Continuous production method and apparatus for vacuum glass

A technology for vacuum glass and production equipment, applied in glass production, glass manufacturing equipment, glass molding, etc., can solve the problems of low production efficiency, poor product durability and weather resistance, low product qualification rate, etc., to ensure temperature uniformity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

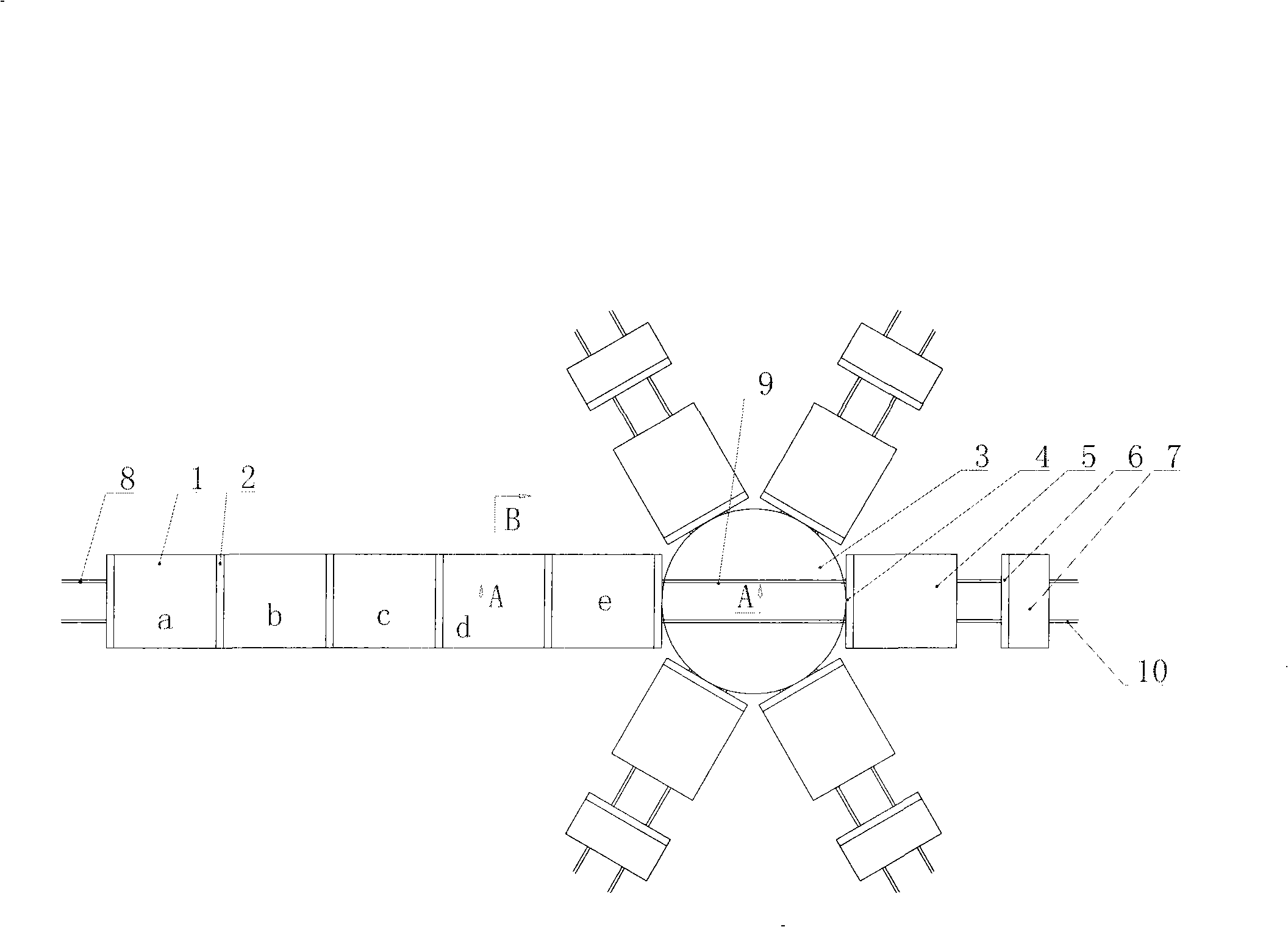

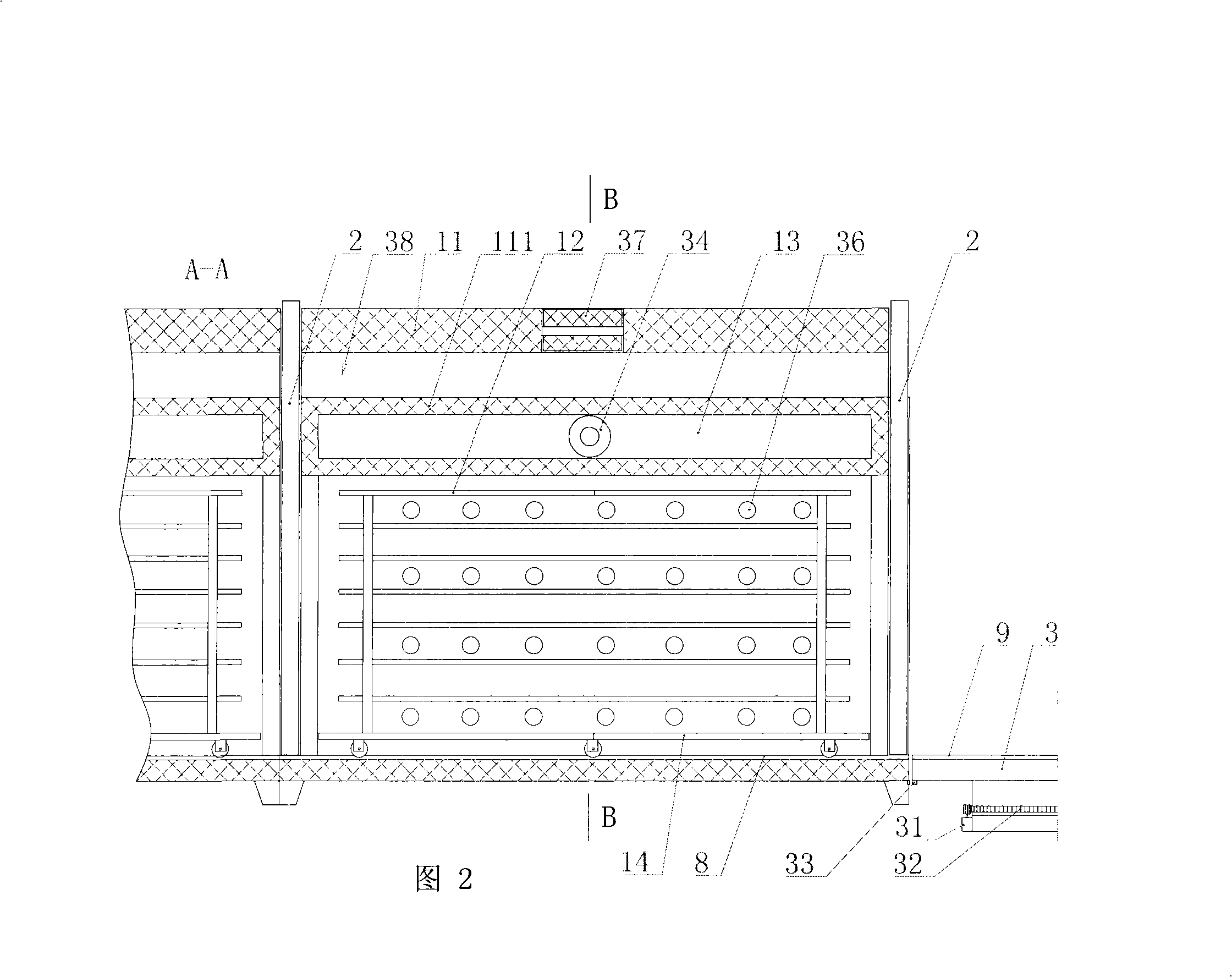

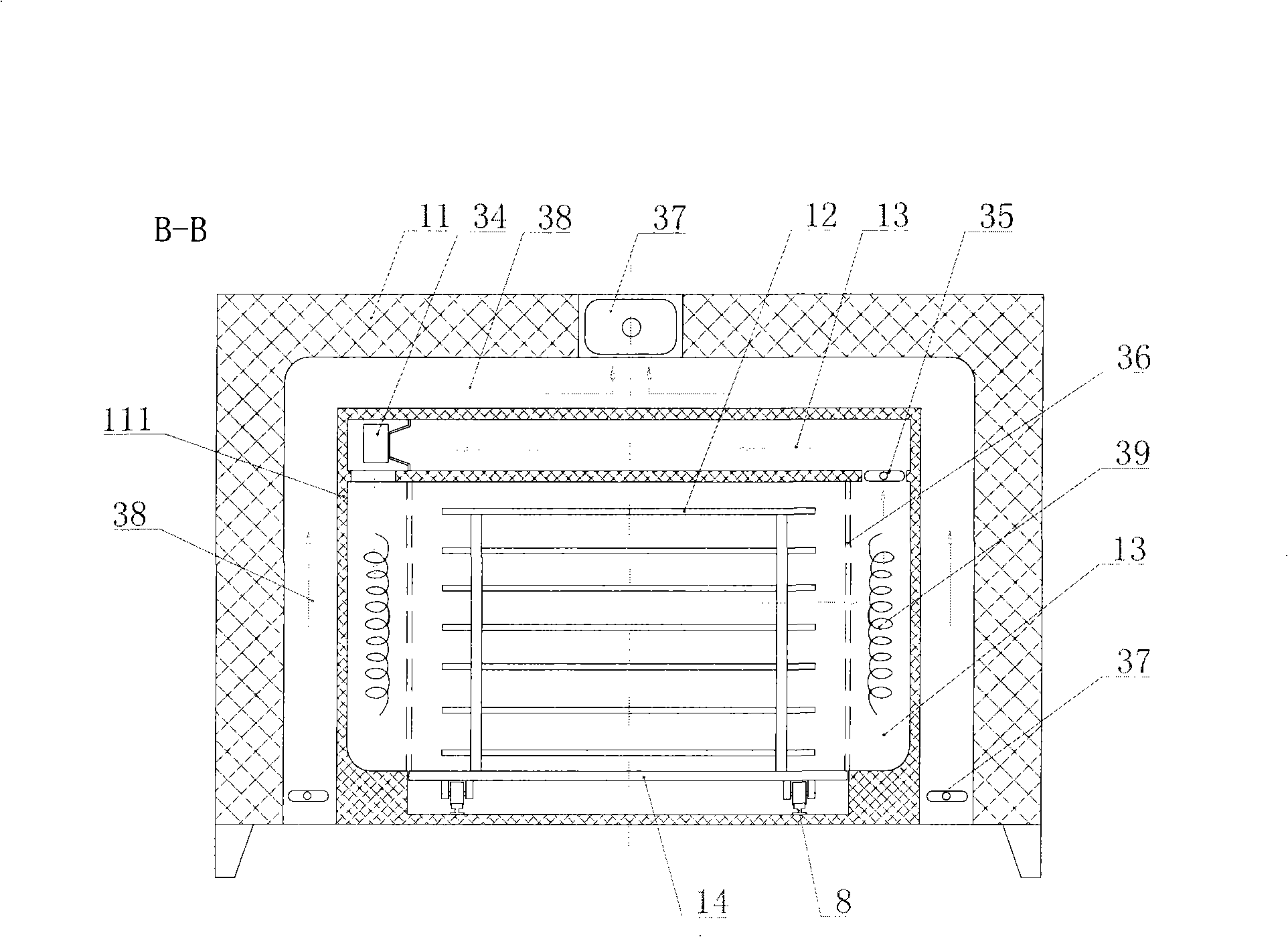

[0021] see Figure 1 ~ Figure 3 , the present invention comprises edge banding furnace body column, sealing furnace body 5, turntable 3, vacuum device 7 and the feeding trolley 14 that can move in and out of furnace body. The edge-banding furnace body row is formed by a plurality of single edge-banding furnace body 1 end-to-end butt joints, and there are lifts that can be opened and closed at both ends of the edge-banding furnace body row and between each edge-banding furnace body 1 . Type (or push-pull) furnace door 2, each single edge-banding furnace body 1 is provided with a track 8 corresponding to each other, and the rollers of the feeding trolley 14 are placed on the track 8. A turntable 3 is installed at one end of the edge banding furnace body row, and a turntable track 9 matching the track 8 is installed on the turntable 3 . Around said turntable 3 several described sealing furnace bodies 5 are housed, and track 10 is housed in each said sealing furnace body 5, and c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com