Digitally printed furniture and methods for manufacture thereof

a technology of digital printing and furniture, applied in the field of digital printing furniture, can solve the problems of affecting the appearance of the wood inlay surface design, easy peeling of the thin plastic coating layer, accidental cutting or damage, etc., and achieve the effect of high quality and inexpensive manufacturing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

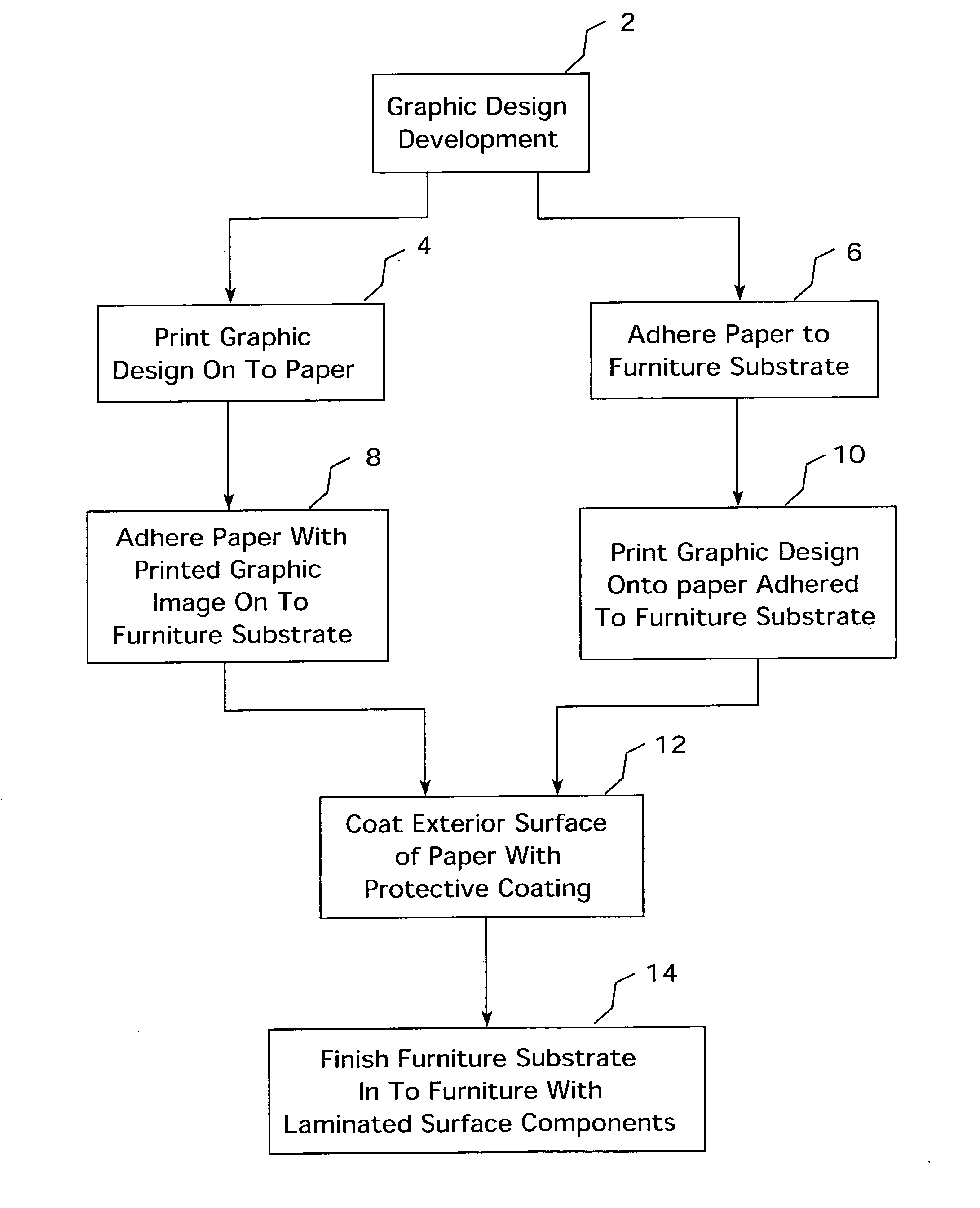

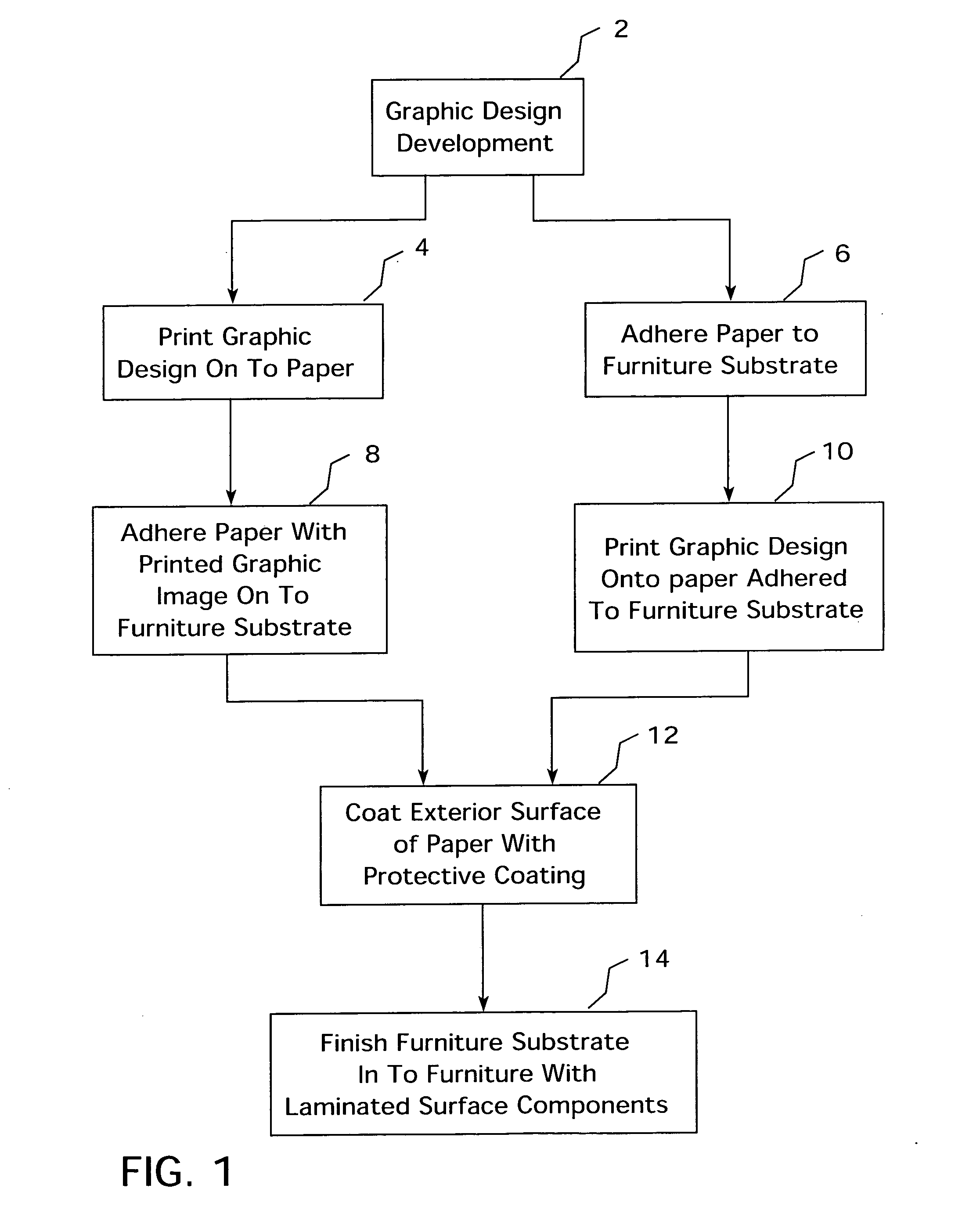

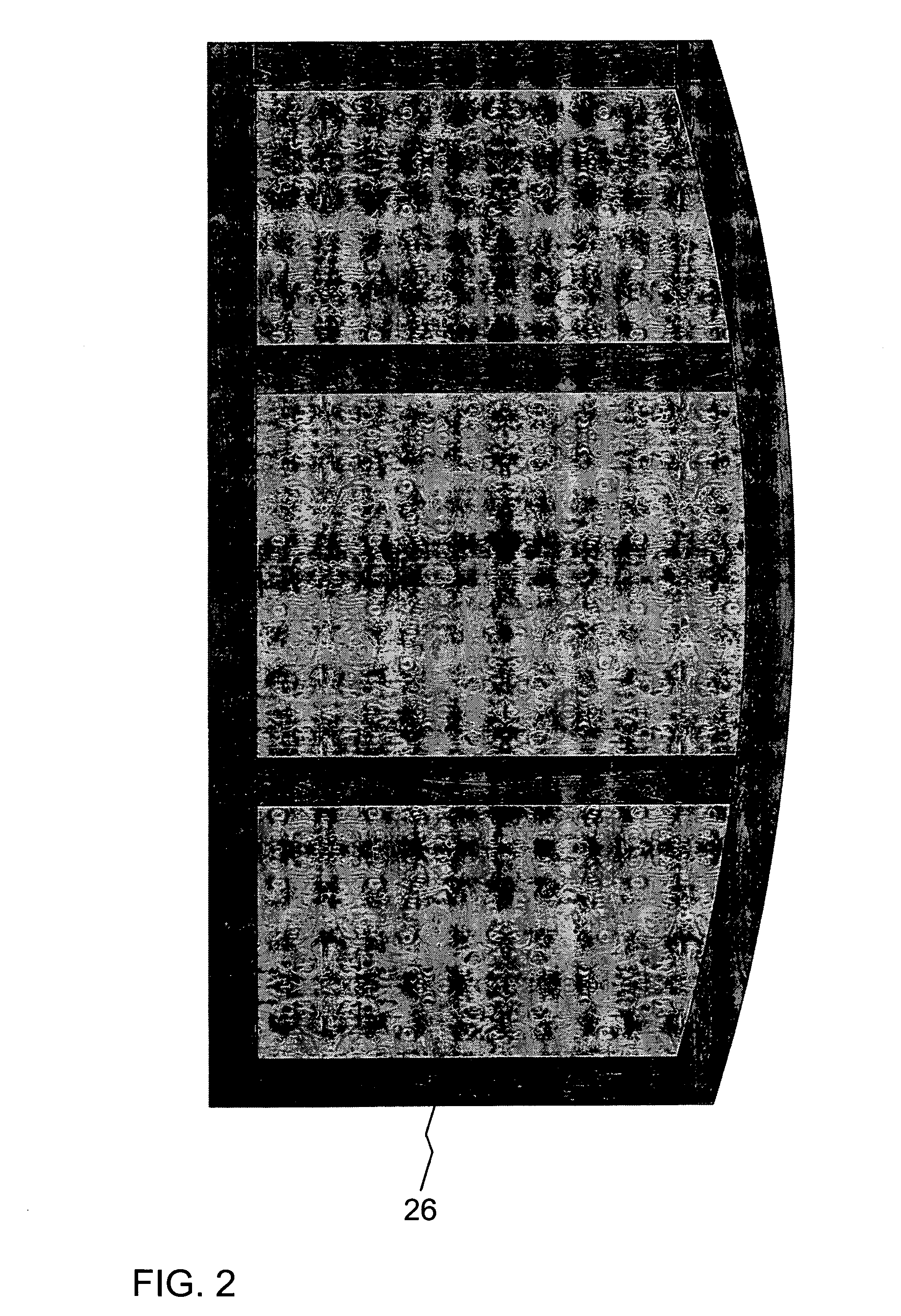

[0021] In reference to the disclosure of the invention, similar references to similar parts are used uniformly throughout the disclosure. For example, the phrase “graphic image” means any wood grain design, a wood grain inlay design such as those shown in FIGS. 2, 3 and 5, or another custom design. The phrase “furniture substrate” means any piece of solid wood, wood-based substrate such as any available density of particleboard, or other acceptable furniture substrate known by those skilled in the art that is cut into the primary structural components of a piece of furniture. The words “laminated” and “lamination” mean the composite layers of adhesive, printer paper, printed graphic image and protective coating used to create a laminated surface on the underlying furniture substrate in accordance with the present invention. The phrases “furniture component” and “corresponding furniture components” mean any or all pieces of laminated furniture substrates that are used to assemble a d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com