Preparation method of spherical water absorption resin

A water-absorbent resin, spherical technology, applied in the field of water-absorbent resin preparation, can solve the problems of poor water-absorbent permeability, different product particle sizes, resin fragmentation, etc., and achieve the effects of low cost, simple process and simple production equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

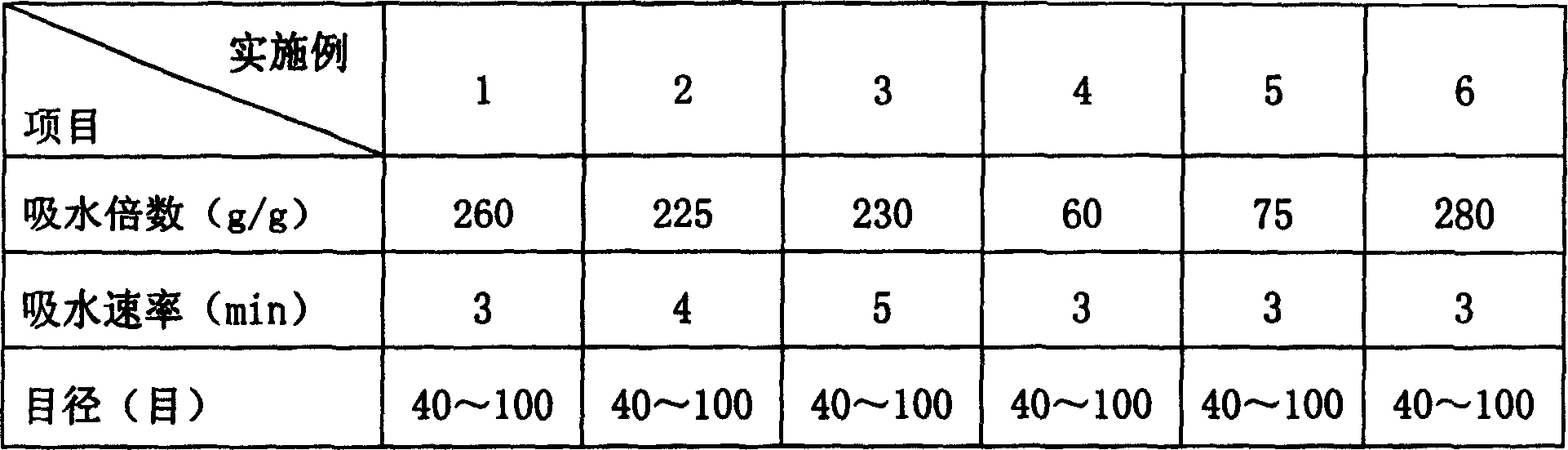

Examples

Embodiment 1

[0026] Weigh 15 kg of acrylic acid, add it into a stainless steel neutralization kettle with a jacket and a stirrer, fill the jacket with circulating water, slowly add 27% ammonia water (wherein the alkali is NH 3 Content is 3.25 kg), so that the neutralization temperature is controlled at 20 ° C, at this time PH = 6 ~ 7, then add 2.5 kg of acrylamide, cross-linking agent N, N, - methylene bisacrylamide 0.005 kg, after stirring and dissolving water box.

[0027] Start the shear emulsification mixer, add 13.5 kg of kerosene, 80.6 kg of Span, and 0.3 kg of monoglyceride into the dispersion medium, stir and mix and heat to 60-65°C to dissolve, then add the water phase to the oil phase, and stir After 1-2 hours, a reverse phase suspension was obtained. After putting the reverse phase suspension into the container, the temperature of the reverse phase suspension is controlled at 5°C and placed in 60 In the Co-γ-ray field, the dose rate is 0.05KGy / h, and the dose is 2KGy. No need ...

Embodiment 2

[0029] Weigh 25 kg of acrylic acid, add it into a stainless steel neutralization kettle with a jacket and agitator, fill the jacket with circulating water, configure 15.5 kg of potassium hydroxide into a 30% aqueous solution, slowly add it to the acrylic acid, and control the neutralization temperature At 20°C, when the pH is 6-7, add 2.5 kg of methacrylic acid and 0.05 kg of polyethylene glycol bis(meth)acrylate, stir and dissolve to form a water phase.

[0030] Start the shear emulsification mixer, add 15.5 kg of gasoline, 80, 9.5 kg of Span, and 0.6 kg of monoglyceride into it, stir and mix and heat to 60-65°C to dissolve, then add the water phase to the oil phase, and stir for 1-2 After 1 hour a reverse phase suspension was obtained. After filling the reverse phase suspension into the container, place 60 In the Co-γ-ray field, the dose rate is 0.05KGy / h, the dose is 3KGy, the temperature of the reverse phase suspension is controlled at 30°C, it is subjected to radiation a...

Embodiment 3

[0032] Weigh 26.25 kg of acrylic acid, add it to a stainless steel neutralization kettle with jacket and stirrer, fill the jacket with circulating water, configure 10.5 kg of sodium hydroxide into a 20.7% aqueous solution, slowly add it to acrylic acid, and control the neutralization temperature At 50°C, when the pH is 6-7, then add 1.5 kg of butyl acrylate and 0.025 kg of N,N,-methylenebisacrylamide, stir and dissolve to form an aqueous phase.

[0033] Start the shear emulsification mixer, add kerosene 20.5 kg, Span 80, 9.5 kg, and monoglyceride 0.25 kg, stir and mix and heat to 60-65°C to dissolve, then add the water phase to the oil phase, stir for 1-2 After 1 hour a reverse phase suspension was obtained. After filling the reverse phase suspension into the container, place 60 In the Co-γ-ray field, the dose rate is 1KGy / h, the dose is 3kGy, the temperature of the reverse phase suspension is controlled at 10°C, it is subjected to radiation and polymerized at rest, and the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com