Method for modifying polyacrylonitrile by using gamma ray irradiation

A technology of polyacrylonitrile and polyacrylonitrile fibers, applied in the direction of single-component synthetic polymer rayon, chemical characteristics of fibers, textiles and papermaking, etc. The effect of process cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

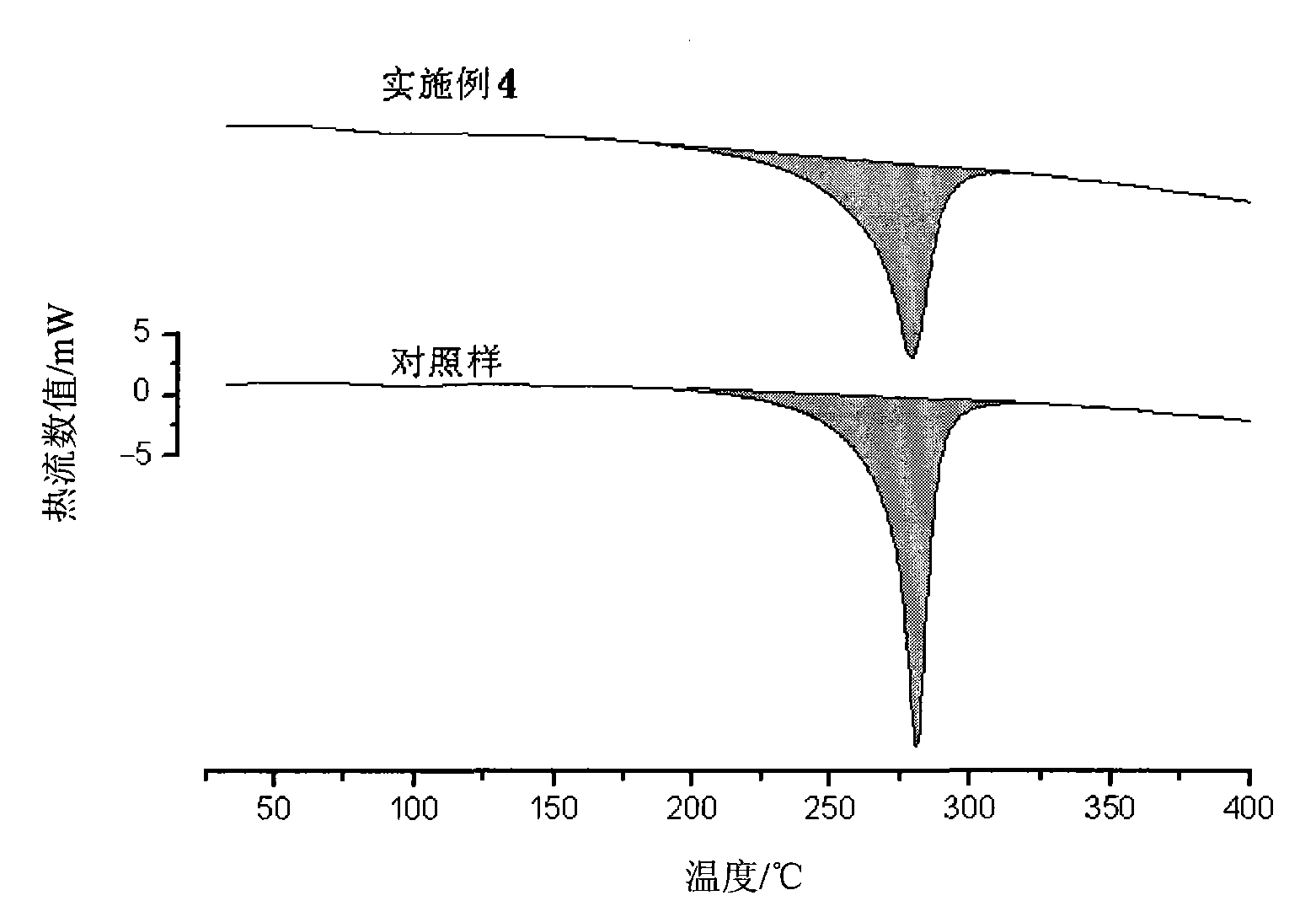

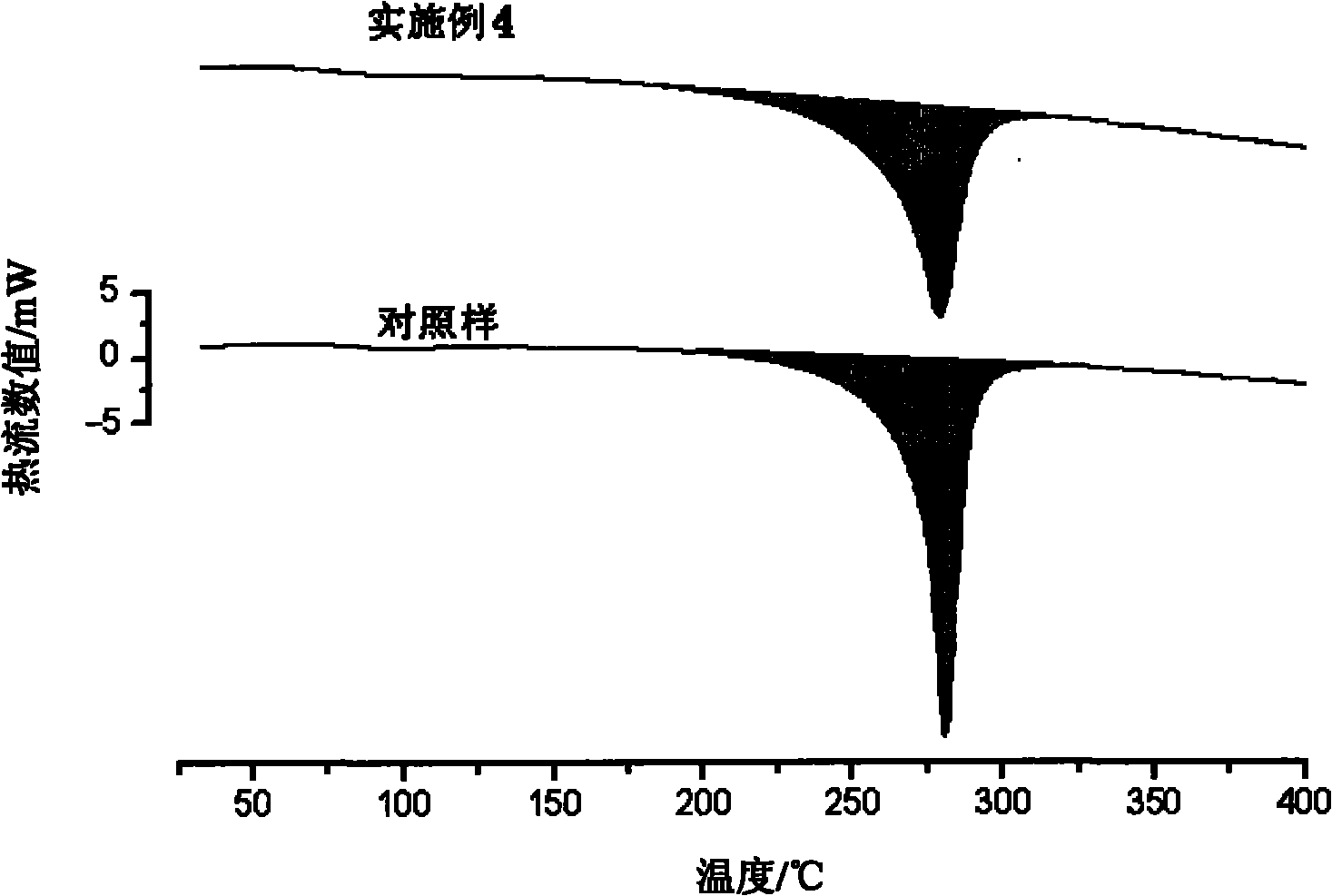

[0022] A polyacrylonitrile film (100 microns thick, 99% acrylonitrile content) is placed in a glass vacuum irradiation tube, and the air in the tube is drawn out with a vacuum pump and sealed (pressure 100Pa). Put the irradiation tube into the cobalt source and irradiate for 50 hours at a dose rate of 2kGy / h, with a total irradiation dose of 100kGy. After taking it out, the exothermic heat of cyclization was measured by DSC, and the results are listed in Table 1.

Embodiment 2

[0024] A polyacrylonitrile film (100 μm thick, 99% acrylonitrile content) was placed in a glass vacuum irradiation tube in an air atmosphere. Put the irradiation tube into the cobalt source and irradiate for 50 hours at a dose rate of 2kGy / h, with a total irradiation dose of 100kGy. After taking it out, the exothermic heat of cyclization was measured by DSC, and the results are listed in Table 1.

Embodiment 3

[0026] Put pure polyacrylonitrile fibers in a glass vacuum irradiation tube, use a vacuum pump to pump out the air in the tube and seal it. Put the irradiation tube into the cobalt source and irradiate for 50 hours at a dose rate of 2kGy / h, with a total irradiation dose of 100kGy. After taking it out, the exothermic heat of cyclization was measured by DSC, and the results are listed in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com