Method for preparing water-absorbing resin by ultraviolet and gamma-ray radiation ionization technique

A technology of radiation ionization and water-absorbing resin, applied in the field of preparing water-absorbing resin by solution polymerization, can solve the problems of difficult to meet the comprehensive practical performance of the product, poor liquid permeability and dispersibility of the product, difficult to stabilize the product performance, etc. The effect of good sex and strong resistance to salt absorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

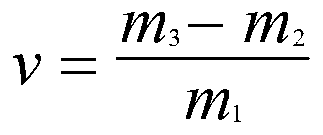

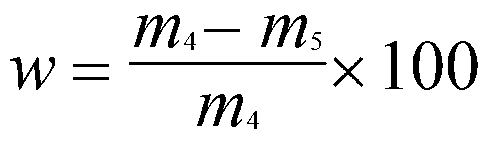

Embodiment 1

[0020] Put 30kg of acrylic acid into a neutralization kettle with a stirring and cooling device. The temperature of the cooling medium is controlled at 5-15°C. While stirring, add 23% by weight aqueous sodium hydroxide solution dropwise, and the neutralization temperature is controlled at 25°C. ~35°C, neutralize to pH 7, then add 1kg of methacrylamide, stir well until completely dissolved, then put it into a PE plastic bag, first place it in a UV light with a wavelength of 365nm and an illumination of 4000μw / cm2 Under the light source, irradiate for 60 minutes, the material liquid undergoes polymerization reaction to form an elastic gel, and the elastic gel after ultraviolet light polymerization is placed in a γ-ray nuclear radiation device with a radiation dose rate of 7kGy / h for irradiation, so that the irradiation dose reaches 10kGy. Then the elastic gel is crushed, dried, pulverized, sieved, and then treated with a surface treatment agent to obtain a white powder with high...

Embodiment 2

[0044] Put 30kg of acrylic acid into a neutralization kettle with a stirring and cooling device. The temperature of the cooling medium is controlled at 5-15°C. Under stirring, add a 20% by weight potassium hydroxide aqueous solution dropwise, and the neutralization temperature is controlled at 25°C. ~35°C, neutralize to pH 7, then add 3kg of acrylamide and 1kg of 2-acrylamide-2-methylpropanesulfonic acid, stir well until completely dissolved, then put it into a PE plastic bag, put it in The wavelength is 365nm, and the illumination is 5000μw / cm 2 Under the ultraviolet light source, it is irradiated for 90 minutes, and the material liquid undergoes polymerization reaction to form an elastic gel. The elastic gel after ultraviolet light polymerization is placed in a γ-ray nuclear radiation device with a radiation dose rate of 8kGy / h for irradiation, so that the irradiation The dose reaches 15kGy. Then the elastic gel is crushed, dried, pulverized, sieved, and then treated with a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com