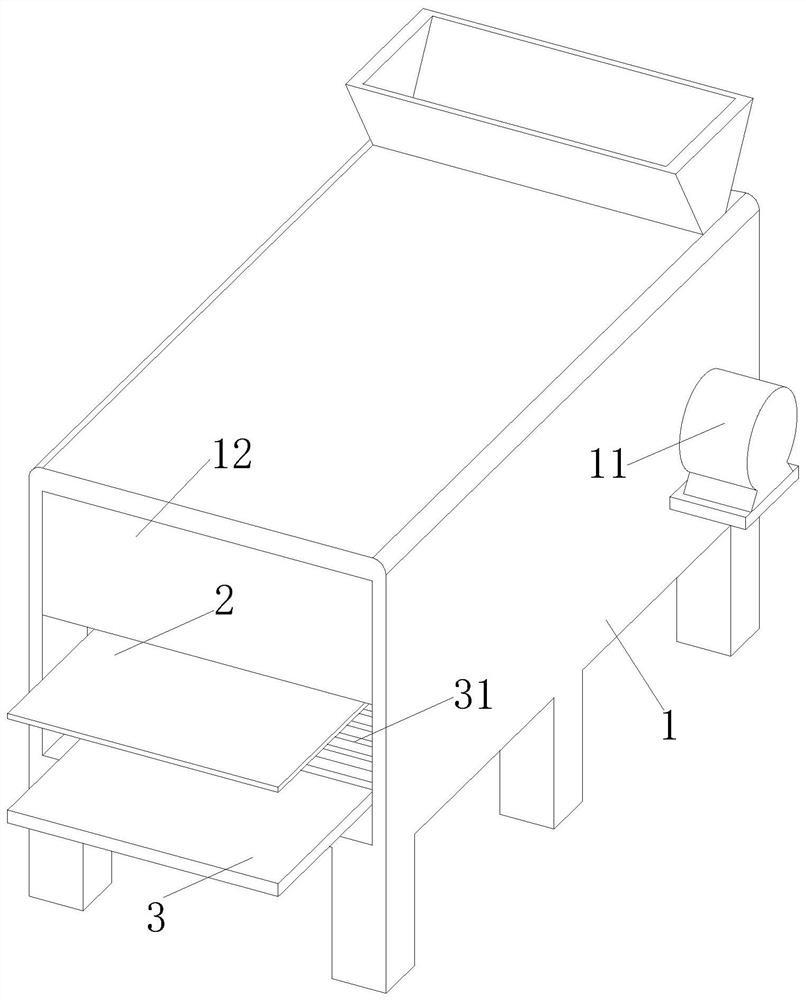

Fine rice processing system

A technology of rice and sieve plate, applied in the direction of solid separation, sieve, grille, etc., can solve the problems affecting the quality of rice processing products, large stones and small stones cannot be distinguished and screened, etc., to increase the stone removal effect and increase the removal rate Stone efficiency, the effect of increasing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

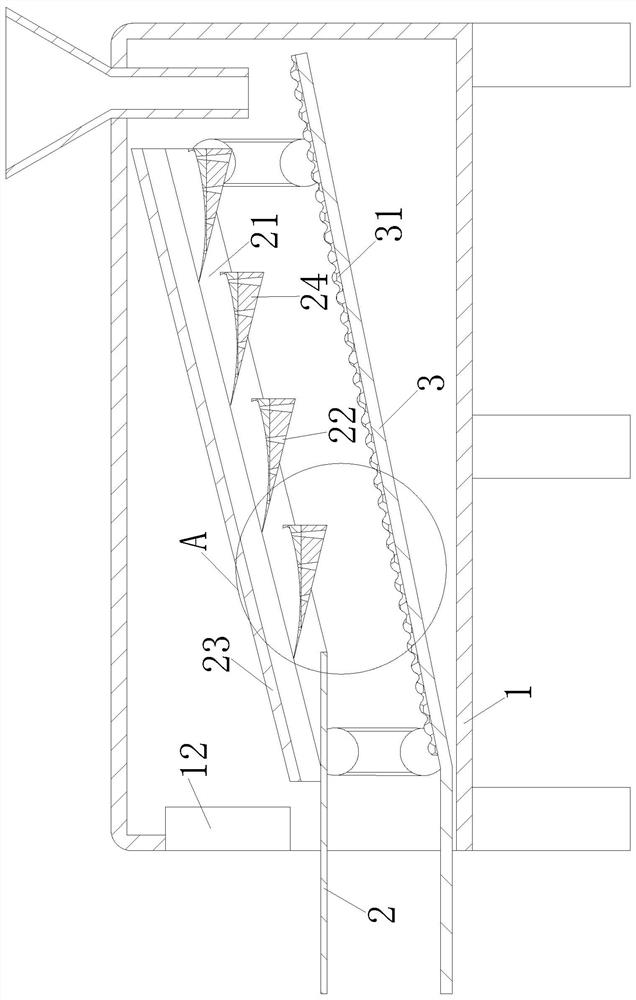

[0034] As a specific embodiment of the present invention, the diameter of the screen hole 22 close to the vibration plate 3 is large, and the diameter of the screen hole 22 away from the vibration plate 3 is small.

[0035] During use, when the rice is in a dispersed state and descends, the rice touches the sieve hole 22 on the sieve plate 2, and the small stones in the rice and the smaller broken rice fall through the sieve hole 22, and the small stones in the rice and the smaller broken rice fall through the sieve hole 22. When the broken rice passes through the sieve hole 22, because the sieve hole 22 is set to have a large aperture close to the vibrating plate 3, and the sieve hole 22 is away from the small aperture of the vibrating plate 3, the small stones in the rice and the smaller broken rice pass through the sieve hole 22 The smooth falling of the inner wall increases the screening effect of the sieve hole 22, thereby increasing the screening effect of the stone remov...

Embodiment approach

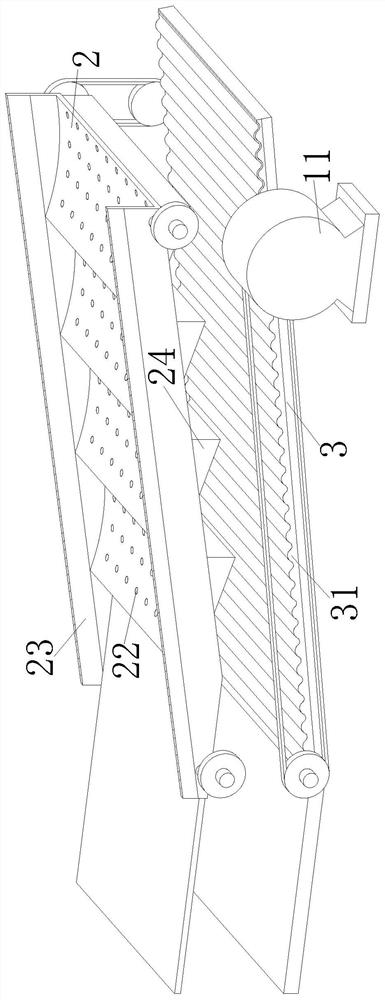

[0036] As an embodiment of the present invention, a group of guide blocks 24 are evenly fixed on the surface of the sieve plate 2 facing the vibrating plate 3, and the guide blocks 24 are arranged obliquely. One end of the block 24 near the exhaust fan 12 is at a higher level.

[0037] When in use, the vibrating plate 3 throws up the rice when it moves to the highest point, and the sieve plate 2 moves to the lowest point to collect the vacated part of the rice, and the vacated rice rises, and the vibrating plate 3 drives the guide block 24 to move and is in the process of rising The rice bumps into the guide block 24, because the guide block 24 is inclined to set, part of the rice bumps into the guide block 24 and is affected by the inclined surface of the guide block 24 to change the rebound angle, because the inclined surface of the rice in the collision guide block 24 is inclined at The slope of the guide block 24, part of the paddy bounces off the angle after colliding wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com