Field emission ionization source for time-of-flight mass spectrometer

A technology of time-of-flight mass spectrometry and field emission, which is applied in the field of electron impact ionization sources, and can solve problems such as difficulties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

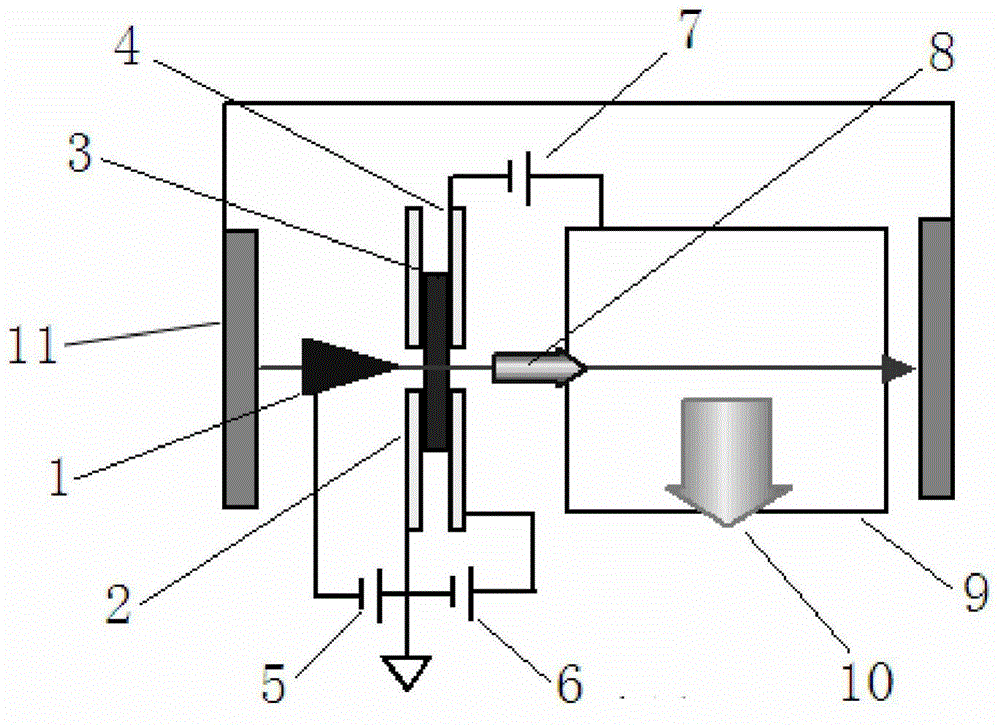

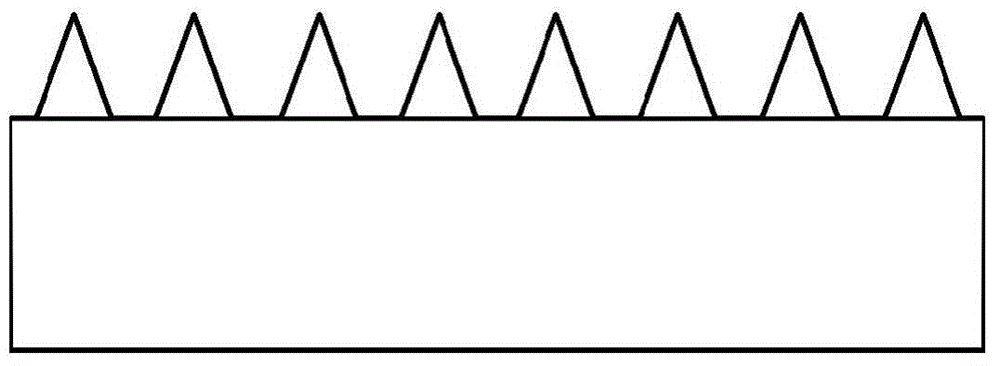

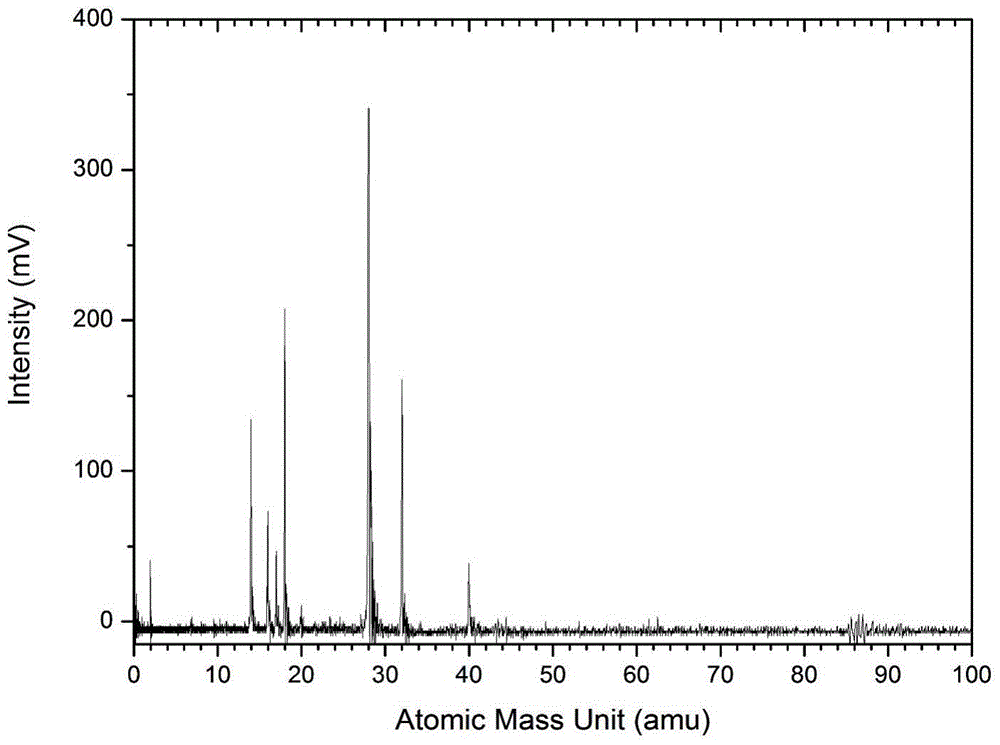

[0024] The following is a realization method of a miniature TOF-MS ionization source based on blade-shaped cathode field emission. use figure 2 As shown in the "serrated blade" cathode emitter 1, the cathode emitter 1 has a width of 10 mm and a thickness of 0.1 mm. The radius of curvature of all tips on the cathode emitter 1 is less than 100 nm, and the spacing is 20-50 microns. The metal cathode of this shape can be used directly, or a layer of nanomaterials (such as carbon nanotubes) can be attached to its tip. The slit width of the anode slit electrode 2 is 0.2-0.8 mm, and the slit length is 12 mm. The distance between cathode and anode is adjustable from 2-100 microns. The output electrode of the microchannel plate (that is, the MCP slit electrode) and the corresponding slit on the ionization box have a width of 0.8-1.2 mm and a length of 12 mm. All electrodes are machined from non-magnetic stainless steel sheets with a thickness of 0.5 mm. A 200-1000 Gauss magnetic f...

Embodiment 2

[0027] The following is a realization method of a miniature TOF-MS ionization source based on planar cathode field emission. A mixture of single-wall carbon nanotubes and titanium dioxide nanoparticles (titanium dioxide accounts for about 7% of the total weight) was wipe-coated on the surface of a frosted copper sheet as a cathode emitter by mechanical wiping. Fix the cathode copper sheet to an electrode sheet. Then align the cathode emitter with the anode slit electrode, and connect the anode slit electrode with ceramic sheets and nylon screws. The width of the anode slit is 0.2-0.8 mm, and the length of the slit is 12 mm. By adjusting the thickness of the ceramic sheet, the distance between the cathode and the anode is 20-100 microns. The output electrode of the microchannel plate (that is, the MCP slit electrode) and the corresponding slit on the ionization box have a width of 0.8-1.2 mm and a length of 12 mm. All electrodes are machined from non-magnetic stainless steel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com