A method for reducing the formation of disinfection by-products in water treatment

A technology for disinfection by-products and water treatment, applied in the field of water treatment, can solve the problems of low redox potential and slow pre-oxidation speed, and achieve the effects of overcoming uneven mixing of water and gas, strong oxidizing ability and improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

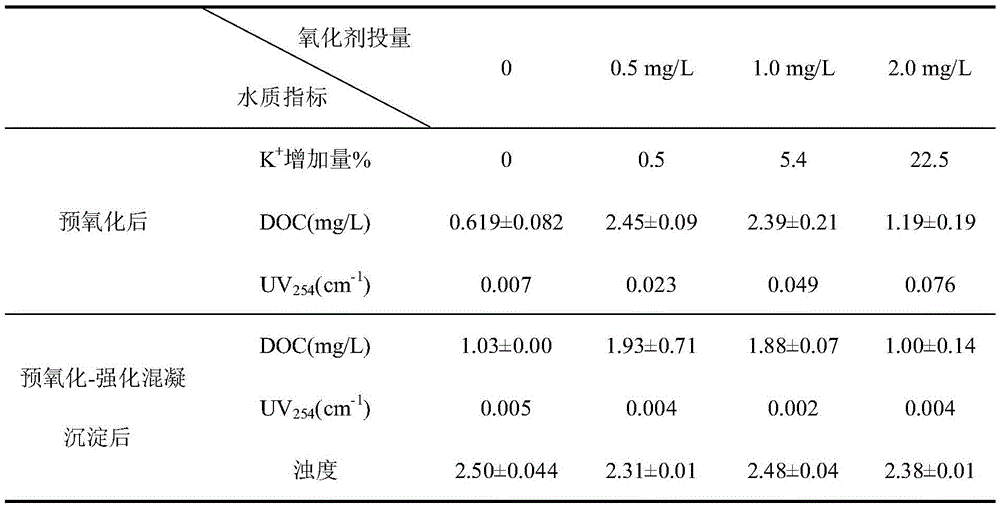

[0030] The reaction was carried out in a tank containing 1L Microcystis aeruginosa cell suspension (7.32×10 7 cell / L) in the six-coagulation mixer, the specific steps are as follows:

[0031] (1) Pre-oxidation stage: add a certain dose of potassium ferrate (0.5-20mg / L) to the water, react quickly at a speed of 200r / min for 10min, and control the reaction pH at 6-12; Take 50mL sample at 2cm, quench with 0.5M sodium sulfite, filter with 0.45μm membrane, test dissolved organic carbon concentration (DOC), potassium ion concentration (K + ) and UV absorption value at 254nm (UV 254 ).

[0032] (2) Pre-oxidation-intensified coagulation and precipitation stage: Add coagulant polyaluminum chloride (PAC, 10mg / L) to the water sample obtained in step (1), and first stir rapidly at a speed of 200r / min for 3min , and then slowly stirred at 40r / min for 15min, then statically settled for 30min; after statically settling, take 50mL of water sample at 2cm underwater, quench with 0.5M sodium ...

Embodiment 2

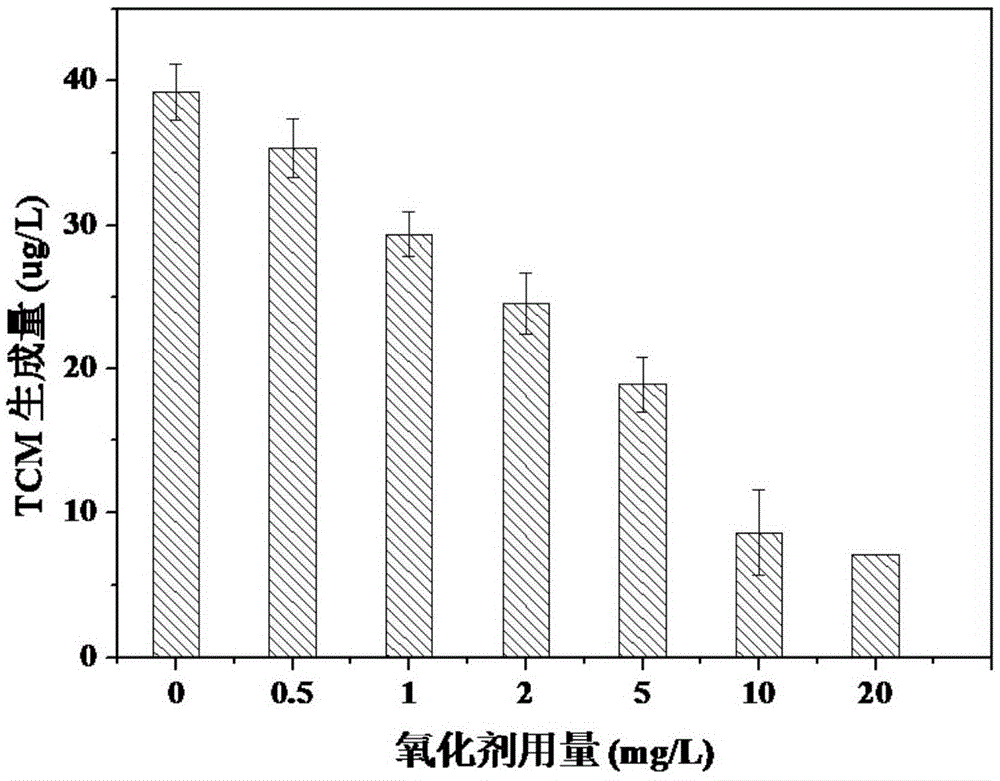

[0037] The reaction was carried out in a tank containing 1L algae cell suspension (Microcystis aeruginosa (7.32×10 7 cell / L)) in the six-coagulation mixer, adding a certain dose of potassium ferrate (0, 0.5, 1.0, 2.0mg / L, 5.0mg / L, 10.0mg / L, 20.0mg / L) to the water L), react quickly with a rotating speed of 250r / min for 30min, and the pH is controlled at 6-12; Stir slowly at 40r / min for 15min (when the dosage of high iron is increased to above 5mg / L, the reaction time is based on the disappearance of the purple color of the solution as the reaction end time), then settle for 30min; Add sodium hypochlorite (12.8 mg / L as available chlorine) for chlorination, react in the dark for 3 days, and measure the chloroform concentration (TCMFP).

[0038] Such as figure 1As shown, compared with simple coagulation and precipitation, when the dosage of potassium ferrate was 0.5-20 mg / L, TCM was reduced by 10%, 26%, 38, 52, 78 and 82%, respectively. It can be seen that ferrate preoxidation-...

Embodiment 3

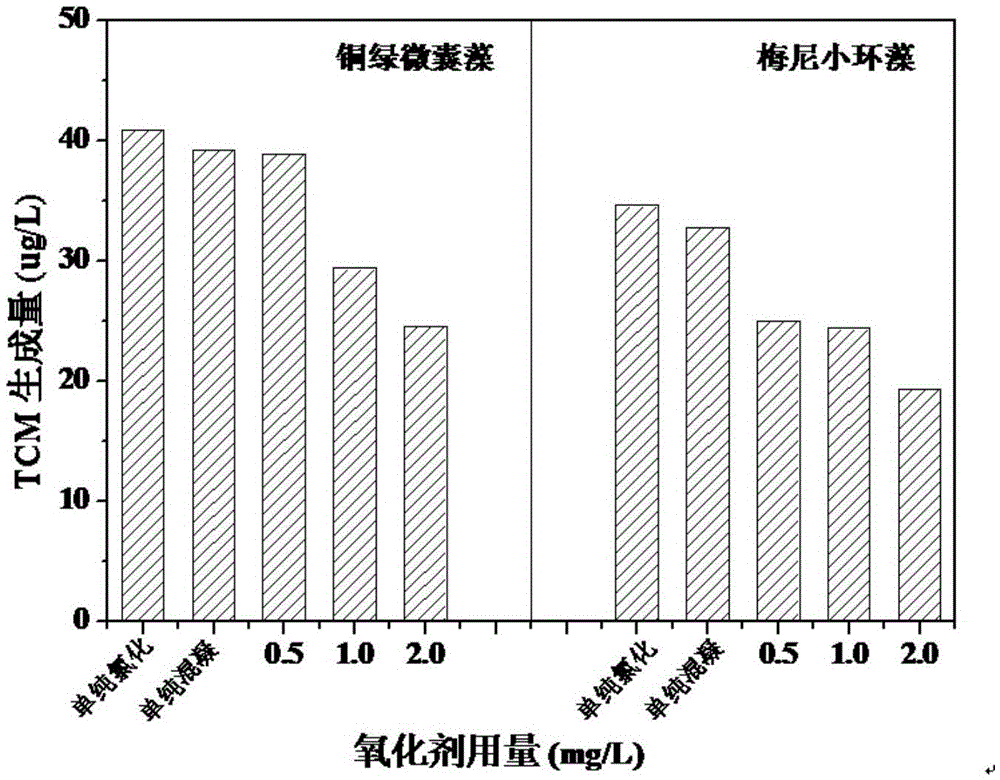

[0040] The reactions were carried out in 1L Microcystis aeruginosa (7.32×10 7 cell / L) cell suspension and Cyclotella menielis (2.06×10 7 cell / L) in the six-coagulation agitator of the cell suspension, add a certain dose of potassium ferrate (0, 0.5, 1.0, 2.0mg / L) to the water of different algae cell suspensions respectively, at 250r / L min speed reaction for 30 min; add coagulant polyaluminum chloride (PAC, 10mg / L), first stir quickly at 200r / min for 3min, then slowly stir at 40r / min for 15min, then settle for 30min; After sinking, take 100mL of water sample at 2cm below the water, add sodium hypochlorite (12.8mg / L in terms of available chlorine) for chlorination, react in the dark for 3 days, and measure its TCMFP.

[0041] Such as figure 2 It was shown that after adding ferrate, the precursors of TCM were effectively removed during the enhanced coagulation process of the two algae cells. Ferrate has strong oxidizing properties in water, can destabilize various algae, oxid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com