona dischargeElectrometer

The invention relates to a mechanism for classifying inhalable particles and measuring concentration as well as a detection method of the mechanism. One end of a fine particle collecting probe is sequentially communicated with one end of a heat insulating drying chamber, one end of an aerosol neutralizer and one end of a corona discharger; the other end of the corona discharger is divided into two paths, wherein one path is sequentially communicated with a low-voltage cascade-stage striker and a multi-channel electrometer, and the other path is sequentially communicated with a high-voltage electrode electric field and an air purifier. The mechanism disclosed by the invention is small in size, rapid in response, capable of being used for all-weather detection and playing of PM values, designed according to a standard data interface and compatible to various external equipment; the collected sample fine particle gas has collision with free electrons to form electron avalanche; the particles are classified into a plurality of grades according to the inertia of the particles and pneumatic particle sizes; current value generated by deposition of charged fine particles in various particle sizes is measured by the multi-channel electrometer; the concentration of the particles is reflected according to the current value of each particle size, and measurement results are shown in various forms, thus ancillary support and mass reliable data are provided for environmental monitoring and treatment.

Owner:天津圣纳科技有限公司

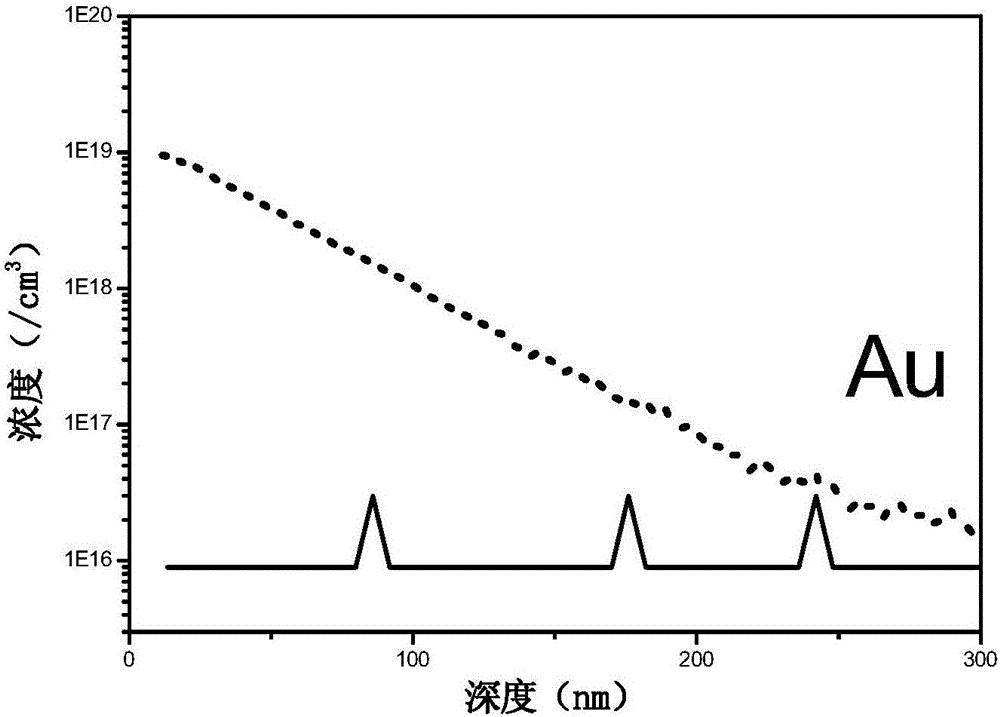

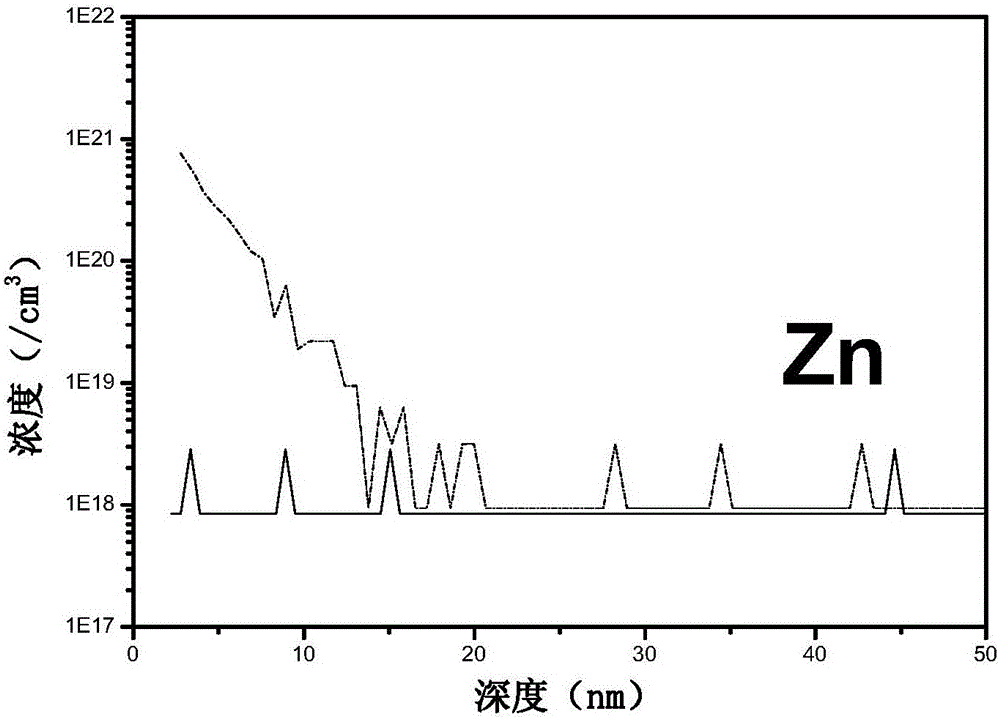

Method for introducing solid impurities into silicon material under room temperature environment

ActiveCN106098543AFor the purpose of dopingIncrease surface concentrationSemiconductor/solid-state device manufacturingElectron collisionRoom temperature

The invention discloses a method for introducing solid impurities into a silicon material under a room temperature environment. A solid impurity source is processed by using plasmas generated by inert gas under the room temperature environment, so that atoms or ions in the solid impurity source enter into the plasmas, the atoms or ions acquire kinetic energy through collision of positive ions and electrons in the plasmas, and then the atoms or ions enter into the silicon material. According to the method, due to the fact that high temperature is not needed, the method can be used for doping silicon wafers and can also be used for doping silicon devices, and compared with a traditional impurity introduction manner, the method is convenient and economical.

Owner:PEKING UNIV

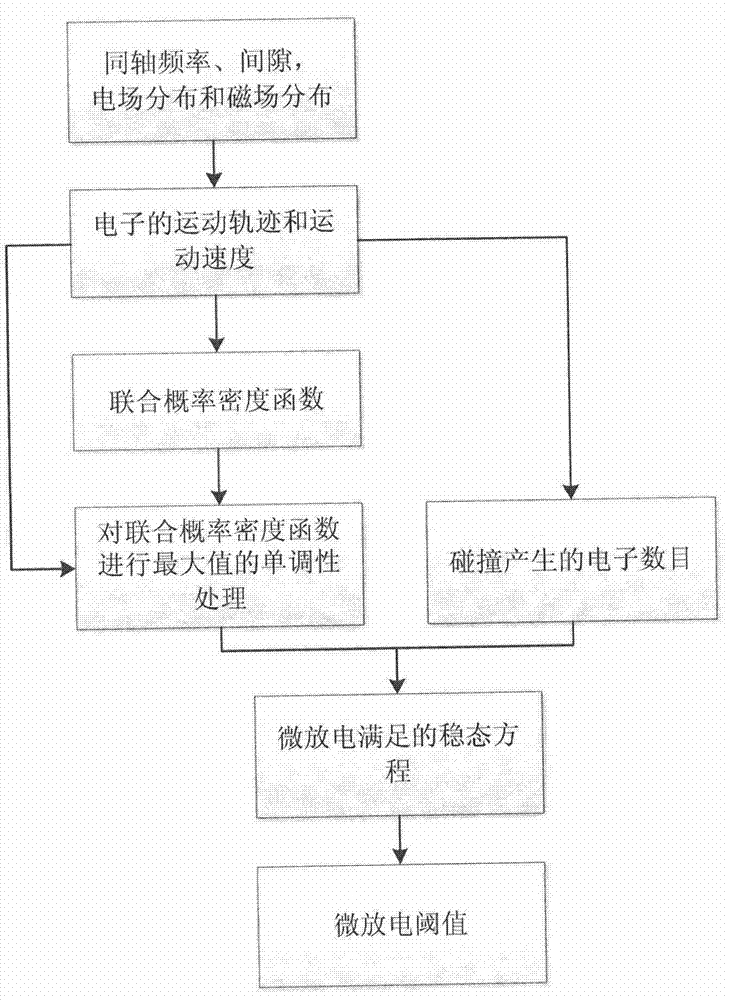

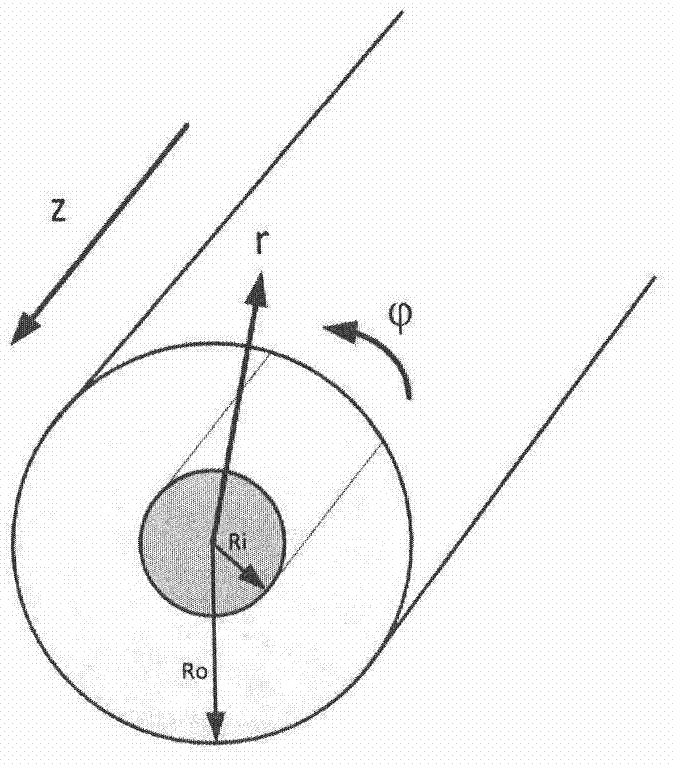

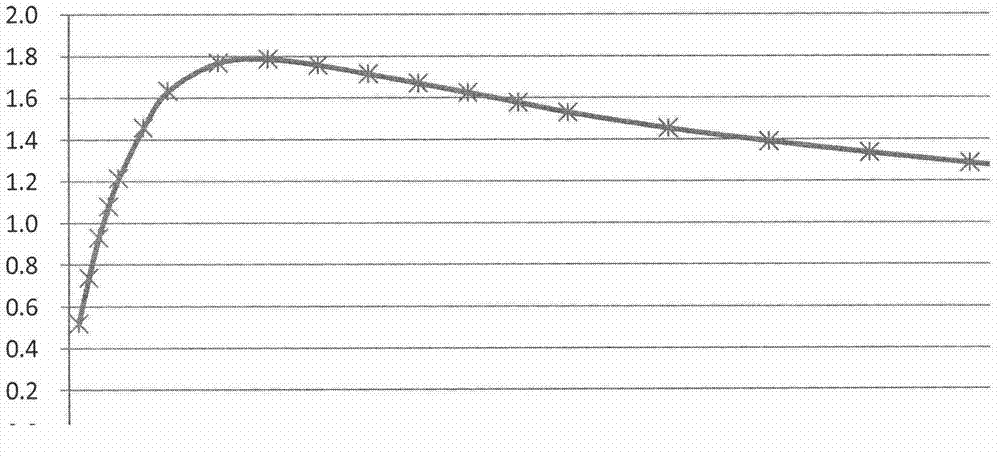

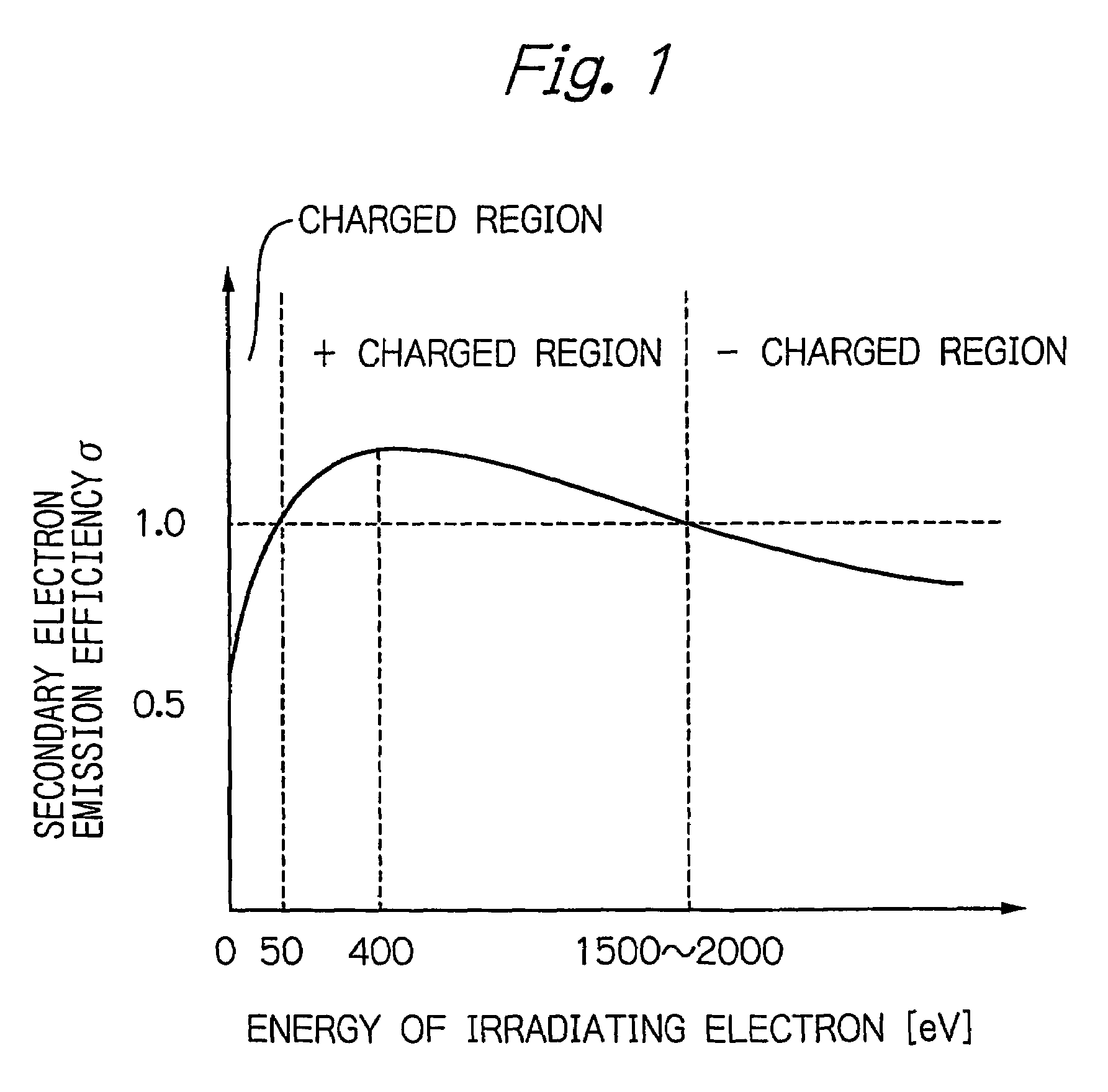

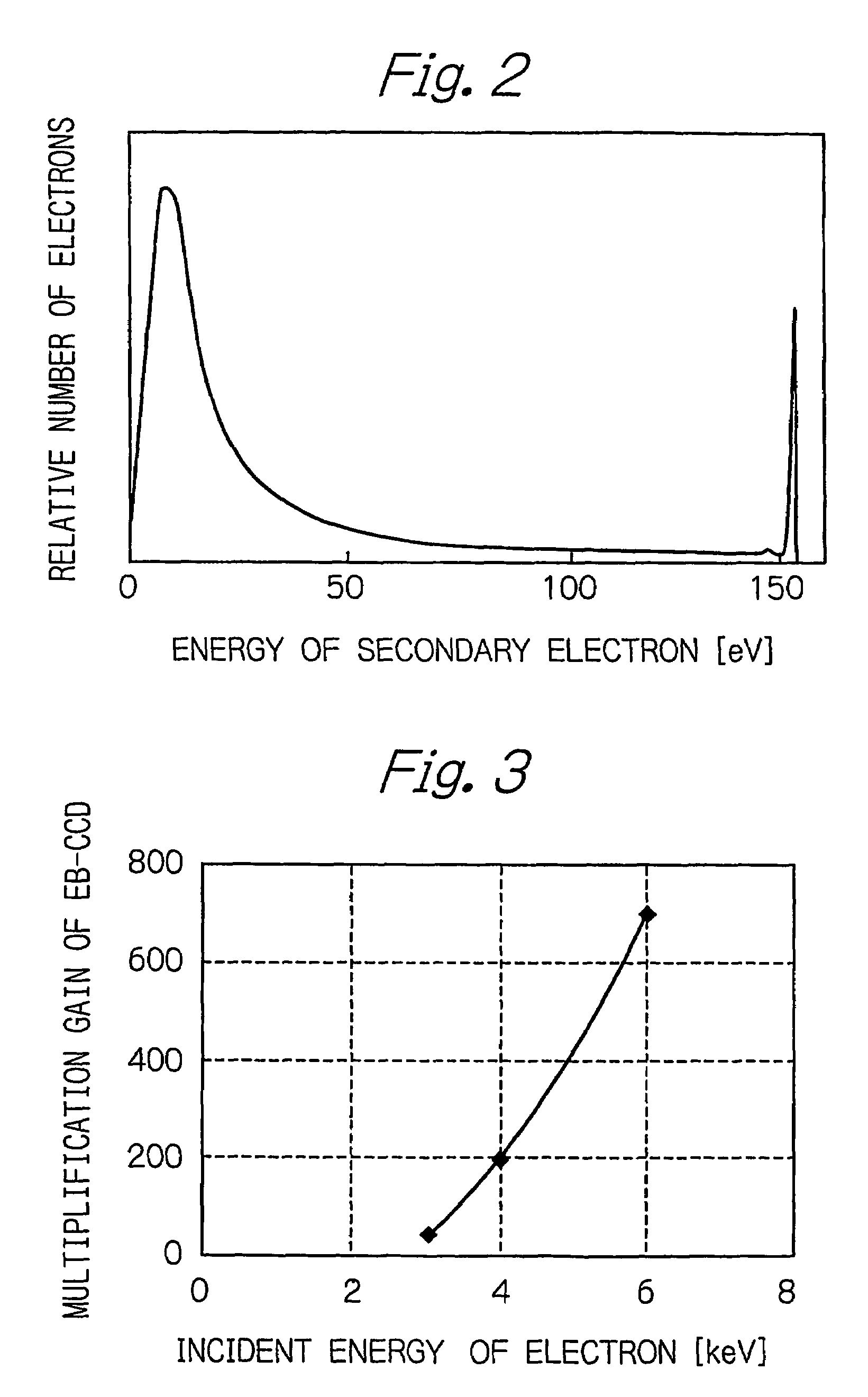

Method for determining coaxial configuration micro-discharging threshold value

ActiveCN102880783AIn line with the actual stateThe calculation result is accurateSpecial data processing applicationsSecondary electronsSteady state

The invention discloses a method for determining a coaxial configuration micro-discharging threshold value. The method comprises the following steps of: determining an electronic movement locus and an electronic movement speed in a coaxial structure; converting probability of an emergence speed satisfying Maxwellian distribution into a joint probability density function of transit time; respectively carrying out maximum value and monotonicity processing to four classes of probability density functions to obtain a processed joint probability density function; taking an electron collision kinetic energy as an incidence electron energy of a secondary electron emission characteristic of a material to obtain a secondary electron multiplication function generated during electron collision under the transit time; constructing a steady-state equation which satisfies the electron number during micro discharging; judging whether a voltage generates micro discharging by solving an effective secondary electron multiplication rate in the steady-state equation; and gradually calculating an effective multiplication rate of a next voltage with a bisection method, wherein a corresponding voltage is a micro-discharging threshold value when the effective multiplication rate is 1. According to the method disclosed by the invention, an accurate micro-discharging threshold value can be obtained, and meanwhile, the threshold value can be quickly obtained.

Owner:XIAN INSTITUE OF SPACE RADIO TECH

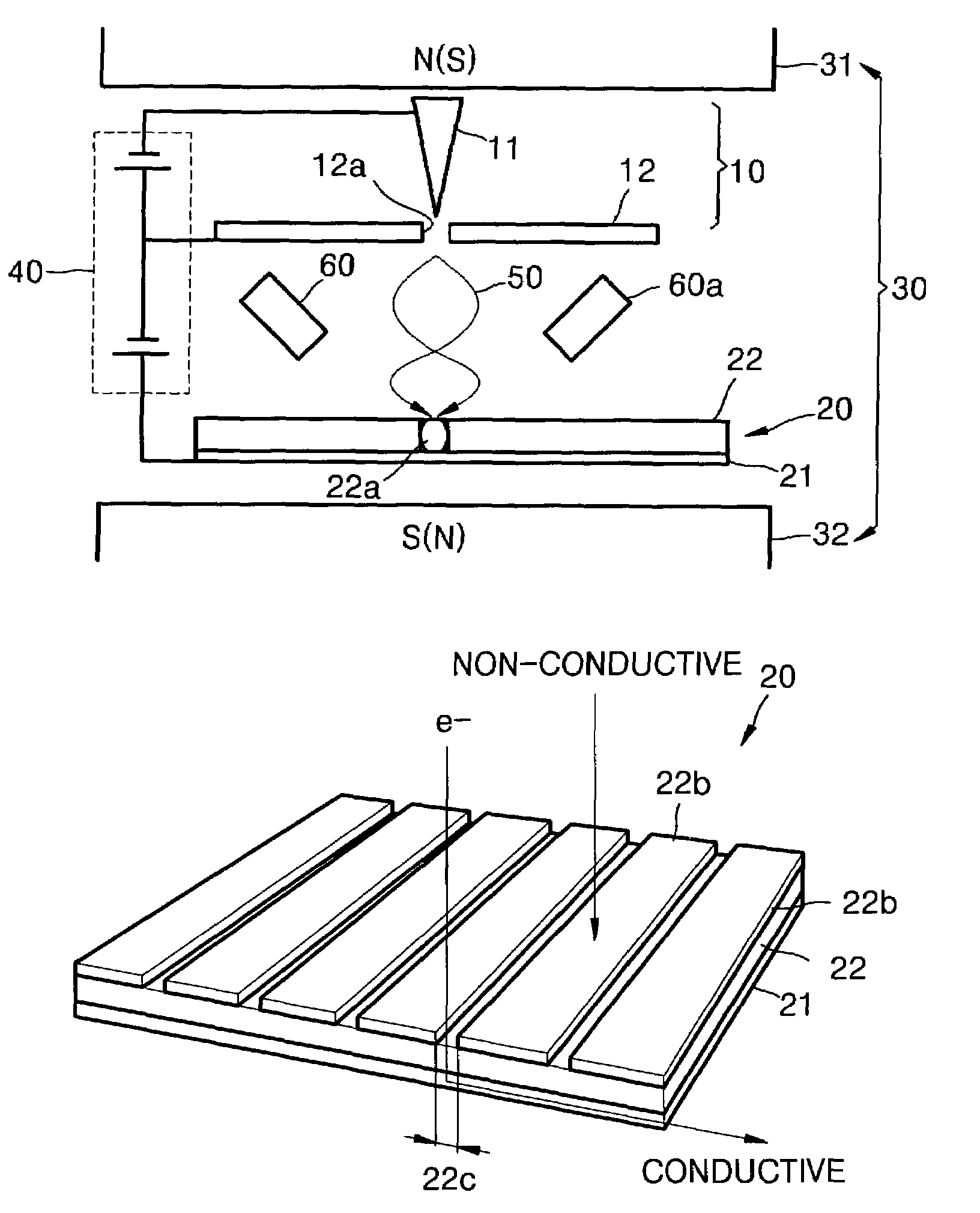

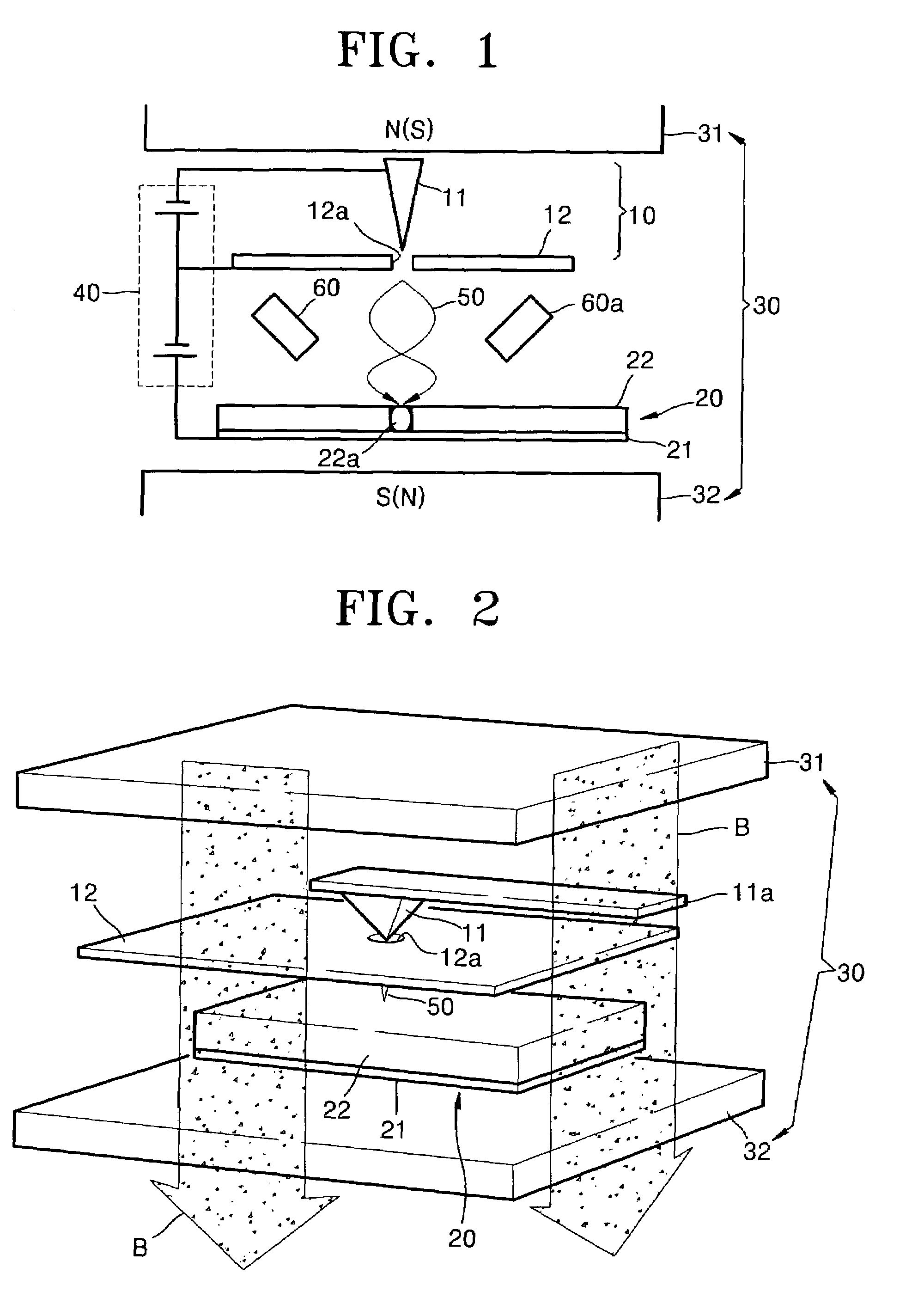

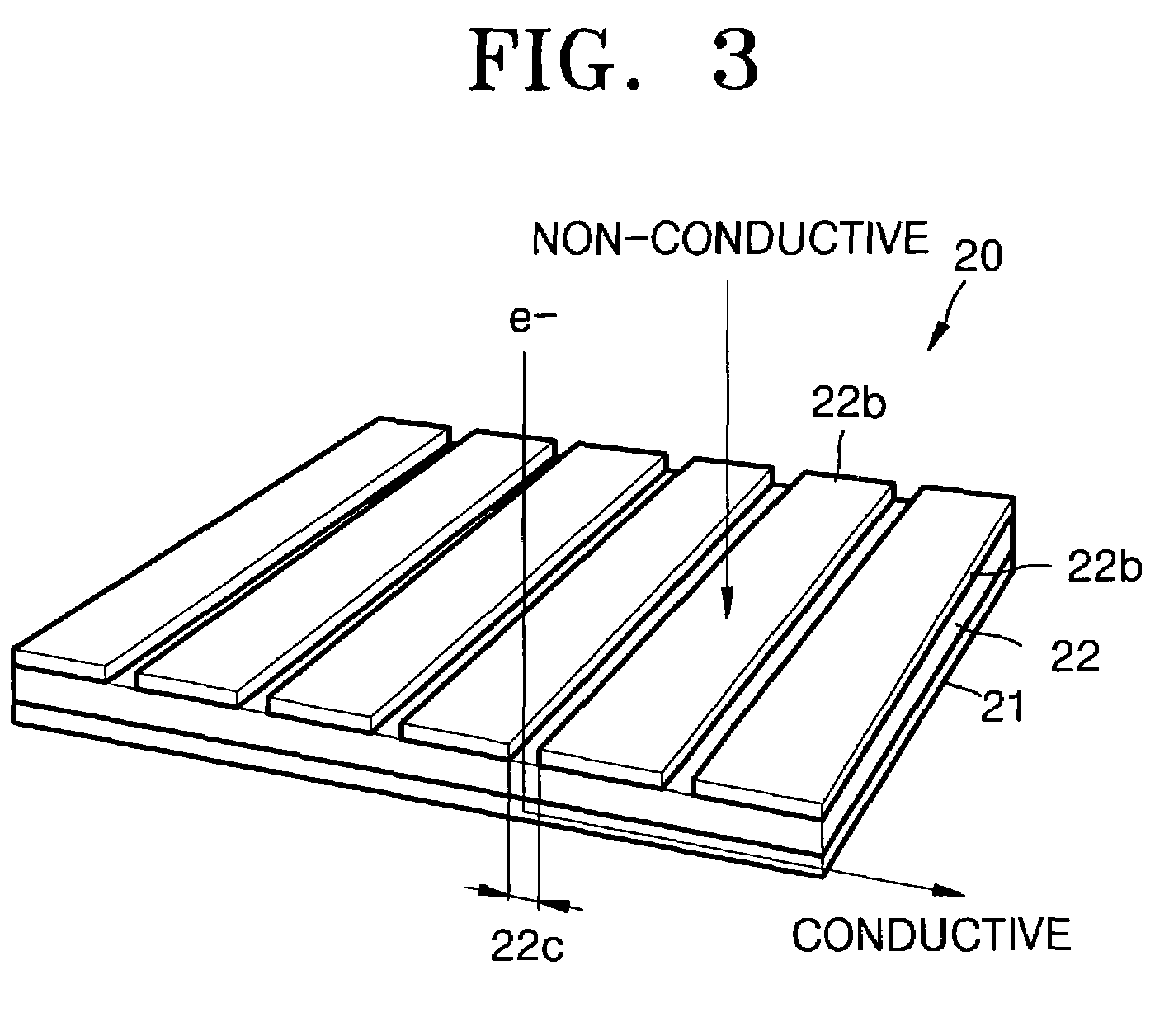

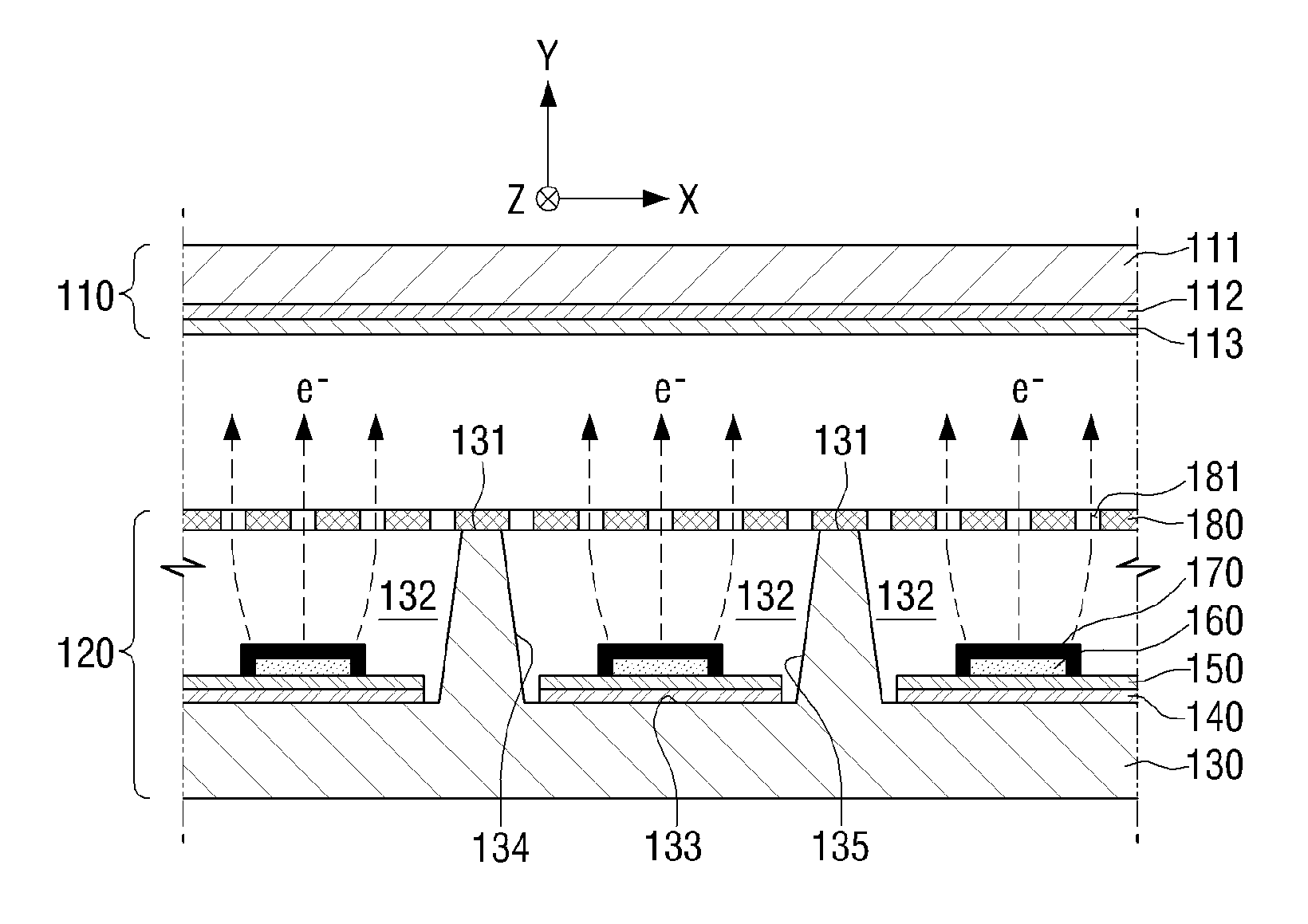

High density data recording/reproduction method utilizing electron emission and phase change media, and data recording system adopting the same, and media for the system

A rapid data recording / reproducing method, a data recording system adopting the same, media for the system, and a tracking method, wherein the recording / reproducing method includes preparing media having a data recording layer in which a phase change is generated through electron absorption, generating electrons using an electron generating source at a position separated from the data recording layer by a predetermined interval, forming a magnetic field on the path of the electrons and cyclotron moving the electrons, recording data through local melting and cooling due to absorption of the electrons by the data recording layer. A micro-tip does not contact the data recording layer during electron collisions therewith, hence no damage is caused by or to the micro-tip. The present invention allows the region where the electron beam reaches the data recording layer to be minimized thereby maximizing the data recording density.

Owner:SAMSUNG ELECTRONICS CO LTD

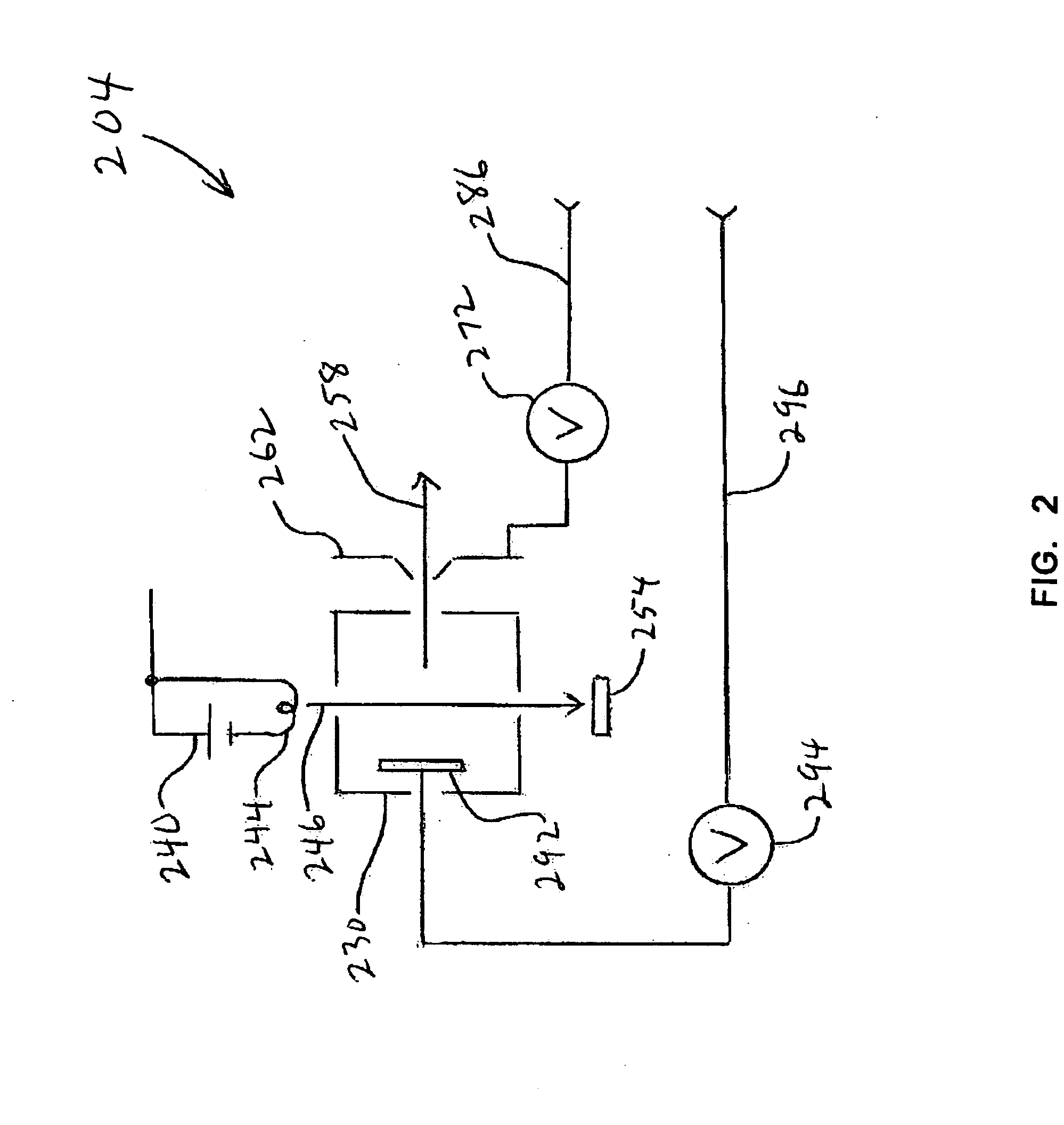

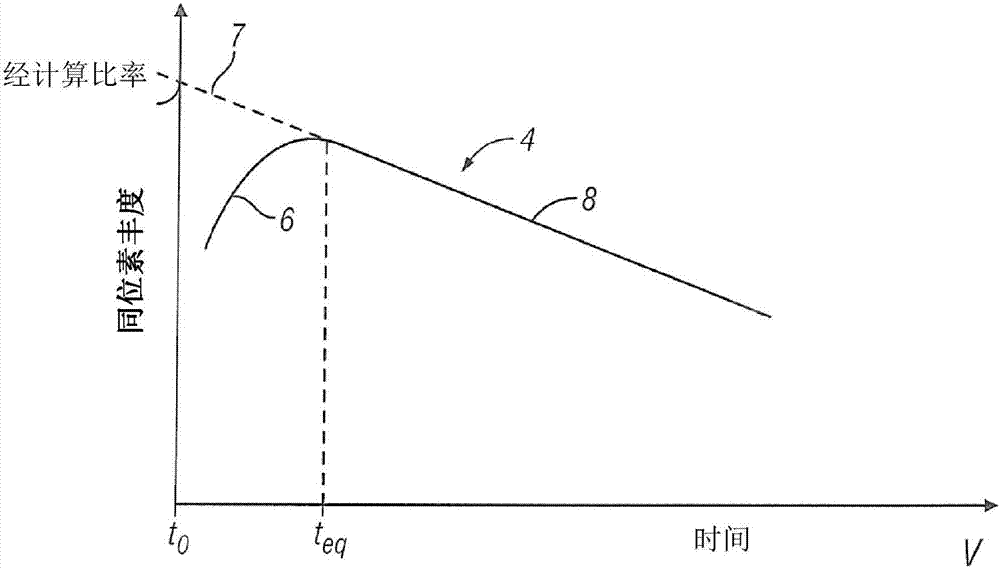

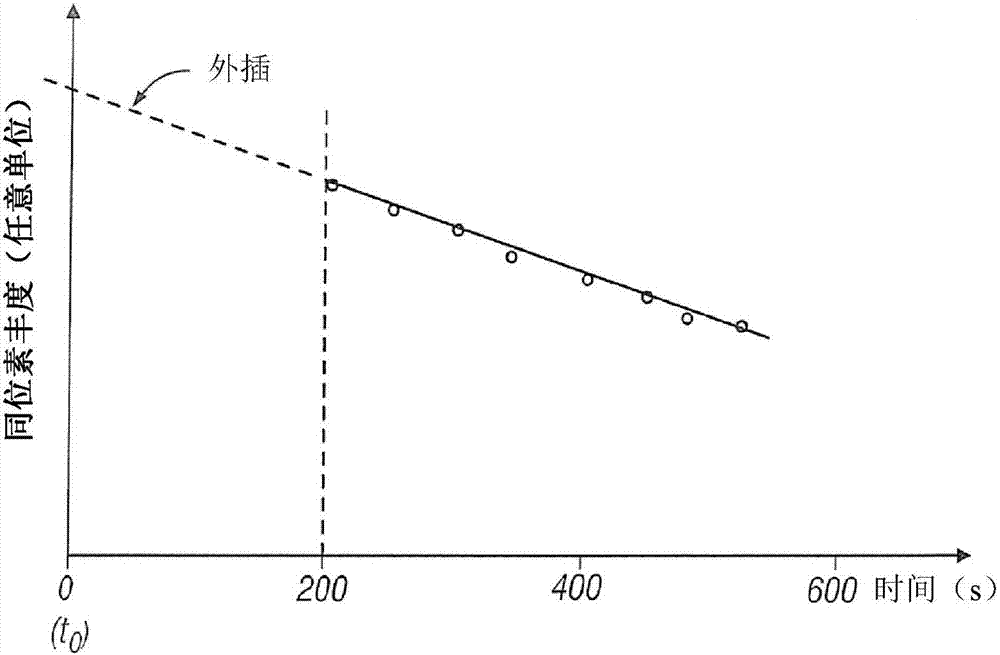

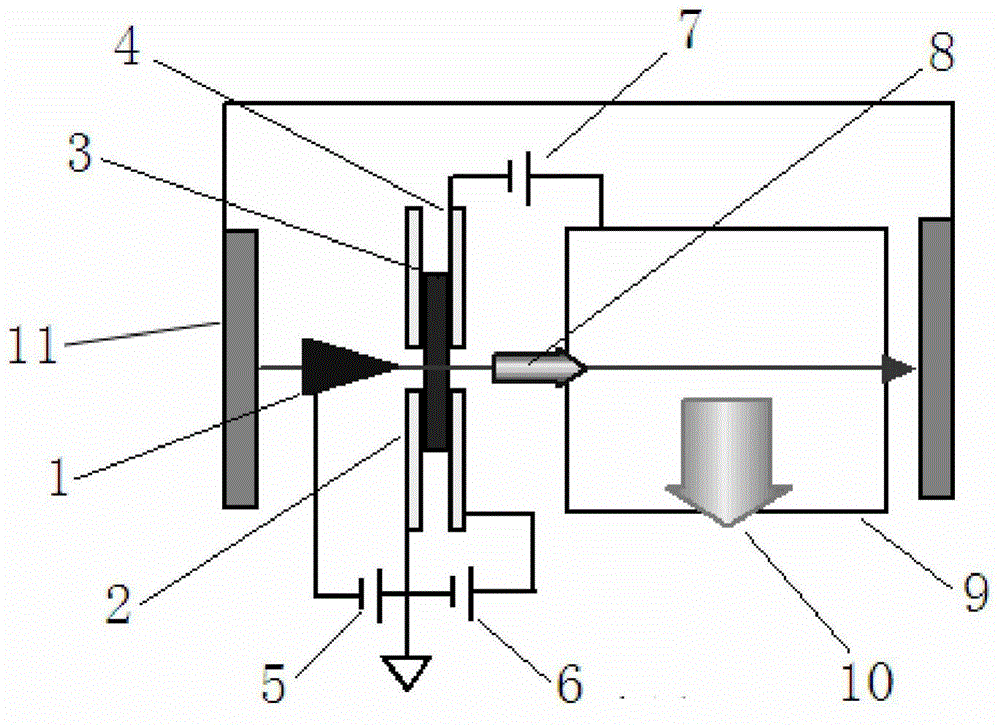

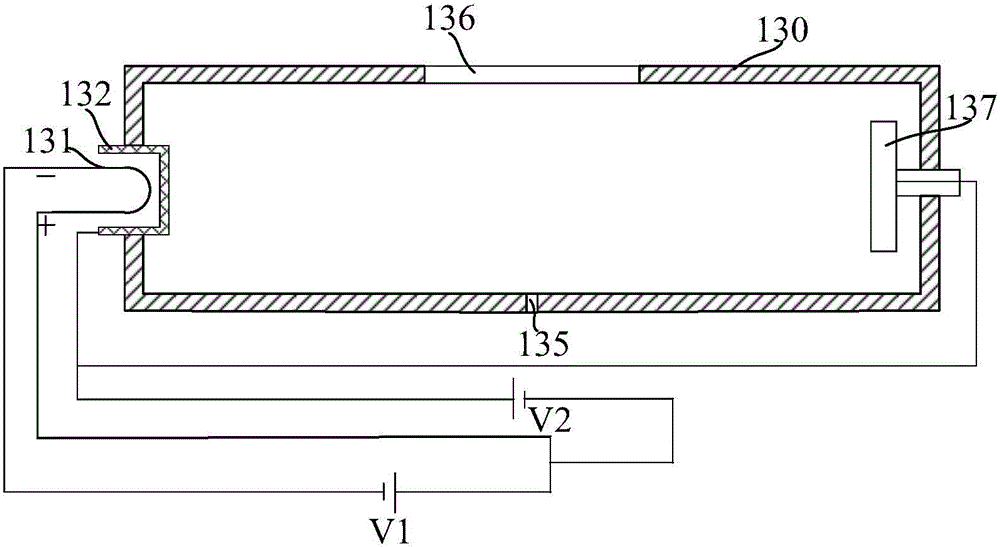

Apparatus and method for static gas mass spectrometry

ActiveCN107462622ASmall volumeRemove uncertaintyMaterial analysis by electric/magnetic meansTube vacuum systemsElectron collisionMass Spectrometry-Mass Spectrometry

A method of static gas mass spectrometry is provided. The method includes the steps of: introducing a sample gas comprising two or more isotopes to be analyzed into a static vacuum mass spectrometer at a time, t0; operating an electron impact ionization source of the mass spectrometer with a first electron energy below the ionization potential of the sample gas for a first period of time that is following t0until a time t1; and operating the electron impact ionization source with a second electron energy at least as high as the ionization potential of the sample gas for a second period of time that is after time t1. The first time period from t0 to t1 is a period corresponding to a period taken for the isotopes of the sample gas to equilibrate in the mass spectrometer. A constant ion source temperature is preferably maintained. Also provided is a static gas mass spectrometer.

Owner:THERMO FISHER SCI BREMEN

On-axis electron impact ion source

Owner:AGILENT TECH INC

Field emission ionization source for time-of-flight mass spectrometer

ActiveCN104103488AImprove resolutionReduced field emission cathode requirementsIon sources/gunsLow voltageHigh energy

The invention provides a field emission ionization source for a time-of-flight mass spectrometer. The field emission ionization source aims at solving the problems that a glow wire of a glow wire emission electron collision ionization source has high energy consumption and high-temperature thermal desorption, and cannot be miniaturized. The field emission ionization source adopts the technical scheme that a blade coated with a nanomaterial or a planar electrode directly coated with the nanomaterial serves as a cold cathode emitter; an anode is in a slit structure; a microchannel plate component is designed behind a slit of the anode, and used for amplifying electron current and adjusting electron energy; and finally an electron beam with appropriate energy strikes an ionization box to ionize gas molecules under magnetic field constraint. Therefore, a field emission cathode can operate at lower voltage and is not easy to damage, and the electron energy striking the ionization box can be independently controlled to be more suitable for ionizing the gas molecules. In an application, pulsed ionization can be achieved only by applying pulsed negative high voltage on the cathode, so that a pulsed flaky ion beam is generated for perpendicular lead-out and detection analysis.

Owner:PEKING UNIV

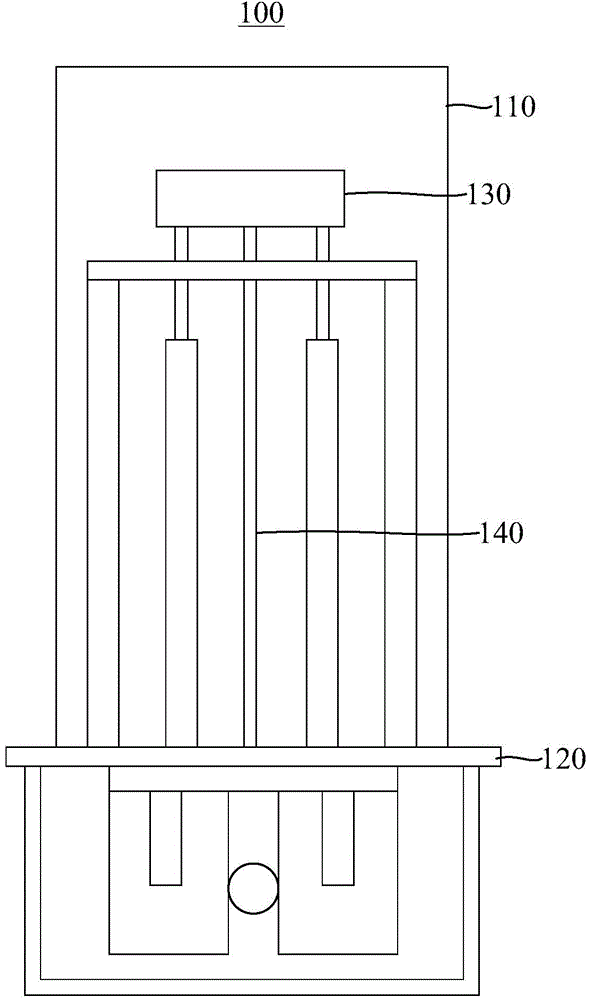

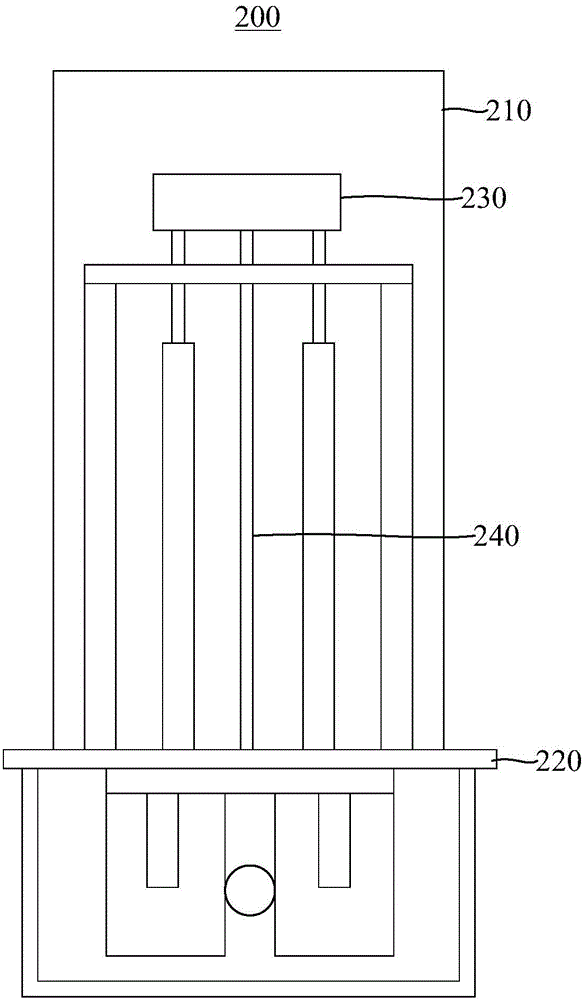

Ion source and ion implantation device

ActiveCN104425198AImprove collision efficiencyIncrease production capacityElectric discharge tubesElectron collisionCold cathode

The invention discloses an ion source and an ion implantation device. The ion source has a vacuum chamber. The vacuum chamber comprises a plasma forming container, a first cathode arranged on one side of the plasma forming container and used for emitting electrons, a first indirectly-heated cathode, a second cathode arranged on the side of the plasma forming container opposite to the first cathode and used for emitting electrons, and a second indirectly-heated cathode, wherein the electrons emitted by the first cathode enter the plasma forming container after colliding the first indirectly-heated cathode, and the electrons emitted by the second cathode enter the plasma forming container after colliding the second indirectly-heated cathode. According to the ion source, when the first cathode or the second cathode is damaged, the ion source can continue to generate plasma only by changing the method of electrification of the first cathode and the second cathode, maintenance through opening the vacuum chamber is avoided, and the production efficiency is improved.

Owner:SEMICON MFG INT (SHANGHAI) CORP

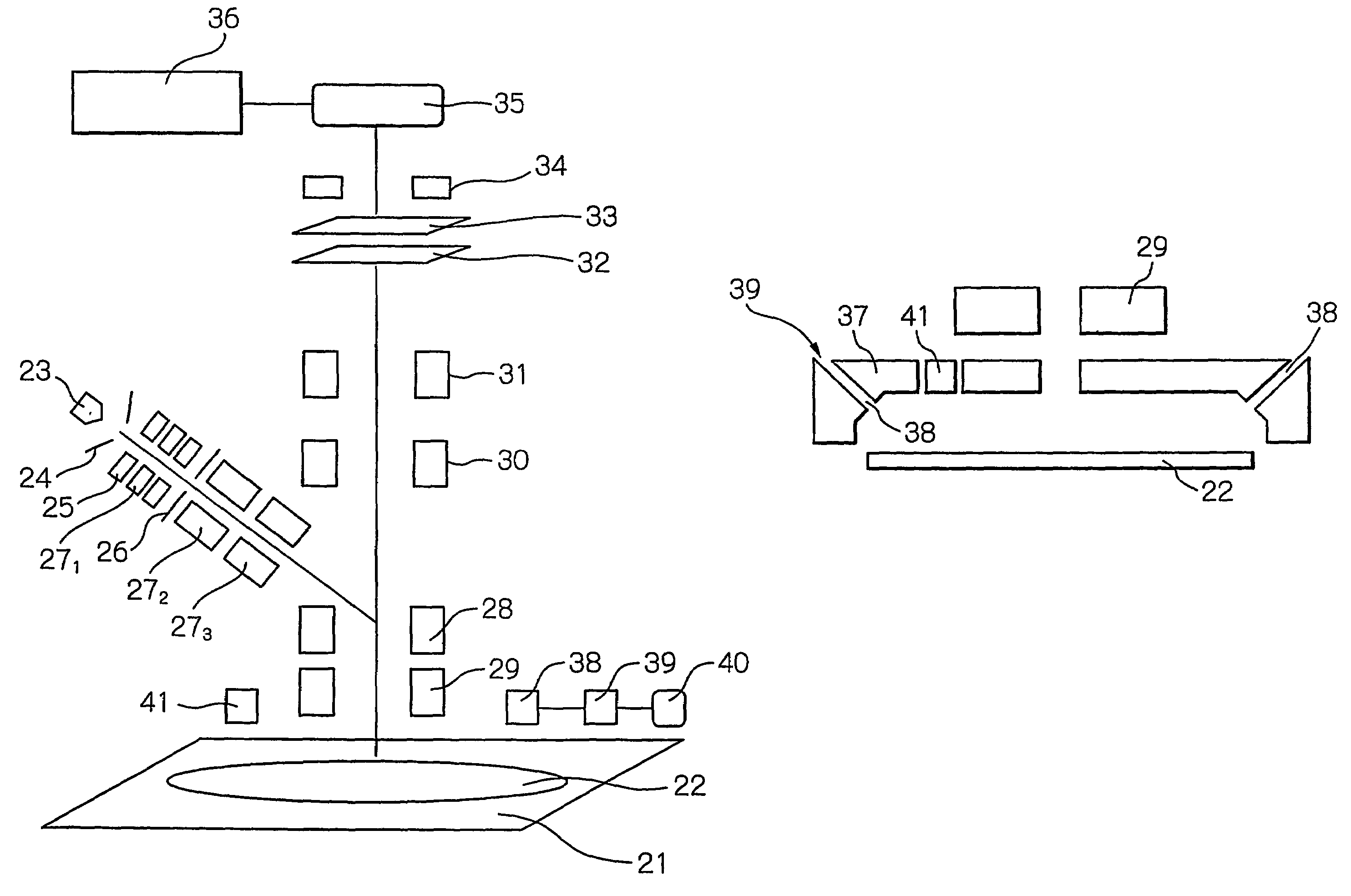

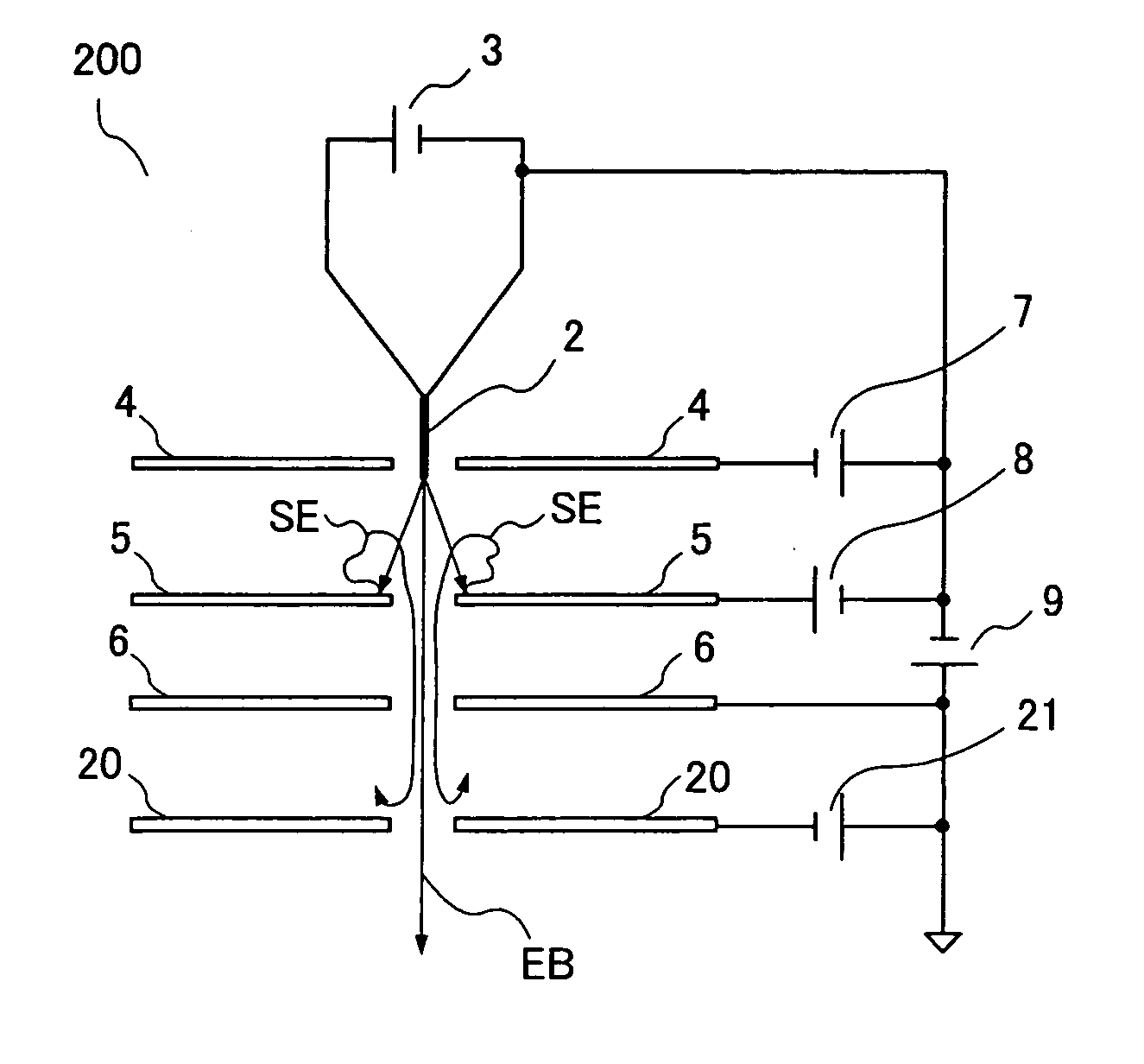

Mapping-projection-type electron beam apparatus for inspecting sample by using electrons reflected from the sample

InactiveUS7592586B2Improve accuracyImprove reliabilityLaser detailsMaterial analysis using wave/particle radiationElectron collisionSecondary electrons

An apparatus capable of detecting defects of a pattern on a sample with high accuracy and reliability and at a high throughput, and a semiconductor manufacturing method using the same are provided. The electron beam apparatus is a mapping-projection-type electron beam apparatus for observing or evaluating a surface of the sample by irradiating the sample with a primary electron beam and forming on a detector an image of reflected electrons emitted from the sample. An electron impact-type detector such as an electron impact-type CCD or an electron impact-type TDI is used as the detector for detecting the reflected electrons. The reflected electrons are selectively detected from an energy difference between the reflected electrons and secondary electrons emitted from the sample. To eliminate charge-up caused on the sample surface by irradiation with the primary electron beam, the surface of the sample is covered with a cover placed above the sample and a gas is supplied to the space above the sample covered with the cover. The gas is brought into contact with the sample surface to reduce charge-up on the sample surface.

Owner:TOSHIBA MEMORY CORP +1

Method for implementing aluminum diffusion on silicon wafer

InactiveCN103000502AHigh voltageHigh product quality controllabilitySemiconductor/solid-state device manufacturingAluminum IonAnhydrous ethanol

The invention relates to a method for implementing aluminum diffusion on a silicon wafer. The method includes making a texture surface on the front surface of the silicon wafer, and coating a silicon oxide isolating membrane on the back surface of the silicon wafer; implanting ions, in other words, selecting solid AlCl<3> as an aluminum diffusion source, heating the solid aluminum source under a high-vacuum condition so that the solid aluminum source sublimates at the temperature of 120-170 DEG C, loading the solid aluminum source into a source region of a filament of an ion implanter by using argon as a carrier, enabling the solid aluminum source to be collided with electrons generated by the filament to form the charged aluminum ions, accelerating the charged aluminum ions by high voltage, screening the ions by a magnetic analyzer, and further doping aluminum impurities into the silicon wafer; cleaning the silicon wafer; dehydrating the cleaned silicon wafer by anhydrous ethanol and placing the silicon wafer in a drying oven at the temperature of 100-110 DEG C to dry the silicon wafer; and placing the dried silicon wafer in a diffusion furnace, heating the diffusion furnace so that the temperature of the diffusion furnace is 1250-1260 DEG C, and keeping the temperature constant for 10-12 hours. The method has the advantages that the total doping contents for ion implantation are accurately controlled, the precision and the repeatability of a diffusion process are improved, and a large-area uniform doping effect is realized.

Owner:江苏卡迪诺节能保温材料有限公司

Ion source with device for oxidising a sample

InactiveUS8729494B2Increase spacingMaterial analysis by electric/magnetic meansMaterial analysis by optical meansGas phaseElectron collision

An ion source is disclosed wherein a sample is introduced into the sample chamber of the ion source in the gas phase via a sample introduction capillary tube. The sample is directed onto a heated surface coated with an oxidizing reagent such as copper oxide. Carbon in the sample is oxidized to form carbon dioxide. The resulting carbon dioxide molecules are then ionised by electron impact ionization with an electron beam and the resulting ions are passed to a mass analyzer for mass analysis.

Owner:MICROMASS UK LTD

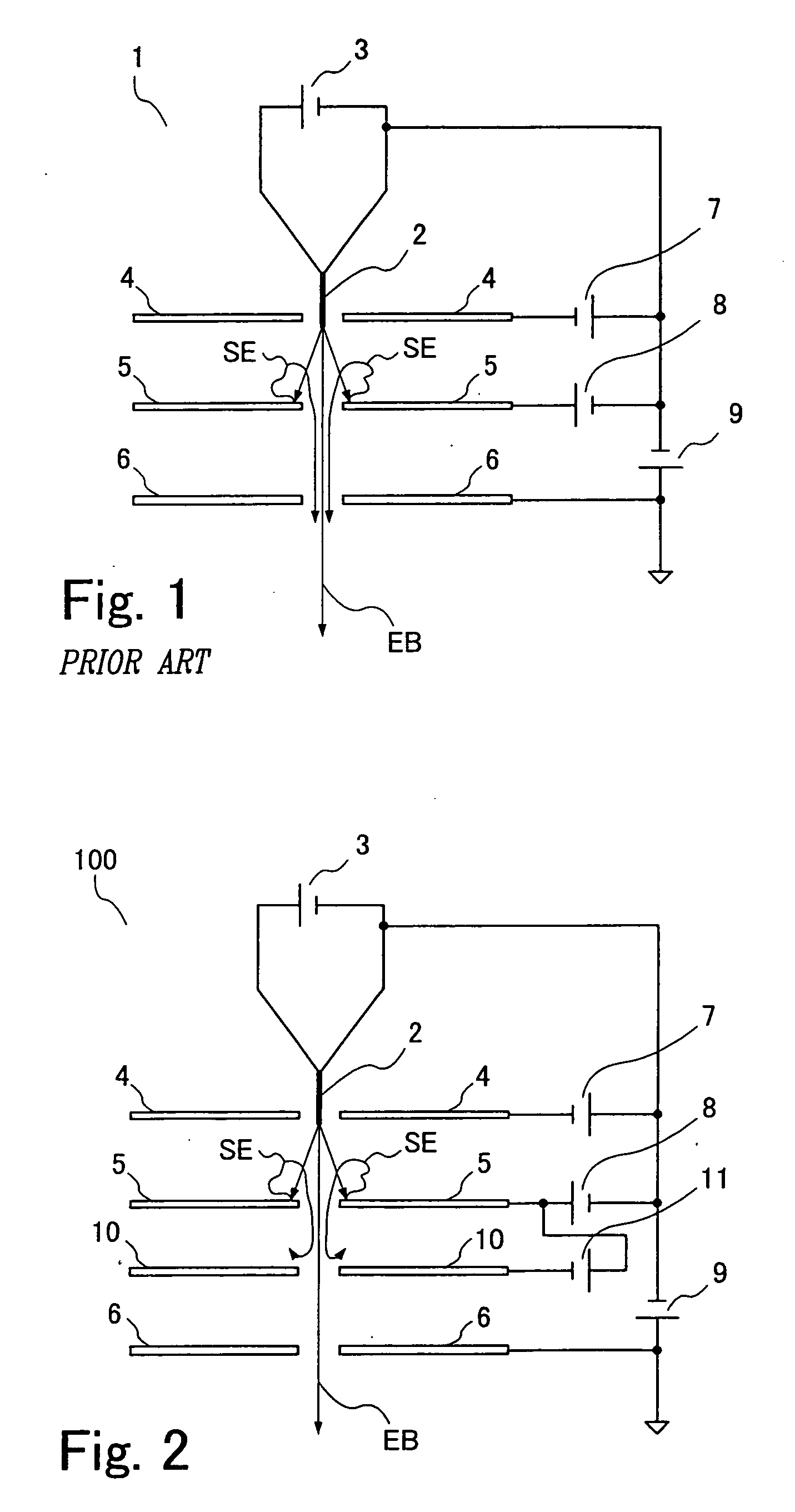

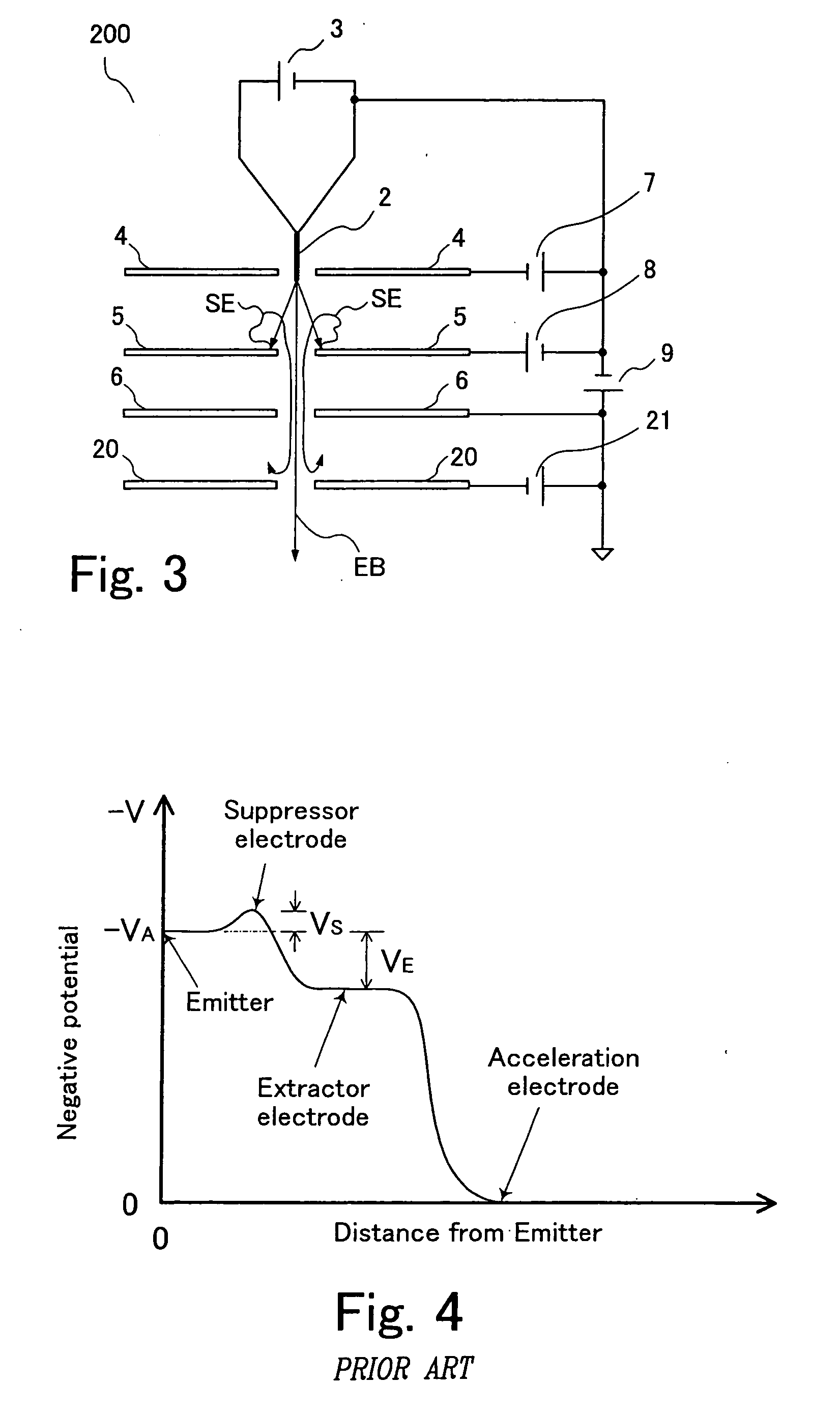

Field emission electron gun

InactiveUS20070096838A1Improve image qualityImprove resolutionElectric discharge tubesOscillations generatorsElectron collisionSecondary electrons

Electron beam equipment fitted with a field emission electron gun (FEG) having an extractor electrode, an acceleration electrode, a repeller electrode disposed between the extractor electrode and the acceleration electrode, and a repeller power supply for applying a given voltage to the repeller electrode. Electrons extracted from the emitter collide against the extractor electrode, producing secondary electrons moving toward the acceleration electrode. The secondary electrons are repelled by the repeller electrode and thus prevented from reaching the specimen.

Owner:JEOL LTD

Waste water treatment device and waste water treatment method

InactiveCN102432086AEasy to handleCollision fastWater/sewage treatment by irradiationWater/sewage treatment by electrochemical methodsOperational costsChemical reaction

The invention discloses a waste water treatment device and a waste water treatment method. In the device, a high voltage discharge connected with a high voltage source performs glow discharge in a waste water treatment tank where the electroplating wastewater passes through so as to generate low-temperature plasmas, high-energy electrons, ultraviolet light and ozone, based on high-level strong oxidation reaction between the plasmas and the electroplating wastewater, the device can perform comprehensive treatment, which is integrated with three actions of high-energy electron collision, ozone oxidation and ultraviolet light degradation, on the waste water. The method needs simple equipment and small area, saves investment, and has low energy consumption and low operating cost; and the method needs no chemical reaction additives, produces less sludge storage after oxidation, and causes no secondary pollution; and the purified water can be recycled and discharged after meeting the discharge standards.

Owner:苏汉明

Field emission panel, liquid crystal display and field emission display having the same

InactiveUS20120319561A1Reduce fabrication timeLow costElectrode assembly support/mounting/spacing/insulationDischarge tube luminescnet screensColor imageDisplay device

A field emission panel, a liquid crystal display and a field emission display having the same are provided. The field emission panel includes a lower plate emitting electrons and an upper plate generating white light or a color image through collision with the electrons. The lower plate includes plural field emission elements, plural cathode electrodes and plural gate electrodes forming an electric field for electron emission from the electron emission elements, and a glass plate supporting the electron emission elements, the cathode electrodes, and the gate electrodes. The gate electrodes are arranged on an upper surface of the glass plate, and the glass plate has plural accommodation grooves for accommodating the plural electron emission elements and the plural cathode electrodes.

Owner:SAMSUNG ELECTRONICS CO LTD

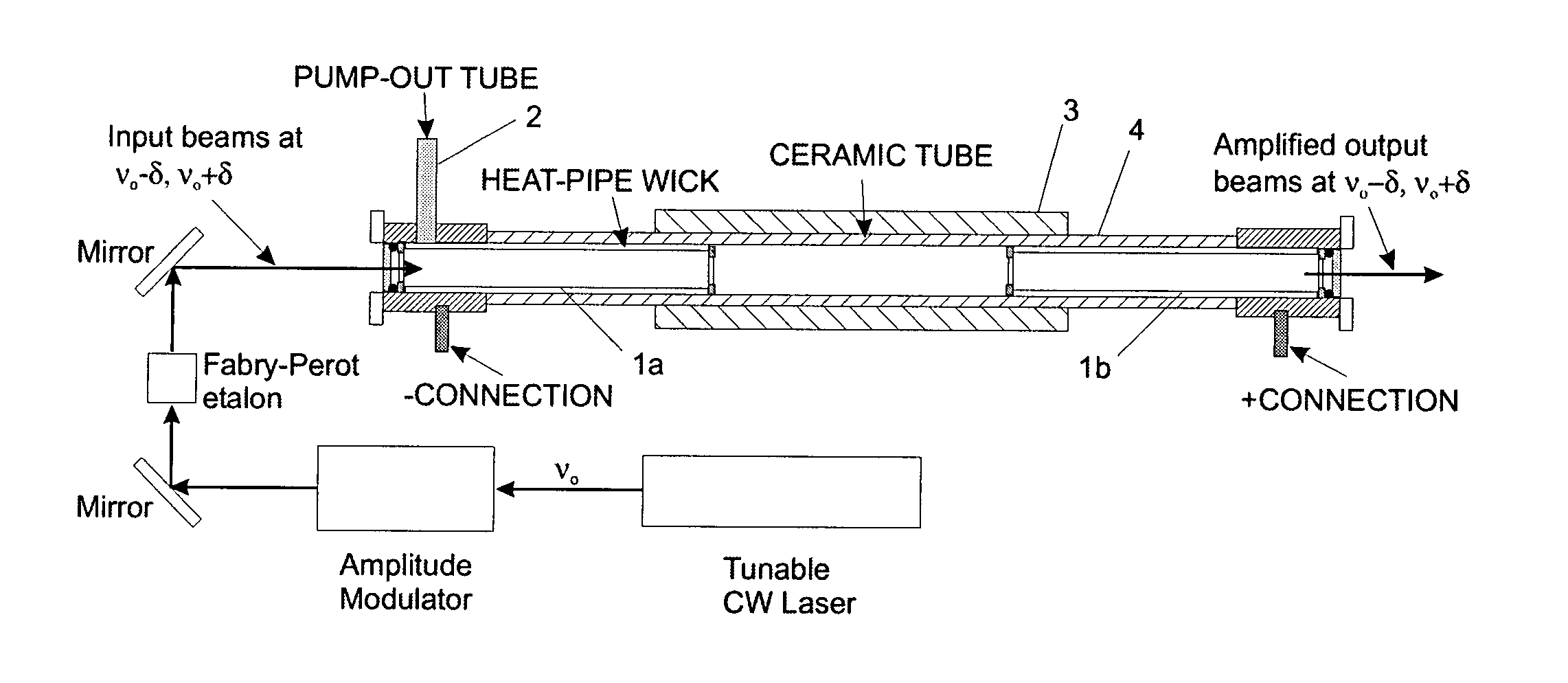

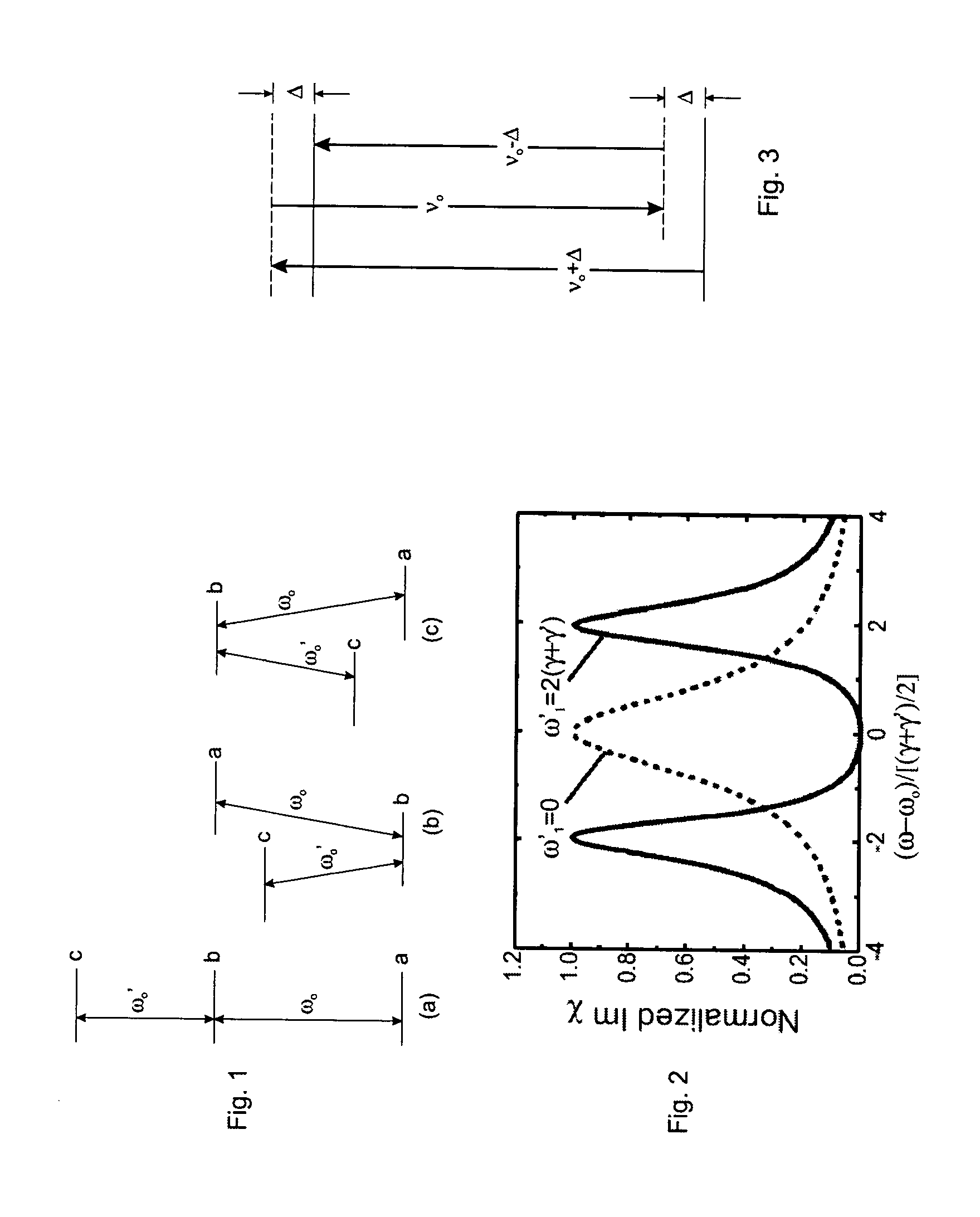

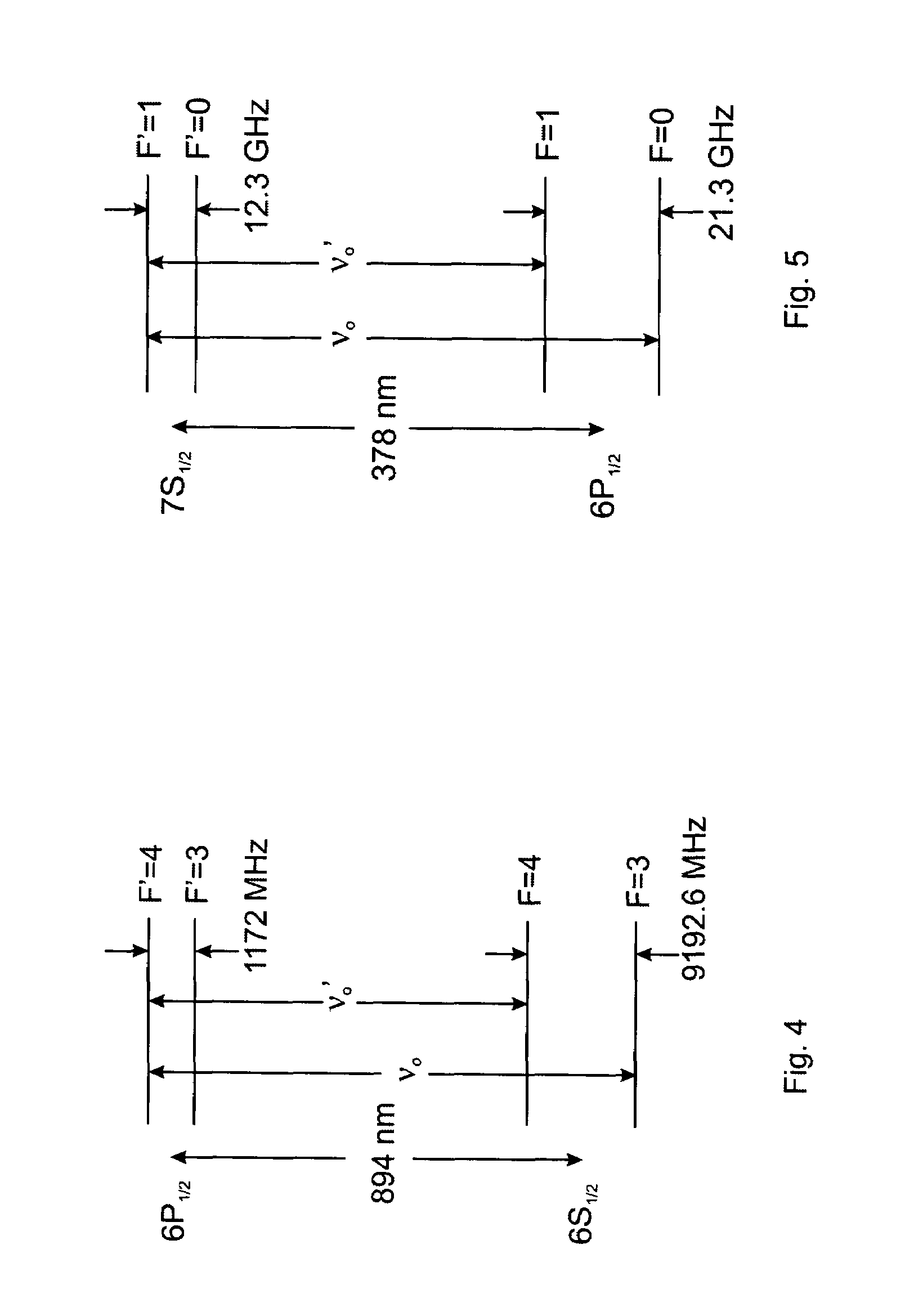

Discharge-pumped “dressed-atom” coherent light amplifier and generators

A novel practicable type of gaseous optical gain medium for efficiently generating intense, highly monochromatic, continuous-wave (CW) or pulsed, coherent light beams is disclosed. Gain results from nonlinear optical pumping of a gas of Λ-type “three-level” atoms, coherently phased (“dressed”) via application to the medium of two monochromatic laser beams tuned to the resonance frequencies ω0 and ω′0. Nonlinear optical pumping of the “dressed-atom” gas is accomplished through the combined action of two separate physical processes: (1) A low pressure gaseous discharge, occurring continuously within the vessel containing the gain medium, produces intense narrow-band fluorescence at ω0 and ω′0 through the process of electron impact excitation (EE). (2) Via a specific form of the nonlinear photonic process of stimulated hyper-Raman scattering (SHRS), photons comprised by the narrow-band fluorescence generated in (1) are efficiently converted to photons comprised by the propagating coherent light beams at ω0 and ω′0, thus effecting amplification of the latter.

Owner:SOROKIN PETER P +2

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com