Super absorbent resin with high antibacterial property and high salt tolerance as well as preparation method and application thereof

A super absorbent resin, antibacterial technology, used in absorbent pads, medical science, bandages, etc., can solve the problems of low salt resistance absorption performance and pressure resistance absorption rate, blocking liquid flow speed, and low water retention rate, etc. Performance and range of use, improved absorption performance, low-cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

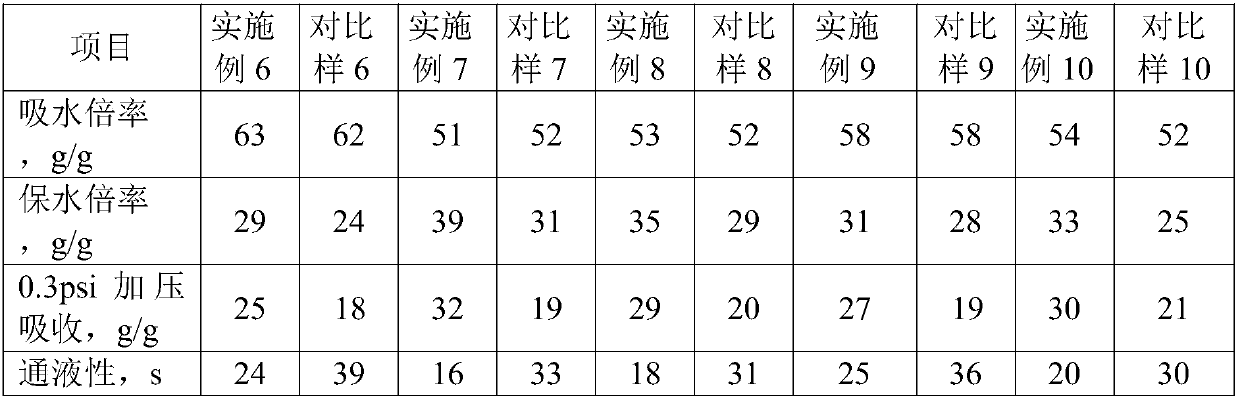

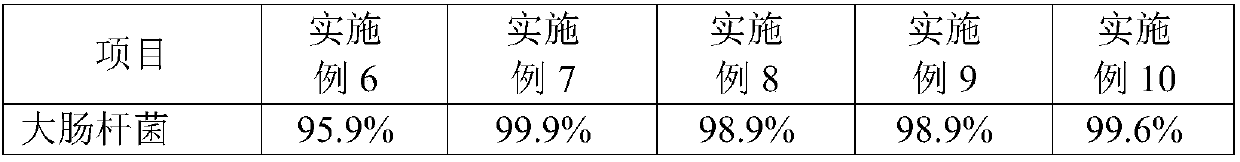

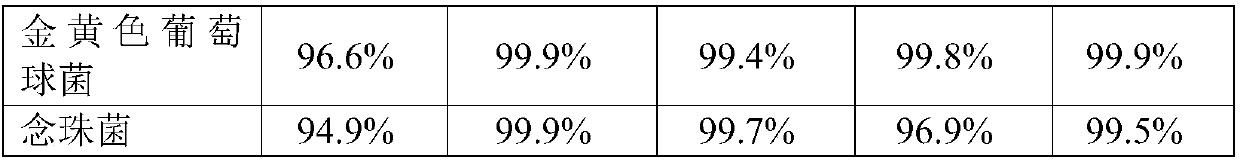

Examples

Embodiment 1

[0063] The tea saponin intercalated graphene antibacterial composition in this embodiment is composed of the following parts by weight: 5 g of tea saponin, 10 g of graphene oxide, and 0.01 g of sodium lauryl sulfate. Wherein, the purity of the tea saponin is 75%.

[0064] The graphene oxide is porous graphene oxide, and the polar oxygen-containing functional group of the porous graphene oxide is carboxylated, and the pore diameter is 0.5-100 nm.

[0065] The tea saponin intercalated graphene antibacterial composition described in this embodiment is prepared by the following steps:

[0066] Step 1: Dissolve an appropriate amount of tea saponin in deionized water to form a tea saponin solution with a mass concentration of 5%.

[0067] Step 2: Add sodium lauryl sulfate in deionized water and stir well, then add graphene oxide to deionized water to make the concentration of graphene oxide 0.2mg / mL, and ultrasonically disperse for 30-240min to form graphite Olefin suspension.

[0068] Step...

Embodiment 2

[0072] The tea saponin intercalated graphene antibacterial composition in this embodiment is composed of the following parts by weight: 45 g of tea saponin, 50 g of graphene oxide, and 2 g of sodium lauryl sulfonate. Wherein, the purity of the tea saponin is 85%. The graphene oxide is selected from porous graphene oxide, and the polar oxygen-containing functional group of the porous graphene oxide is carboxylated, and the pore diameter is 0.5-100 nm.

[0073] The tea saponin intercalated graphene antibacterial composition described in this embodiment is prepared by the following steps:

[0074] Step 1: Dissolve an appropriate amount of tea saponin in deionized water to form a tea saponin solution with a mass concentration of 20%.

[0075] Step 2: Add sodium dodecyl sulfonate into deionized water and stir evenly, then add graphene oxide to deionized water so that the concentration of graphene oxide is 20mg / mL, and ultrasonically disperse for 30-240min to form graphite Olefin suspens...

Embodiment 3

[0080] The tea saponin intercalated graphene antibacterial composition in this embodiment is composed of the following parts by weight: 25 g of tea saponin, 30 g of graphene oxide, and 1.0 g of sodium dodecylbenzene sulfonate. Wherein, the purity of the tea saponin is 80%. The graphene oxide is selected from porous graphene oxide, and the polar oxygen-containing functional group of the porous graphene oxide is carboxylated, and the pore diameter is 0.5-100 nm.

[0081] The tea saponin intercalated graphene antibacterial composition described in this embodiment is prepared by the following steps:

[0082] Step 1: Dissolve an appropriate amount of tea saponin in deionized water to form a tea saponin solution with a mass concentration of 12%.

[0083] Step 2: Add sodium dodecylbenzene sulfonate into deionized water and stir it evenly, then add graphene oxide to deionized water so that the concentration of graphene oxide is 10mg / mL, and ultrasonically disperse for 30-240min. Graphene s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Hole diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com