Magnetic hollow circular cylinder filler based on residual activated sludge and preparation method thereof

A residual active, hollow technology, applied in chemical instruments and methods, water/sludge/sewage treatment, biological water/sewage treatment, etc., can solve the problems of environmental pollution of residual sludge, achieve resource utilization, low cost, The effect of increased porosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

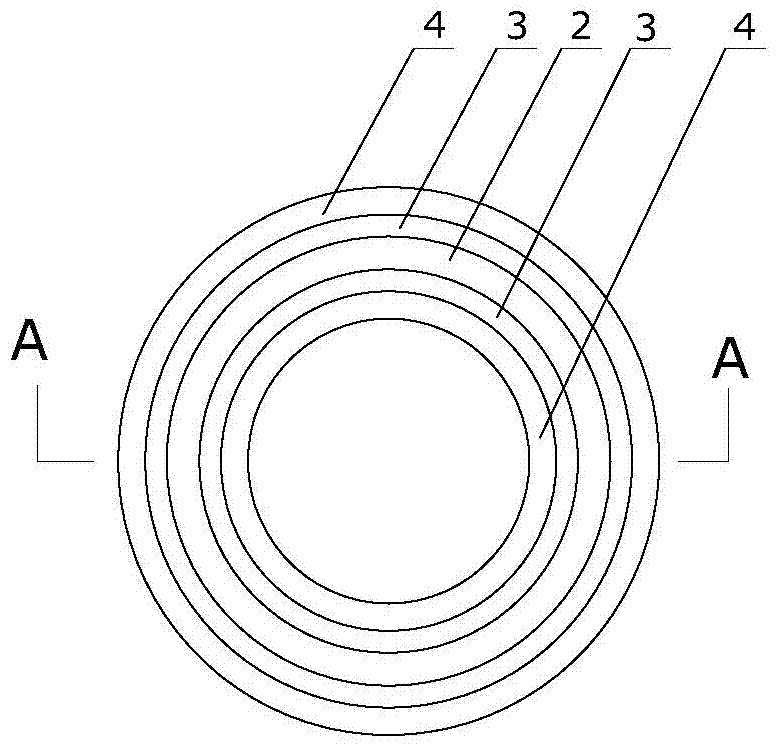

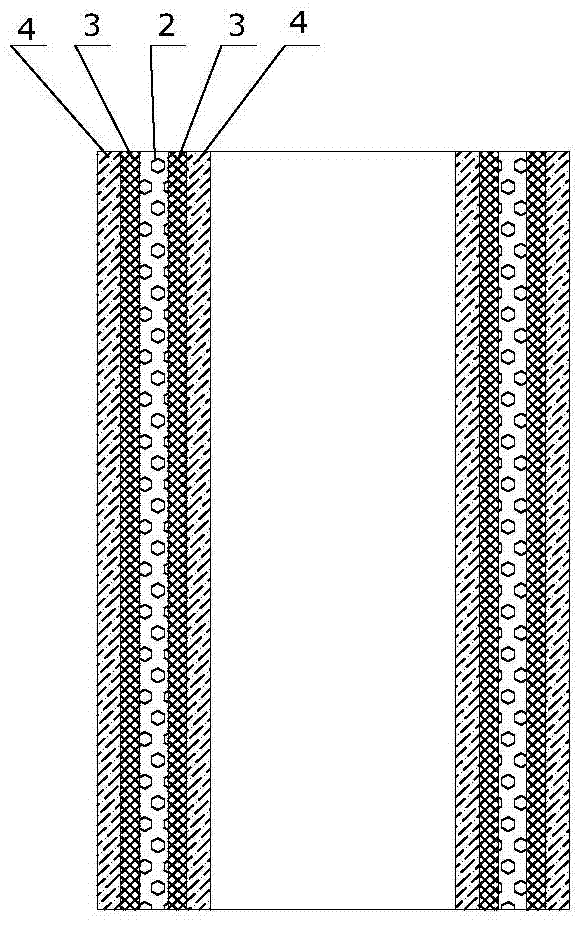

[0029] Such as Figure 1 to Figure 3 The following method is used to prepare the magnetic hollow cylindrical filler 1 based on excess activated sludge, which consists of a matrix 2 , a magnetic ferrite layer 3 and a biofilm carrier layer 4 . Wherein the substrate 2 is a hollow cylinder with an outer diameter of 20mm, an inner diameter of 16mm, and a length of 25mm; the inner and outer surfaces of the hollow cylinder are covered with a magnetic ferrite layer 3, and the thickness of the magnetic ferrite layer 3 is 0.5mm; The surface of the magnetic ferrite layer 3 is covered with a biofilm carrier layer 4, and the thickness of the biofilm carrier layer 4 is 1.5mm.

[0030] The preparation method is:

[0031] (1) A cylindrical mold is used, and the fly ash, yellow sand and cement slurry forming the matrix 2 are coated on its surface, and the two ends of the cylindrical mold are not coated. The weight percentages of the fly ash, yellow sand and cement slurry are 37% cement, 20% ...

Embodiment 2

[0041] The following method is used to prepare the magnetic hollow cylindrical filler 1 based on residual activated sludge, which consists of a substrate 2 , a magnetic ferrite layer 3 and a biofilm carrier layer 4 . Wherein the substrate is a hollow cylinder, the outer diameter of the cylinder is 30mm, the inner diameter is 22mm, and the length is 22mm; the inner and outer surfaces of the hollow cylinder are covered with a magnetic ferrite layer 3, and the thickness of the magnetic ferrite layer 3 is 1mm; The surface of the oxygen body layer is covered with a biofilm carrier layer 4, and the thickness of the biofilm carrier layer 4 is 2 mm.

[0042] The preparation method is:

[0043] (1) A cylindrical mold is used, and the fly ash, yellow sand and cement slurry forming the matrix 2 are coated on its surface, and the two ends of the cylindrical mold are not coated. The weight percentages of the fly ash, yellow sand and cement slurry are 44% cement, 26% fly ash, 5% yellow san...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com