Coarse cereal processing method

A processing method and technology of miscellaneous grains, applied in application, grain processing, agriculture, etc., can solve the problems of reducing grain yield and poor grain quality, and achieve the effect of improving grain yield and quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

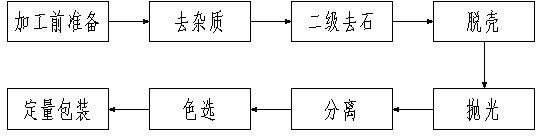

[0029] Such as figure 1 Shown, the processing method of this miscellaneous grains, comprises the following steps:

[0030] 1. Preparation before processing

[0031] Load the miscellaneous grains to be processed into the granary;

[0032] 2. Remove impurities

[0033] The miscellaneous grains in the granary are conveyed to the grain cleaning machine through the lifting cylinder, and the large stones, grass stalks and other impurities in the miscellaneous grains with a particle size ≥ 3mm are removed;

[0034] 3. Secondary stone removal

[0035] Such as figure 2 As shown, the miscellaneous grains that have been removed from impurities are continuously passed through two destoners to remove stones, so that the miscellaneous grains fall under the stone-removing sieve plate. Air volume is 3900m 3 / h;

[0036] 4 Shelling

[0037] Grind the miscellaneous grains through three shelling machines, separate the hulls of the miscellaneous grains from the grain, and remove the hul...

Embodiment 2

[0047] Such as figure 1 Shown, the processing method of this miscellaneous grains, comprises the following steps:

[0048] 1. Preparation before processing

[0049] Load the miscellaneous grains to be processed into the granary;

[0050] 2. Remove impurities

[0051] The miscellaneous grains in the granary are conveyed to the grain cleaning machine through the lifting cylinder, and the large stones, grass stalks and other impurities in the miscellaneous grains with a particle size ≥ 3mm are removed;

[0052] 3. Secondary stone removal

[0053] Such as figure 2 As shown, the miscellaneous grains that have been removed from impurities are continuously passed through two destoners to remove stones, so that the miscellaneous grains fall under the stone-removing sieve plate. Air volume is 4100 m 3 / h;

[0054] 4 Shelling

[0055] Grind the miscellaneous grains through three shelling machines, separate the hulls of the miscellaneous grains from the grain, and remove the hul...

Embodiment 3

[0065] Such as figure 1 Shown, the processing method of this miscellaneous grains, comprises the following steps:

[0066] 1. Preparation before processing

[0067] Load the miscellaneous grains to be processed into the granary;

[0068] 2. Remove impurities

[0069] The miscellaneous grains in the granary are conveyed to the grain cleaning machine through the lifting cylinder, and the large stones, grass stems and other impurities with a particle size of ≥3mm are removed;

[0070] 3. Secondary stone removal

[0071] The miscellaneous grains from which impurities have been removed go through two destoners continuously to remove stones, so that the miscellaneous grains fall under the stone-removing sieve plate. The horizontal inclination of the stone-removing sieve plate is 12°, and then the miscellaneous grains are blown out by a fan, and the air volume is controlled at 4000 m 3 / h;

[0072] 4 Shelling

[0073] Grind the miscellaneous grains through three shelling machi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com