Oil-water separation system with high-efficiency electromagnetic synchronous synergy

A technology for oil-water separation and synergy, which is applied in the field of multiphase separation of oil and gas gathering and transportation systems, and can solve problems such as unfavorable installation and fixation, short-circuit accidents, and low separation efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

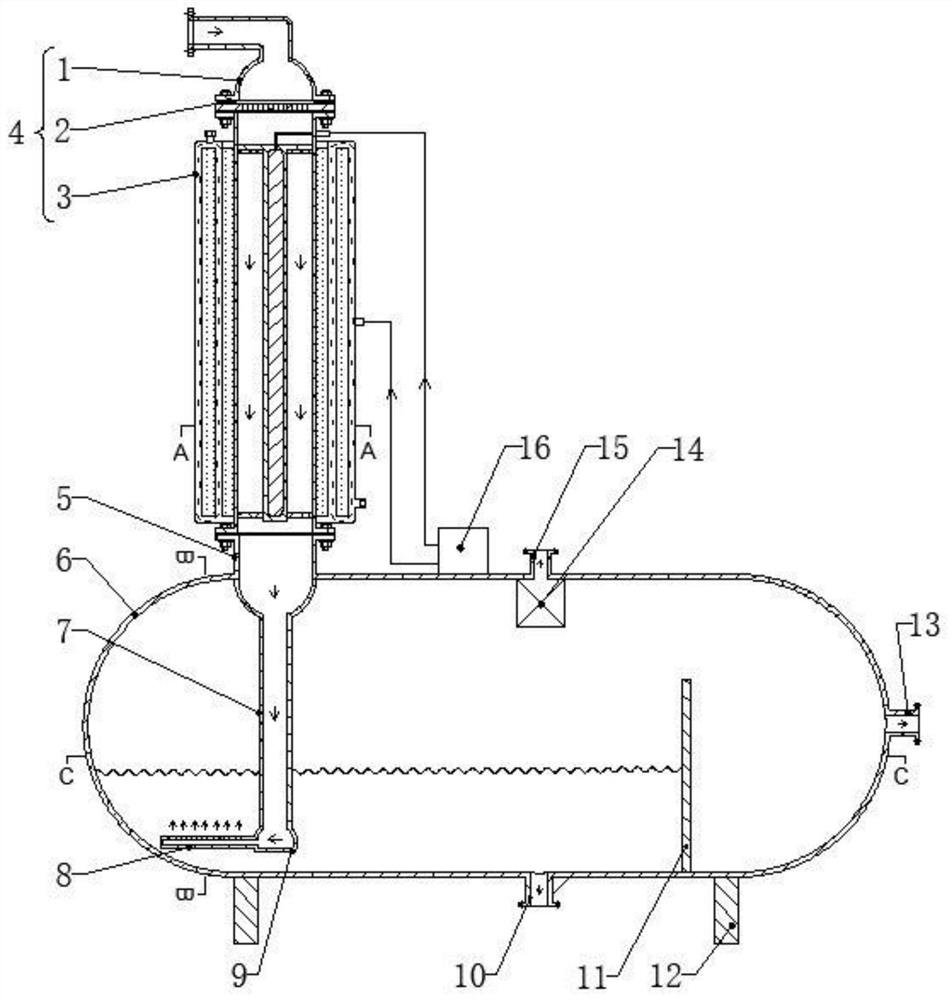

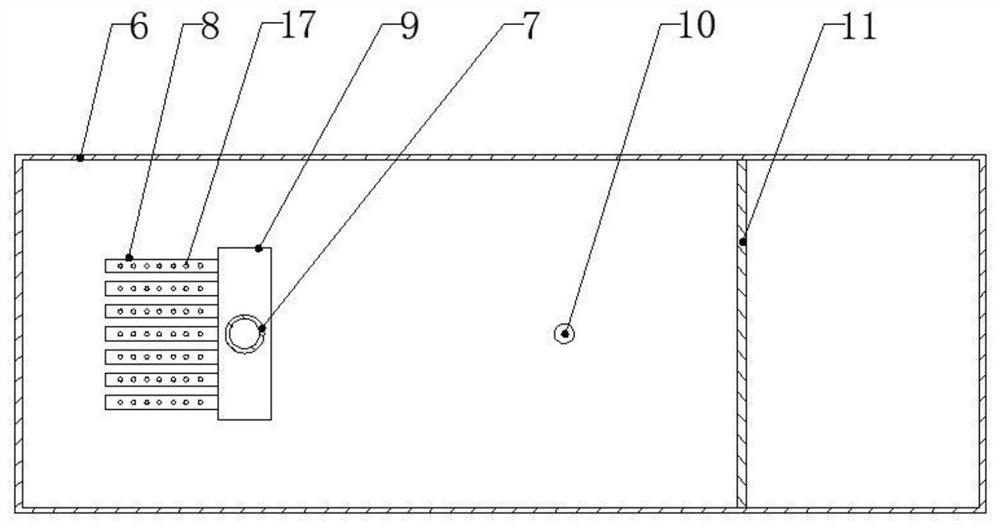

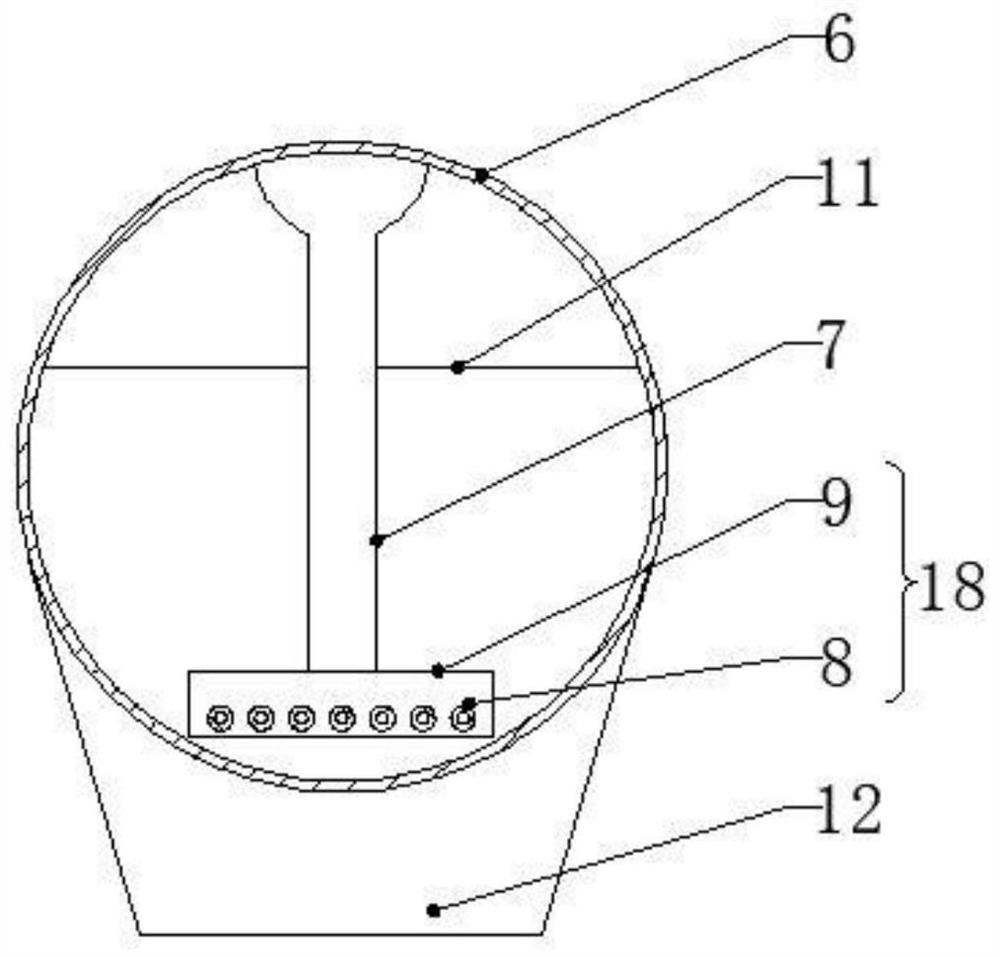

[0040] Such as figure 1 , Figure 4 and Figure 5 , the present invention includes an oil-water separation main body and a matching power supply, and is characterized in that the oil-water separation main body is composed of two parts: an enhanced coalescence device 4 and a sedimentation separation device 6, wherein the enhanced coalescence device 4 includes an emulsion entering The inlet head 1 with a flange at the upper end, the electromagnetic coalescing assembly 3, and the liquid distribution orifice 2 between the two are composed of three parts. The electromagnetic coalescing assembly 3 includes an electric field generating assembly 24 powered by a power supply 16 and magnetic field excitation assembly 29, the two are coaxially distributed, wherein the electric field is distributed horizontally from the electrode 23 to the outer electrode 21, the magnetic field is parallel to the vertical distribution of the electrode 23, and the two are orthogonally distributed synchron...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com