Efficient pre-oxidation method for general-grade asphalt-based non-woven felt

A pre-oxidation, pitch-based technology, applied in the direction of textiles and papermaking, fiber chemical characteristics, etc., can solve the problems of compacted oxidized felt and low pre-oxidation efficiency, and achieve the effect of avoiding fusion and improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

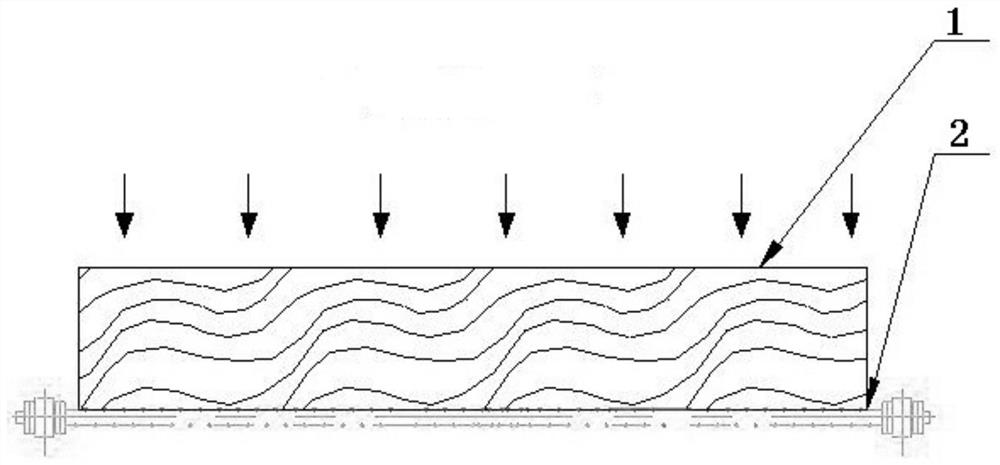

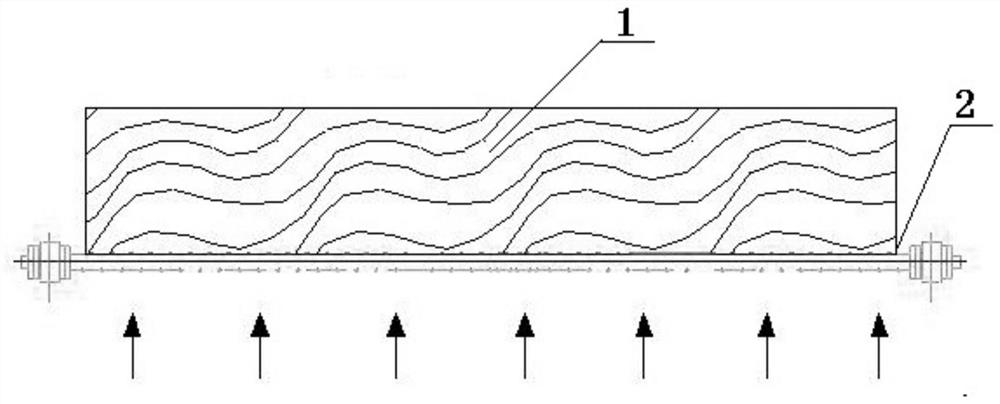

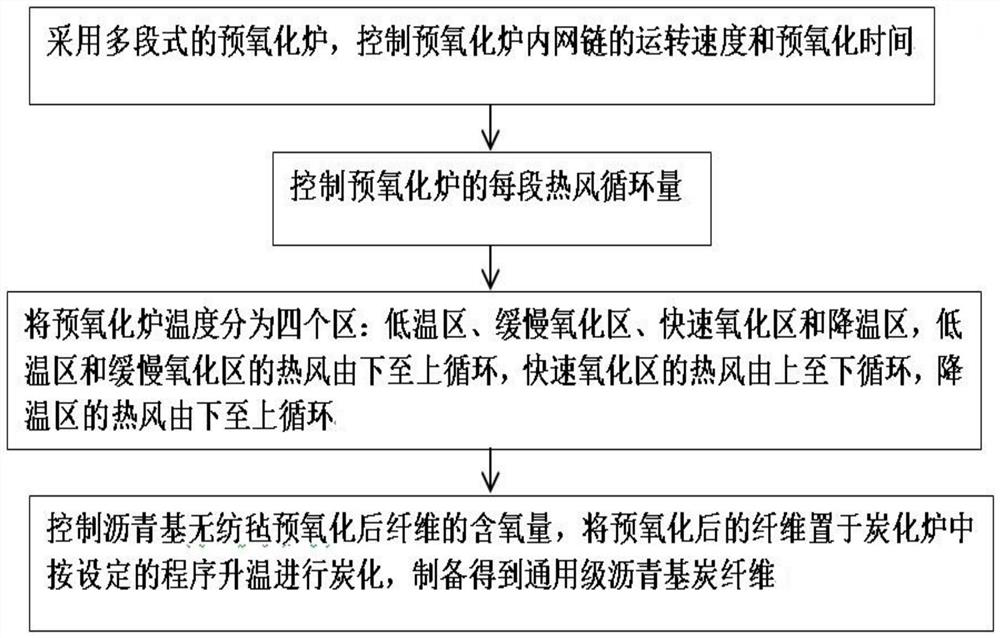

[0028] as attached figure 1 , attached figure 2 And attached image 3 Shown, the efficient pre-oxidation method of a kind of general grade asphalt-based non-woven mat, comprises the following steps:

[0029] Step 1: The thickness of the precursor of the general-purpose asphalt non-woven felt 1 that needs to be pre-oxidized is 9cm, and the width is 45cm. A multi-stage pre-oxidation furnace is used. The total length of the pre-oxidation furnace is 60 meters. The length is 1.5m, the running speed of the network chain 2 in the pre-oxidation furnace is controlled to 0.5m / min, and the pre-oxidation time in the pre-oxidation furnace is 2h;

[0030] Step 2: The pre-oxidation furnace is a multi-section combined type, each section has an independent hot air heating and hot air circulation system, and the hot air circulation volume of each section in the pre-oxidation furnace is set to 500m 3 / h;

[0031] Step 3: Divide the temperature of the pre-oxidation furnace into four zones: S...

no. 2 example

[0035] The second embodiment of the present invention is similar to the first embodiment except for the following design changes. A high-efficiency pre-oxidation method for a general-purpose asphalt-based non-woven felt, comprising the steps of:

[0036] Step 1: The thickness of the general-grade asphalt raw silk that needs to be pre-oxidized is 9cm, and the width is 45cm. A multi-stage pre-oxidation furnace is used. The total length of the pre-oxidation furnace is 60 meters. Control the speed of the network chain in the pre-oxidation furnace 0.5m / min, the pre-oxidation time in the pre-oxidation furnace is 2h;

[0037] Step 2: The pre-oxidation furnace is a multi-section combined type, each section has an independent hot air heating and hot air circulation system, and the hot air circulation volume of each section in the pre-oxidation furnace is set to 880m 3 / h;

[0038] Step 3: Divide the temperature of the pre-oxidation furnace into four zones: Sections 1-10 of the pre-ox...

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com