Gravel clearing device for train rails

A technology for removing devices and rails, which is applied in the direction of track cleaning, track, cleaning methods, etc., can solve the problems of train bumps, train derailment, low efficiency, etc., and achieve the effect of improving ride comfort, improving stability, and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

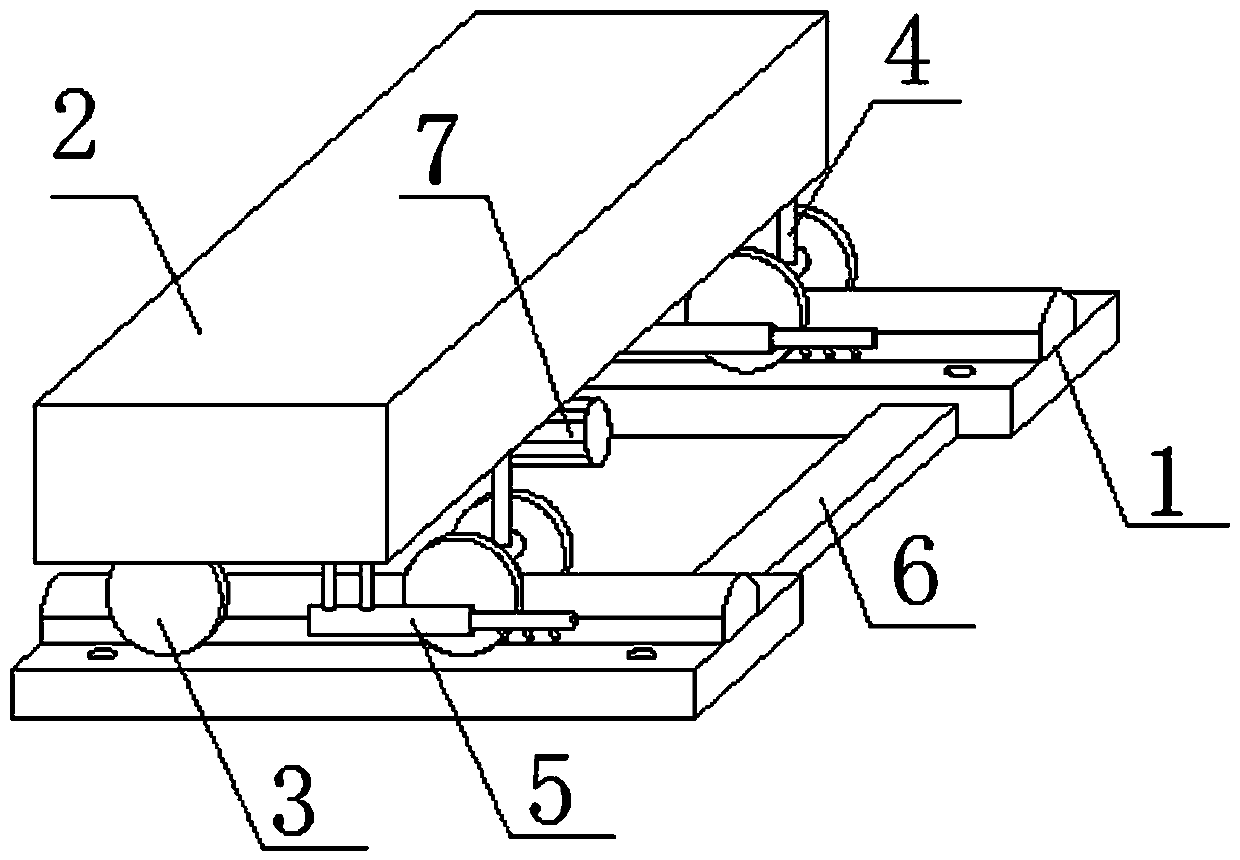

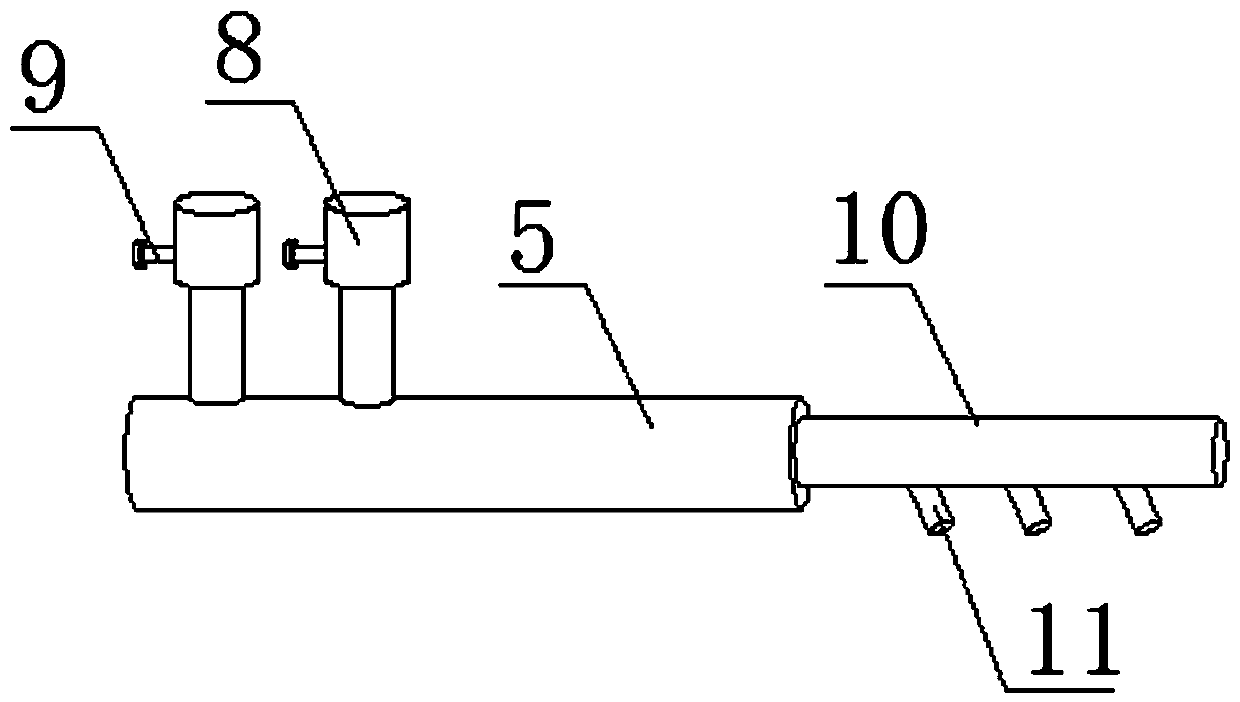

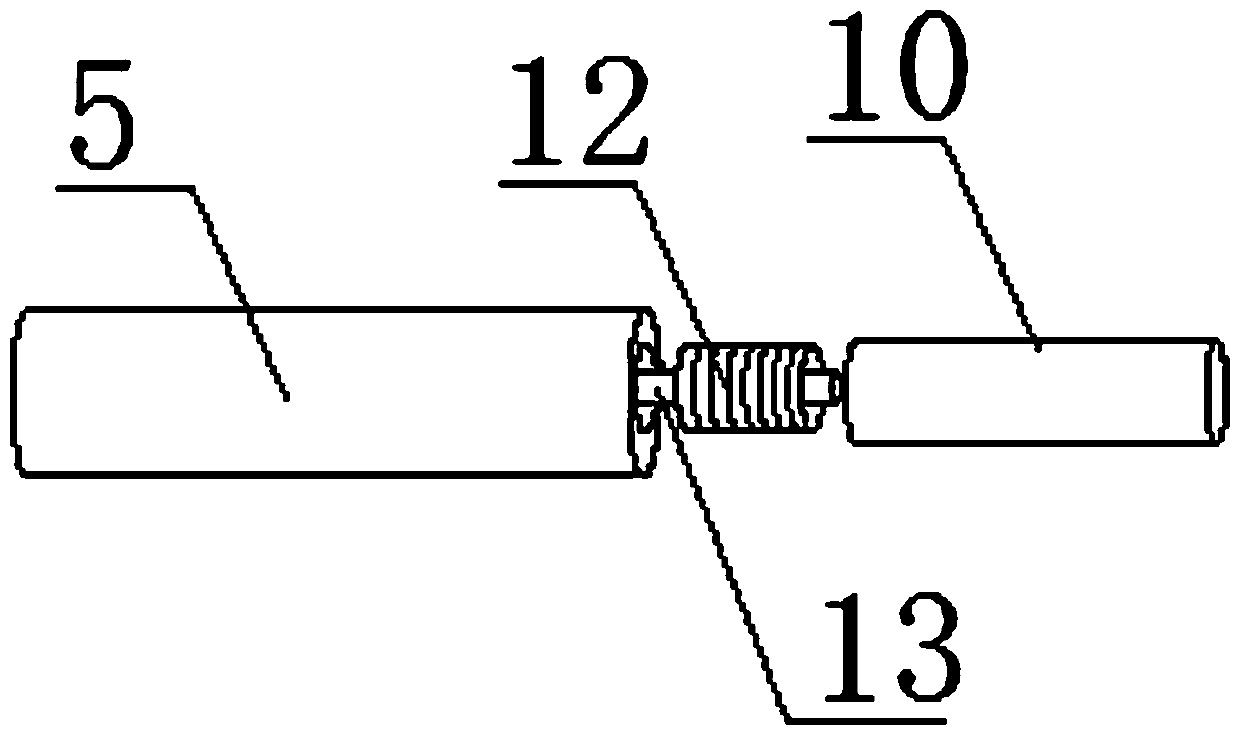

[0017] Such as Figure 1-3 As shown, a gravel removal device for train rails includes a rail 1, a locomotive 2 and a stone removing rod 10, a rail tie 6 is connected inside the rail 1, a locomotive 2 is connected to the top of the rail 1, and the bottom of the locomotive 2 is connected to the rail 1 Wheel 3 is installed at the junction of the wheel 3, and the junction of the wheel 3 and the headstock 2 is connected with a shock-absorbing arm 4, and several telescopic columns 8 are installed on both sides of the bottom of the front wheel 2 near the wheel 3, and the bottom of the telescopic column 8 is welded with a connecting rod 5. And one end of the connecting rod 5 is connected with a stone removing rod 10, and the connection between the inside of the connecting rod 5 and the removing stone rod 10 is provided with a damping spring 12, and one side of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com