Suction type impurity and stone removing machine for grains

A technology for stone removal and grain removal, which is applied in the fields of food processing institutions and agricultural machinery, can solve the problems affecting the quality of grains and the quality of grain particles, and achieve the effect of good separation effect and high stone removal efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

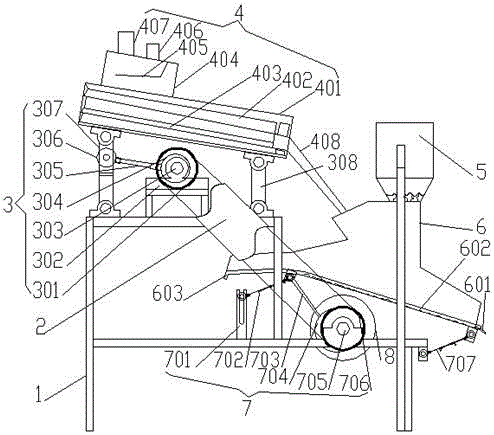

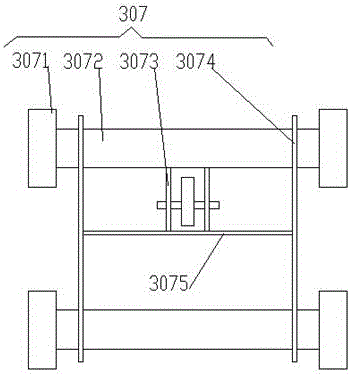

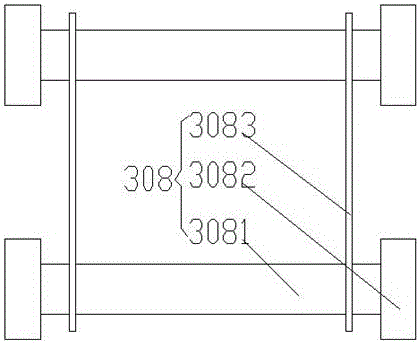

[0026] A grain suction type de-stoner machine, comprising a frame 1, a shield 2, an upper eccentric mechanism 3, a plane sieve 4, a fan 5, a de-stoner 6, a lower eccentric mechanism 7, and a large pulley 8. The upper left part of the frame 1 is connected to the upper eccentric mechanism 3, and the flexible rubber bearing group of the upper eccentric mechanism 3 is connected to the bottom frame of the plane screen 4. The stone remover 6 is erected on the right side of the frame 1 through the lower eccentric mechanism 7, the upper part of the stone remover 6 is connected to the suction fan 5, and the suction fan 5 is fixedly connected between the vertical poles on the right side of the frame 1, and the lower eccentric The rear end of the main shaft 705 of the mechanism 7 is connected with the large pulley 8, and the large pulley 8 is connected to the motor by a belt, and the motor is installed on the bottom of the frame 1. The front end of the main shaft 705 of the lower eccentri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com