Stability-enhancing underlayer for exchange-coupled magnetic structures, magnetoresistive sensors, and magnetic disk drive systems

a magnetic structure and stability-enhancing technology, applied in the field of exchange-coupled magnetic structures containing underlayers, can solve the problems of weak pinning field, low signal, and high critical layer thickness, and achieve the effect of improving stability and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

first embodiment

[0041] Spin Valve Magnetoresistive Sensor

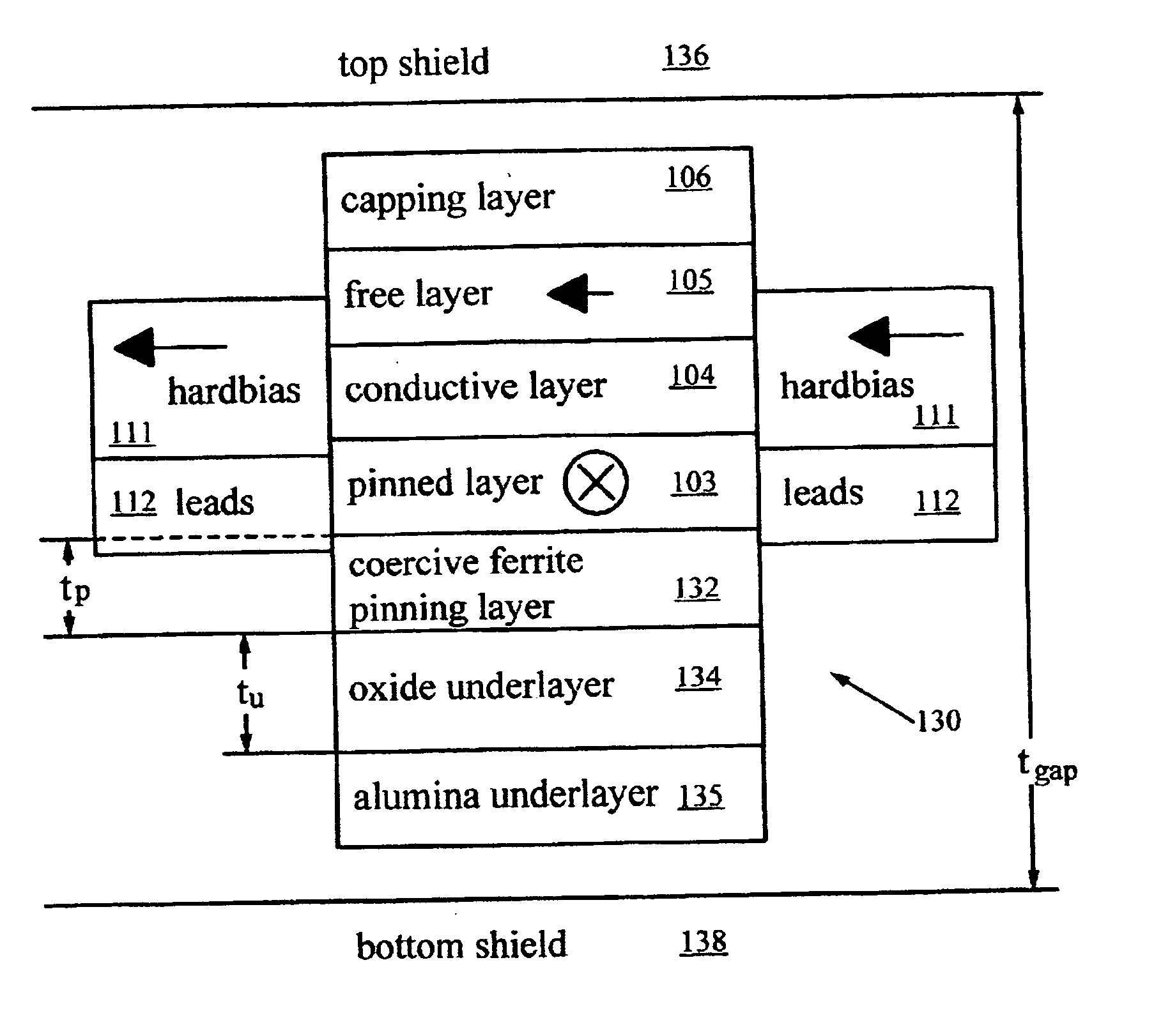

[0042]FIG. 3A illustrates the underlayer of the present invention in a simple spin valve magnetoresistive sensor 130, shown in cross section. Sensor 130 contains substantially the same layer structure as prior art spin valve MR sensor 100, including pinned layer 103, conductive layer 104, free layer 105, capping layer 106, hard-bias material 111, and leads 112. It also contains a coercive ferrite pinning layer 132 of thickness tp and an oxide underlayer 134 of thickness tu. As explained below, oxide underlayer 134 directs the growth of coercive ferrite layer 132, thereby increasing its coercivity and thermal stability. As a result, coercive ferrite layer 132 can be made very thin; tp is between 1 and 30 nm; tu is between 1 and 30 nm. Sensor 130 fits in a gap of thickness tgap between a top shield 136 and a bottom shield 138 of a magnetic read head. Sensor 130 also typically contains an insulating underlayer 135 such as alumina.

[0043] Underla...

second embodiment

[0067] Hard Biasing for Spin-Valves and Magnetic Tunnel Junctions

[0068] This embodiment of the invention relates to exchange-coupled structures such as spin valves and magnetic tunnel junctions (MTJs). MTJs have been proposed for magnetic memory cells (MRAM) and magnetoresistive read heads. A magnetic tunnel junction consists of two ferromagnetic layers separated by an insulating non-magnetic tunneling barrier. The barrier is thin enough that quantum-mechanical tunneling occurs between the ferromagnetic layers. Since the tunneling probability is spin-dependent, the tunneling current is a function of the relative orientation of the two magnetic layers. Thus a MTJ can serve as a MR sensor. For a constant applied voltage, the resistance of the MTJ changes from a low to a high state as the relative orientation of the two ferromagnetic layers changes. Depending upon the electronic band structure of the two ferromagnetic layers, either parallel or antiparallel alignment of the ferromagnet...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com