Roller screen type stone extractor for separating soil and stone

A technology of soil-rock separation and stone removal machine, which is applied in the direction of solid separation, filter screen, grille, etc., which can solve the problems of waste of resources, production interruption, etc., and achieve the effects of high work efficiency, easy operation and wide range of moisture content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

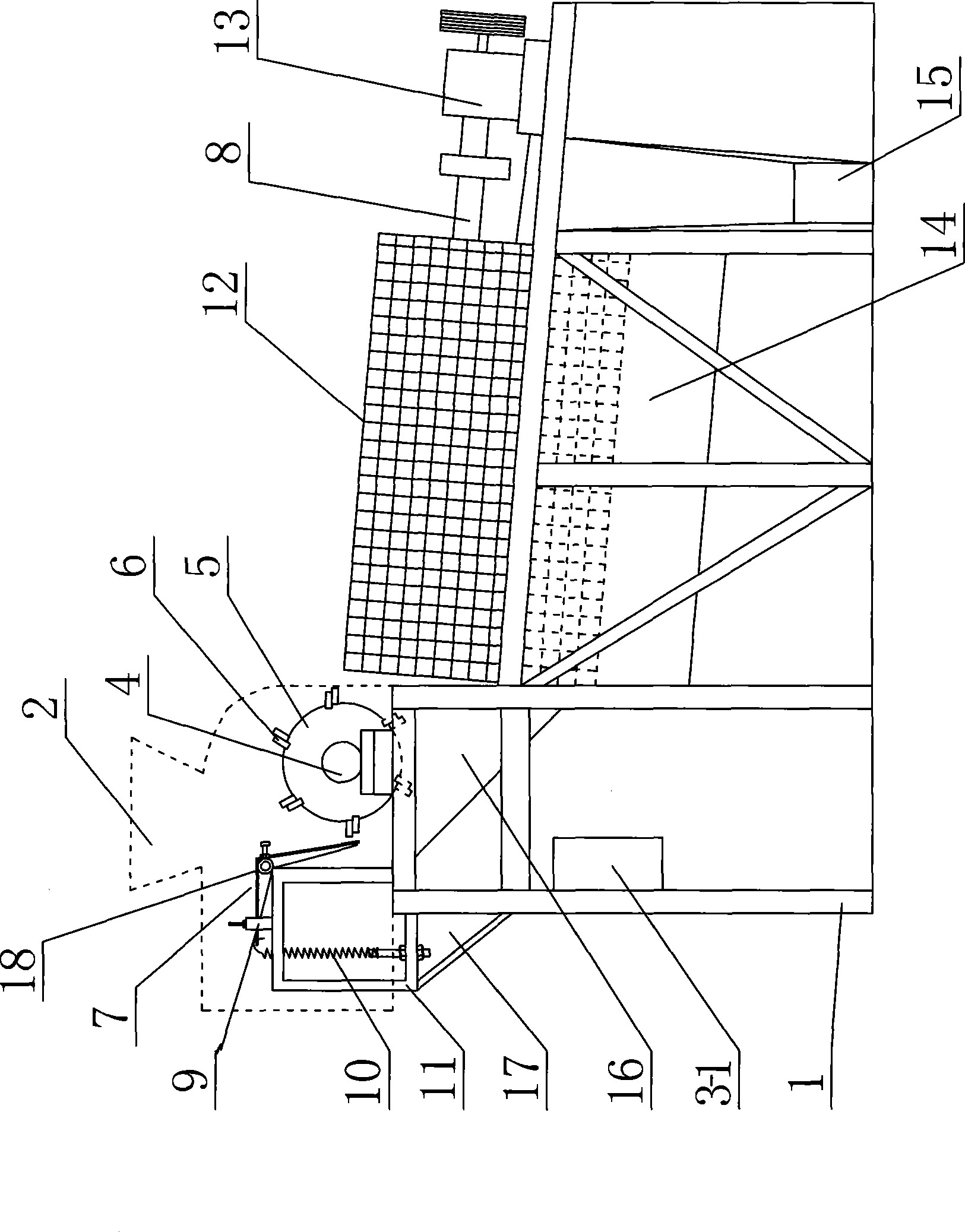

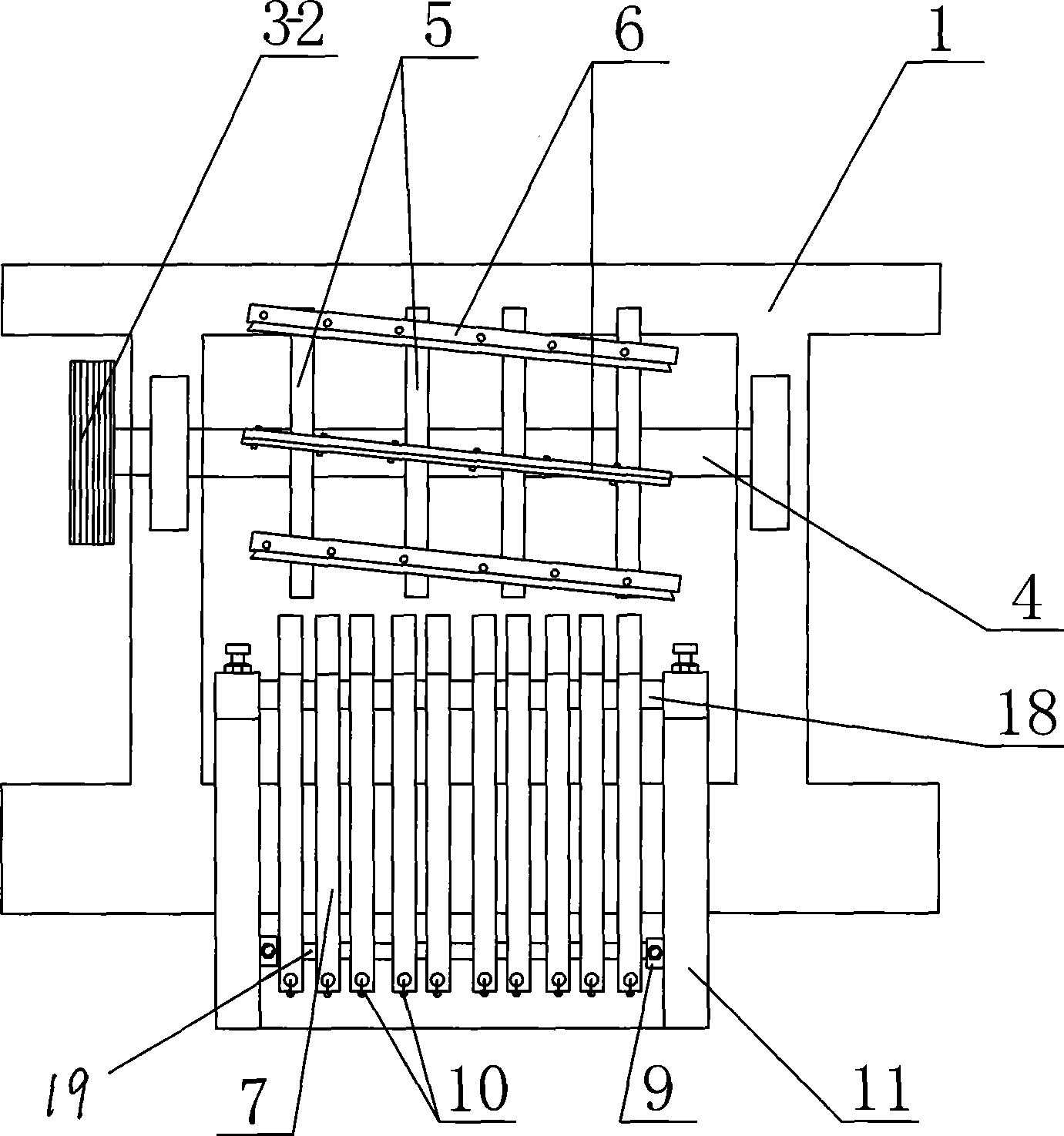

[0021] Such as figure 1 with figure 2 As shown, the present invention includes a frame 1, in which a hopper 16, a storage hopper 14, and a stone-discharging trough 15 are arranged successively from left to right in the inside of the frame 1, and a roller shaft is arranged on the frame 1 above the hopper 16 4. A drive device 1 is connected to the roller shaft 4, wherein the roller shaft 4 is longitudinally arranged on the frame 1 through the bearing seats located on both sides thereof, and a plurality of turntables 5 are uniformly installed on the roller shaft 4, and the turntable 5 passes through The bolt is provided with a plurality of soil-crushing knives 6 , and the soil-crushing knives 6 are evenly distributed longitudinally on the outer diameter of the turntable 5 , wherein the soil-crushing knives 6 and the turntable 5 form an angle of 65°-75°.

[0022] Located on the left side of the roller shaft 6 and on the frame 1, a fixed frame 11 is provided through a slanted sup...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com