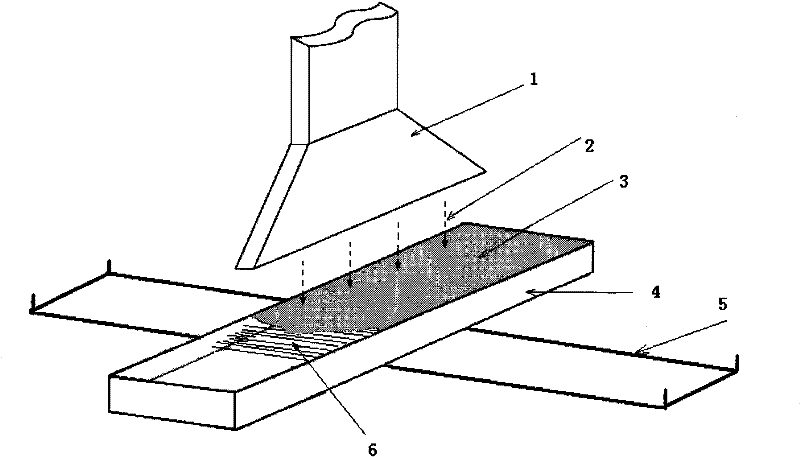

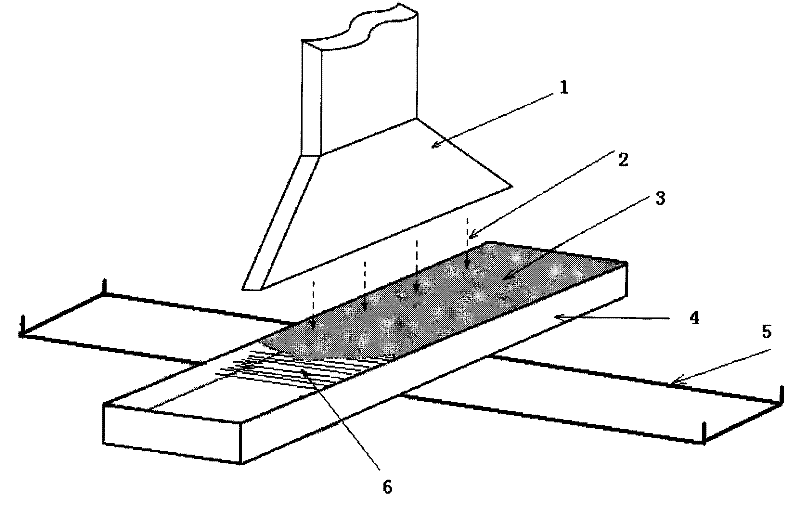

Method for modifying polyacrylonitrile by using electron beam irradiation

A technology of polyacrylonitrile fiber and electron beam irradiation, which is used in fiber processing, textile and papermaking, physical processing, etc., can solve problems such as lack of power, and achieve the effects of large processing capacity, improved pre-oxidation efficiency, and high radiation dose rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

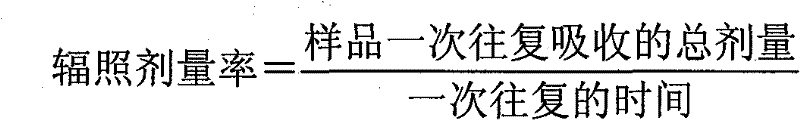

[0035]Carry out according to the above implementation procedures, the irradiation sample is the PAN precursor (3K, that is, 3000 monofilaments / bundle, domestic, acrylonitrile content 96%) for the manufacture of carbon fiber, tiled in the tray, the apparent tiled thickness is about 3mm , the electron beam energy is 1.7MeV, the dose rate is 333Gy / s, the irradiation time is 600s, and the total irradiation dose is 200kGy.

Embodiment 2

[0037] According to the above implementation procedures, the irradiated samples are the same as in Example 1, tiled in the tray, the apparent tiled thickness of the samples is about 3mm, the electron beam energy is 1.7MeV, the dose rate is 333Gy / s, the irradiation time is 1500s, and the irradiation time is 1500s. The total dose is 500kGy, and the cyclization heat generation and density changes before and after preoxidation of the obtained irradiated samples are listed in Table 1.

Embodiment 3

[0039] According to the above implementation procedures, the irradiated samples are the same as in Example 1, tiled in the tray, the apparent tiled thickness of the samples is about 3mm, the electron beam energy is 1.7MeV, the dose rate is 1000Gy / s, the irradiation time is 100s, and the irradiation time is 100s. The total dose is 100kGy, and the cyclization heat generation and density changes before and after pre-oxidation of the obtained irradiated samples are listed in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com